service JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1801 of 2490

Condenser:

Multi-pass fin-over-tube type, mounted in front of the engine cooling pack and directly to the radiator.

Pressure (Bitron) switch:

Located in the discharge pipe. Provides a signal, via the A/CCM, to th e ECM, to disengage the compressor clut ch should the refrigerant pressure be

< 2 bar or > 30 bar.

Provides a hard-wired signal to the ECM, to switch the cool ing fans to HIGH speed at 22 bar rising pressure and to

LOW speed at 17,5 bar falling pressure.

Provides a hard-wired signal to the ECM, to switch the radiator cooling fans to LOW speed at 12 bar rising pressure

and to switch the fans OFF at 8 bar falling pressure.

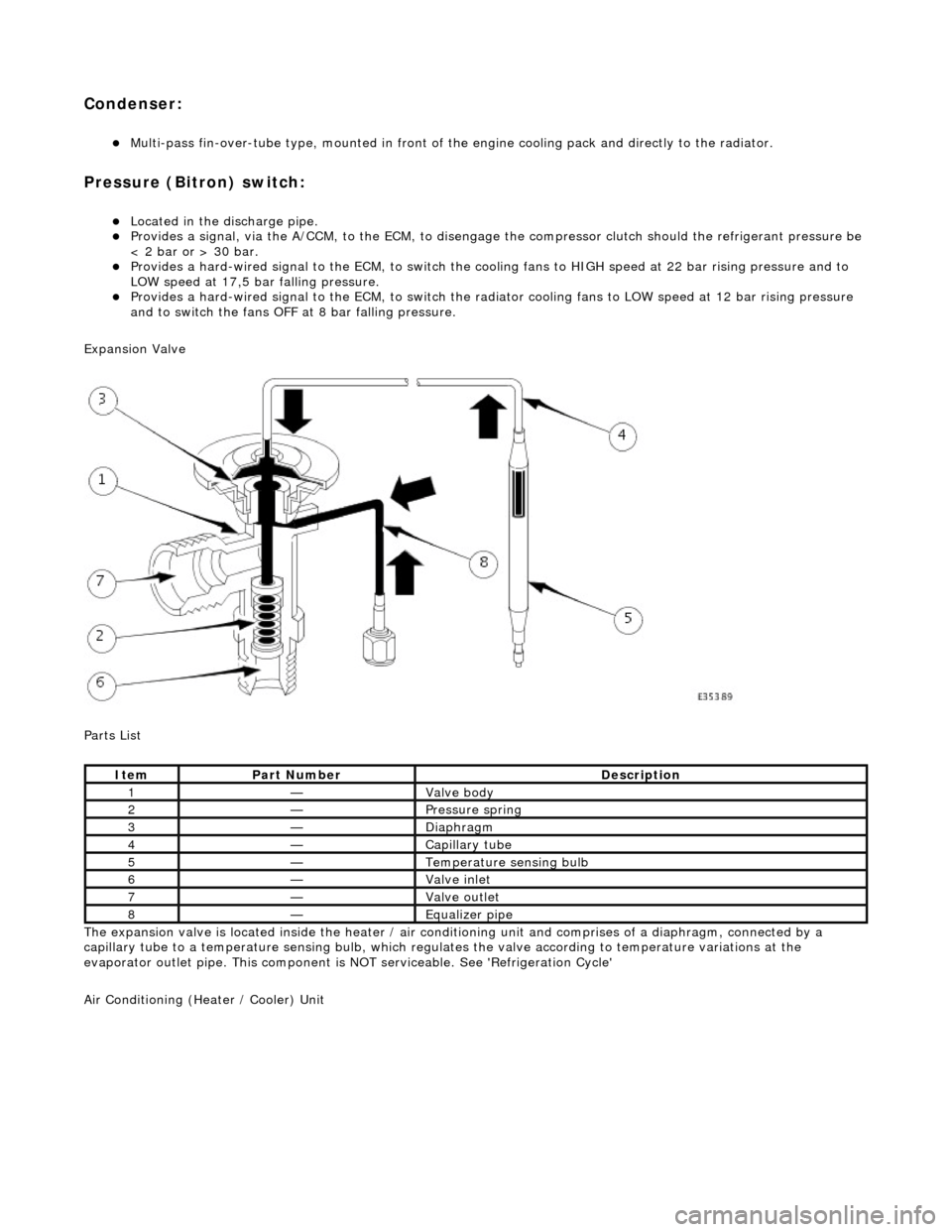

Expansion Valve

Parts List

The expansion valve is located inside the heater / air conditioning unit and comprises of a diaphragm, connected by a

capillary tube to a temperat ure sensing bulb, which regulates the valve according to temperature variations at the

evaporator outlet pipe. This component is NOT serviceable. See 'Refrigeration Cycle'

