warning JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2372 of 2490

Supplemental Restraint System - Driver Air Bag Module

Removal and Installation

Removal

• WARNINGS:

FOLLOWING DISCONNECTION OF THE BATTERY, A PERIOD OF AT LEAST ONE MINUTE MUST BE ALLOWED TO ELAPSE

BEFORE ANY WORK IS CARRIED OUT ON AN AIR BAG MODULE.

FOLLOWING TEN YEARS IN SERVICE, AN AIR BAG MO DULE MUST BE REMOVED AND DISPOSED OF IN THE

APPROVED MANNER, AND A NEW AIR BAG MUST BE FITTED.

AIR BAGS CONTAIN A CHEMICAL IRRITANT. IF AN AIR BAG IS RENEWED, THE ORIGINAL UNIT MUST BE DISPOSED

OF IN ACCORDANCE WITH CURRENT SAFETY PROCEDURES.

IN THE EVENT OF A FAULT RUPTURING THE 10A BATTERY SUPPLY FUSE (F4 LOCATED IN THE FUSE-BOX AT THE

DRIVER'S END OF THE FASCIA), THE FUSE MUST NOT BE RENEWED UNTIL THE AIRBAG/SRS SYSTEM HAS BEEN DE-

ACTIVATED. FUSES OF ANY OTHER VALUE MUST NEVER BE USED, AS THIS CAN CAUSE DISARM FAILURE.

Installation

1. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

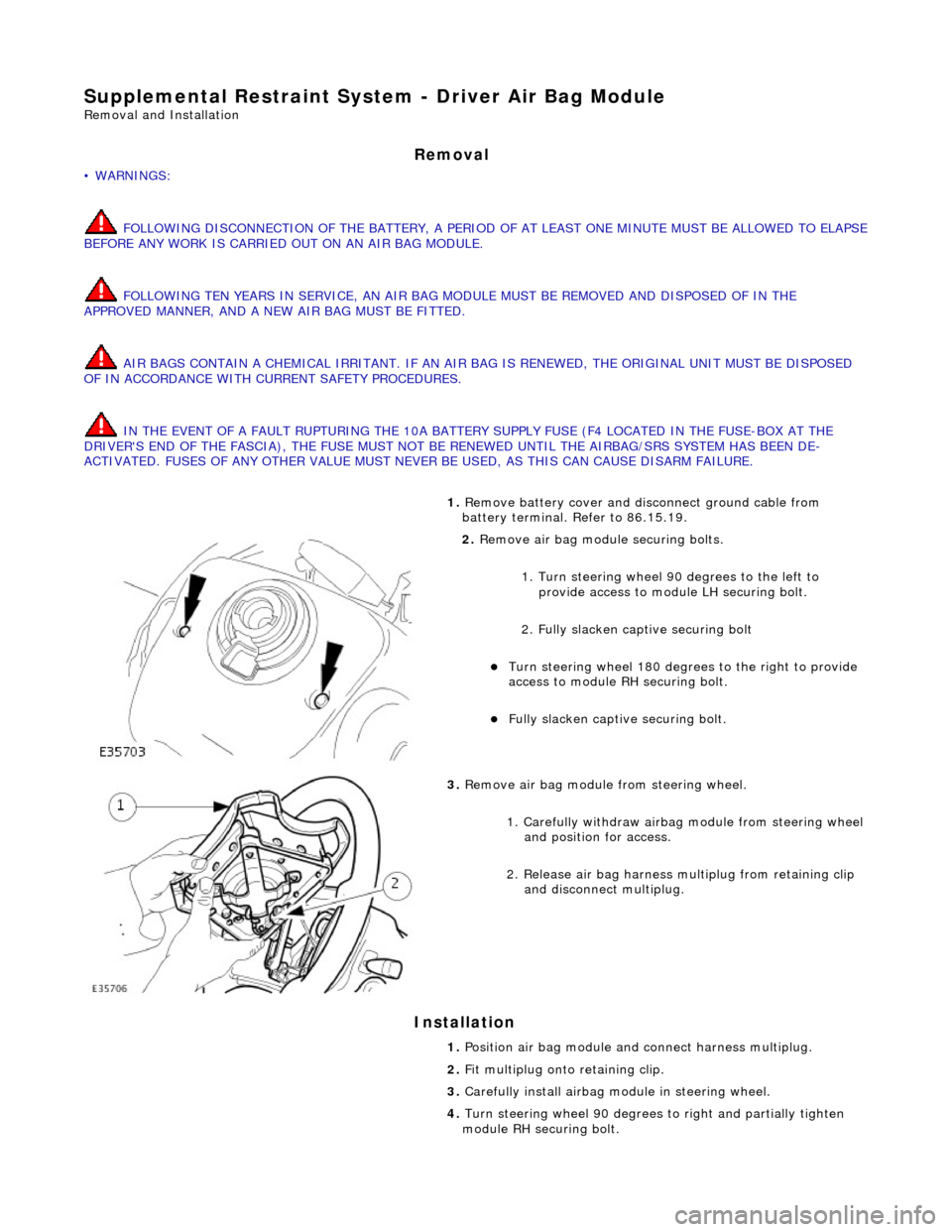

2. Remove air bag module securing bolts.

1. Turn steering wheel 90 degrees to the left to

provide access to module LH securing bolt.

2. Fully slacken captive securing bolt

Turn steering whee l 180 degrees to the right to provide

access to module RH securing bolt.

Fully slacken captive securing bolt.

3. Remove air bag module from steering wheel.

1. Carefully withdraw airbag module from steering wheel

and position for access.

2. Release air bag harness mu ltiplug from retaining clip

and disconnect multiplug.

1. Position air bag module and connect harness multiplug.

2. Fit multiplug onto retaining clip.

3. Carefully install airbag mo dule in steering wheel.

4. Turn steering wheel 90 degrees to right an d partially tighten

module RH securing bolt.

