manifold JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1659 of 2490

6. R

aise the vehicle on a ramp.

7. R

emove the bolts which secure

the rear of the front muffler

assembly to the engine rear mounting.

8. R

emove the nuts which secure

the front flanges of the front

muffler to the downpipe flanges.

9. R

emove the gasket from the front

muffler flange at each side.

R

eposition the front silencer rearwards.

R

emove the gasket from each flange.

10

.

Remove the downpipe catalytic converter.

R

emove the bolts which se

cure the downpipe lower

mounting bracket.

Remove the

downpipe assembly.

11. Remove gasket from the manifold flange.

Clean and inspect th

e manifold joint faces.

Clean and inspect th

e threads

on the downpipe studs.

Page 1660 of 2490

In

stallation

1.

Fit a ne

w gasket to the mani

fold mating flange on the

downpipe.

2. Fit

the downpipe catalytic converter.

1. Fit the downpipe assembly to the manifold.

Fit,

but do not fully tighten, the mounting bracket securing

bolts. (Leave loose until the nu ts securing the downpipe to

the exhaust manifold are fitted.)

3. Lower the ramp.

4. Tigh te

n the nuts securing the downpipe flange to the manifold

flange.

5. Connec t

the oxygen sensor multiplugs.

Con

n

ect the plug(s) to the respective (previously noted)

sensor(s).

Cor r

ectly position the multiplu

gs on the mounting bracket.

6. Fi

t the coolant header tank.

1. Reposition the tank and fit the securing nuts.

2. Connect the harness connector

7. Refit the centre trim panel and th e left hand enclosure panel to

the engine compartment.

Page 1662 of 2490

Exha

ust System - Catalyti

c Converter Gasket RH4. 0L NA V8 - AJ27/3.2L

NA V8 - AJ26

Re mo

val and Installation

Remova

l

Installation

1. Op

en the engine compartment and fit paintwork protection

sheets.

2. Remove the front muffler; refer to Operation 30.10.18 in this

section.

3. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

Di spl

ace the multiplugs from the engine mounting bracket.

Dis

connect the plug(s) from the oxygen sensor(s).

4.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

5. Raise the vehicle on a ramp.

6. Re

move the downpipe catalytic converter.

R

e

move the bolts which se

cure the downpipe lower

mounting bracket.

Remove the down

pipe assembly.

7. Remove gasket from the manifold flange.

Clean and inspect th e manif

old joint faces.

Clean and inspect th

e threads on th

e downpipe studs.

1. Fit a new gasket to the mani fold mating flange on the

Page 1663 of 2490

do

wnpipe.

2. F

it the downpipe catalytic converter.

Fit the down

pipe assemb

ly to the manifold

Fi

t, but do not fully tighten, the mounting bracket securing

bolts. (Leave loose until the nu ts securing the downpipe to

the exhaust manifold are fitted.)

3. Lower the ramp.

4. Tigh

ten the nuts securing the downpipe flange to the manifold

flange..

5. Connec

t the oxygen sensor multiplugs.

Con

nect the plug(s) to the respective (previously noted)

sensor(s).

Cor

rectly position the multiplu

gs on the mounting bracket.

6. Raise the ramp.

7. Tigh

ten the mounting brac

ket securing bolts.

8. Fit the front muffler; refer to Operation 30.10.18.

9. Lower the ramp.

10

.

Remove the paintwork protection sheets and close the engine

cover.

Page 1664 of 2490

Exha

ust System - Cataly

tic Converter Gasket RH 4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

Di spl

ace the multiplugs from the engine mounting bracket.

Dis

connect the plug(s) from the oxygen sensor(s)

3.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

4. Raise the vehicle on a ramp.

5. Re

move the bolts which secure

the rear of the front muffler

assembly to the engine rear mounting.

6. Remove the nuts which secure the front flanges of the front

muffler to the downpipe flanges.