Air Conditioning (Heater / Cooler) Unit

ItemPart NumberDescription

1—Valve body

2—Pressure spring

3—Diaphragm

4—Capillary tube

5—Temperature sensing bulb

6—Valve inlet

7—Valve outlet

8—Equalizer pipe

Page 1808 of 2490

Air Conditioning - Condenser Core

Removal and Installation

Removal

1. Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Drain radiator coolant only; refer to 26.10.01 or (SC)

26.10.01.

3. Recover refrigerant from air co nditioning system; refer to

82.30.30.

4. Release both gas struts, set the engine cover fully forward to

the service access position an d support with a wooden (or

similar) strut.

5. CAUTION: Take care not to damage hood or radiator

grille.

Remove twin fan and motor as sembly; refer to 26.25.12.

6. Disconnect radiator bleed hose.

Release connection.

7. Remove retaining clip which secures transmission oil cooler

upper and lower pipes.

8. Disconnect transmission oil cooler lower pipe from radiator.

1. Release union nut and disconne ct pipe.

Discard O-ring seal.

2. Install suitable blanking plugs.

9. From above the vehicle, discon nect transmission oil cooler

upper pipe from radiator.

1. Release union nut and disconne ct pipe.

Discard O-ring seal.

2. Install suitable blanking plugs.

Page 1882 of 2490

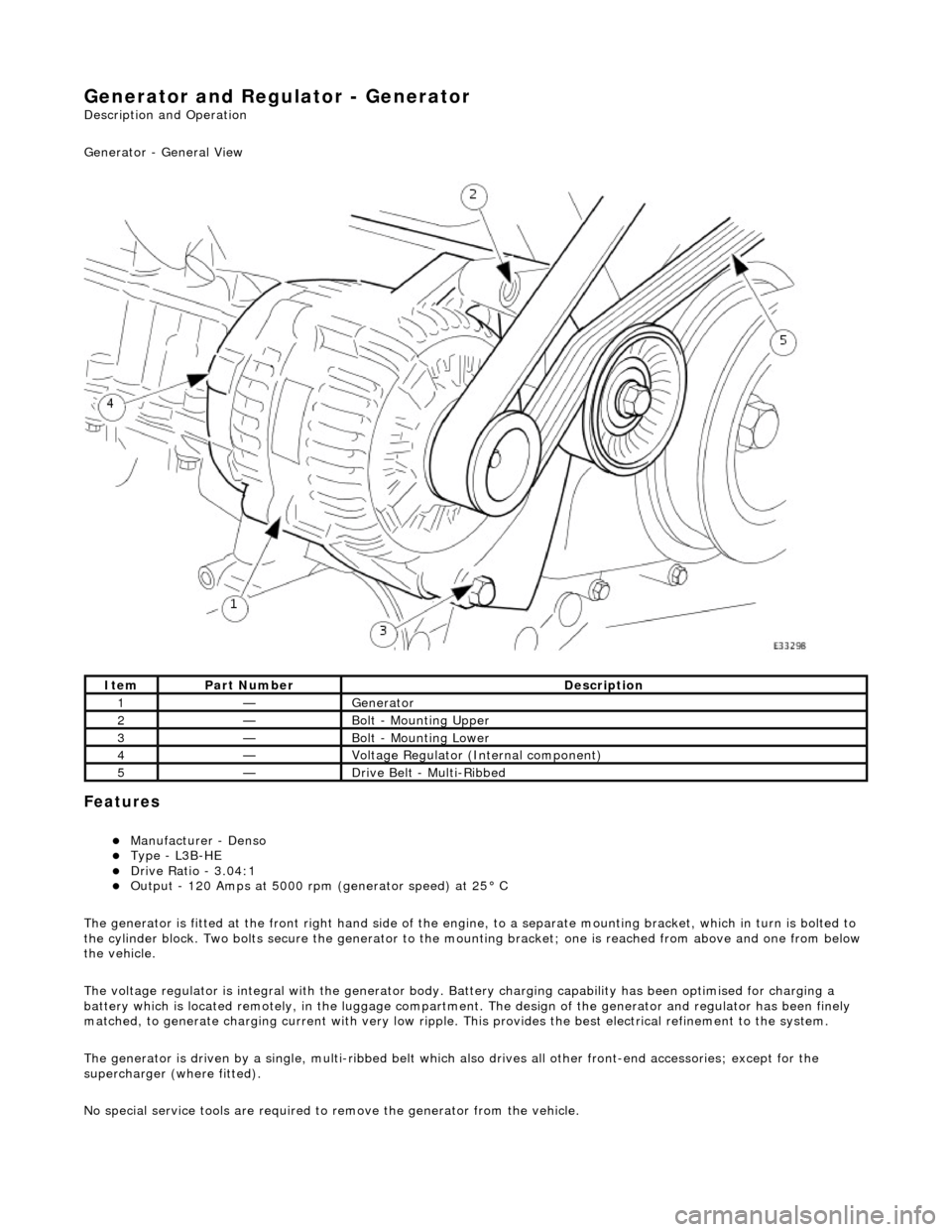

Generator and Regulator - Generator

Description and Operation

Generator - General View

Features

Manufacturer - Denso Type - L3B-HE Drive Ratio - 3.04:1 Output - 120 Amps at 5000 rpm (generator speed) at 25° C

The generator is fitted at the front right hand side of the engine, to a sepa rate mounting bracket, which in turn is bolted to

the cylinder block. Two bolts secure th e generator to the mounting bracket; one is reached from above and one from below

the vehicle.

The voltage regulator is integral with th e generator body. Battery charging capabi lity has been optimised for charging a

battery which is located remotely, in the luggage compartment. The design of the generator and regulator has been finely

matched, to generate charging current with very low ripple. This provides the best electrical refinement to the system.

The generator is driven by a single, multi-ribbed belt which also drives all other front-e nd accessories; except for the

supercharger (where fitted).

No special service tools are required to remove the generator from the vehicle.

ItemPart NumberDescription

1—Generator

2—Bolt - Mounting Upper

3—Bolt - Mounting Lower

4—Voltage Regulator (Internal component)

5—Drive Belt - Multi-Ribbed

Page 1883 of 2490

Belt tension is achieved by an automatic tensioner; neither the belt nor the tensioner require service apart from checking

the belt wear indicators at each normal service interval.

The minimum service life of the drive belt is 100,000 miles.

Never apply oil to the belt or to the belt tensioner.