Page 2374 of 2490

Supplemental Restraint System - Passenger Air Bag Module

Removal and Installation

Removal

• WARNINGS:

FOLLOWING DISCONNECTION OF THE BATTERY, A PERIOD OF AT LEAST ONE MINUTE MUST BE ALLOWED TO ELAPSE

BEFORE ANY WORK IS CARRIED OUT ON AN AIR BAG MODULE.

FOLLOWING TEN YEARS IN SERVICE, AN AIR BAG MO DULE MUST BE REMOVED AND DISPOSED OF IN THE

APPROVED MANNER, AND A NEW AIR BAG MUST BE FITTED.

AIR BAGS CONTAIN A CHEMICAL IRRITANT. IF AN AIR BAG IS RENEWED, THE ORIGINAL UNIT MUST BE DISPOSED

OF IN ACCORDANCE WITH CURRENT SAFETY PROCEDURES.

IN THE EVENT OF A FAULT RUPTURING THE 10A BATTERY SUPPLY FUSE (F4 LOCATED IN THE FUSE-BOX AT THE

DRIVER'S END OF THE FASCIA), THE FUSE MUST NOT BE RENEWED UNTIL THE AIRBAG/SRS SYSTEM HAS BEEN DE-

ACTIVATED. FUSES OF ANY OTHER VALUE MUST NEVER BE USED, AS THIS CAN CAUSE DISARM FAILURE.

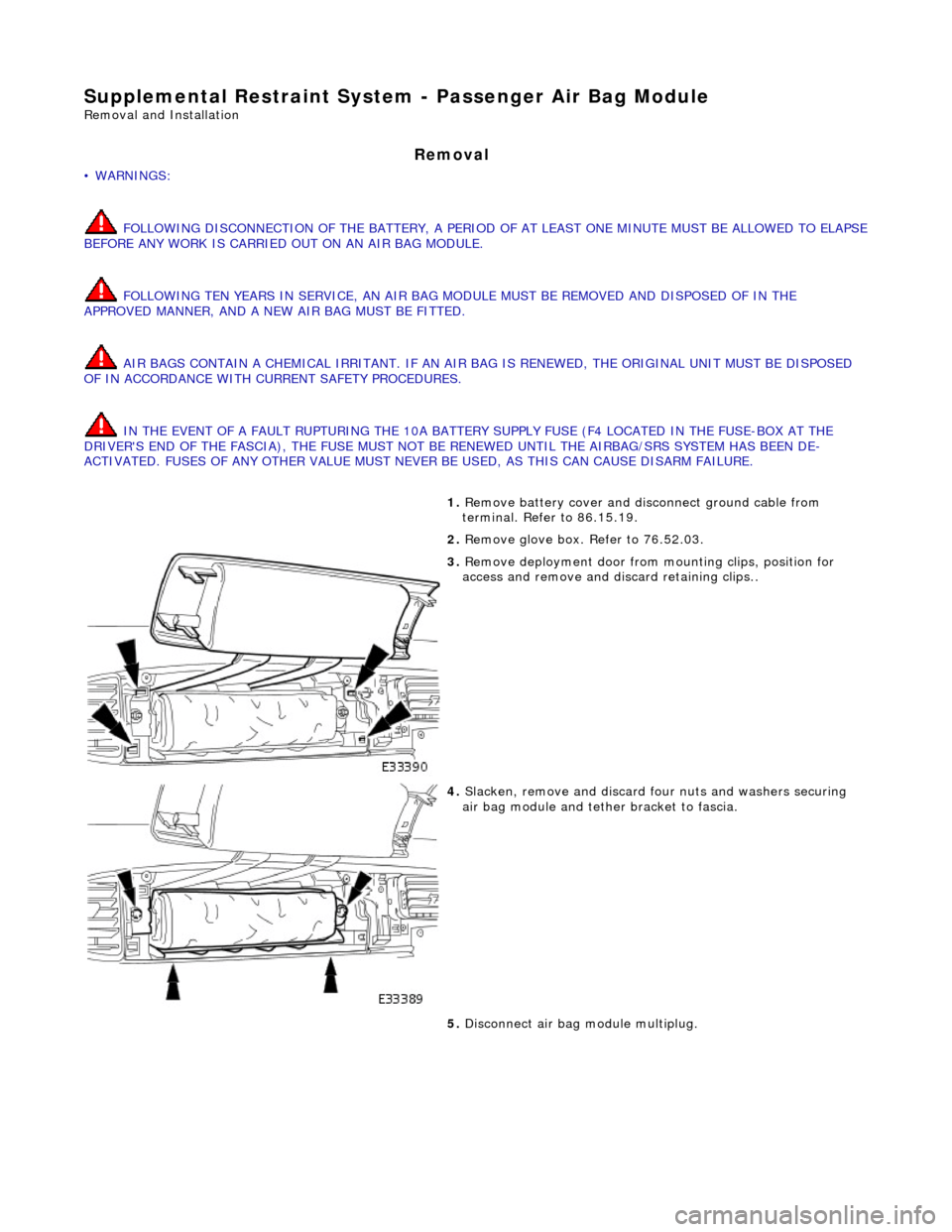

1. Remove battery cover and disc onnect ground cable from

terminal. Refer to 86.15.19.

2. Remove glove box. Refer to 76.52.03.

3. Remove deployment door from mounting clips, position for

access and remove and di scard retaining clips..

4. Slacken, remove and discard fo ur nuts and washers securing

air bag module and tether bracket to fascia.

