ECU JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 560 of 2490

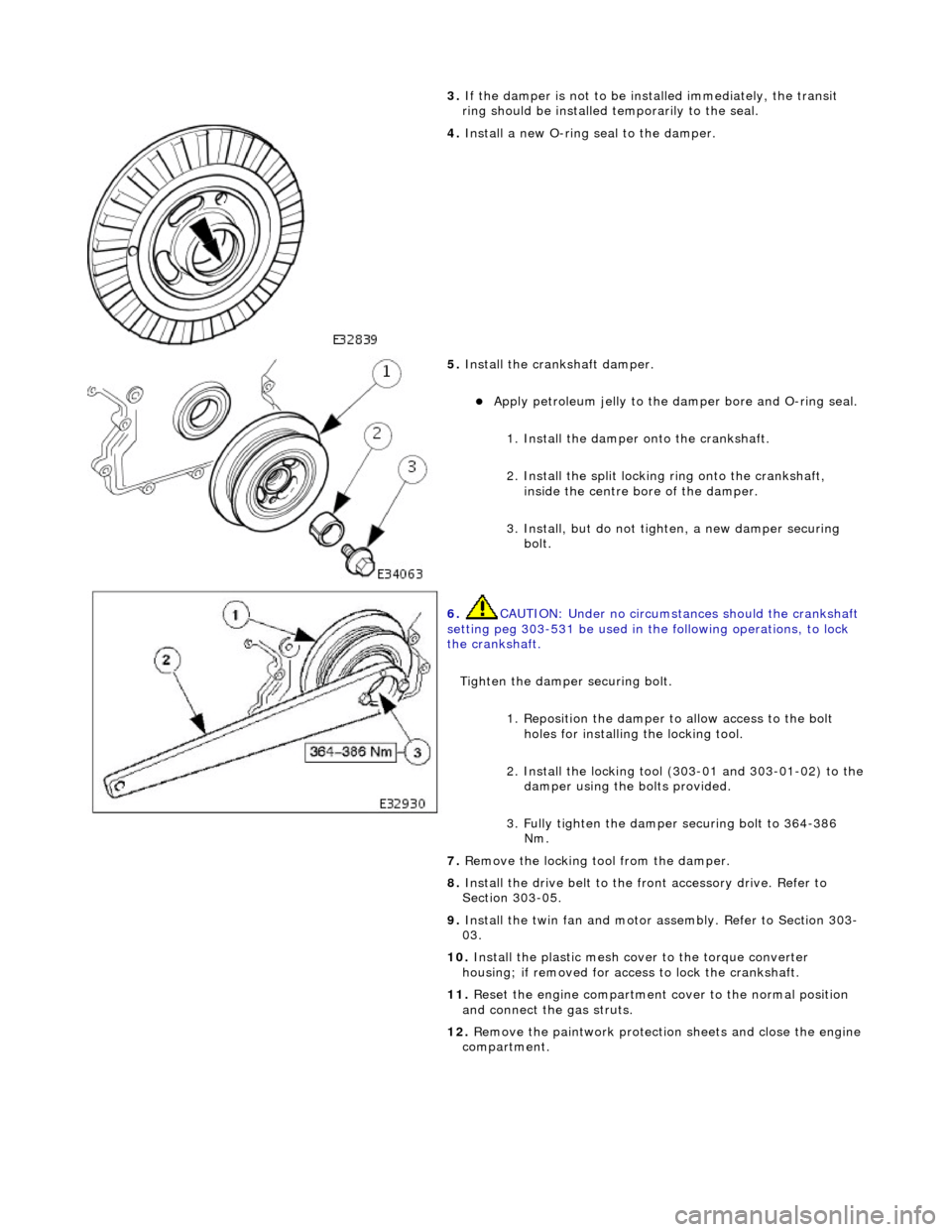

3.

If

the damper is not to be installed immediately, the transit

ring should be installed temporarily to the seal.

4. Install a new O-ri

ng seal to the damper.

5. Instal

l the crankshaft damper.