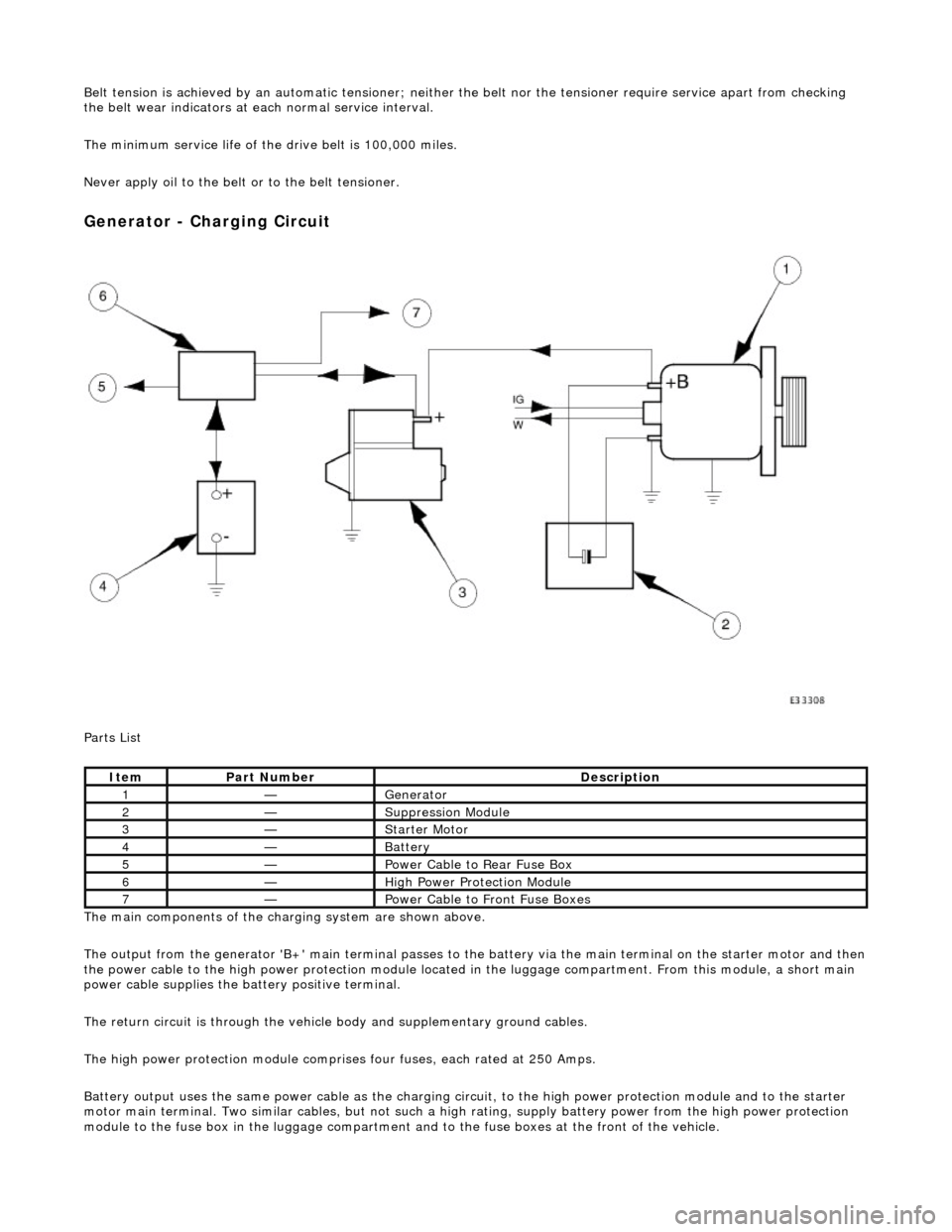

Generator - Charging Circuit

Parts List

The main components of the charging system are shown above.

The output from the generator 'B+' main te rminal passes to the battery via the main terminal on the starter motor and then

the power cable to the high power protection module located in the luggage compartment. From this module, a short main

power cable supplies the ba ttery positive terminal.

The return circuit is through the vehicle body and supplementary ground cables.

The high power protection mo dule comprises four fuses, each rated at 250 Amps.

Battery output uses the same power cable as the charging circ uit, to the high power protection module and to the starter

motor main terminal. Two similar cables, but not such a high rating, supply battery power from the high power protection

module to the fuse box in the luggage compartment an d to the fuse boxes at the front of the vehicle.

