head bolt JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 594 of 2490

Instal

l the crankshaft locking tool to the damper.

1. Install adaptor 303-191-02 to the main locking tool 303-191.

2. Reposition the cranks haft/damper to align the

mounting holes and install the locking tool to the

damper using the bolts provided with the tool.

3. Loosen, but do not remove the damper securing bolt

from the crankshaft.

6. Remove the locking tool from the damper.

Remove

the damper securing bolt.

7. NOTE : Th

e damper only needs to be withdrawn along the

crankshaft nose by approximat ely 2mm before removing the

puller. The damper will then either be loose or only require a

sharp tap with a mallet to release it from the split locking ring.

Remove the damper from the crankshaft.

1. Transfer the adaptor 303 -191-02 from the crankshaft

locking tool to the damper extractor tool 303-588

(Use the socket head screws provided with the

puller).

2. Locate the thrust button into the end of the crankshaft; the O-ring holds it in place.

Ass

emble the puller to the damper.

Ex

trac

t the damper from the crankshaft.

8. Remove the puller components from the damper.

Re

move the thrust button from the end of the crankshaft.

9. Re

move the split locking ring from the damper.

10. Remove the internal O-ring seal.

Page 605 of 2490

Engine - Crankshaft

Rear Seal4.0L

NA V8 - AJ27/3.2 L NA V8 - AJ26

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Crankshaft Rear Oi

l Seal Remover /

Replacer.

303 - 538

1. Open the engine compartment and fit paint protection sheets.

2. Di

sconnect the batt

ery ground cable.

R

emove the battery cover.

3. Remove the transmission. Refer to Operation 44.20. 01 in

Section 307-01A.

4. Remove the drive plate. Refer to Operation 12.53.13.

5. F

it and align the seal removal tool 303 - 538 to the crankshaft.

1. Unscrew the two nuts towards the head of each bolt to allow the bolts to fit fully into the crankshaft.

2. Unscrew the center bolt until it is below the face of the main tool and position the tool to the rear of the

crankshaft.

3. Lightly tighten the two bolts so that they fully locate in the crankshaft.

6. Hold the tool against th

e cran

kshaft and lightly and evenly

tighten the two nuts to the face of the tool; to secure the tool

and to hold it parallel to the face of the crankshaft.

7. Secure the oil seal to the tool using the three self-tapping

Page 608 of 2490

Engine - Crankshaft Rear Seal4.0L SC V8 - AJ26

In-vehic

le Repair

Remov

a

l

S

p

ecial Tool(s)

Crankshaft Rear Oi

l Seal R

emover /

Replacer.

303 - 538

1. Open the engine compartment and fit paint protection sheets.

2. Disc

onnect the batt

ery ground cable.

Re

move the battery cover.

3. Remove the transmission. Refer to Operation 44.20. 01 in

Section 307-01B.

4. Remove the drive plat e. Refer to Operation (SC) 12.53.13.

5. Fi

t and align the seal removal tool 303 - 538 to the crankshaft.

1. Unscrew the two nuts towards the head of each bolt to allow the bolts to fit fully into the crankshaft.

2. Unscrew the center bolt until it is below the face of the main tool and position the tool to the rear of the

crankshaft.

3. Lightly tighten the two scre ws so that they fully locate

in the crankshaft.

6. Hold the tool against th e cr

an

kshaft and lightly and evenly

tighten the two nuts to the face of the tool; to secure the tool

and to hold it parallel to the face of the crankshaft.

