steering JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2373 of 2490

5.

Turn steering wheel 90 degrees to left and partially tighten

module LH securing bolt.

6. Repeat steps 3 and 4 to fully ti ghten securing bolts and return

steering wheel to central position.

7. Fit ground cable to battery terminal. Refer to 86.15.15.

Page 2381 of 2490

The body is pre-treated to ensure high resistance to corrosion and stone chip dama ge. Prior to the first major pre-treatment process, the body shell is high-pressure washed to remove any metal dust and residual oil.

The first major pre-treatment process consists of phosphate and electro-paint deposition, which together with zinc coating,

forms the basis of the corrosion protection. This process includes high pressure knock-off, alkali de-greasing, zinc phosphate

conversion of body steel (dissolving iron and coating with zinc phosphate crystals), trivalent chrome rinsing and

demineralized water rinsing, seal ing all chemicals and impurities.

Both dip and spray techniques are employed and the bodies are submerged to the waistline during the first and third rinses

of the main phosphate clean. Chemical strengths and soluti on temperatures are continuously monitored and accurately

controlled throughout the process.

An 80% water primer is then cathodic elec tro-deposition applied to the thoroughly cleansed bodies in a uniform 'sag-free'

film 18 to 32 micron thick. Optimum durabi lity of the electroprimer is achieved by finally curing in a stoving oven at 165 °C

for a period of 20 minutes.

All underbody seams of the fully primed bo dies are then manually sealed, to prevent water and dust ingress into the vehicle

and to enhance corrosion protection.

An 800 to 1000 g/m2 PVC coating is semi-automatic airless sp ray applied to the underside of the main floor panels, trunk

floor and rear wheel arches (ref. illustration above).

The upper panels of primed and external ly sealed bodyshells are next lightly scuffed to remove imperfections and a PVC

coating is applied to all internal seams by an airless spray technique. A PVC bead seal is also applied to the doors, hood and

trunk clinch joints.

Following anti-corrosion, sealing and primin g treatment, the bodies enter the first stage of 'cosmetic' painting. This consists

of the application of two coats of a highly chip resistant po lyester surfacer, employing high voltage electrostatic 'spinning

bells', to achieve a final film thickness of 35 to 50 micron. Between surfacer coats, a polyurethane coat is automatically

applied to the sills to impart even greater resistance to stone chipping.

All interior panels are then painted us ing a color keyed sealer, wet-on-wet wi th a surfacer material, after which the

bodyshells are stoved at 160 °C for a period of 20 minutes. Further protection agai nst corrosion is provided by a medium

solids black pigmented wax which is airless spray applied to vehicle undersides.

Wax Injected Box Sections

Critical body box-sections are si milarly protected by spray injecting a high solids wax. This is then re-flowed at 70 to 90 °C

to achieve optimum seam/joint penetratio n and form a resilient and durable internal coating (ref. illustration above).

After full wet sanding, rinsing and drying to provide a good su bstrate, a color-keyed semi-matt sealer co at is applied using

electrostatic bells to achieve a film build of 25 to 35 micron . The bodies are then stoved for a further 20 minutes at a

temperature of 145 °C and subjected to a local 'seek-and-find' de -nib operation prior to the final two coat process. The final

top coat finish is achieved by using poly ester base coat colors and an acrylic sag resistant clear coat. This clear over base

(COB) process produces a high gloss, durabl e paint finish with a film thickness of 50 to 65 micron, which is finally cured at a

temperature of 135°C for 20 minutes.

The Munsell three dimensional system of color management is em ployed to achieve highly accurate control of vehicle colors.

This system ensures that paint pigmentations are accurately maintained and facilitates vigorous final checking of finished

vehicles for color match. The hu e of individual panels such as trunk lids, doors and hoods is in some instances adjusted to

offset the effects of differing light angles. Where applicable, coachlines are manually applied and radiant heat cured on the

completed and valeted vehicle prior to hand spray applic ation of a protective wax coat.

Introduction

All repairs, whether structural or cosmetic must return the vehicle to the original manufactured condition with regard to

occupant safety, dimensional accuracy, fi nish and corrosion protection, and ensure continuation of the Paint Surface and

Corrosion warranty where applicable.

Similarly, repaired vehicles must be fu lly checked, and where appropriate reset, with regard to steering, suspension,

braking, and occupant restraint systems.