Apply petroleum jelly to the damper

bore and O-ring seal.

1. Install the damper onto the crankshaft.

2. Install the split locking ring onto the crankshaft,

inside the centre bo re of the damper.

3. Install, but do not tigh ten, a new damper securing

bolt.

6. CAUTIO

N: Under no circumstan

ces should the crankshaft

setting peg 303-531 be used in the following operations, to lock

the crankshaft.

Tighten the damper securing bolt. 1. Reposition the damper to allow access to the bolt holes for installing the locking tool.

2. Install the locking tool (303-01 and 303-01-02) to the

damper using the bolts provided.

3. Fully tighten the damper securing bolt to 364-386 Nm.

7. Re

move the locking tool from the damper.

8. Install the drive belt to the fr ont accessory drive. Refer to

Section 303-05.

9. Install the twin fan and motor assembly. Refer to Section 303-

03.

10. Install the plastic mesh cove r to the torque converter

housing; if removed for acce ss to lock the crankshaft.

11. Reset the engine compartment cover to the normal position

and connect the gas struts.

12. Remove the paintwork protection sheets and close the engine

compartment.

Page 562 of 2490

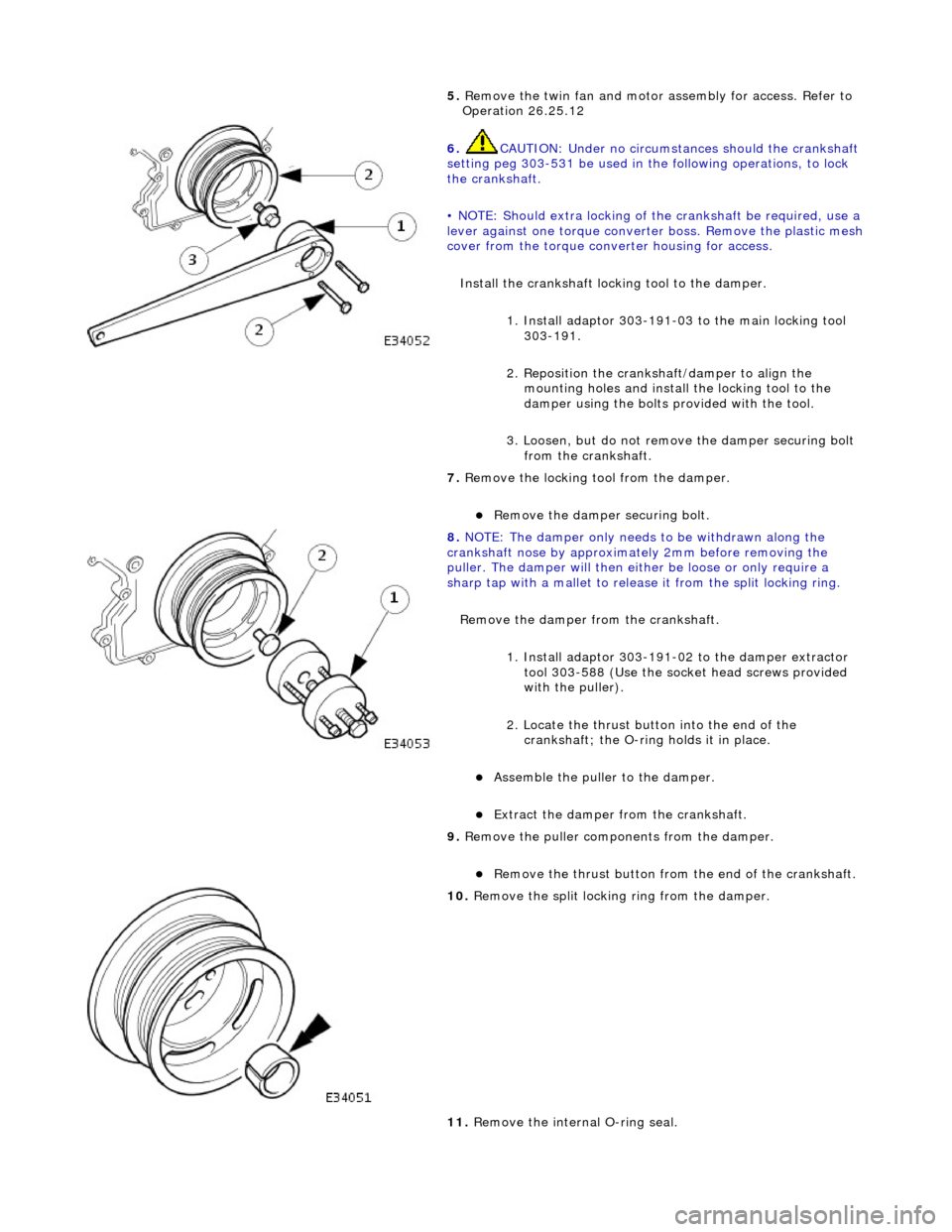

5. Re

move the twin fan and motor

assembly for access. Refer to

Operation 26.25.12

6. CAUTIO

N: Under no circumstan

ces should the crankshaft

setting peg 303-531 be used in the following operations, to lock

the crankshaft.

• NOTE: Should extra locking of the crankshaft be required, use a

lever against one torque converte r boss. Remove the plastic mesh

cover from the torque converter housing for access.

Install the crankshaft locking tool to the damper. 1. Install adaptor 303-191-03 to the main locking tool 303-191.

2. Reposition the cranks haft/damper to align the

mounting holes and install the locking tool to the

damper using the bolts provided with the tool.

3. Loosen, but do not remove the damper securing bolt

from the crankshaft.

7. Re

move the locking tool from the damper.

Re

move

the damper securing bolt.

8. NOTE : Th

e damper only needs to be withdrawn along the

crankshaft nose by approximat ely 2mm before removing the

