Drive shaft JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1342 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Extension Housing Seal

In-vehicle Repair

Removal

Special Tool(s)

Drive shaft flange wrench

205-053

Coupling nut socket

307-356

Oil seal replacer

307-358

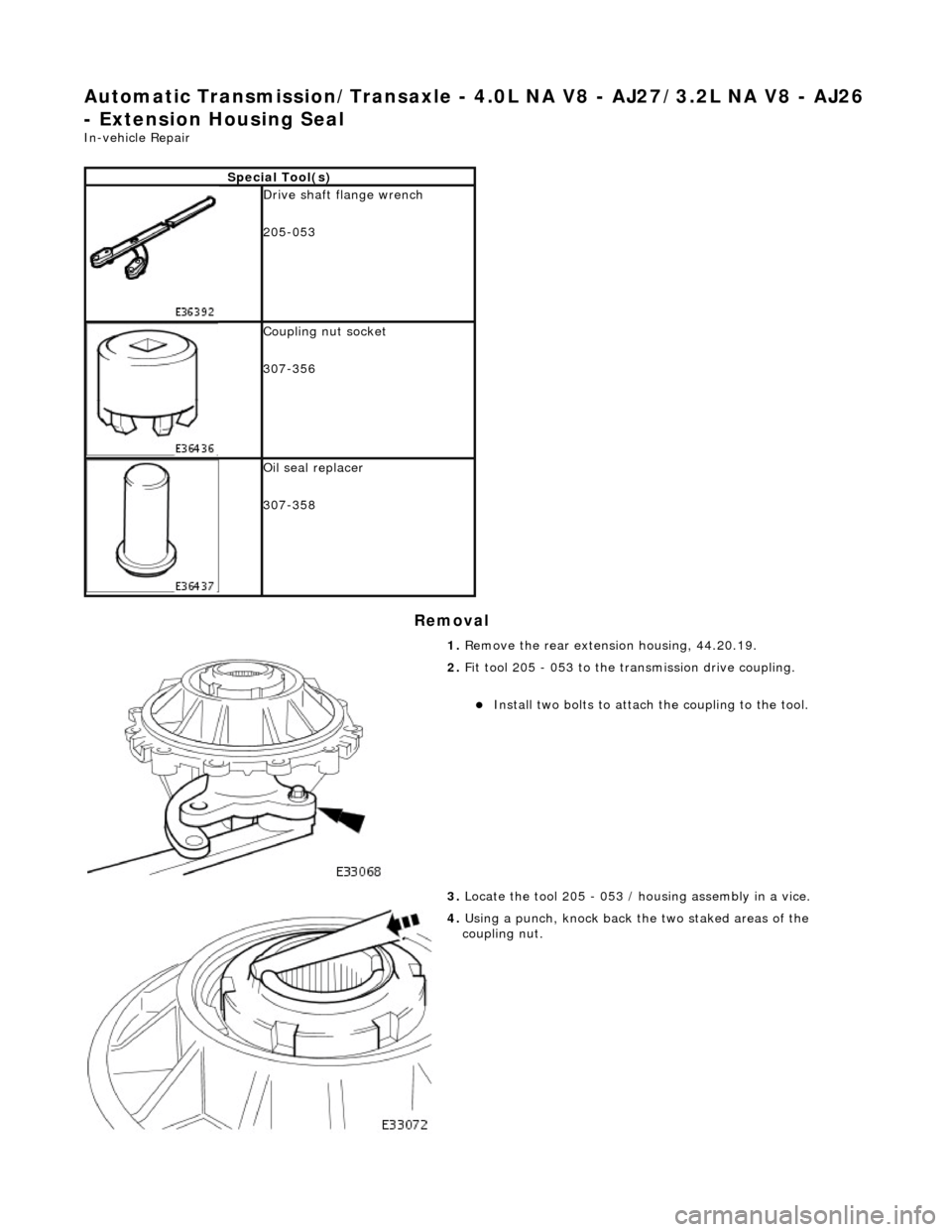

1. Remove the rear extension housing, 44.20.19.

2. Fit tool 205 - 053 to the transmission drive coupling.

Install two bolts to attach the coupling to the tool.