Page 2423 of 2490

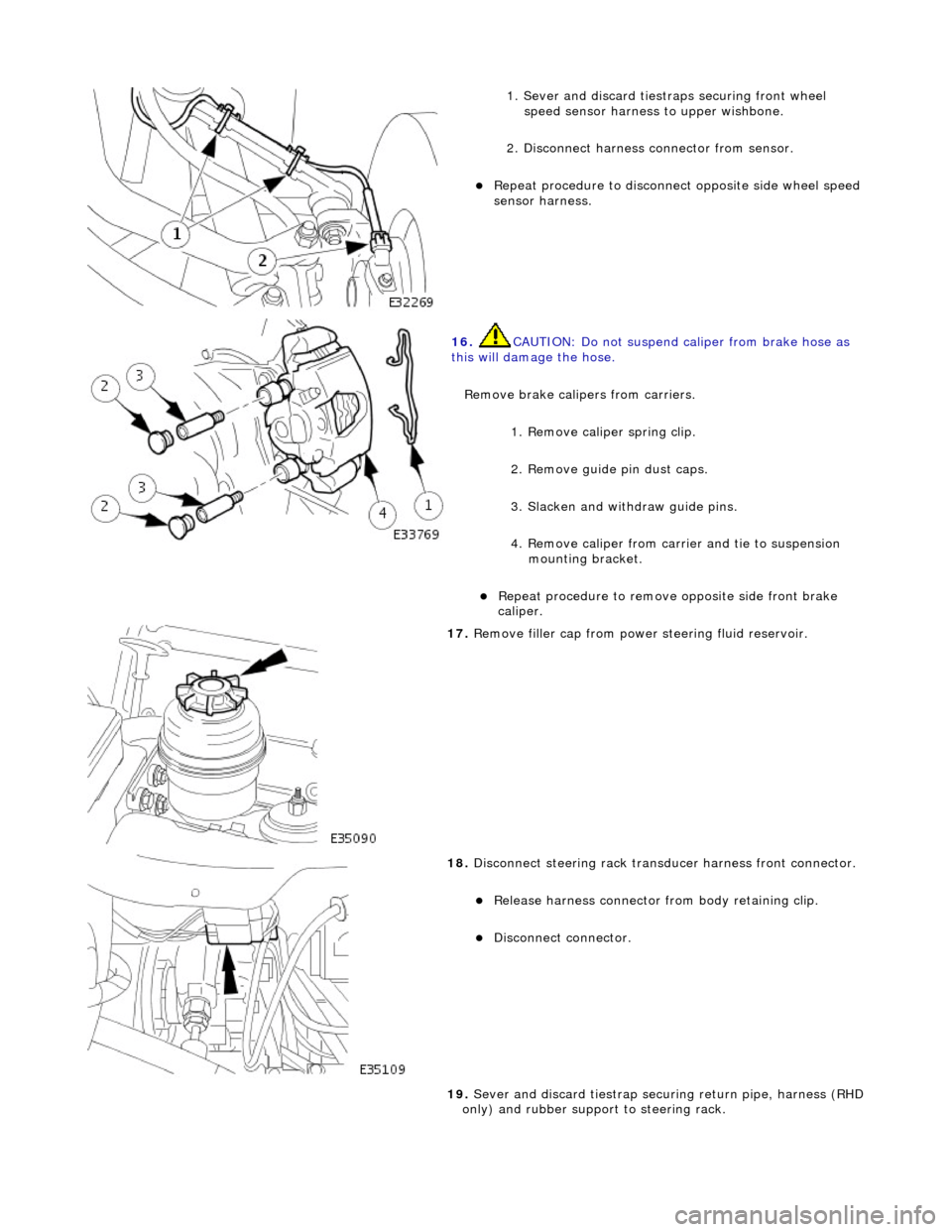

1. Sever and discard tiestraps securing front wheel

speed sensor harness to upper wishbone.

2. Disconnect harness connector from sensor.

Repeat procedure to disconnect opposite side wheel speed

sensor harness.

16. CAUTION: Do not suspend caliper from brake hose as

this will damage the hose.

Remove brake calipers from carriers.

1. Remove caliper spring clip.

2. Remove guide pin dust caps.

3. Slacken and withdraw guide pins.

4. Remove caliper from carrier and tie to suspension mounting bracket.

Repeat procedure to remove opposite side front brake

caliper.