ItemPart NumberDescription

1—Generator

2—Suppression Module

3—Starter Motor

4—Battery

5—Power Cable to Rear Fuse Box

6—High Power Protection Module

7—Power Cable to Front Fuse Boxes

Page 1886 of 2490

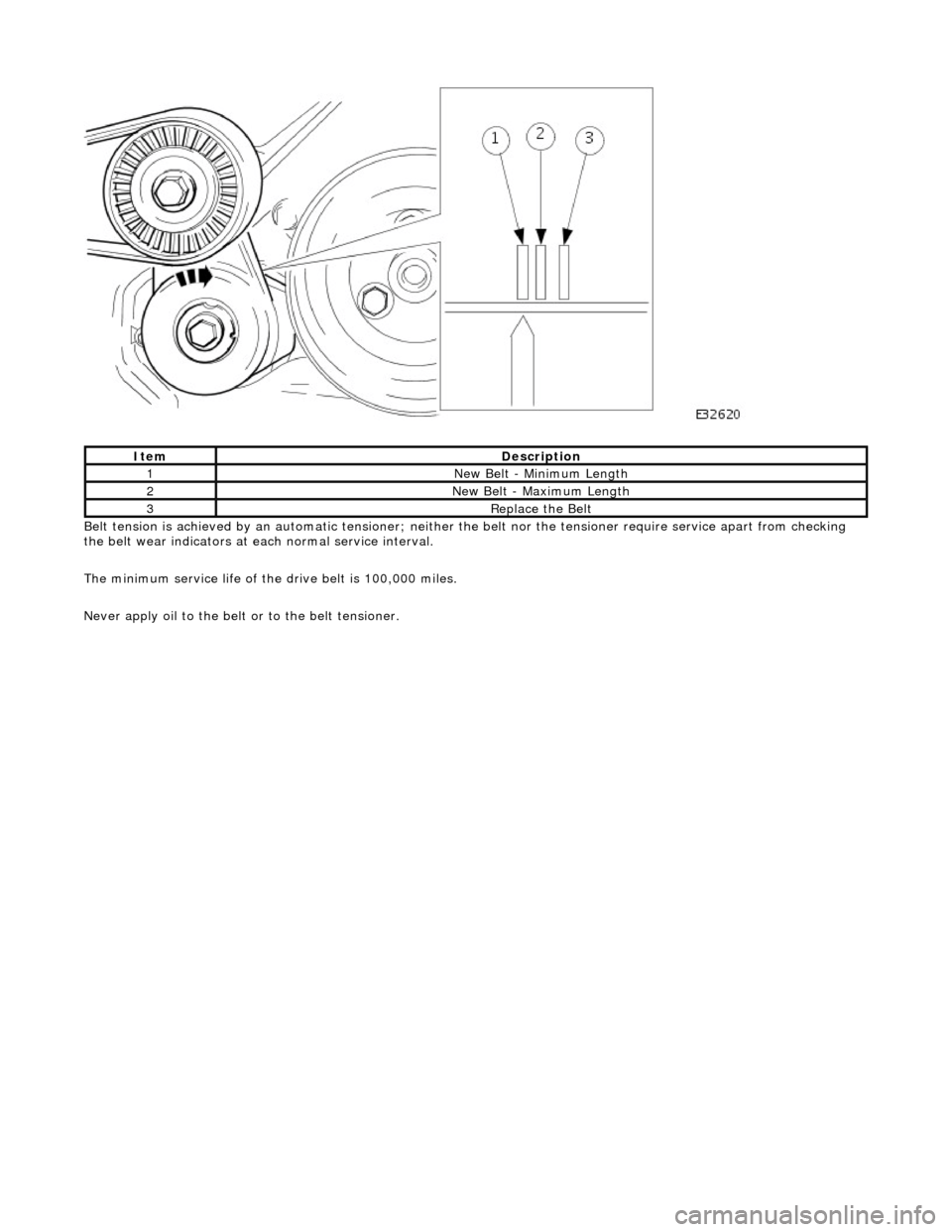

Belt tension is achieved by an automatic tensioner; neither the belt nor the tensioner require service apart from checking

the belt wear indicators at each normal service interval.

The minimum service life of the drive belt is 100,000 miles.

Never apply oil to the belt or to the belt tensioner.

ItemDescription

1New Belt - Minimum Length

2New Belt - Maximum Length

3Replace the Belt

Page 2242 of 2490

Instrument Panel and Console - Instrument Panel

Removal and Installation

Removal

1. Turn ignition switch to position II.

2. Motor driver and front passenger seats rearward.

3. Position steering wheel in stra ight ahead position and fully

lower and extend steering column.

4. Turn ignition switch to position O.

5. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

6. Remove 'J' gate finish er. Refer to 76.25.24.

7. Remove 'J' gate finisher retain ing panel. Refer to 76.25.26.

8. Remove centre console veneer panel. Refer to 76.47.26.

9. Disconnect and remove radio.

10. Remove centre console switch module. Refer to 86.80.32.

11. Remove centre console. Refer to 76.25.01.

12. Slacken and remove centre cons ole vent duct rear securing