Page 1665 of 2490

I

nstallation

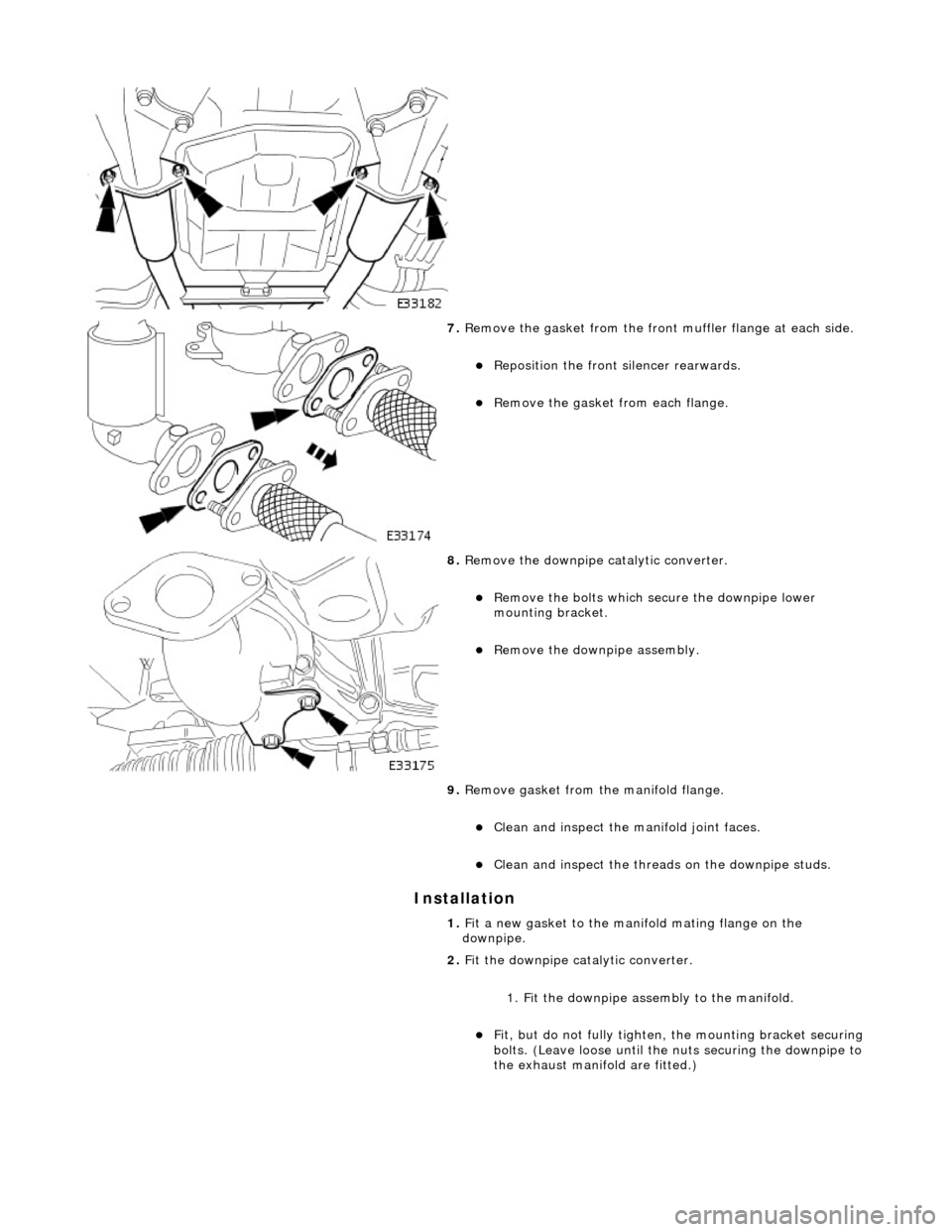

7.

R

emove the gasket from the front

muffler flange at each side.

R

eposition the front silencer rearwards.

R

emove the gasket from each flange.

8. R

emove the downpipe catalytic converter.

R

emove the bolts which se

cure the downpipe lower

mounting bracket.

Remove the

downpipe assembly.

9. Remove gasket from the manifold flange.

Clean and inspect th

e manifold joint faces.

Clean and inspect th

e threads

on the downpipe studs.

1. Fit a new gasket to the mani fold mating flange on the

downpipe.

2. Fit the downpipe catalytic converter.

1. Fit the downpipe assembly to the manifold.

Fi

t, but do not fully tighten, the mounting bracket securing

bolts. (Leave loose until the nu ts securing the downpipe to

the exhaust manifold are fitted.)

Page 1666 of 2490

3. Lower the ramp.

4. Tighte

n the nuts securing the downpipe flange to the manifold

flange.

5. Connec t

the oxygen sensor multiplugs.

Con

n

ect the plug(s) to the respective (previously noted)

sensor(s).

Cor r

ectly position the multiplu

gs on the mounting bracket.

6. Raise the vehicle on the ramp.

7. Tigh ten th

e mounting brac

ket securing bolts.

8. Connect the downpipe catalytic converter to the front muffler.

1. Position a new gasket to the flange studs at each side.

Page 1688 of 2490

Fuel System - General Inform

ation - Fuel System

Description an

d Operation

The fuel tank is mounted across the vehicle behind the passenger compartment bulkhead.

Fuel is drawn by the fuel pump from the tank and then supplied to the two fuel rails, via a filter.

Fuel injectors are installed in the fuel ra ils on each side of the intake manifold.

The amount of fuel injected into th e engine is controlled by the ECM.

A cross-over pipe connects the two fuel ra ils together at the front of the manifold.

