speed JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1397 of 2490

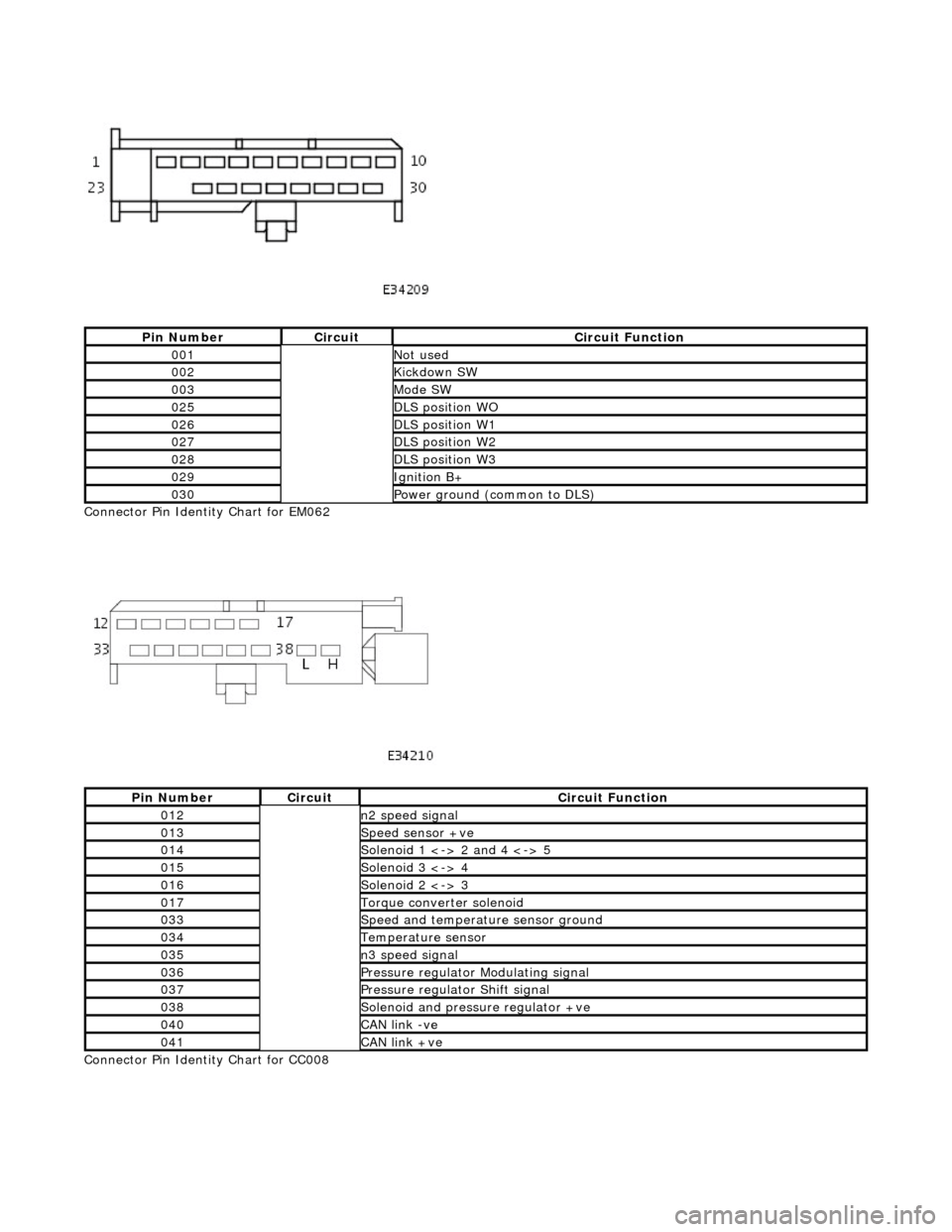

Connector Pin Identity Chart for EM062

Connector Pin Identity Chart for CC008

Pin NumberCircuitCircuit Function

001Not used

002Kickdown SW

003Mode SW

025DLS position WO

026DLS position W1

027DLS position W2

028DLS position W3

029Ignition B+

030Power ground (common to DLS)