screw and withdraw duct assemb ly from air conditioning unit

manifold.

13. WARNING: BEFORE ANY AIRBAG/SRS SERVICE IS

PERFORMED, AT LEAST ONE MINUTE MUST ELAPSE AFTER

DISCONNECTION OF THE BATTERY CABLE, TO ALLOW

DISSIPATION OF BACK-UP POWER SUPPLY ENERGY.

Remove driver airbag. Refer to 76.73.39.

14. Remove steering wheel. Refer to Section 211-04.

15. Remove steering column lo wer cowl. Refer to 76.46.03.

16. Remove steering column u pper cowl. Refer to 76.46.02.

17. Remove driver side unders cuttle. Refer to 76.46.11.

18. Remove combined windshield wiper/washer switch and

audible warning speaker assembly. Refer to 86.65.42.

19. Remove glovebox. Refer to 76.52.03.

20. Remove 'A' post lower trim pads. refer to 76.13.30.

21. Carefully withdraw driver stowage bin trim, remove bin

securing screw and remove bin from facia.

Page 2273 of 2490

Handles, Locks, Latches and Entry Systems - Handles, Locks, Latches and

Entry Systems

Description and Operation

Door Lock Mechanism

For most markets, the remote central locking system also, in corporates deadlocking facilities for optimum security. Door

locks are eight disc, bayonet fixing barrels with integral lock / unlock switches. Keys include 'in-key' transponders which are

programmed to the vehicle via the Jaguar Diagnostic Sy stem and operate the engine immobilisation system.