A test valve in the cross-over pipe allo ws the fuel rail to be pressurized and de-pressurized during the servicing and

troubleshooting procedures.

A pressure regulator on the rear of the right fuel rail controls the pressure in the fuel rails.

A return line directs excess fuel from the pressure regulator back to the fuel tank.

Operation and service procedures

The fuel injector

s, rails, pres

sure regulator and, wher e fitted, supercharger are described in greater detail in Section 303-04

together with servicing procedures.

The fuel tank, pump, fuel level senders and fuel lines are similarly covered in Section 310-01.

Page 1756 of 2490

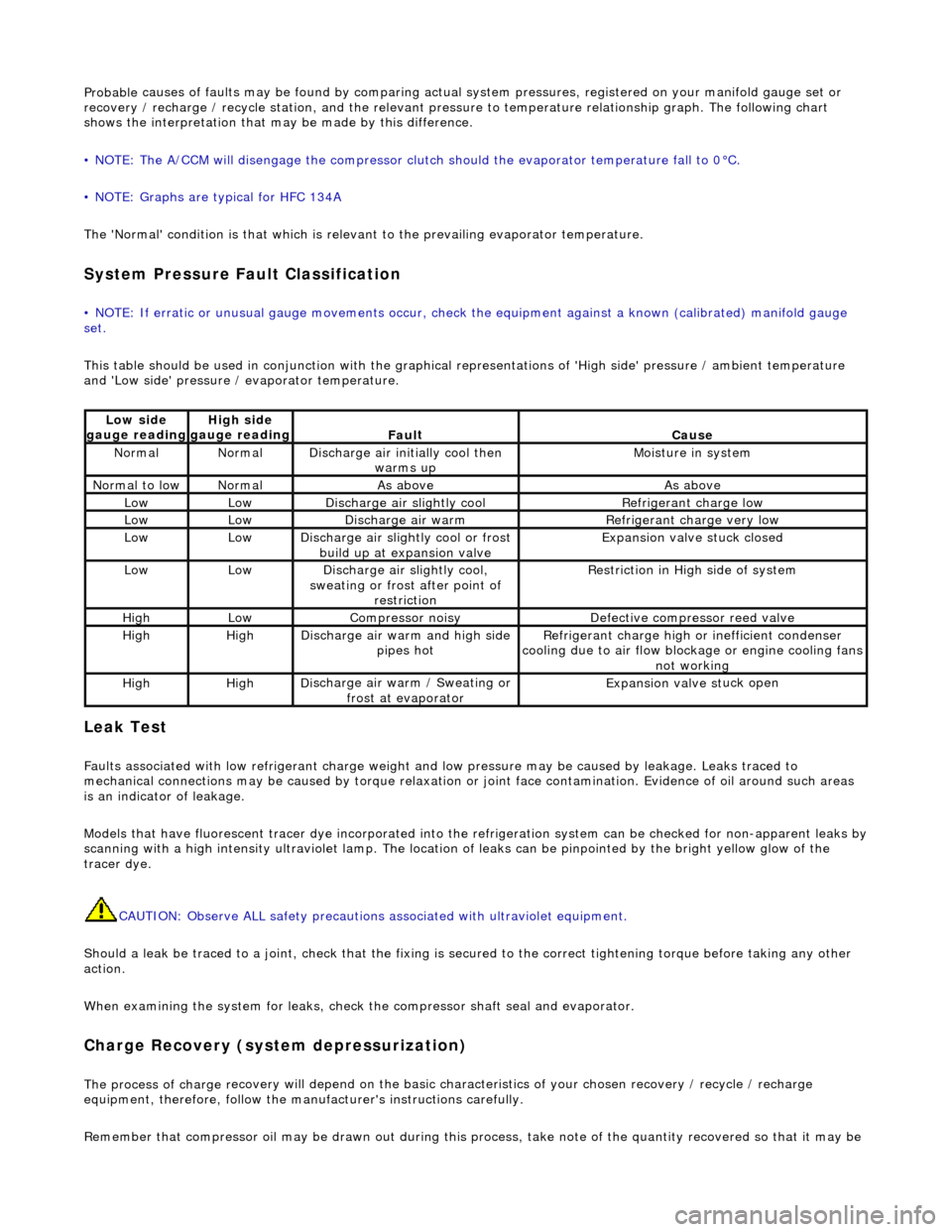

Probable

causes of faults may be found by comparing actual

system pressures, registered on your manifold gauge set or

recovery / recharge / recycle station, and the relevant pressure to temperature relationship graph. The following chart

shows the interpretation that ma y be made by this difference.

• NOTE: The A/CCM will disengage the compressor clutch should the evaporator temperature fall to 0°C.

• NOTE: Graphs are typical for HFC 134A

The 'Normal' condition is that which is relevant to the prevailing evaporator temperature.