Pin NumberCircuitCircuit Function

012n2 speed signal

013Speed sensor +ve

014Solenoid 1 <-> 2 and 4 <-> 5

015Solenoid 3 <-> 4

016Solenoid 2 <-> 3

017Torque converter solenoid

033Speed and temperature sensor ground

034Temperature sensor

035n3 speed signal

036Pressure regulator Modulating signal

037Pressure regulator Shift signal

038Solenoid and pressure regulator +ve

040CAN link -ve

041CAN link +ve

Page 1398 of 2490

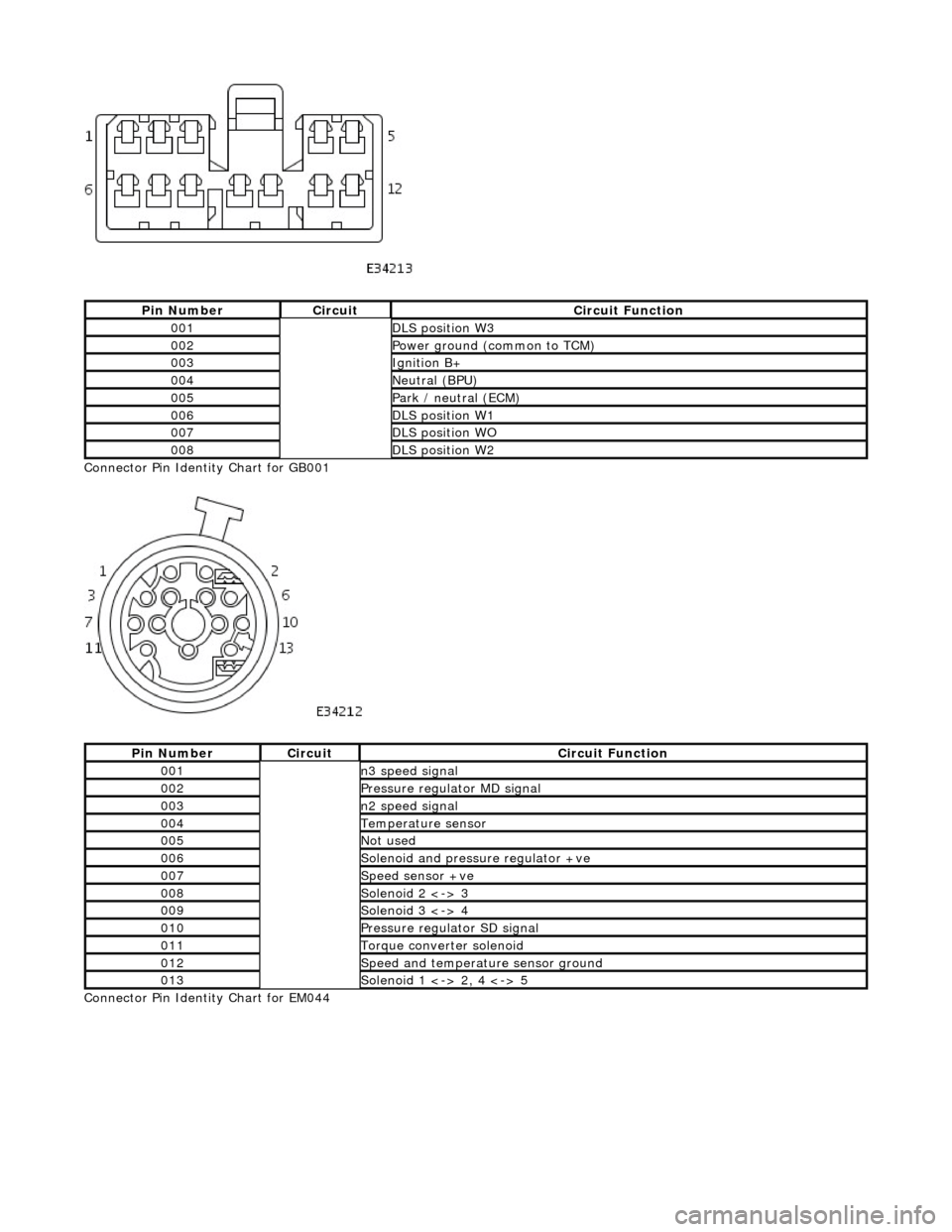

Connector Pin Identity Chart for GB001

Connector Pin Identity Chart for EM044

Pin NumberCircuitCircuit Function

001DLS position W3

002Power ground (common to TCM)

003Ignition B+

004Neutral (BPU)

005Park / neutral (ECM)