The central locking system employs single key access to the driv er's door, trunk lid and ignition switch/steering column lock.

An additional green headed valet or park ing services key permits access via the driver's door, and ignition/start-up, but

denies access to the trunk and glovebox.A valet switch located on the centre console switch panel above the radio,

precludes normal internal access to the trunk.When the vehicle is not locked, each door catch can be externally released by

the corresponding external door handle which operates via a si ngle rod. When unlocked, or 'single action' locked, the door

catches can also be released via the interior handles, each of which operates via a single cable. Operation of the front door

interior handles will also unlock the rear doors. Use of either key in the external door barrel, operates the lock via a short

rod to provide locking of the door latch. These locking functions can also be achieved by use of the remote transmitter.The

trunk lid can be independently unlatched via a switch located on the driver's side underscuttle. This will only operate at

vehicle speeds up to 8 km/h (5 mph).

All doors and the trunk can be manually lock ed simultaneously from inside by pressing the driver or front passenger door sill

button down. Each rear door can be independently locked by si milarly depressing the sill button and in some markets can be released by operating the internal door handle.

For most markets, a 'drive-away door locking' feature automati cally locks all doors and the trunk when the gear selector is

moved from the Park position.

Key Operation

To 'single action' lock or unlock the vehicle, the key is inserted in the door lock , turned towards the front or rear of the

vehicle respectively, and released. Holding the key in the lock position will close all windows. Releasing the key stops all

operations. 'single action' locking of the vehicle locks all doors, the trunk lid and the fuel filler flap, and sets the alarm

system.

In addition to all of the above functions, deadlocking prevents door opening from th e interior. To deadlock the vehicle, the

key is inserted in the door lock and turned to the unlock (rearw ard) position, then within three seconds, turned to the lock

(forward) position and released.

Remote Operation

Page 2308 of 2490

The rain sensor unit is installed on the inside of the windshield within the rear view mirror stem cover. The unit is secured t o

the glass by a special adhesive th at facilitates service removal. When installing a rain sensor unit, it must be positioned in

the clear circle within the obscuration band.

The rain sensor control module is a non- serviceable unit installed in the engine bay cool box and connected to the rain

sensor unit and the body processor module.