5. Disconnect air bag module multiplug.

Page 2377 of 2490

Supplemental Restraint System - Side Air Bag Module

Removal and Installation

Removal

• WARNINGS:

A SIDE AIR BAG MUST ONLY BE RENEWED IF A FAULT FLAG HAS OCCURRED. IN THE EVENT OF SIDE AIR BAG

DEPLOYMENT DUE TO SIDE IMPACT, THE COMPLETE SEAT MUST BE RENEWED.

FOLLOWING TEN YEARS IN SERVICE, AN AIR BAG MO DULE MUST BE REMOVED AND DISPOSED OF IN THE

APPROVED MANNER, AND A NEW AIR BAG MUST BE FITTED.

FOLLOWING DISCONNECTION OF THE BATTERY, A PERIOD OF AT LEAST FIFTEEN MINUTES MUST BE ALLOWED TO

ELAPSE BEFORE DISCONNECTING THE SINGLE-POINT SENSIN G (SPS) UNIT AND AN ELAPSE OF 2 MINUTES ALLOWED

BEFORE DISCONNECTING ANY OTHER SUPPLEMENTARY RESTRAINT SYSTEM COMPONENT.

AIR BAGS CONTAIN A CHEMICAL IRRITANT. IF AN AIR BAG IS RENEWED, THE DISCARDED UNIT MUST BE DISPOSED

OF IN ACCORDANCE WITH CURRENT SAFETY PROCEDURES.

IN THE EVENT OF A FAULT RUPTURING THE 10A BATTERY SUPPLY FUSE (F4 LOCATED IN THE FUSE-BOX AT THE

DRIVER'S END OF THE FASCIA), THE FUSE MUST NOT BE RENEWED UNTIL THE AIRBAG/SRS SYSTEM HAS BEEN DE-

ACTIVATED. FUSES OF ANY OTHER VALUE MUST NEVER BE USED, AS THIS CAN CAUSE DISARM FAILURE.

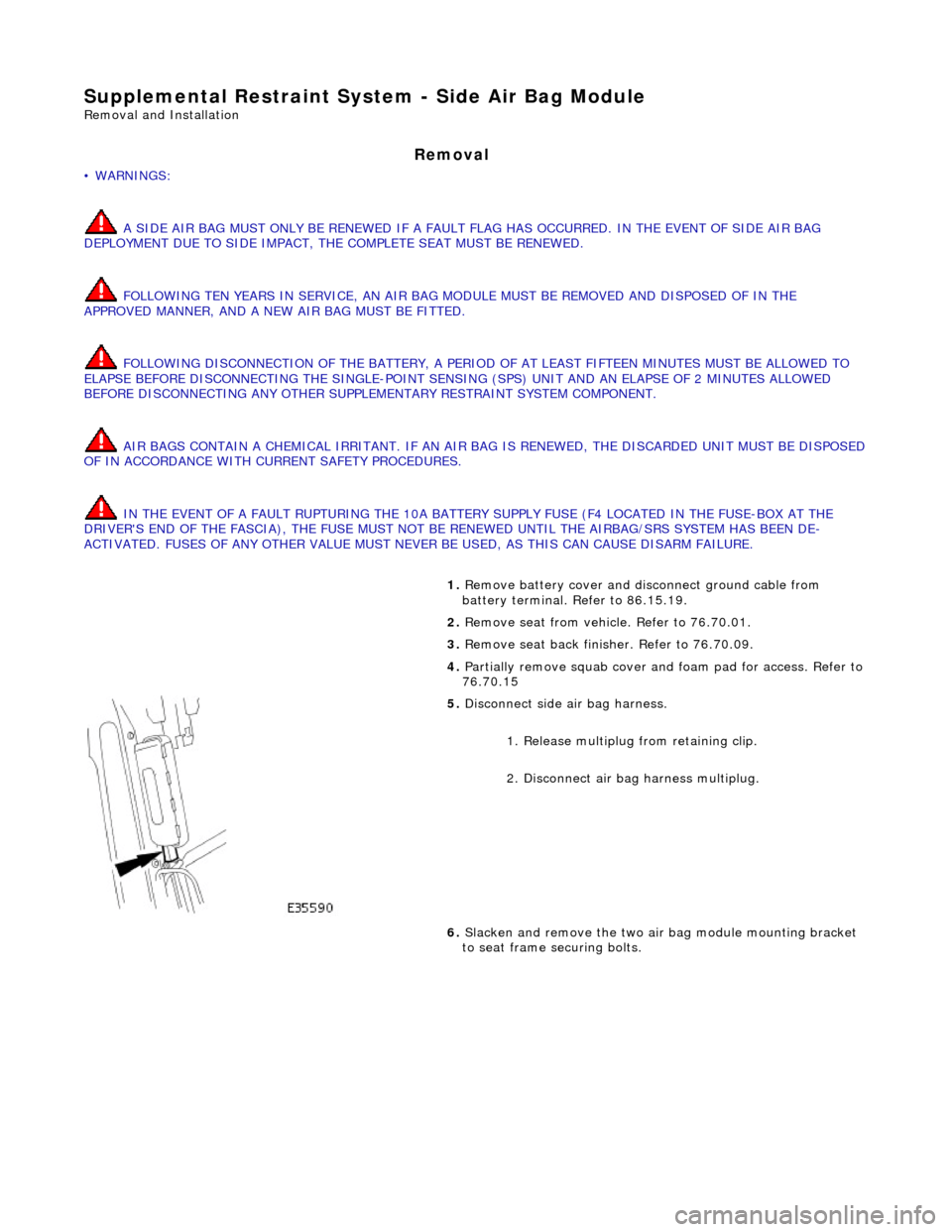

1. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Remove seat from vehi cle. Refer to 76.70.01.

3. Remove seat back fini sher. Refer to 76.70.09.

4. Partially remove squab cover and foam pad for access. Refer to

76.70.15

5. Disconnect side air bag harness.

1. Release multiplug from retaining clip.

2. Disconnect air ba g harness multiplug.

6. Slacken and remove the two air bag module mounting bracket

to seat frame securing bolts.