puller. The damper will then either be loose or only require a

sharp tap with a mallet to release it from the split locking ring.

Remove the damper from the crankshaft.

1. Install adaptor 303-191-02 to the damper extractor tool 303-588 (Use the socket head screws provided

with the puller).

2. Locate the thrust button into the end of the crankshaft; the O-ring holds it in place.

Ass

emble the puller to the damper.

Ex

trac

t the damper from the crankshaft.

9. Remove the puller components from the damper.

Re

move the thrust button from the end of the crankshaft.

10 . R

emove the split locking ring from the damper.

11. Remove the internal O-ring seal.

Page 564 of 2490

3.

If

the damper is not to be installed immediately, the transit

ring should be installed temporarily to the seal.

4. Install a new O-ri

ng seal to the damper.

5. Instal

l the crankshaft damper.

Apply petroleum jelly to the damper

bore and O-ring seal.

1. Install the damper onto the crankshaft.

2. Install the split locking ring onto the crankshaft,

inside the centre bo re of the damper.

3. Install, but do not tigh ten, a new damper securing

bolt.

6. CAUTIO

N: Under no circumstan

ces should the crankshaft

setting peg 303-531 be used in the following operations, to lock

the crankshaft.

Tighten the damper securing bolt.

1. Reposition the damper to allow access to the bolt holes for installing the locking tool.

2. Install the locking tool (303-191 and 303-191-03) to the damper using the bolts provided.

3. Fully tighten the damper securing bolt to 364-386 Nm.

7. Re

move the locking tool from the damper.

8. Install the drive belt to the fr ont accessory drive. Refer to

Operation 12.10.40.

9. Install the supercharger driv e belt. Refer to Operation

18.50.08.

10. Install the twin fan and motor assembly. Refer to Section

303-03.

11. Install the plastic mesh cove r to the torque converter

housing; if removed for acce ss to lock the crankshaft.

12. Reset the engine compartment cover to the normal position

and connect the gas struts.

13. Remove the paintwork protection sheets and close the engine

compartment.