7. Secure the oil seal to the tool using the three self-tapping

Page 612 of 2490

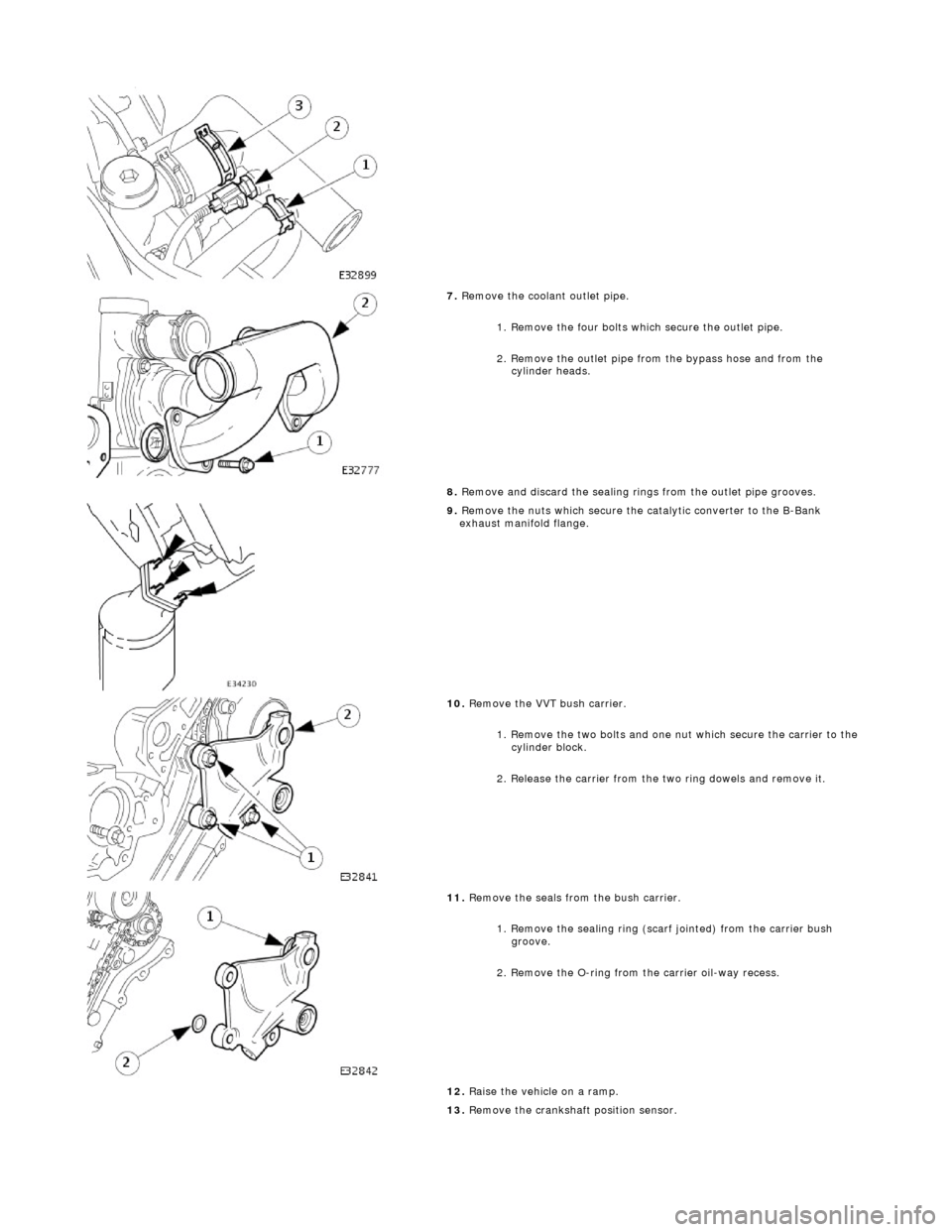

7.

Remove the coolant outlet pipe.

1. Remove the four bolts which secure the outlet pipe.

2. Remove the outlet pipe from the bypass hose and from the cylinder heads.

8. Remove and discard the sealing ring s from the outlet pipe grooves.

9.

Remove the nuts which secure the catalytic converter to the B-Bank

exhaust manifold flange.

10 . Re

move the VVT bush carrier.

1. Remove the two bolts and one nut which secure the carrier to the cylinder block.

2. Release the carrier from the two ring dowels and remove it.

11. R

emove the seals from the bush carrier.

1. Remove the sealing ring (scarf jointed) from the carrier bush groove.

2. Remove the O-ring from the carrier oil-way recess.

12. Raise the vehicle on a ramp.

13. Remove the crankshaft position sensor.

Page 614 of 2490

21. L

oosen the bolt which secures the VVT unit to the camshaft.

22. Remove the camshaft locking tool 303 - 530 (installed for previous

operation).

23 . R

emove the primary chain tensioner bolts.

24 . R

emove the tensioner assembly.

1. Remove the tensioner.

2. Remove the tens ioner back-plate.

25 . R

emove the primary chain tensioner blade.

1. Remove the pivot bolt which secures the tensioner blade.

2. Remove the tensioner blade.

26. Reposition the VVT unit along the cam journal to allow the chain to clear

the head casting.

Di s

connect the primary chain from the VVT unit and secure it to the

bypass hose retaining clip, using a Ty-strap.

27. Remove the VVT unit and exhaust camshaft sprocket.

1. Remove the securing bolt from both the VVT unit and the exhaust cam sprocket.

2. Remove the VVT unit, exhaust sprocket and secondary chain as an assembly (release the chain from the tensioner which is still

secured to the cylinder head).