3. Locate the tool 205 - 053 / housing assembly in a vice.

4. Using a punch, knock back the two staked areas of the

coupling nut.

Page 1345 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Extension Housing O-Ring Seal

In-vehicle Repair

Removal

1. Select N position.

2. Raise the vehicle for access.

3. Remove the front muffler, 30.10.18.

4. Locate a transmission jack, Epco V-100 or similar, under the

transmission unit.

Adjust the angle of the jack to suit the transmission.

Secure the side clamps.

Pass the safety chain over the transmission unit and

secure.

Take the weight of the transmission and engine.

5. Remove the engine rear mounting bracket.

1. Remove the engine rear mounting to bracket bolt.

2. Remove the mounting bracket to body bolts.

6. Gently lower the transmission jack.

7. CAUTION: Under no circumstan ces remove the driveshaft

to flexible coupling fixings.

Detach the driveshaft fro m the transmission unit.

Mark the position of the coupling to drive flange.

Remove the three bolts which secure the transmission

drive flange to the flexible coupling .

8. Remove the rear extension housing assembly.

1. Remove the ten bolts, noting their location for installation.

2. Remove and discard the O-ring.

Page 1346 of 2490

Installation

9. Clean the mating faces.

1. Installation is the reverse of the removal procedure noting

that;

1. Install a new O-ring seal.

2. Tighten the ten bolts to the specified torque figure.

2. Align the driveshaft with the tr ansmission drive flange using

the marks made on removal.

Tighten the three bolts to the specified torque figure.

3. Raise the transmission carefu lly to position, using the

transmission jack

4. Fit the engine rear mounting and tighten the centre bolt and

outer bolts to the specified torque figures.

Check that the safety chain on the transmission jack will

not be trapped when the mounting is fitted.

5. Remove the transmission jack.

Page 1377 of 2490

16. Remove the engine rear mounting bracket.

1. Remove the engine rear mounting to bracket bolt.

2. Remove the mounting bracket to body bolts.

17. Detach the driveshaft from th e transmission drive flange.

If the transmission is to be refitted, mark the position of

the coupling to drive flange.

17. CAUTION: Under no circ umstances remove the

driveshaft to flexible coupling fixings.

Remove the transmission drive flange to flexible coupling

three fixings.

18. Lower the transmission unit by carefully releasing the engine

support beam and by loweri ng the transmission jack.

19. Detach the gear selector cable from the transmission unit.

1. Remove the selector cable ball pin to selector lever nut.

2. Remove the selector cable to transmission casing bolts.

20. Disconnect the transmission harness multiplug.

1. Rotate the locking lever to release.

2. Disconnect the multiplug.

Page 1378 of 2490

21. Detach the rotary switch.

1. Remove the switch fixings.

2. Displace the switch harness from the clips.

22. Disconnect the fluid cooler pipes.

Unscrew the cooler pipe tube nu ts, one at each side of the

transmission casing.

Discard the 'O' rings.

Plug the pipes an d transmission.

23. Remove the three bolts which se cure the torque converter to

the drive plate.

1. Remove the access cover.

2. Rotate the crankshaft and hold to prevent movement, and remove the bolts.

24. Remove the LH and RH cataly st mounting brackets from the

transmission case.

Remove the bolts.