Page 2322 of 2490

Wipers and Washers - Windshield Wiper/Washer Switch

Removal and Installation

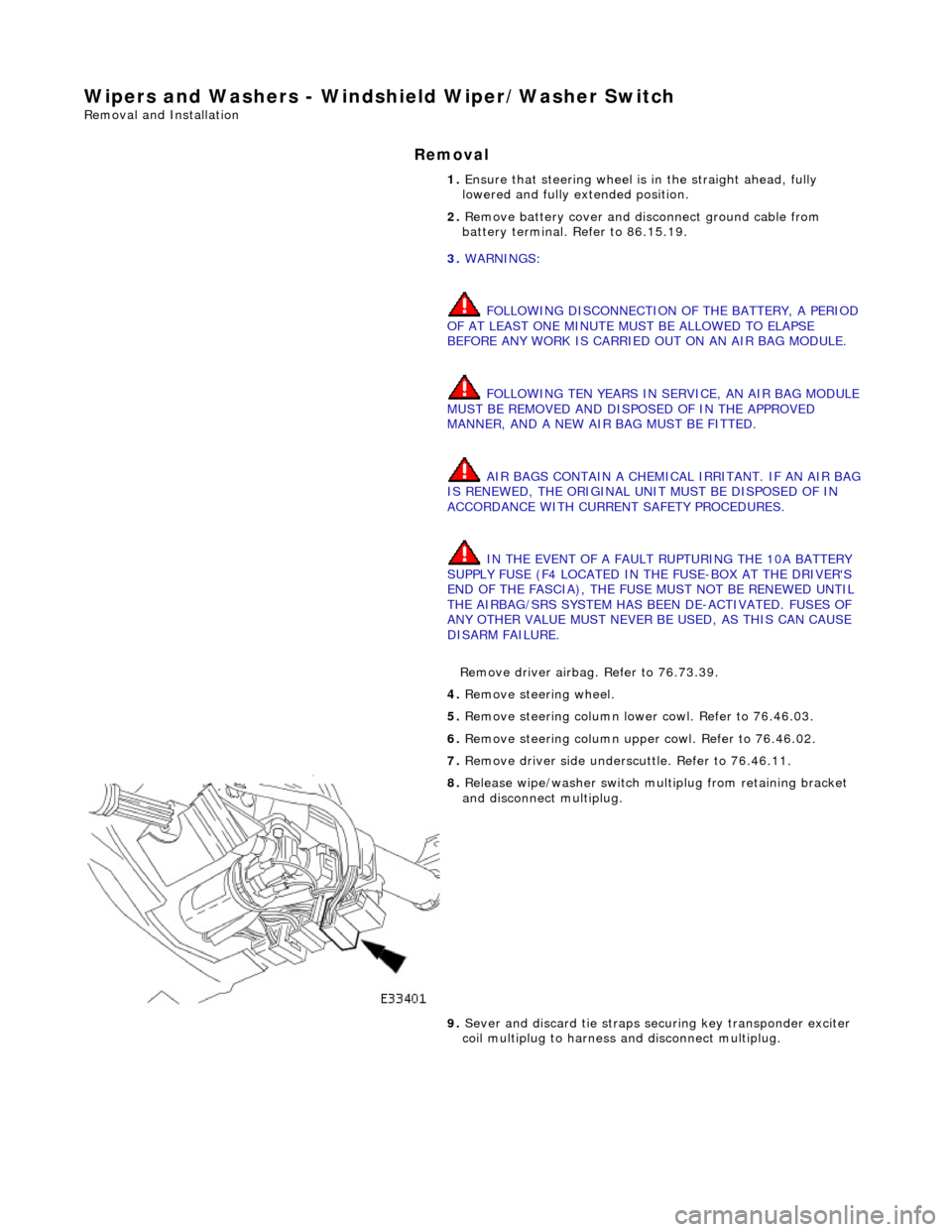

Removal

1. Ensure that steering wheel is in the straight ahead, fully

lowered and fully ex tended position.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. WARNINGS:

FOLLOWING DISCONNECTION OF THE BATTERY, A PERIOD

OF AT LEAST ONE MINUTE MUST BE ALLOWED TO ELAPSE

BEFORE ANY WORK IS CARRIED OUT ON AN AIR BAG MODULE.

FOLLOWING TEN YEARS IN SERVICE, AN AIR BAG MODULE

MUST BE REMOVED AND DISPOSED OF IN THE APPROVED

MANNER, AND A NEW AIR BAG MUST BE FITTED.

AIR BAGS CONTAIN A CHEMICAL IRRITANT. IF AN AIR BAG

IS RENEWED, THE ORIGINAL UNIT MUST BE DISPOSED OF IN

ACCORDANCE WITH CURRENT SAFETY PROCEDURES.

IN THE EVENT OF A FAULT RUPTURING THE 10A BATTERY

SUPPLY FUSE (F4 LOCATED IN THE FUSE-BOX AT THE DRIVER'S

END OF THE FASCIA), THE FUSE MUST NOT BE RENEWED UNTIL

THE AIRBAG/SRS SYSTEM HAS BEEN DE-ACTIVATED. FUSES OF

ANY OTHER VALUE MUST NEVER BE USED, AS THIS CAN CAUSE

DISARM FAILURE.

Remove driver airbag. Refer to 76.73.39.

4. Remove steeri ng wheel.

5. Remove steering column lowe r cowl. Refer to 76.46.03.

6. Remove steering column upper cowl. Refer to 76.46.02.

7. Remove driver side unders cuttle. Refer to 76.46.11.

8. Release wipe/washer switch mult iplug from retaining bracket

and disconnect multiplug.

9. Sever and discard tie straps se curing key transponder exciter

coil multiplug to harness and disconnect multiplug.