Page 565 of 2490

Engine - Crankshaft

Inner Sp

rocket4.0L NA V8 - AJ27

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Camshaft setting

3

03 - 530

T

iming chain tensioning

303 - 532

Wedges, primary ch

ain

303 - 533

Cranksh

aft setting

303 - 531

1. Open the engine compartment and fit paintwork protection

sheets.

2. Set the engine compartment cover to the service access

position.

3. Di

sconnect the batt

ery ground cable.

R

emove the battery cover.

4. Remove the Timing Co ver. Refer to Operation 12.65.01 in this

Section.

5. Remove the VVT bush carrier from the A-Bank.

1. Remove the three bolts which secure the carrier to the cylinder block.

Page 566 of 2490

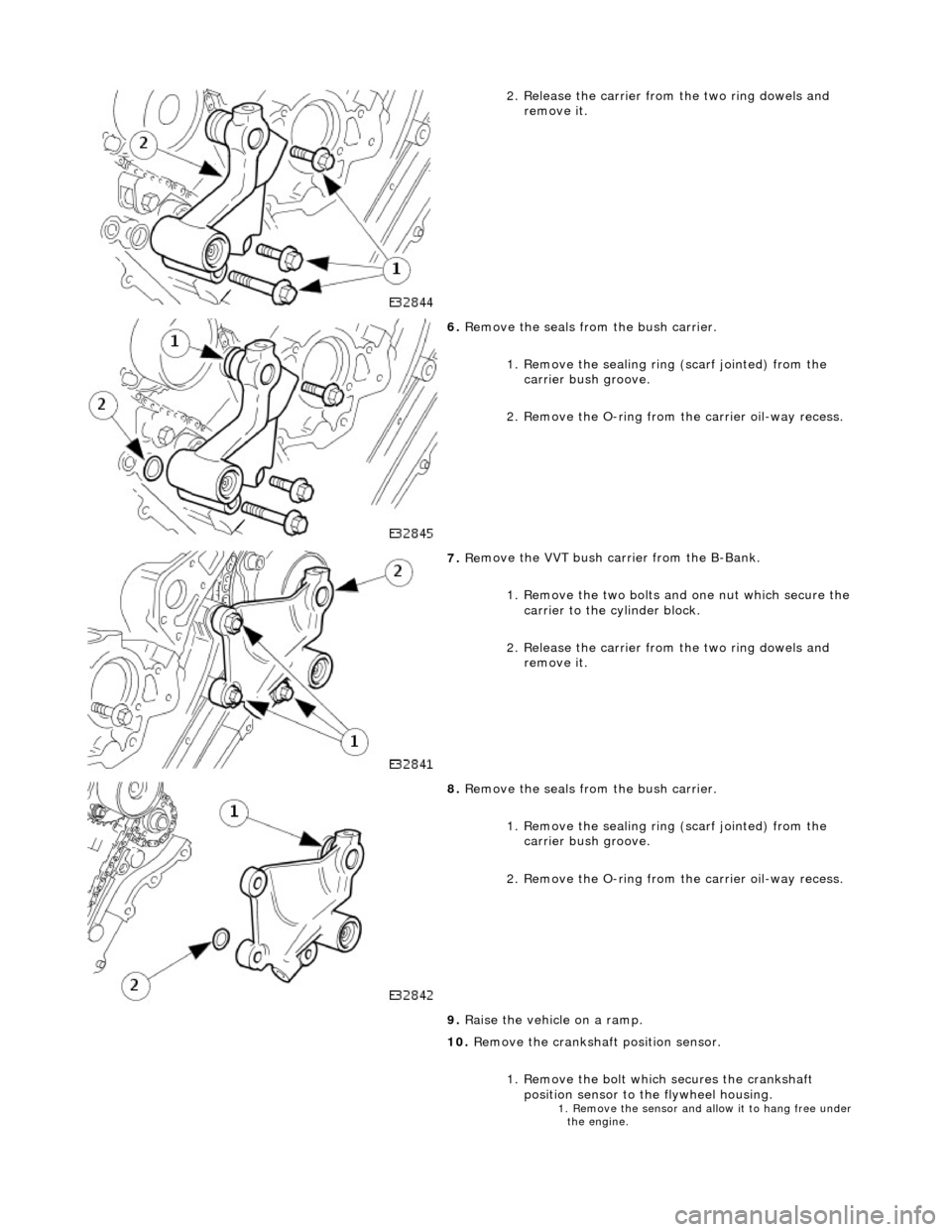

2.