Page 1383 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Transmission

Installation

Installation

Special Tool(s)

Engine support

303-021

Engine lifting brackets

303-536

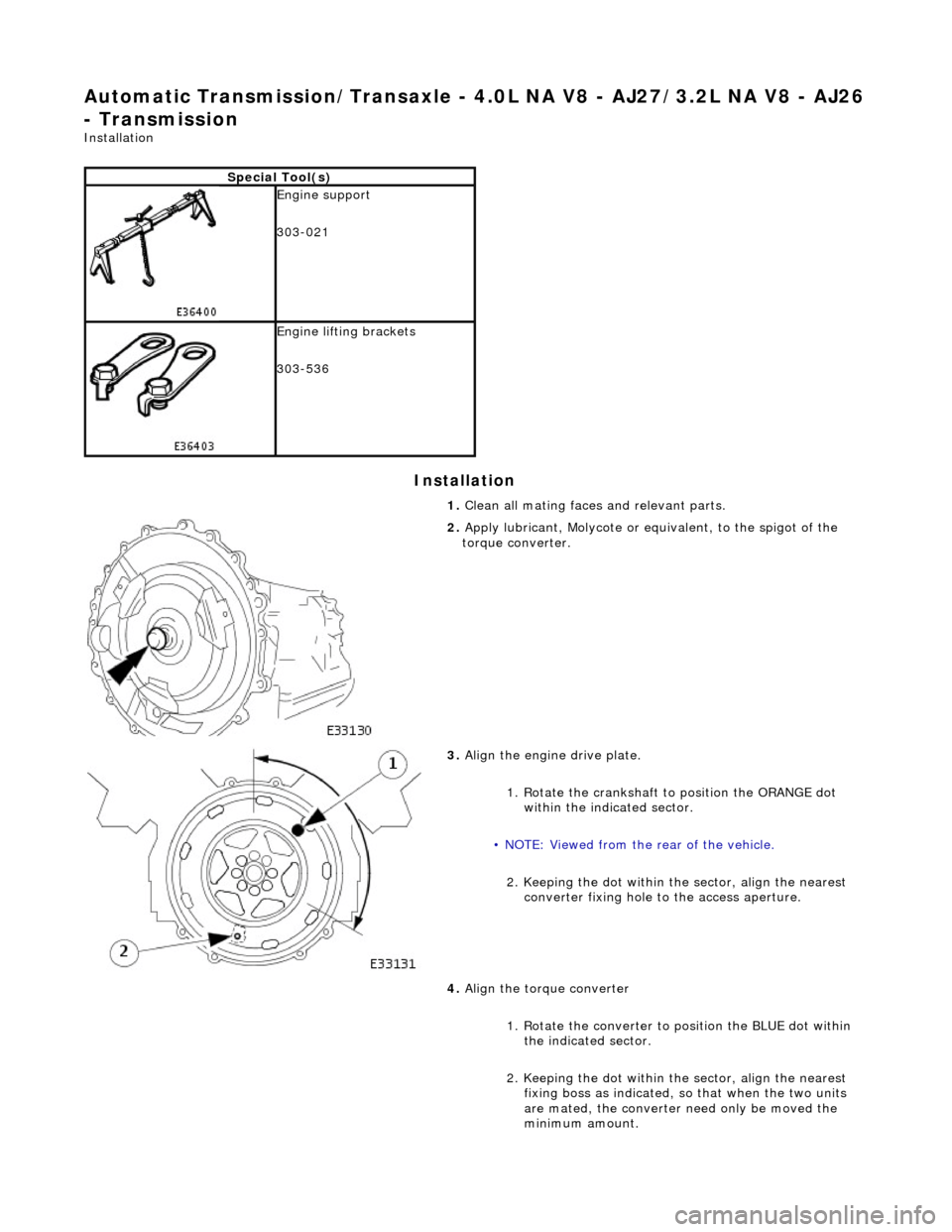

1. Clean all mating faces and relevant parts.

2. Apply lubricant, Molycote or equivalent, to the spigot of the

torque converter.

3. Align the engine drive plate.

1. Rotate the crankshaft to position the ORANGE dot

within the indicated sector.

• NOTE: Viewed from the rear of the vehicle.