Re

move the secondary chain from

the VVT unit and the sprocket.

Page 615 of 2490

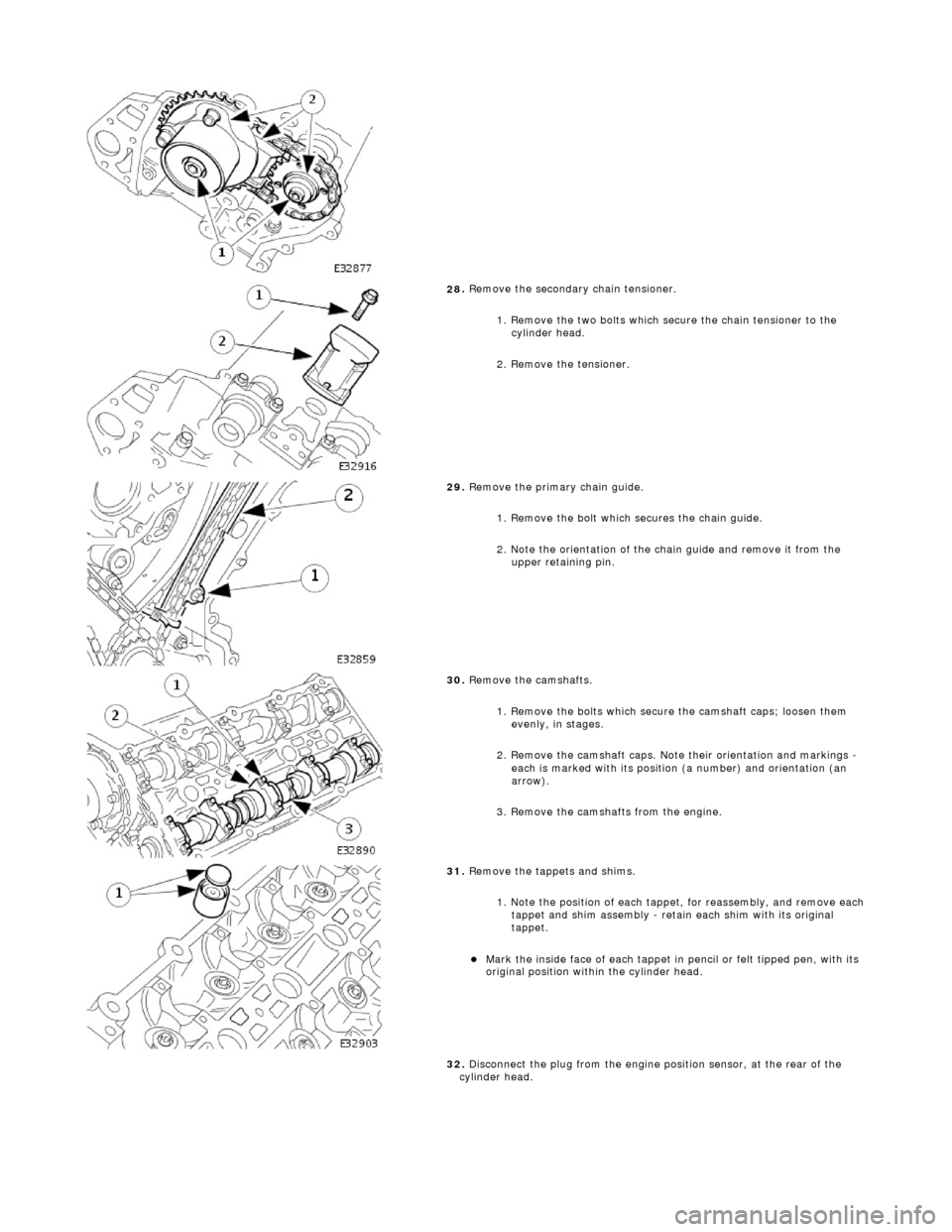

28

.

Remove the secondary chain tensioner.

1. Remove the two bolts which secure the chain tensioner to the cylinder head.

2. Remove the tensioner.

29

.

Remove the primary chain guide.

1. Remove the bolt which secures the chain guide.

2. Note the orientation of the chain guide and remove it from the upper retaining pin.

30

.

Remove the camshafts.

1. Remove the bolts which secure the camshaft caps; loosen them evenly, in stages.

2. Remove the camshaft caps. Note their orientation and markings -

each is marked with its position (a number) and orientation (an

arrow).

3. Remove the camshafts from the engine.

31

.

Remove the tappets and shims.

1. Note the position of each tappet, for reassembly, and remove each

tappet and shim assembly - retain each shim with its original

tappet.