17. Remove filler cap from power steering fluid reservoir.

18. Disconnect steering rack transducer harness front connector.

Release harness connector from body retaining clip.

Disconnect connector.

19. Sever and discard tiestrap secu ring return pipe, harness (RHD

only) and rubber support to steering rack.

Page 2424 of 2490

20. RHD vehicles. Sever and discard tiestrap securing harness to

steering rack.

21. Route harness from behind steering return pipe.

22. Position a drain receptacle below pinion housing.

23. Remove pipe retaining plate secu ring bolt and withdraw plate.

24. Drain power steering fluid.

Disconnect pipes and al low fluid to drain.

Remove and discard 'O'-ring seals from pipe connectors.

Fit blanking plugs to pipe connectors and pinion housing

ports.

25. Remove drain receptacle.

26. Remove pipe support from steering rack.

Release return pipe from support.

Page 2425 of 2490

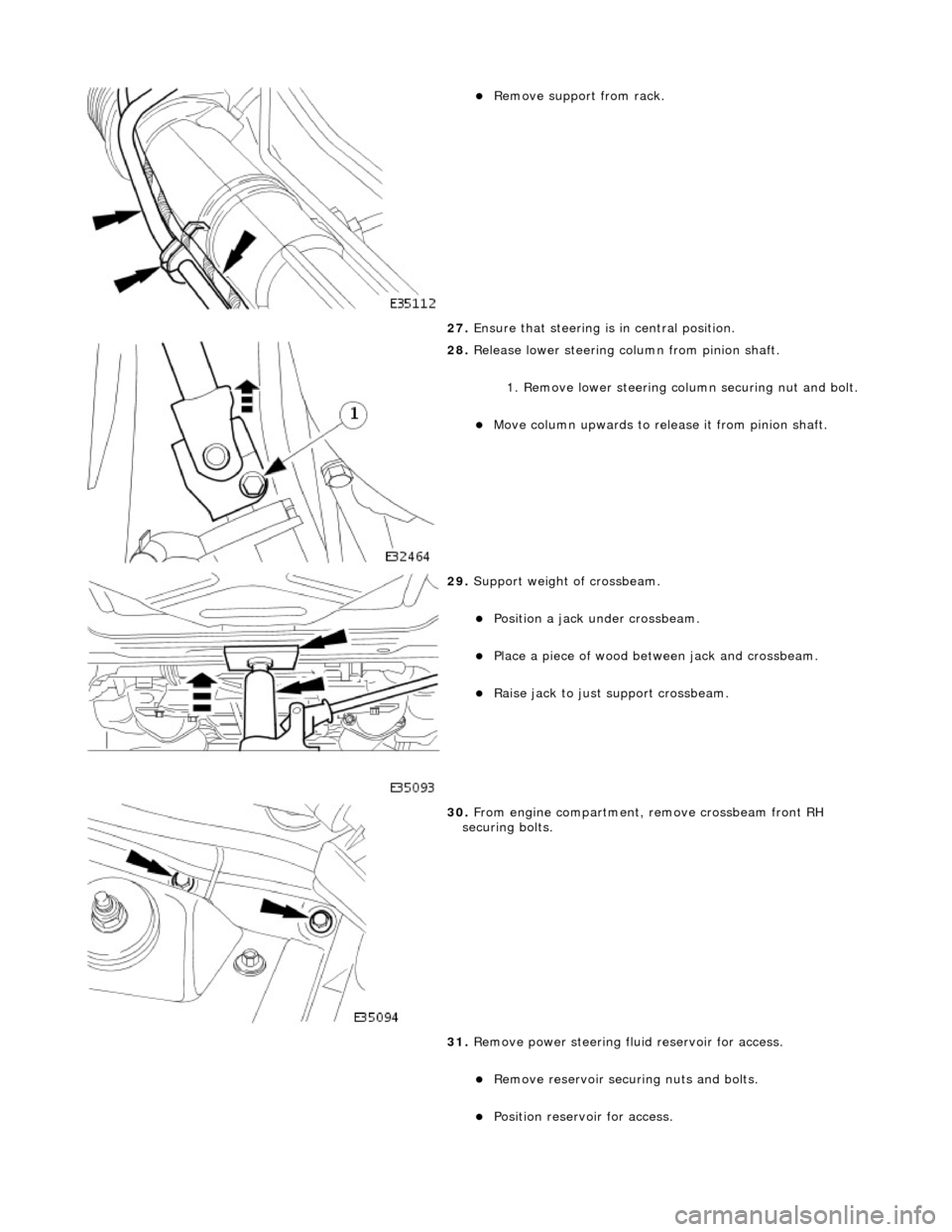

Remove support from rack.