2. Keeping the dot within the sector, align the nearest converter fixing hole to the access aperture.

4. Align the torque converter

1. Rotate the converter to position the BLUE dot within the indicated sector.

2. Keeping the dot within the sector, align the nearest fixing boss as indicated, so that when the two units

are mated, the converter need only be moved the

minimum amount.

Page 1384 of 2490

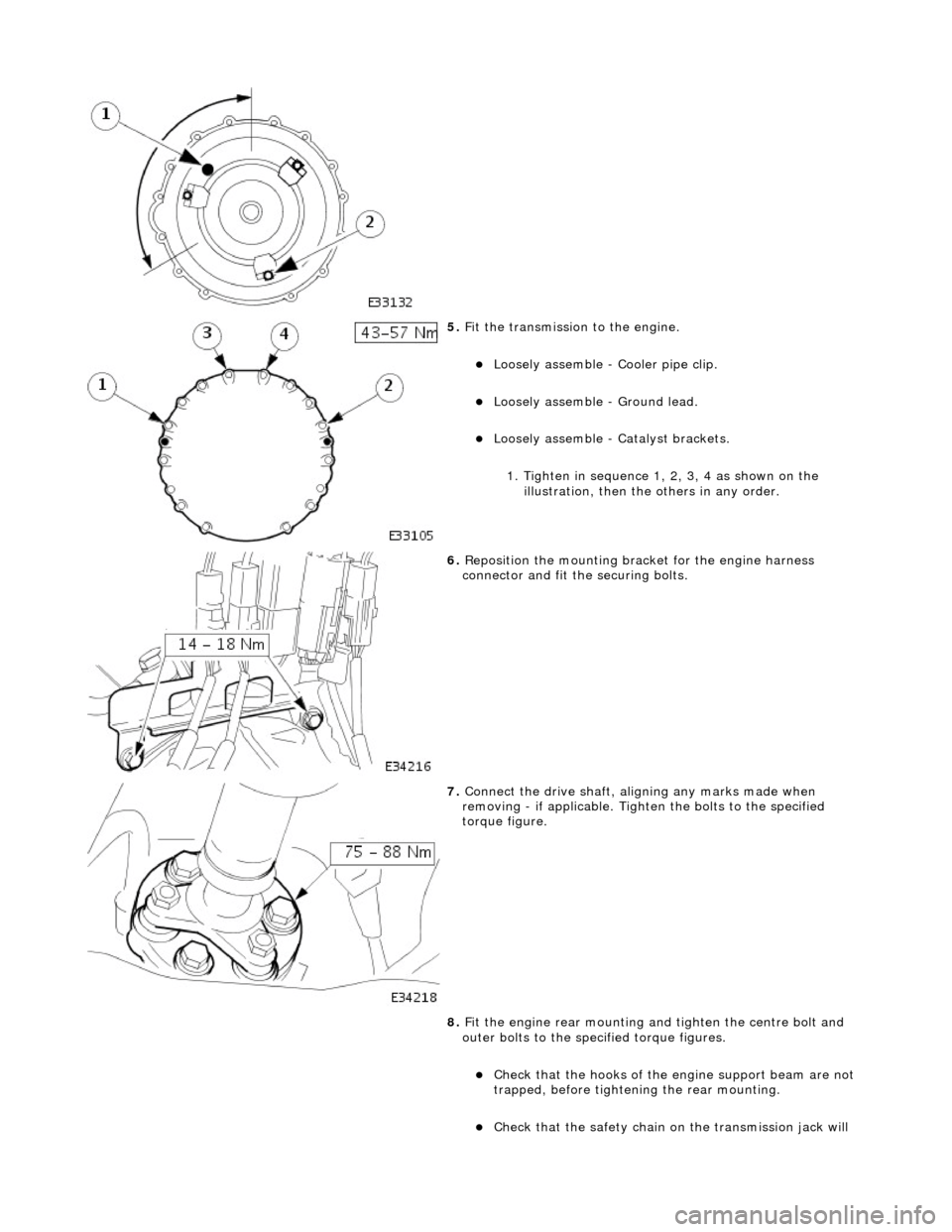

5. Fit the transmission to the engine.

Loosely assemble - Cooler pipe clip.