006DLS position W1

007DLS position WO

008DLS position W2

Pin NumberCircuitCircuit Function

001n3 speed signal

002Pressure regulator MD signal

003n2 speed signal

004Temperature sensor

005Not used

006Solenoid and pressure regulator +ve

007Speed sensor +ve

008Solenoid 2 <-> 3

009Solenoid 3 <-> 4

010Pressure regulator SD signal

011Torque converter solenoid

012Speed and temperature sensor ground

013Solenoid 1 <-> 2, 4 <-> 5

Page 1399 of 2490

Pin NumberCircuitCircuit Function

001n3 speed signal

002Pressure regulator MD signal

003n2 speed signal

004Temperature sensor

005Solenoid 1 <-> 2, 4 <-> 5

006Solenoid and pressure regulator +ve

007Speed sensor +ve

008Solenoid 2 <-> 3

009Solenoid 3 <-> 4

010Pressure regulator SD signal

011Torque converter solenoid

012Speed and temperature sensor ground

Page 1400 of 2490

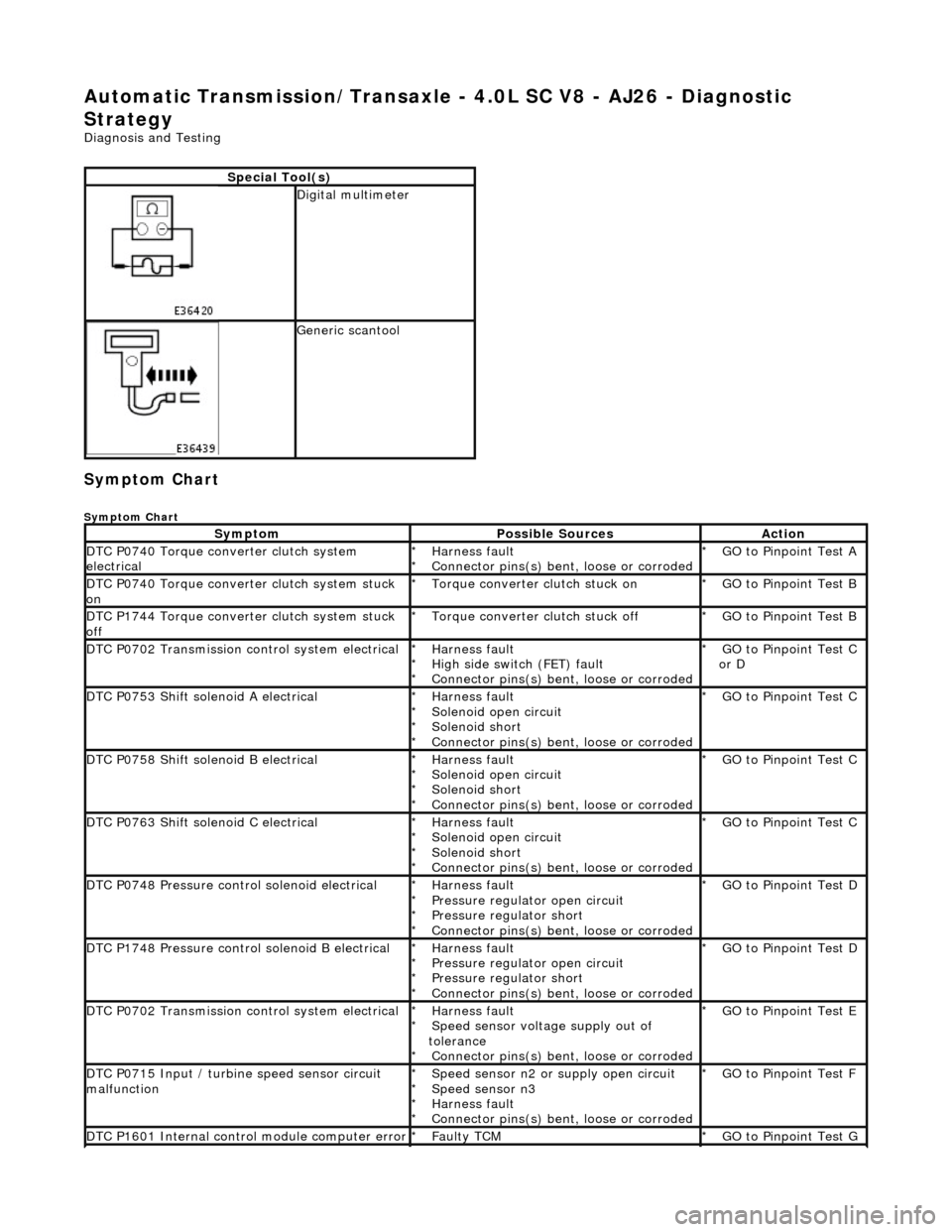

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Diagnostic

Strategy

Diagnosis and Testing

Symptom Chart

Symptom Chart

Special Tool(s)