Page 2362 of 2490

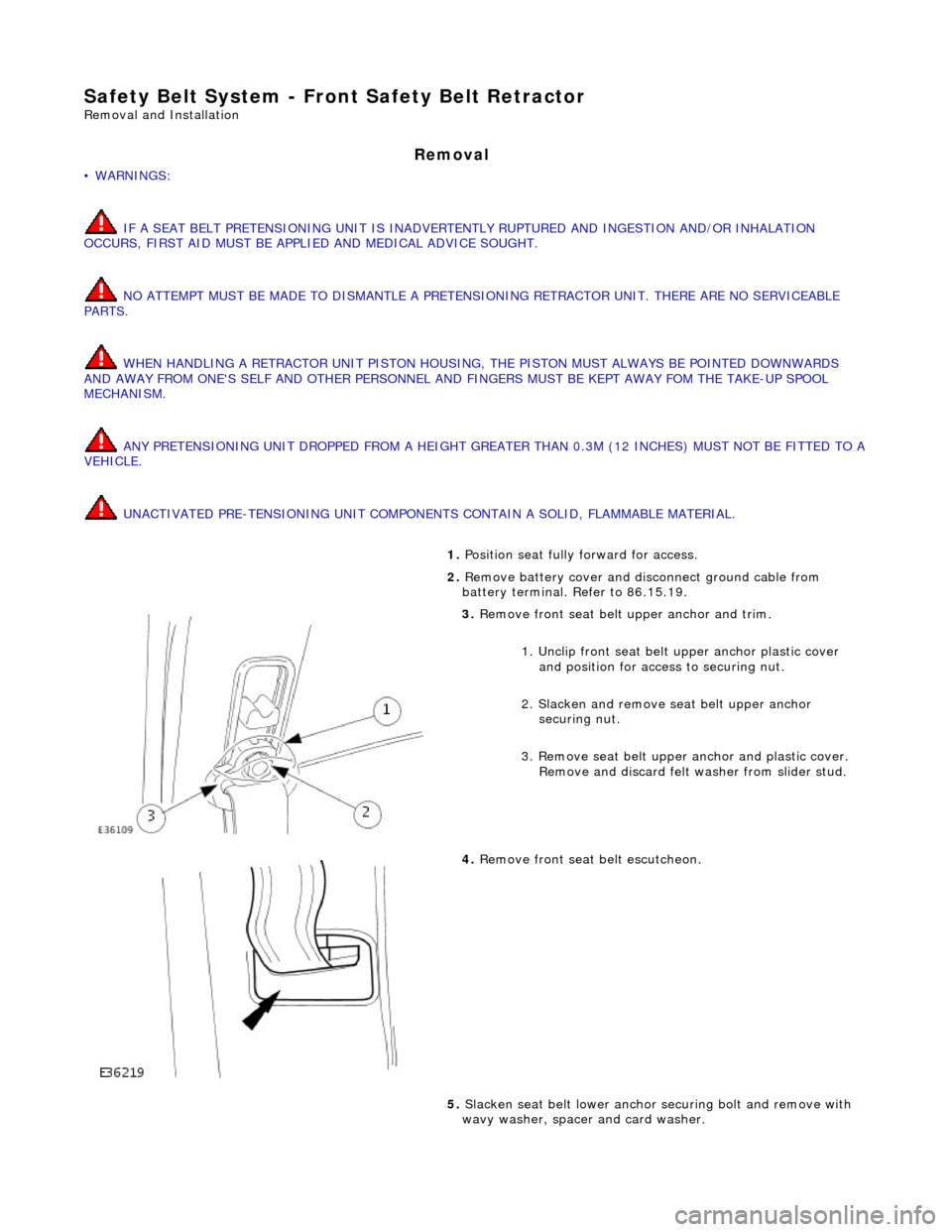

Safety Belt System - Front Safety Belt Retractor

Removal and Installation

Removal

• WARNINGS:

IF A SEAT BELT PRETENSIONING UNIT IS INADVERTENTLY RUPTURED AND INGESTION AND/OR INHALATION

OCCURS, FIRST AID MUST BE APPLIED AND MEDICAL ADVICE SOUGHT.

NO ATTEMPT MUST BE MADE TO DISMANTLE A PRETENSIONING RETRACTOR UNIT. THERE ARE NO SERVICEABLE

PARTS.

WHEN HANDLING A RETRACTOR UNIT PISTON HOUSING, THE PISTON MUST ALWAYS BE POINTED DOWNWARDS

AND AWAY FROM ONE'S SELF AND OTHER PERSONNEL AND FINGERS MUST BE KEPT AWAY FOM THE TAKE-UP SPOOL

MECHANISM.

ANY PRETENSIONING UNIT DROPPED FROM A HEIGHT GREA TER THAN 0.3M (12 INCHES) MUST NOT BE FITTED TO A

VEHICLE.

UNACTIVATED PRE-TENSIONING UNIT COMPONENTS CONTAIN A SOLID, FLAMMABLE MATERIAL.

1. Position seat fully forward for access.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove front seat belt upper anchor and trim.

1. Unclip front seat belt upper anchor plastic cover

and position for access to securing nut.

2. Slacken and remove se at belt upper anchor

securing nut.

3. Remove seat belt upper anchor and plastic cover. Remove and discard felt washer from slider stud.

4. Remove front seat belt escutcheon.

5. Slacken seat belt lower anchor securing bolt and remove with

wavy washer, spacer and card washer.