Loosely assemble - Ground lead.

Loosely assemble - Ca talyst brackets.

1. Tighten in sequence 1, 2, 3, 4 as shown on the illustration, then the others in any order.

6. Reposition the mounting brac ket for the engine harness

connector and fit the securing bolts.

7. Connect the drive shaft, aligning any marks made when

removing - if applicable. Tighten the bolts to the specified

torque figure.

8. Fit the engine rear mounting and tighten the centre bolt and

outer bolts to the specified torque figures.

Check that the hooks of the engine support beam are not

trapped, before tighteni ng the rear mounting.

Check that the safety chain on the transmission jack will

Page 1385 of 2490

not be trapped when the mounting is fitted.

9. Remove the transmission jack.

10. Fit the three bolts which secure the torque converter to the

drive plate.

1. Loosely assemble all three drive plate to torque converter bolts. Whilst preventing crankshaft

rotation, tighten the three converter bolts to the

specified torque figure.

2. Fit the blanking plug.

11. Connect the transmission harness multiplug.

1. Engage the multiplug.

2. Rotate the locking lever to secure.

12. Connect the selector cable to the selector lever and fit the

abutment bracket to the transmission casing. Tighten the nut

and two bolts to the specified torque figure.

Page 1388 of 2490

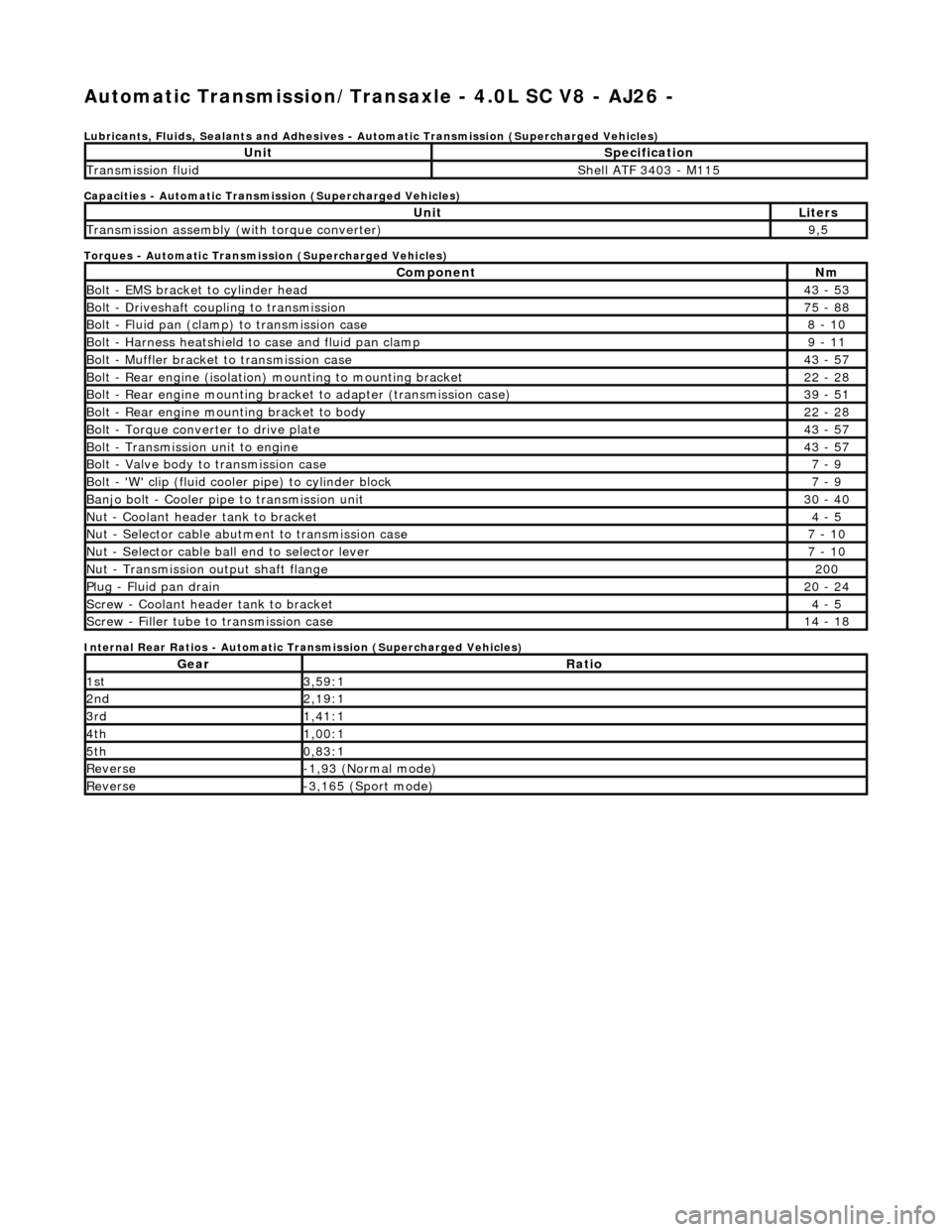

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 -

Lubricants, Fluids, Sealants and Adhesives - Automatic Transmission (Supercharged Vehicles)