Page 2379 of 2490

Supplemental Restraint System - Side Impact Sensor

Removal and Installation

Removal

• WARNINGS:

FOLLOWING DISCONNECTION OF THE BA TTERY, A PERIOD OF AT LEAST FIFTEEN MINUTES MUST BE ALLOWED TO

ELAPSE BEFORE DISCONNECTING THE SINGLE-POINT SENSING (SPS) UNIT.

IN THE EVENT OF A FAULT RUPTURING THE 10A BATTER Y SUPPLY FUSE (F4 LOCATED IN THE FUSE-BOX AT THE

DRIVER'S END OF THE FASCIA), THE FUSE MUST NOT BE RENEWED UNTIL THE AIRBAG/SRS SYSTEM HAS BEEN DE-

ACTIVATED. FUSES OF ANY OTHER VALUE MUST NEVER BE USED, AS THIS CAN CAUSE DISARM FAILURE.

Installation

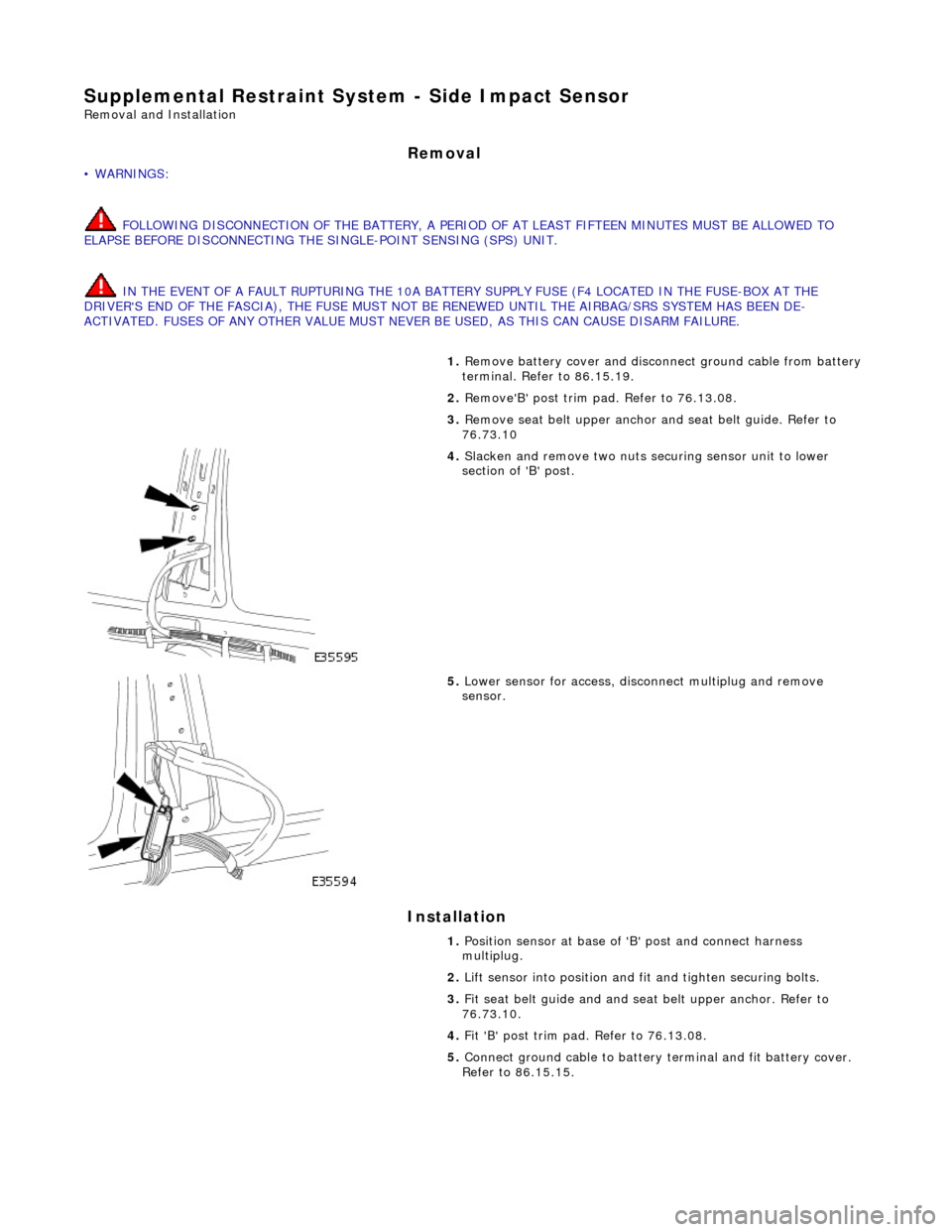

1. Remove battery cover and disconnect ground cable from battery

terminal. Refer to 86.15.19.

2. Remove'B' post trim pa d. Refer to 76.13.08.

3. Remove seat belt upper anchor and seat belt guide. Refer to

76.73.10

4. Slacken and remove two nuts securing sensor unit to lower

section of 'B' post.

5. Lower sensor for access, disco nnect multiplug and remove

sensor.

1. Position sensor at base of 'B' post and connect harness

multiplug.

2. Lift sensor into position and fit and tighten securing bolts.

3. Fit seat belt guide and and seat belt upper anchor. Refer to

76.73.10.

4. Fit 'B' post trim pad. Refer to 76.13.08.

5. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 2382 of 2490

Health and Safety

It is the duty of both employer and employee to ensure safe working conditions and practices. Correct safety procedures

and equipment must be applied to any potential hazards that are notified, or identified by an operator.

Employees must observe local legislation go verning working conditions and practices at all times and must always act in a

responsible manner in the workplace. In the event of personal injury resulting from any workshop activity, medical help

should be obtained as soon as poss ible. Self-treatment other than by first aid, should not be attempted.