Digital multimeter

Generic scantool

SymptomPossible SourcesAction

DTC P0740 Torque converter clutch system

electricalHarness fault

Connector pins(s) bent , loose or corroded

*

*GO to Pinpoint Test A

*

DTC P0740 Torque converter clutch system stuck

onTorque converter clutch stuck on

*GO to Pinpoint Test B

*

DTC P1744 Torque converter clutch system stuck

offTorque converter clutch stuck off

*GO to Pinpoint Test B

*

DTC P0702 Transmission control system electricalHarness fault

High side switch (FET) fault

Connector pins(s) bent , loose or corroded

*

*

*GO to Pinpoint Test C

or D

*

DTC P0753 Shift solenoid A electricalHarness fault

Solenoid open circuit

Solenoid short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint Test C *

DTC P0758 Shift solenoid B electricalHarness fault

Solenoid open circuit

Solenoid short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint Test C *

DTC P0763 Shift solenoid C electricalHarness fault

Solenoid open circuit

Solenoid short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint Test C *

DTC P0748 Pressure control solenoid electricalHarness fault

Pressure regulator open circuit

Pressure regulator short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint Test D *

DTC P1748 Pressure control solenoid B electricalHarness fault

Pressure regulator open circuit

Pressure regulator short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint Test D *

DTC P0702 Transmission control system electricalHarness fault

Speed sensor voltage supply out of

tolerance Connector pins(s) bent , loose or corroded

*

*

*GO to Pinpoint Test E

*

DTC P0715 Input / turbine speed sensor circuit

malfunctionSpeed sensor n2 or supply open circuit

Speed sensor n3

Harness fault

Connector pins(s) bent , loose or corroded

*

*

*

*GO to Pinpoint Test F

*

DTC P1601 Internal control module computer errorFaulty TCM

*GO to Pinpoint Test G *

Page 1424 of 2490

With EM062 and GB001 disconnected, measure the

resistance between GB001/012 and EM062/033 1

Is the resistance < 0.5 OHM?

Yes GO to F4

No Inspect EM062, EM044 and GB001 for corrosion, bent /

pushed back pins or locate harness. Repair as necessary

and test the system fo r normal operation.

F4: CHECK SIGNAL CONTINUITY (N2 SPEED SENSOR)

Page 1425 of 2490

With EM062 and GB001 disconnected, measure the

resistance between GB001/003 and EM062/012 1

Is the resistance < 0.5 OHM?

Yes Reconnect GB001

GO to F5

No Inspect EM062, EM044 and GB001 for corrosion, bent /

pushed back pins or locate harness. Repair as necessary

and test the system fo r normal operation.

F5: CHECK SIGNAL CONTINUITY (N3 SPEED SENSOR)