Capacities - Automatic Transmission (Supercharged Vehicles)

Torques - Automatic Transmission (Supercharged Vehicles)

Internal Rear Ratios - Automatic Transmission (Supercharged Vehicles)

UnitSpecification

Transmission fluidShell ATF 3403 - M115

UnitLiters

Transmission assembly (with torque converter)9,5

ComponentNm

Bolt - EMS bracket to cylinder head43 - 53

Bolt - Driveshaft coupling to transmission75 - 88

Bolt - Fluid pan (clamp) to transmission case8 - 10

Bolt - Harness heatshield to case and fluid pan clamp9 - 11

Bolt - Muffler bracket to transmission case43 - 57

Bolt - Rear engine (isolation) mounting to mounting bracket22 - 28

Bolt - Rear engine mounting brac ket to adapter (transmission case)39 - 51

Bolt - Rear engine mounting bracket to body22 - 28

Bolt - Torque converter to drive plate43 - 57

Bolt - Transmission unit to engine43 - 57

Bolt - Valve body to transmission case7 - 9

Bolt - 'W' clip (fluid cooler pipe) to cylinder block7 - 9

Banjo bolt - Cooler pipe to transmission unit30 - 40

Nut - Coolant header tank to bracket4 - 5

Nut - Selector cable abutment to transmission case7 - 10

Nut - Selector cable ball end to selector lever7 - 10

Nut - Transmission output shaft flange200

Plug - Fluid pan drain20 - 24

Screw - Coolant header tank to bracket4 - 5

Screw - Filler tube to transmission case14 - 18

GearRatio

1st3,59:1

2nd2,19:1

3rd1,41:1

4th1,00:1

5th0,83:1

Reverse-1,93 (Normal mode)

Reverse-3,165 (Sport mode)