WARNING: READ AND UNDERSTAND WORKING PRACTICE S CONCERNING CLIMATE CONTROL SYSTEMS, SECTION

412, WITH SPECIAL REGARD TO: REFRIGERANT MUST NEVE R BE DIRECTLY VENTED TO ATMOSPHERE. ALWAYS USE

JAGUAR APPROVED RECOVERY / RECYCLE / RECHARGE EQUI PMENT, WEAR SUITABLE EYE AND SKIN PROTECTION AND

OBSERVE ALL APPLICABLE SAFETY REQUIREMENTS.

With the constant introduction of new materials in the manufacture of vehicles, an awareness of the potential risks and

appropriate precauti ons is important.

Notification of Hazards

Symbols, which convey important information, will be positioned at the beginning of any specific operation or text. Standard symbols will be used where repairs or service procedures ar e detailed. All symbols will conform to standard ANSI Z535.3

(American National Standards Institute). The surround shape of the symbol will indicate the basis of the message to be

conveyed (see top three elements of ?) The icon depicting the message will be within the surrounding shape. Once

nominated the icon will retain its meaning.

POTENTIAL RISKS

Paint

Organic solvents, found in paints, may caus e damage or severe irritation to liver, kidneys, digestive tracts and respiratory

system if inhaled over long pe riods of time. Prolonged exposure to isocyanate s can cause lung sensitization with asthma-like symptoms developing on subsequent exposure to even low concentrations of isocyanates. Solvent inhalation can cause

dizziness or loss of consciousness and inhalation of spray dust and sanding debris may cause lung damage.

Spillage or splashes of solvents, paint ac tivators and additives can cause dermatitis or eye injury. Contact with peroxide or

acid catalysts can cause serious burns.

Applied Heat (Welding)

There is considerable risk of damage to eyes and skin if welding or flame cutting is attempted without using the correct

protective equipment. Many materials or fluids within vehicles are highly flammable and toxic and dangerous fumes may

also be liberated if heat is applied to expanded foam, corr osion protection, trim and seat materials, paints containing

isocyanates, and adhesive and sealing compounds.

When heated to a temperature of 300°C, polyurethane based compounds may liberate small quantities of isocyanate. Many

types of nitrogen containing chemicals ma y be liberated as breakdown products which can contain isocyanates, oxides of

nitrogen and hydrogen cyanide.

Potentially toxic or asphyxiant fumes and gases produced when welding include zinc oxide from zinc coated panels, and

ozone gas from the MIG process.

Metal Repair

There is considerable risk of damage to eyes, ears and skin wh en cutting, forming, or dressing metal. Soldering operations

can also be hazardous due to heat generated fumes and the risk of skin contact with hot materials.

PRECAUTIONS

Page 2383 of 2490

Paint

The inhalation of sprays, fumes, or dust during paint application or sanding processes should always be avoided. Ensure

that there is efficient ventilation / extrac tion at all times. Paint spraying should be confined as far as possible to spray

booths. Personnel with a history of asth ma should not be employed in any process involving the use of isocyanates.

Operators working in a spray booth where isocyanate material is present must use air-fed breathing equipment with air

supplied to the visor at the re commended pressure and filtered to remove oil, water, and fumes. Operators involved in

handling mixing or spraying should wear protective clothing including gloves and goggles, to avoid skin and eye contact.

Particle masks or canister type respir atosr should be worn when sanding.

Applied Heat

When welding, flame cutting, brazing etc, the operator shou ld use as appropriate, goggles, mask / fume extractor and

flameproof protective clothing. It is especially important when working with polyurethane compounds to use air-fed

breathing equipment. Appropriat e fire fighting equipment and personnel trai ned in its use must always be available.

Metal Repair

Appropriate eye and hand protection should be worn when sanding, drilling, cutting, chiselling, flatting or welding. Face

masks or air-fed visors should also be wo rn when sanding or flatting either body solder or fillers. On completion of a

soldering operation, swarf must be re moved from the work area and the operat or must wash his hands thoroughly.

GENERAL REPAIR NOTES

The following advice should be noted before any repair work is carried out.

Disconnect the vehicle battery gr ound lead (disconnect the alternator where electric welding is used) and take note of the

reconnection procedures as detailed in 86.15.15.

Where structural parts are straightened or renewed, a body alignment / straightening jig must be used. The application of

heat, especially excessive heat, reduces the strength of steels, where appropriate therefore, structural sections should be

straightened by cold processes.

Repairs may only be carried out successful ly, and any warranties protected, if genuine Jaguar replacement parts and Jaguar

approved materials are used.

The correct tools, procedures and facilities must always be us ed. The quality of the work must not be compromised by using

inappropriate methods or equipment.

All trim and electrical components in the locality of the repair must be removed or disconnected prior to panel removal /

replacement; this is especially important where hollow sectio ns may contain harnesses, tubes or foam, see section A4.3.5.

WARNING: DO NOT WORK IN THE VICINITY OF A LIVE AIR BAG, REMOVE IT COMPLETELY. READ WORKING

PRACTICES AIR BAG, SECTION 20. ANY SEAT BELT WHICH HAS BEEN WORN IN AN ACCIDENT MUST BE RENEWED.

CAUTION: Electric arc welding should not be used on Jaguar vehicles. The high voltages produced by this process will

cause irreparable damage to the electric al control and microprocessor systems.

The following welding and gas processes are the only ones recommended by Jaguar Cars Ltd.

Welding and Gas Processes

Resistance spot welding, MIG welding and all gas processes may only be carried out on bare, unpainted or unplated metal.