Page 1502 of 2490

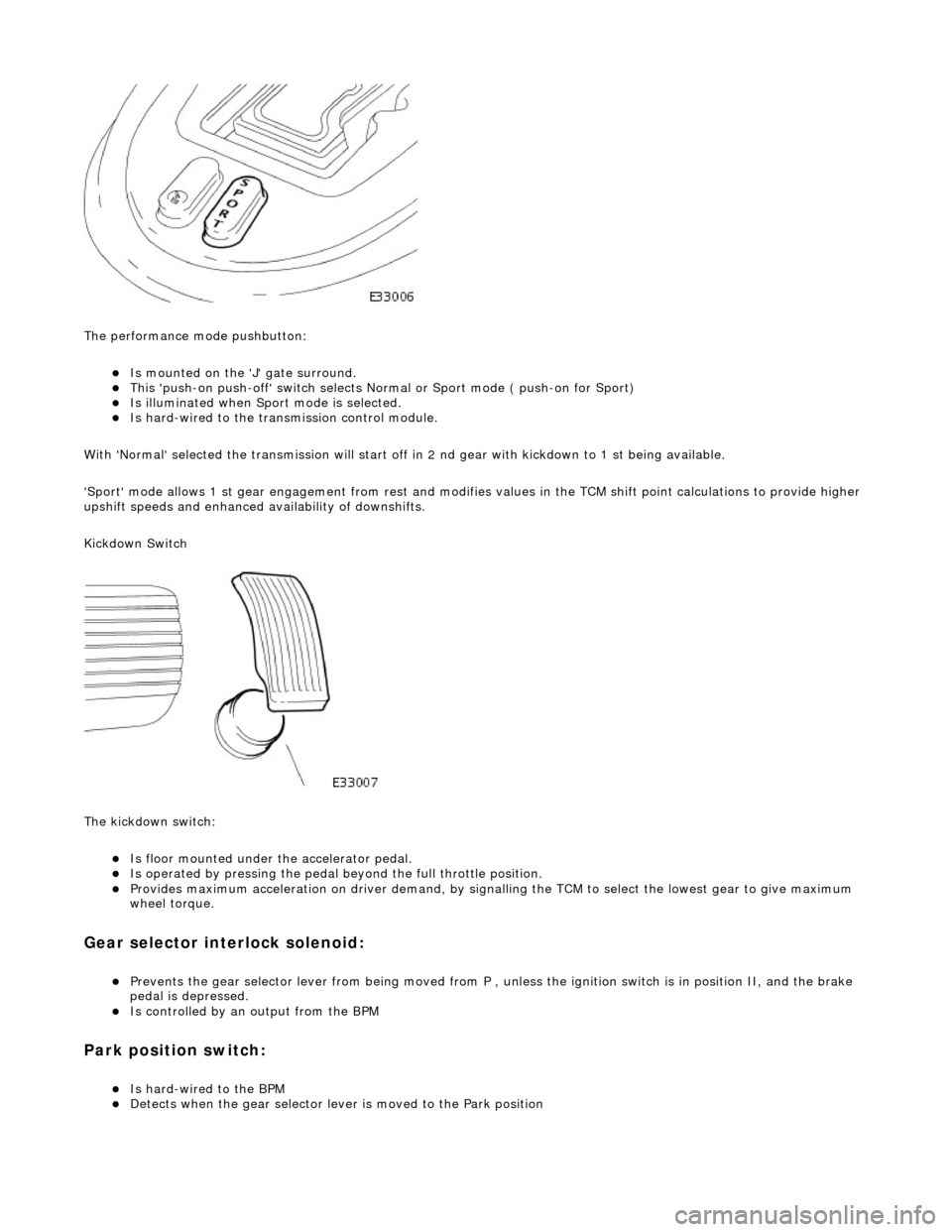

The performance mode pushbutton:

Is mounted on the 'J' gate surround. This 'push-on push-off' swit ch selects Normal or Sport mode ( push-on for Sport) Is illuminated when Sport mode is selected. Is hard-wired to the transmission control module.

With 'Normal' selected the transmissi on will start off in 2 nd gear with kickdown to 1 st being available.

'Sport' mode allows 1 st gear en gagement from rest and modifies values in the TCM shift point calculations to provide higher

upshift speeds and enhanced availability of downshifts.

Kickdown Switch

The kickdown switch:

Is floor mounted under th e accelerator pedal. Is operated by pressing the pedal beyond the full throttle position. Provides maximum acceleration on driver demand, by signalling the TCM to select the lowest gear to give maximum

wheel torque.

Gear selector interlock solenoid:

Prevents the gear selector lever from being moved from P , unless the ignition switch is in position II, and the brake

pedal is depressed.

Is controlled by an output from the BPM

Park position switch:

Is hard-wired to the BPM Detects when the gear selector lever is moved to the Park position