Release the carrier from

the two ring dowels and

remove it.

6. Re

move the seals from the bush carrier.

1. Remove the sealing ring (scarf jointed) from the

carrier bush groove.

2. Remove the O-ring from the carrier oil-way recess.

7. Re

move the VVT bush carrier from the B-Bank.

1. Remove the two bolts and one nut which secure the carrier to the cylinder block.

2. Release the carrier from the two ring dowels and

remove it.

8. Re

move the seals from the bush carrier.

1. Remove the sealing ring (scarf jointed) from the

carrier bush groove.

2. Remove the O-ring from the carrier oil-way recess.

9. Raise the vehicle on a ramp.

10. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

1. Re move

the sensor and allow it to hang free under

the engine.

Page 567 of 2490

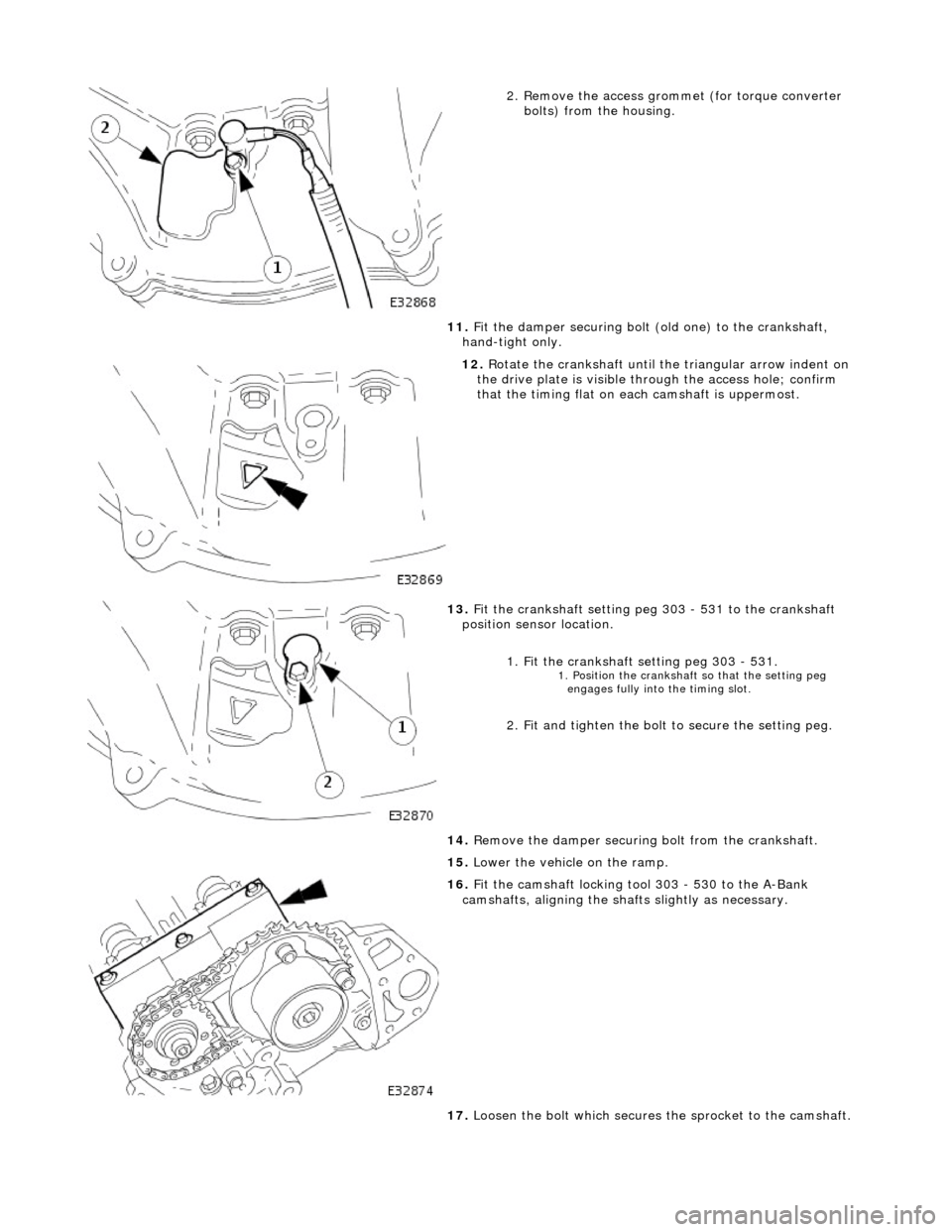

2

. Remove the access grommet (for torque converter

bolts) from the housing.

11. Fit the damper securing bolt (old one) to the crankshaft,

hand-tight only.

12

.

Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

13

.

Fit the crankshaft setting peg 303 - 531 to the crankshaft

position sensor location.

1. Fit the crankshaft setting peg 303 - 531.

1. P

osition the crankshaft so that the setting peg

engages fully into the timing slot.

2

. Fit and tighten the bolt to secure the setting peg.

14. Remove the damper securing bolt from the crankshaft.

15. Lower the vehicle on the ramp.

16

.

Fit the camshaft locking tool 303 - 530 to the A-Bank

camshafts, aligning the shafts slightly as necessary.

17. Loosen the bolt which secures the sprocket to the camshaft.

Page 568 of 2490

18. L

oosen the bolt which secures

the VVT unit to the camshaft.

19 . Re

move the primary ch

ain tensioner bolts.

20 . R

emove the tensioner assembly.

1. Remove the tensioner.

2. Remove the tensioner back-plate.

21. Remove the chain tensioner blade.

1. Remove the pivot bolt which secures the tensioner blade.

2. Remove the tensioner blade.

Page 569 of 2490

22

.

Remove the chain from the VVT unit and from the crankshaft

pulley.

23

.

Remove the camshaft locking tool 303 - 530 and transfer it to

the B-Bank camshafts, aligning the shafts slightly as necessary.

24

.

Loosen the bolt which secures the sprocket to the camshaft.

25

.

Loosen the bolt which secures the VVT unit to the camshaft.