The flanges of panels to be welded toge ther, must be clean, corrosion free and tr eated as appropriate, with either weld-

through primer or inter-weld sealer. Only materials and processes specified in the 'Body Sealing and Preservation Manual'

should be used in the relevant application areas detailed in this section. Refer to 'Zinc Coated Panels' Section

Page 2391 of 2490

ZINC COATED PANELS

Description

Approximately 70% of the 'body in white' (BIW) mass is made up of zinc coated panels.

• NOTE: To maintain the protective qualities of the zinc trea tment, repairs to any damaged coated area must be made as

soon as possible after the damage has occurred.

All exterior skin panels, with the exceptio n of the roof, are double side zinc plated and this coating (nominally 7,5 microns)

provides two way corrosion protection. Should the outer layer of paint become chipped with the zinc coating remain intact,

the zinc will oxidize on contact with air and being impermeable, this coat of oxidation will prevent corrosion damage of the

base metal. If the outer layer of paint and the zinc coating become damaged, the zinc rather than the base metal will react

with the air and 'sacrifice' itself to corrosion as a 'sacrificial anode'.

Welding Preparation

Contamination of the weld with resultant reduction in joint st rength increase and increased electrode tip dressing frequency

will occur zinc coating is not removed. In exceptional cases where the zinc coating must remain intact, the tip pressure and

welding current should be increased by 10 to 20%.

Where 'resistance spot welding' is employed, the zinc coatin g should be lightly abraded away on the mating surfaces and

those in contact with the electrode tips. Do not remove more zinc coating than is absolutely necessary.

Before welding, a weld-through primer or inter-weld sealer should be applied, as detailed in the Body Sealing and

Preservation manual.

Where MIG welding is used as an alternativ e to resistance spot welding for plug and butt welds or due to limited access, the

problems caused by the presence of zinc coating are much the same, with the added complication of increased weld spatter

and nozzle contamination.

Body Fillers

Conventional polyester fillers do not adhere satisfactorily to zinc plated panels, it is ther efore important that only those

products specifically designed for this application are used and the manufacturer's recommendations are followed.

Refinishing

Use only those products approved by Jaguar Cars Ltd and exercise special care on zinc coated panels.

As replacement panels ar e supplied ready primed, the only bare metal that needs to be exposed are those areas prepared

for welding etc, as decribed in 'Welding Preparation. Where any part of a panel is dressed back to the bare surface, it should

be treated with a zinc rich primer compatible with the paint application system.

GENERAL PREPARATION OF PANELS

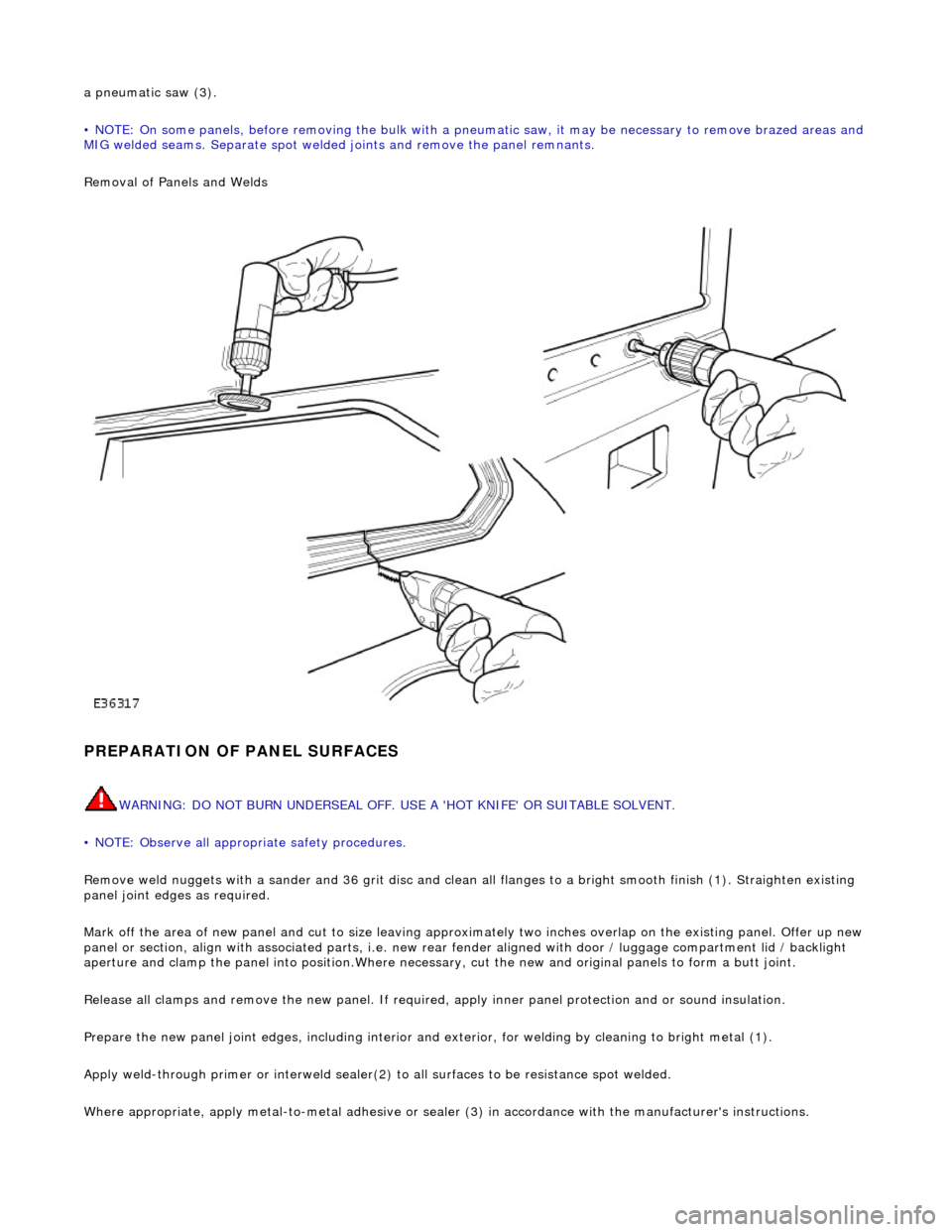

Removal of Panels and Welds

• NOTE: Where other components must be removed for access, refer to the relevant manual section for guidance. This is

particularly important where steerin g, braking, suspension, electrical and safety systems are affected.