System Pressure Fault Classification

• NOTE

: If erratic or unusual gauge move

ments occur, check the equipment against a known (calibrated) manifold gauge

set.

This table should be used in conjunction with the graphical representations of 'High side' pressure / ambient temperature

and 'Low side' pressure / evaporator temperature.

Leak

Test

F

a

ults associated with low re

frigerant charge weight and low pressure ma y be caused by leakage. Leaks traced to

mechanical connections may be caused by to rque relaxation or joint face contamination. Evidence of oil around such areas

is an indicator of leakage.

Models that have fluorescent tracer dye incorporated into the refrigeration system can be checke d for non-apparent leaks by

scanning with a high intensity ultraviolet lamp. The location of leaks can be pinpointed by the bright yellow glow of the

tracer dye.

CAUTION: Observe ALL safety precautions associated with ultraviolet equipment.

Should a leak be traced to a joint, check that the fixing is secured to the correct tightening torque before taking any other

action.

When examining the system for leaks, chec k the compressor shaft seal and evaporator.

Charge Re

covery (system depressurization)

The process of

charge r

ecovery will depe

nd on the basic characteristics of your chosen recovery / recycle / recharge

equipment, therefore, follow the manu facturer's instructions carefully.

Remember that compressor oil may be drawn out during this process, take note of the quantity recovered so that it may be

Lo

w side

gauge reading

High s i

de

gauge reading

Fau l

t

Cause

No

r

mal

No

r

mal

Di

sc

harge air initially cool then

warms up

Mois

ture in system

N

ormal

to low

No

r

mal

As aboveAs above

LowLowD

i

scharge air slightly cool

Ref

r

igerant charge low

LowLowDi

scharge air warm

Refr

igerant charge very low

LowLowDi

scharge air slightly cool or frost

build up at expansion valve

Expansion valve st

uck closed

LowLowDi

scharge air slightly cool,

sweating or frost after point of restriction

Restri

ction in High side of system

HighLowCompressor noisyDe

fe

ctive compressor reed valve

HighHighD

i

scharge air warm and high side

pipes hot

Refri

gerant charge high or inefficient condenser

cooling due to air flow blockage or engine cooling fans

not working

HighHighD i

scharge air warm / Sweating or

frost at evaporator

Expans ion valve st

uck open

Page 1761 of 2490

Climate Co

ntrol System - General In

formation - Air Conditioning (A/C)

System Check - Re tail Procedure

Gen

eral Procedures

E

vacuating the Manifold Gauge Set

Connecting the Manifold Gauge Set

C

AUTION: Only use hoses with connectors wh

ich are dedicated to HFC 134A charge ports.

Stabilizing the System

1.

At

tach the center (service) hose to a vacuum pump and start

the pump. Open fully both high and low valves and allow the

vacuum to remove air and mois ture from the manifold set for

at least five minutes.

CAUTION: It is imperative th at the vacuum pump is not

subjected to a positi ve pressure of any degree. Therefore the

pump must be fitted wi th an isolation valve at the center (service

hose) connection and this valve mu st be closed before the pump

is switched off. This operation replaces the 'purge' procedure used

on previous systems. Observe the manufacturer's

recommendation with regard to vacuum pump oil changes.

Turn the vacuum pump off and isol ate it from the center service

hose but do not open the hose to atmosphere.

1. Att

achment of the hose quick release connectors to the high

and low side system ports is stra ightforward, provided that the

high and low valves are closed and the system is NOT

operational.

WARNING: UNDER NO CIRCUMSTANCES SHOULD THE

CONNECTIONS BE MADE WITH THE SYSTEM IN OPERATION OR

THE VALVES OPEN. SHOULD THE VALVES BE OPEN AND A

VACUUM PUMP OR REFRIGERANT CONTAINER ATTACHED, AN

EXPLOSION COULD OCCUR AS A RESULT OF HIGH PRESSURE

REFRIGERANT BEING FORCED BACK INTO THE VACUUM PUMP OR

CONTAINER.

Assessment of system operating efficiency and fault

classification may be achieved by using the facilities on your

Recovery / Recharging / Recycling station, follow the

manufacturer's instructions implicitly and observe all safety

considerations.

1. Accurate test gauge data wi

ll on

ly be attained if the system

temperatures and pressures are stabilized.

E

nsure that equipment and hoses cannot come into

contact with engine moving parts or sources of heat.

It is recommended th at a free standing air

mover is placed

in front of the vehicle to provide air flow through the

condenser / cooling system.

St

art the engine, allow it to attain normal working

temperature and set at fast idle (typically 1200 to 1500

rpm).

Select full

air condit

ioning performance.

With

all temperatures and pres

sures stable, or displaying

symptoms of faults; begin relevant test procedures.