26. Remove the primary ch ain tensioner bolts.

Page 570 of 2490

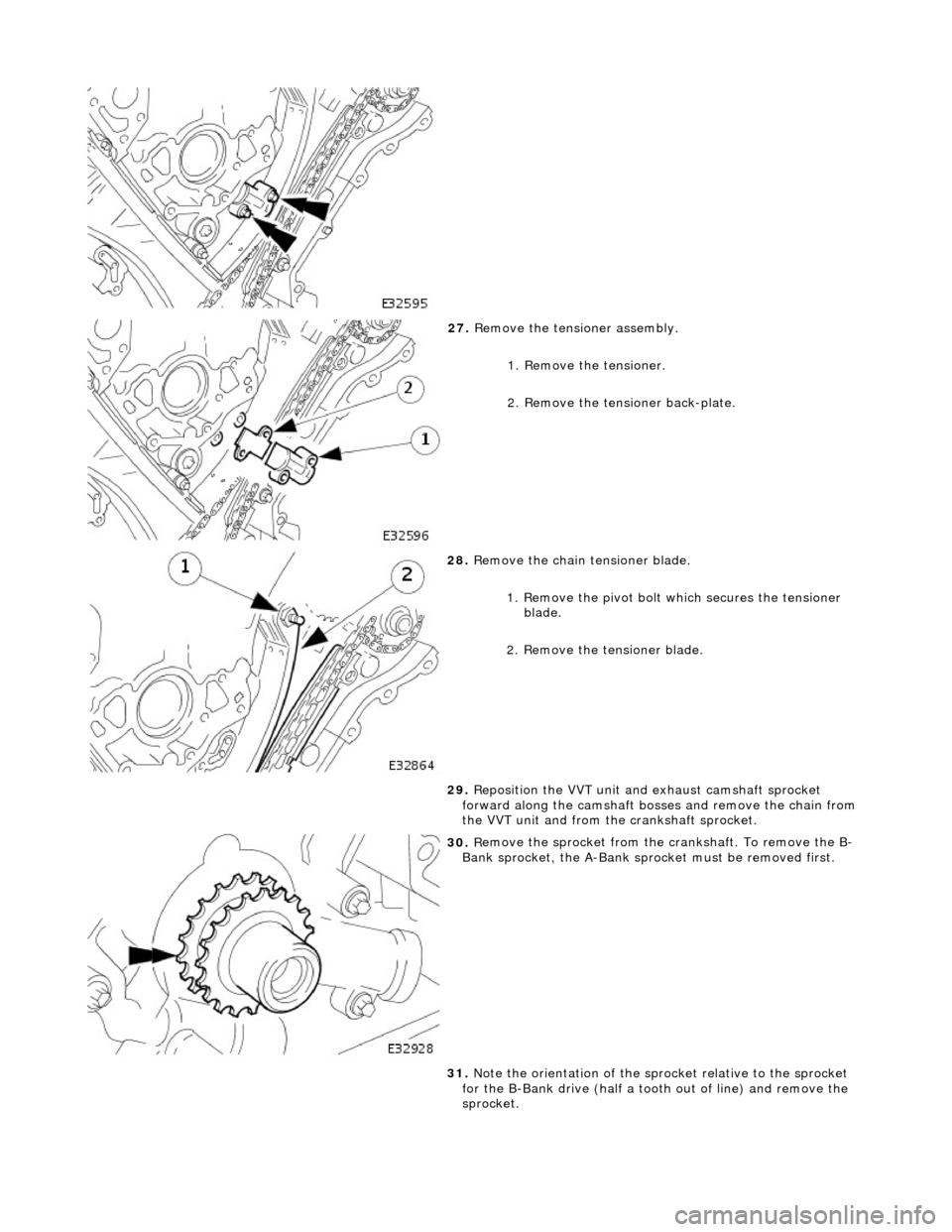

27. R

emove the tensioner assembly.

1. Remove the tensioner.

2. Remove the tensioner back-plate.

28. R

emove the chain tensioner blade.

1. Remove the pivot bolt which secures the tensioner blade.

2. Remove the tensioner blade.

29. Reposition the VVT unit and exhaust camshaft sprocket

forward along the camshaft bosses and remove the chain from

the VVT unit and from th e crankshaft sprocket.

30 . R

emove the sprocket from the

crankshaft. To remove the B-

Bank sprocket, the A-Bank spro cket must be removed first.

31. Note the orientation of the spro cket relative to the sprocket

for the B-Bank drive (half a toot h out of line) and remove the

sprocket.

Page 572 of 2490

2. Fi

t the retaining / pivot bolt and tighten it to 12 - 16

Nm.

5. Refi

t the primary chain tensione

r assembly. Refer to Operation

12.65.55 in this Section.

U s

e a wedge 303 - 533 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

6. Tigh te

n the exhaust camshaft

sprocket securing bolt.

1. Fit the chain tensioner tool 303 - 532 to the sprocket holes.

1. Apply force to the to

ol in

an anti-clockwise direction

to tension the chain on its drive side.

2 .

Whilst applying the opposing force to the sprocket

and chain, tighten the sprock et securing bolt to 115 -

125 Nm.

7. Tigh te

n the VVT unit securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303 - 532), check that the

wedges are still in place, tighten the VVT unit

securing bolt to 115 - 125 Nm.

Re

move the chain tensioning

tool and the wedge(s).

8. Remove the camshaft locking tool 303 - 530 and transfer it to

the A-Bank camshafts, aligning the shafts slightly as necessary.