Expose all resistance spot welds, using a ro tary wire brush fitted to an air drill or a hand held wire brush on those that are

not clearly visible (1).

WARNING: DO NOT BURN UNDERSEAL OFF. USE A 'HOT KNIFE' OR SUITABLE SOLVENT.

Cut out spot welds using a Zipcutter or Roto-Bor (2). At this point it may be necessary to cut out the bulk of the panel using

Page 2392 of 2490

a pneumatic saw (3).

• NOTE: On some panels, before removing the bulk with a pneumatic saw, it may be necessary to remove brazed areas and

MIG welded seams. Separate spot welded joints and remove the panel remnants.

Removal of Panels and Welds

PREPARATION OF PANEL SURFACES

WARNING: DO NOT BURN UNDERSEAL OFF. USE A 'HOT KNIFE' OR SUITABLE SOLVENT.

• NOTE: Observe all appropriate safety procedures.

Remove weld nuggets with a sander and 36 gr it disc and clean all flanges to a bright smooth finish (1). Straighten existing

panel joint edges as required.

Mark off the area of new panel and cut to size leaving approxim ately two inches overlap on the existing panel. Offer up new

panel or section, align with associated pa rts, i.e. new rear fender aligned with door / luggage compartment lid / backlight

aperture and clamp the panel into positi on.Where necessary, cut the new and orig inal panels to form a butt joint.

Release all clamps and remove the new panel. If required, apply inner panel protection and or sound insulation.

Prepare the new panel joint edges, including interior and exterior, for welding by cleaning to bright metal (1).

Apply weld-through primer or in terweld sealer(2) to all surfaces to be resistance spot welded.

Where appropriate, apply metal- to-metal adhesive or sealer (3) in accordance with the manufacturer's instructions.

Page 2441 of 2490

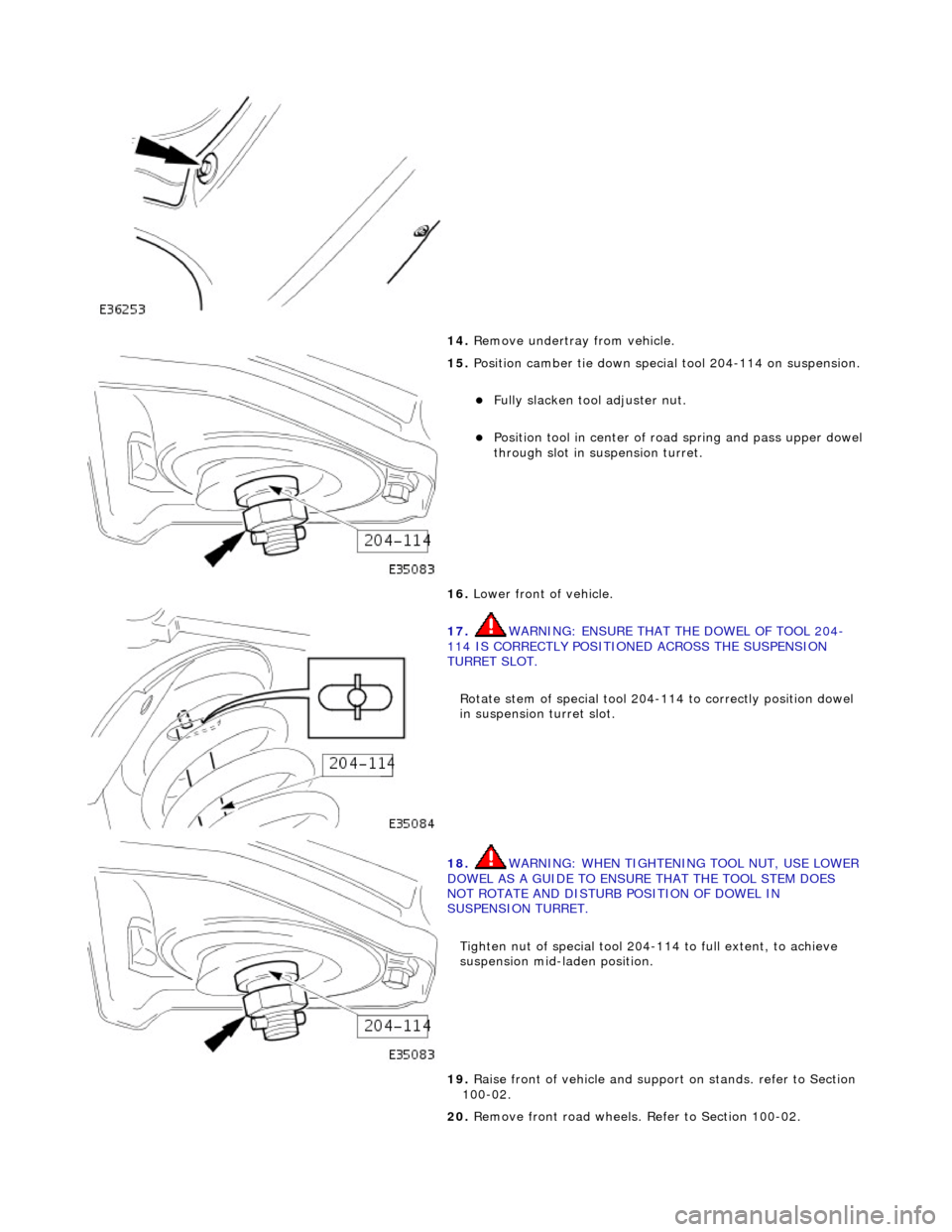

14. Remove undertray from vehicle.

15. Position camber tie down special tool 204-114 on suspension.

Fully slacken tool adjuster nut.