27. Ensure that steering is in central position.

28. Release lower steering column from pinion shaft.

1. Remove lower steering co lumn securing nut and bolt.

Move column upwards to release it from pinion shaft.

29. Support weight of crossbeam.

Position a jack under crossbeam.

Place a piece of wood between jack and crossbeam.

Raise jack to just support crossbeam.

30. From engine compartment, remove crossbeam front RH

securing bolts.

31. Remove power steering fl uid reservoir for access.

Remove reservoir securing nuts and bolts.

Position reservoir for access.

Page 2427 of 2490

36. Ensure that steering transducer harness is clear of return pipe and LH side body.

37. Lower and traverse front suspension assembly clear of

vehicle.

38. With assistance, lift front suspension as sembly onto bench.

39. Remove nut securing each tie ro d outer ball joint to steering

arm.

40. Release tie rod ball joint from steering arm.

1. Install special tool 211-098 on tie rod outer ball joint.

2. Tighten tool bolt to re lease ball joint taper pin.

3. Remove tool and release tie rod from steering arm.

Repeat procedure to release opposite side tie rod ball

joint.

41. Remove steering harness fr om LH suspension turret.

Release harness securing clip s from suspension turret.

Mark position of clips on harness.

Remove tape securing clips to harness and discard clips.

42. Disconnect and remove steering harness.

Page 2428 of 2490

Disconnect harness connector from transducer.

Remove harness from suspension assembly.

43. Remove steering rack from crossbeam.

1. Remove steering rack securing bolts.

2. Remove steering rack and mounting brackets.

44. Release stabilizer bar from link arms.

Remove link arm to stabil izer bar securing nut.

Release link arm from stabilizer bar.

Repeat procedure to release opposite end of stabilizer bar

from link arm.

45. Remove stabilizer bar from crossbeam.

Remove stabilizer bar securing bolts.

Remove stabilizer bar mountin g brackets and remove bar

from crossbeam.

46. Remove wishbone securing nuts.

1. Remove lower wishbone front arm eccentric bolt

securing nut.

2. Remove lower wishbone rear arm eccentric bolt

securing nut.

Page 2431 of 2490

Position stabilizer bar on crossbeam.

Install and tighten bolts to 30-40Nm.

Repeat procedure at opposite end of stabilizer bar.

6. Tighten link arm to stabilizer bar securing nut to 60-80Nm.

Repeat procedure at opposite end of stabilizer bar.

7. Install steering rack on crossbeam.

Ensure that bushes are correct ly positioned on steering

rack.

Position steering rack on crossbeam.

Position support brac kets over bushes.

Install mounting bracket bolt s and tighten to 40-54Nm.

8. Install tie rods on steering arms.

Position and fully seat tie rod ball joint taper pin on

steering arm.

Install tie rod ball joint nu t and tighten to 71-85Nm.

Repeat procedure to install opposite side tie rod ball joint.

9. Install harness on suspension turret.

Noting positions marked during removal, tape new

securing clips to st eering harness.

Install securing clips/harness on LH turret.

Page 2432 of 2490

10. With assistance position crossbeam/suspension assembly on

jack with protective wood under.

11. Traverse assembly into position below vehicle.

12. Ensure steering harn ess connector is positioned to avoid

damage during crossbeam lift .

13. NOTE: It may be necessary to use a hammer and drift to

finally align new mounting with body location.

Carefully raise crossbeam assembly into position.

Ensure that dowels of both crossbeam mountings are

correctly seated in body locations.

14. Ensure that both engine hydram ounts are correctly seated in

crossbeam locations.

15. Install crossbeam rear mountings.

Align rear mounting rubber with body location.

Install rear mounting securing bolt and nut and tighten

nut to 131-185 Nm.

Repeat procedure to install opposite side rear mounting

bolt and nut.

16. From engine compartment, install but do not tighten

crossbeam front RH bolts.