Page 1535 of 2490

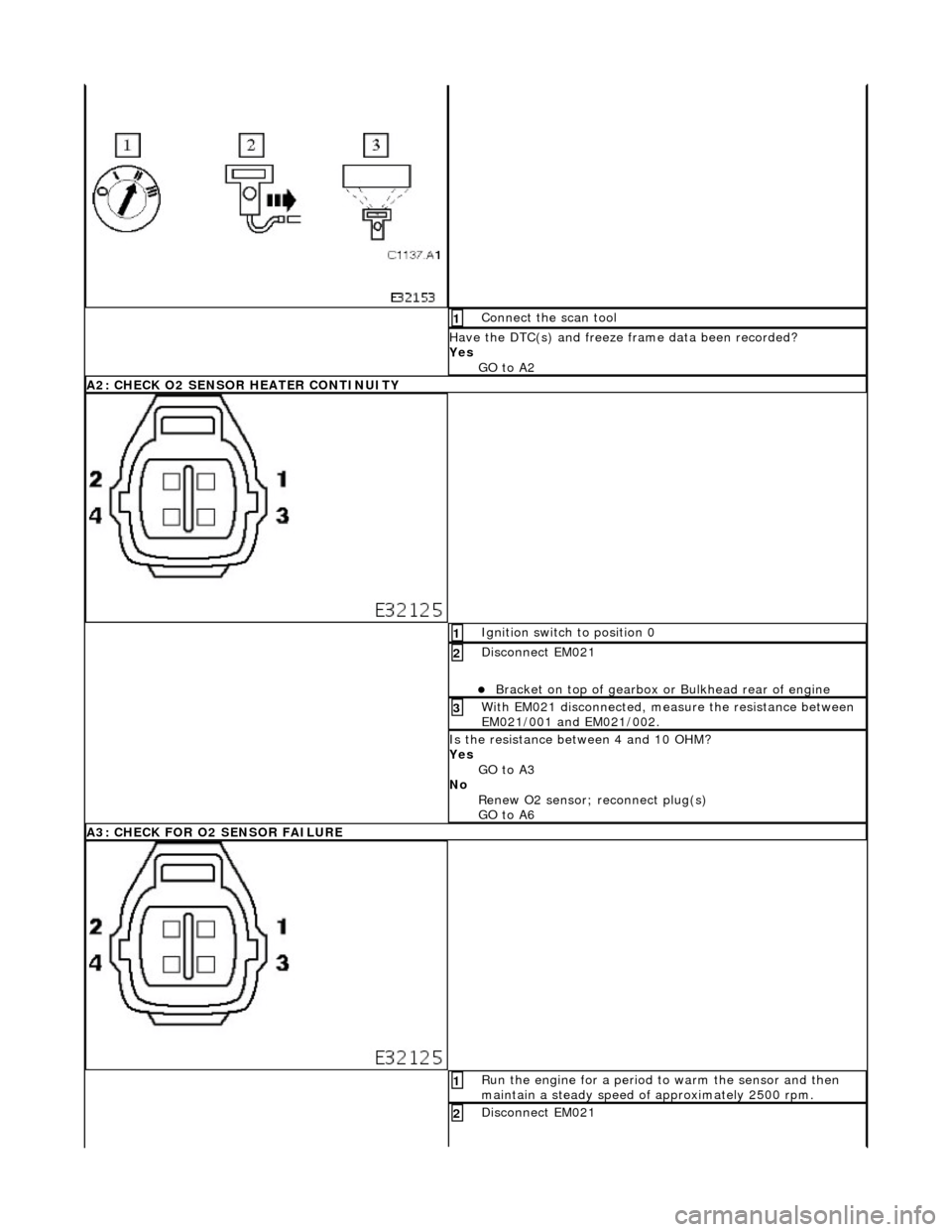

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to A2

A2: CHECK O2 SENSOR HEATER CONTINUITY

Ignition switch to position 0 1

Disconnect EM021

Bracket on top of gearbox or Bulkhead rear of engine

2

With EM021 disconnected, measure the resistance between

EM021/001 and EM021/002. 3

Is the resistance between 4 and 10 OHM?

Yes

GO to A3

No Renew O2 sensor; reconnect plug(s)

GO to A6

A3: CHECK FOR O2 SENSOR FAILURE

Run the engine for a period to warm the sensor and then

maintain a steady speed of approximately 2500 rpm. 1

Disconnect EM021 2

Page 1547 of 2490

Run the engine for a period to warm the sensor and then

maintain a steady speed of approximately 2500 rpm. 1

Measure the voltage between EM021/003 and EM021/004. 2

Is the voltage between 600mV and 1.0 Volt?

Yes

GO to B5

No Renew O2 sensor, reconnect plug(s).

GO to B8

B5: CHECK FOR O2 SENSOR FAILURE

With the conditions held as B4, suddenly decelerate to idle. 1

Has the voltage dropped to 400mV or less ?

Yes GO to B6

No Renew O2 sensor, reconnect plug(s).

GO to B8

B6: CHECK FOR O2 SENSOR FAILURE

With the conditions held as B5, suddenly accelerate to

approximately 2500 rpm. 1

Has the voltage risen to between 600mV and 1 volt?