Position tool in center of ro ad spring and pass upper dowel through slot in suspension turret.

16. Lower front of vehicle.

17. WARNING: ENSURE THAT THE DOWEL OF TOOL 204-

114 IS CORRECTLY POSITIONED ACROSS THE SUSPENSION

TURRET SLOT.

Rotate stem of special tool 204-114 to correctly position dowel

in suspension turret slot.

18. WARNING: WHEN TIGHTENING TOOL NUT, USE LOWER

DOWEL AS A GUIDE TO ENSURE THAT THE TOOL STEM DOES

NOT ROTATE AND DISTURB POSITION OF DOWEL IN

SUSPENSION TURRET.

Tighten nut of special tool 204-114 to full extent, to achieve

suspension mid-laden position.

19. Raise front of vehicle and support on stands. refer to Section

100-02.

20. Remove front road wheels. Refer to Section 100-02.

Page 2452 of 2490

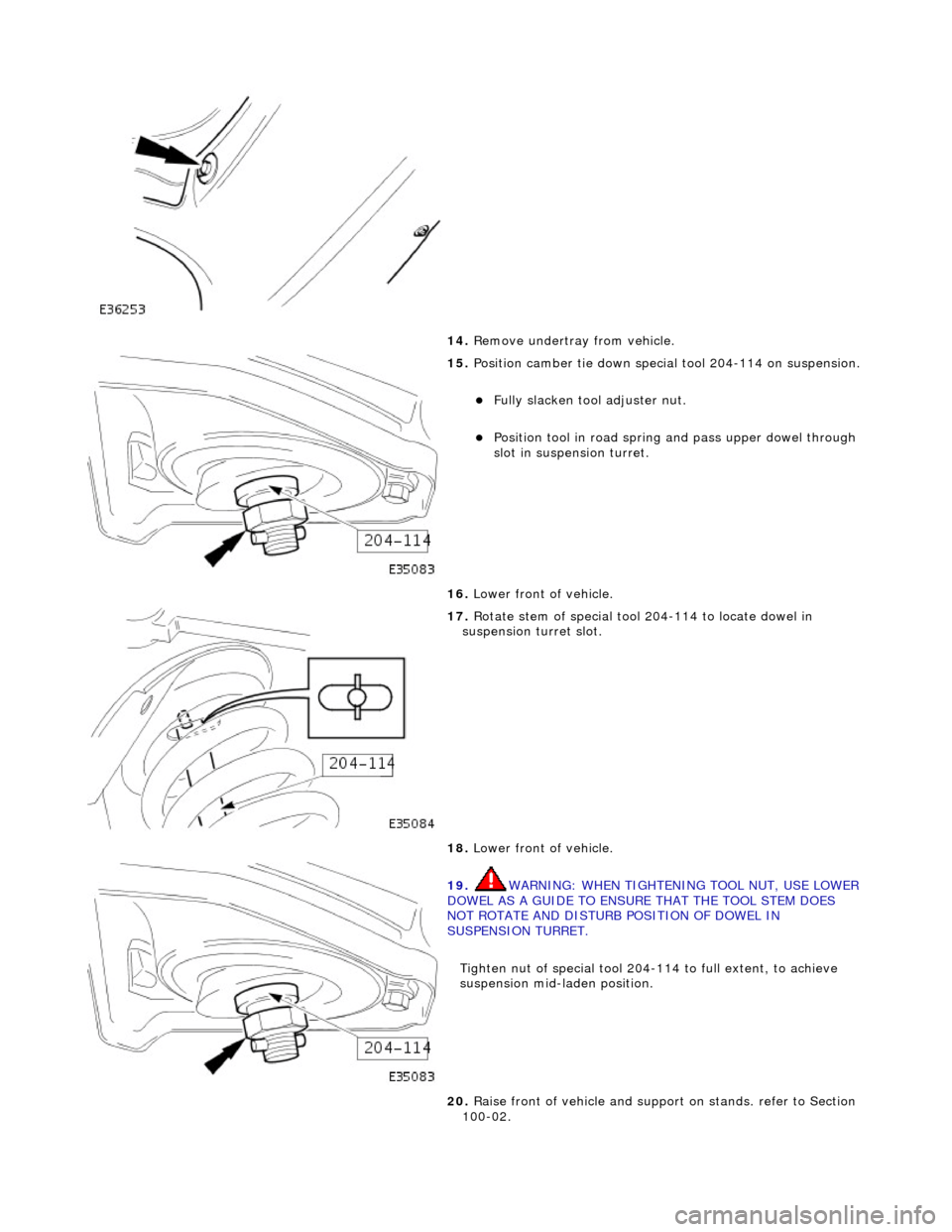

14. Remove undertray from vehicle.

15. Position camber tie down special tool 204-114 on suspension.

Fully slacken tool adjuster nut.

Position tool in road spring and pass upper dowel through

slot in suspen sion turret.

16. Lower front of vehicle.

17. Rotate stem of special tool 204-114 to locate dowel in

suspension turret slot.

18. Lower front of vehicle.

19. WARNING: WHEN TIGHTENING TOOL NUT, USE LOWER

DOWEL AS A GUIDE TO ENSURE THAT THE TOOL STEM DOES

NOT ROTATE AND DISTURB POSITION OF DOWEL IN

SUSPENSION TURRET.

Tighten nut of special tool 204-114 to full extent, to achieve

suspension mid-laden position.

20. Raise front of vehicle and support on stands. refer to Section

100-02.