Page 2433 of 2490

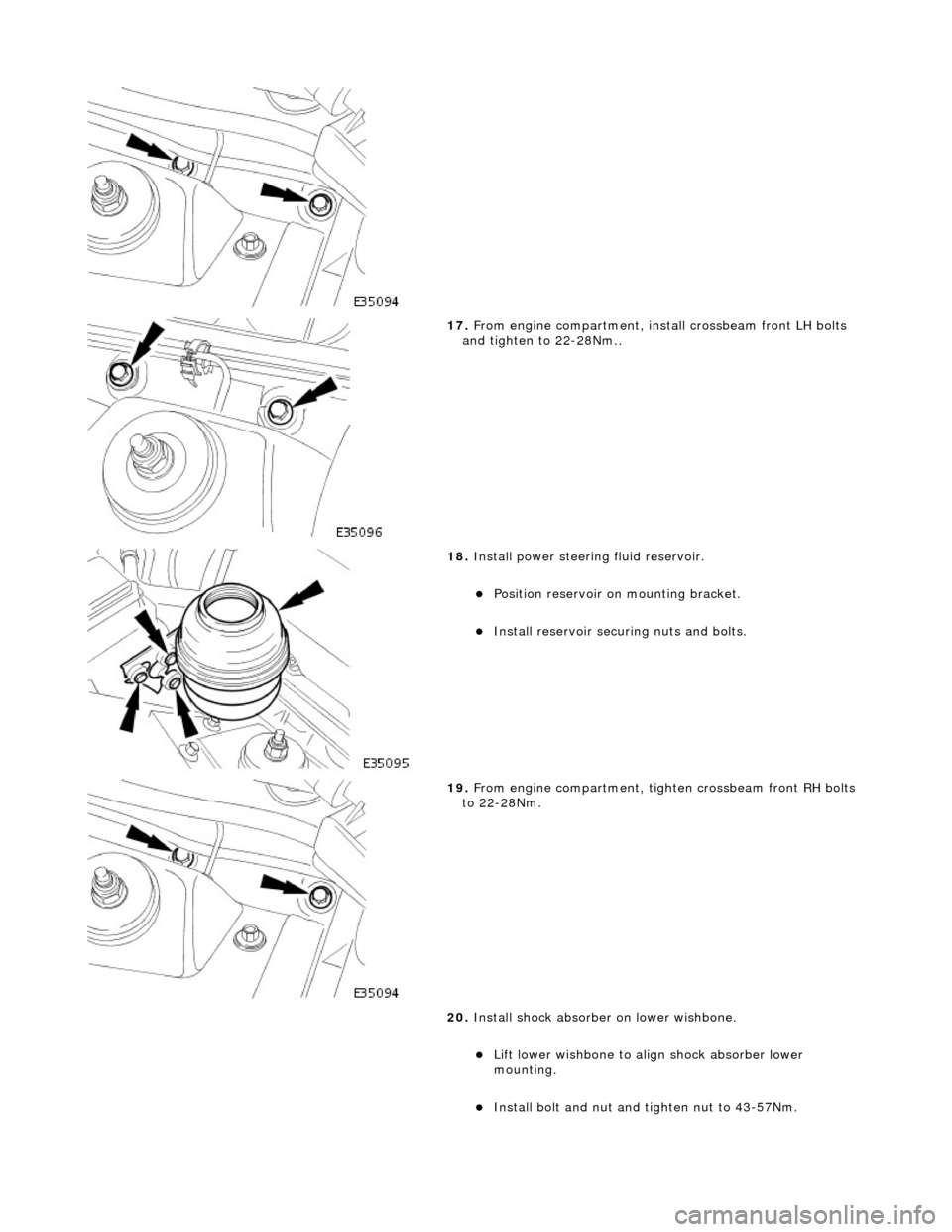

17. From engine compartment, install crossbeam front LH bolts

and tighten to 22-28Nm..

18. Install power steering fluid reservoir.

Position reservoir on mounting bracket.

Install reservoir securi ng nuts and bolts.

19. From engine compartment, tighten crossbeam front RH bolts

to 22-28Nm.

20. Install shock absorber on lower wishbone.

Lift lower wishbone to align shock absorber lower

mounting.

Install bolt and nut and ti ghten nut to 43-57Nm.