Page 1389 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Description

Description and Operation

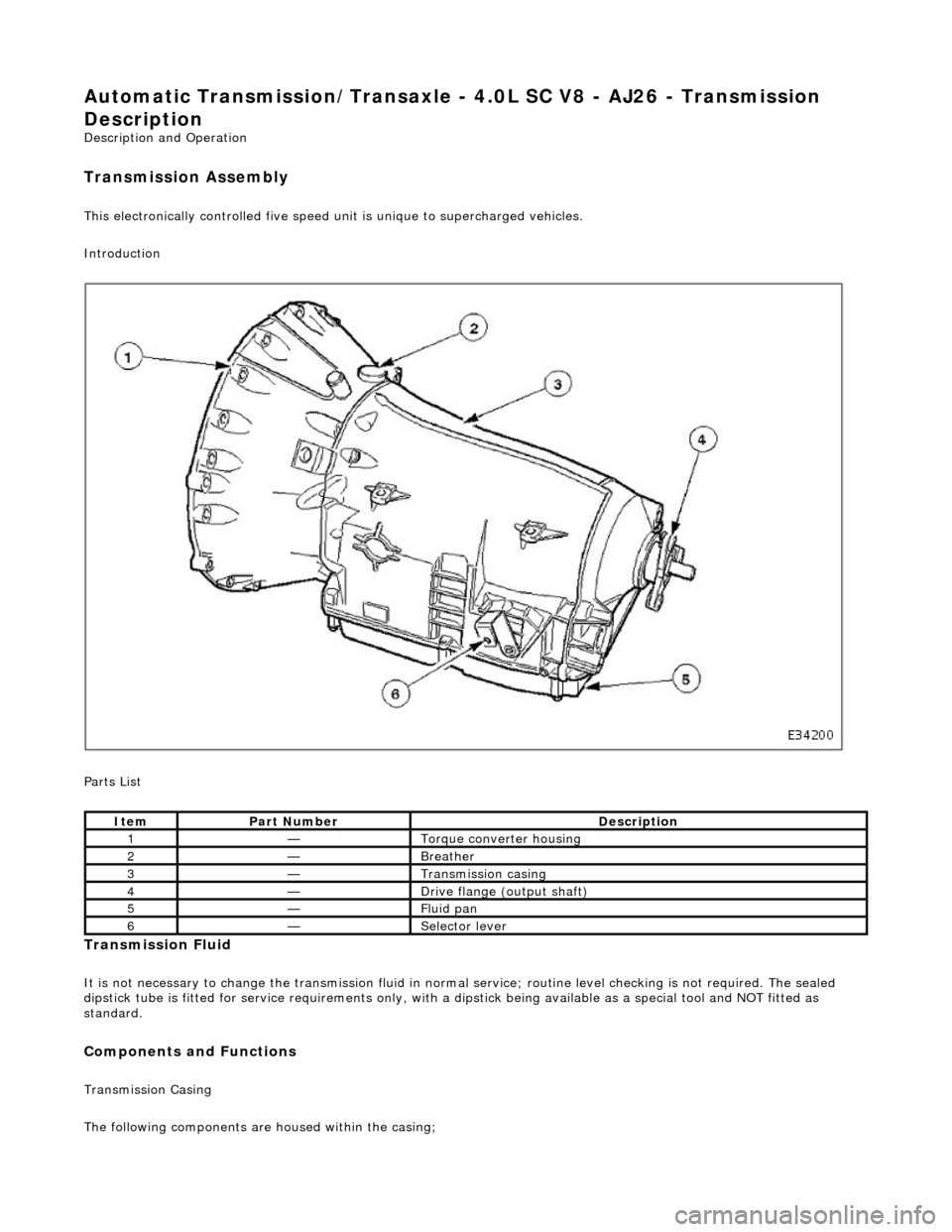

Transmission Assembly

This electronically controlled five speed unit is unique to supercharged vehicles.

Introduction

Parts List

Transmission Fluid

It is not necessary to change the transmis sion fluid in normal service; routine level checking is not required. The sealed

dipstick tube is fitted for service requir ements only, with a dipstick being availa ble as a special tool and NOT fitted as

standard.

Components and Functions

Transmission Casing

The following components are housed within the casing;

ItemPart NumberDescription

1—Torque converter housing

2—Breather

3—Transmission casing

4—Drive flange (output shaft)

5—Fluid pan

6—Selector lever