Yes

Page 1558 of 2490

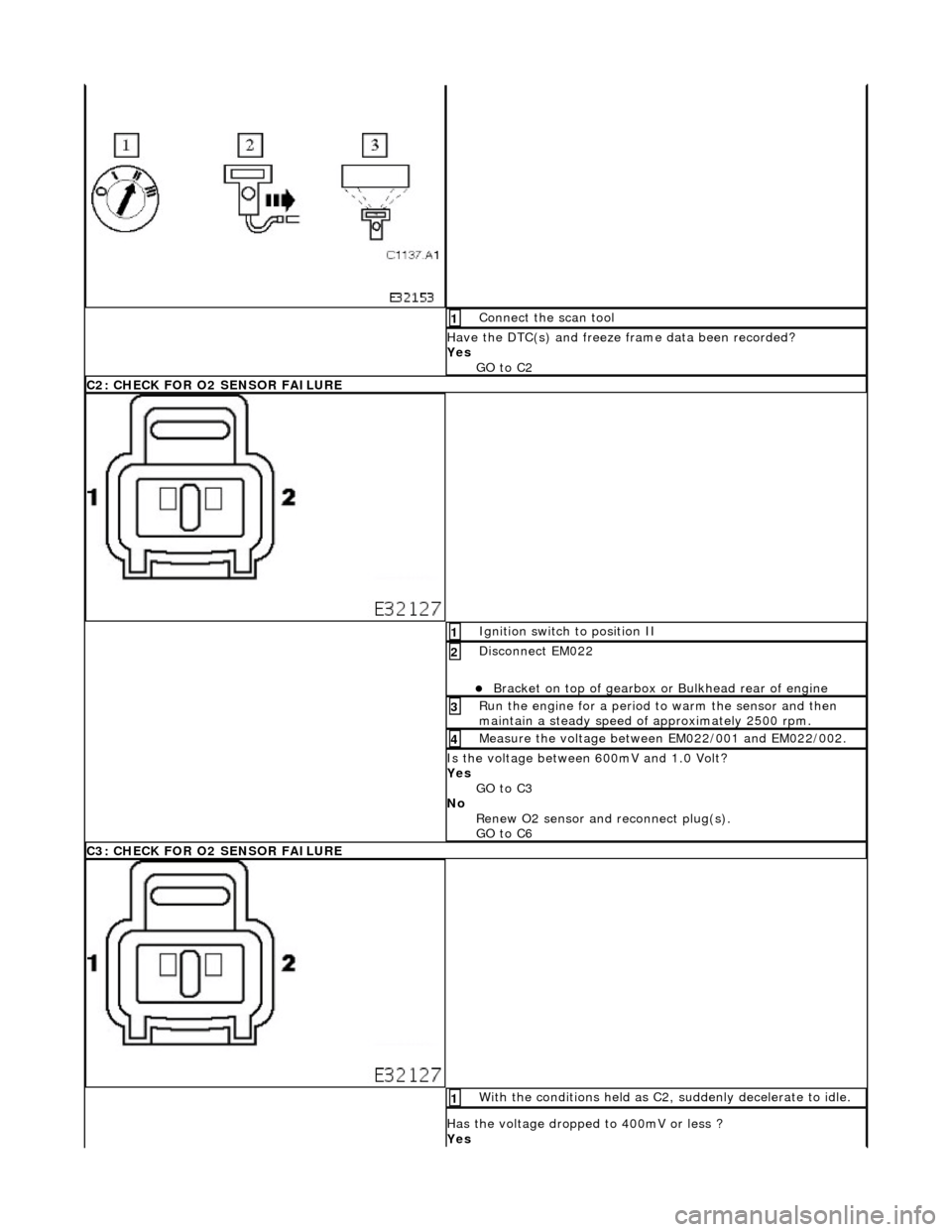

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to C2

C2: CHECK FOR O2 SENSOR FAILURE

Ignition switch to position II 1

Disconnect EM022

Bracket on top of gearbox or Bulkhead rear of engine

2

Run the engine for a period to warm the sensor and then

maintain a steady speed of approximately 2500 rpm. 3

Measure the voltage between EM022/001 and EM022/002. 4

Is the voltage between 600mV and 1.0 Volt?

Yes

GO to C3

No Renew O2 sensor and reconnect plug(s).

GO to C6

C3: CHECK FOR O2 SENSOR FAILURE

With the conditions held as C2, suddenly decelerate to idle. 1

Has the voltage dropped to 400mV or less ?

Yes