Mark

the inside face of each tappet in pencil or felt tipped pen, with its

original position within the cylinder head.

32. Disconnect the plug from the engine position sensor, at the rear of the

cylinder head.

Page 616 of 2490

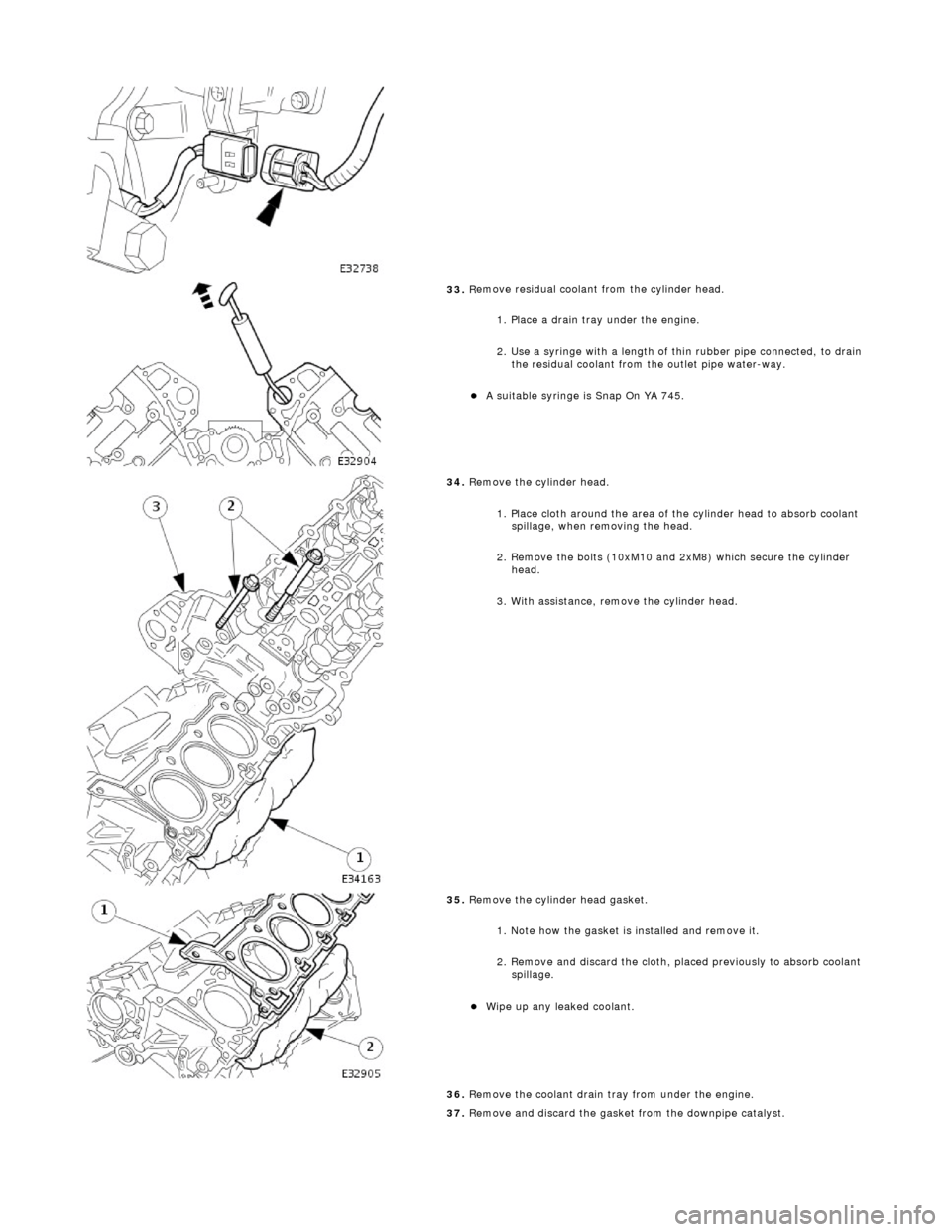

33. R

emove residual coolant from the cylinder head.

1. Place a drain tray under the engine.

2. Use a syringe with a length of thin rubber pipe connected, to drain the residual coolant from the outlet pipe water-way.

A s u

itable syringe is Snap On YA 745.

34 . R

emove the cylinder head.

1. Place cloth around the area of th e cylinder head to absorb coolant

spillage, when removing the head.

2. Remove the bolts (10xM10 and 2xM8) which secure the cylinder head.

3. With assistance, remove the cylinder head.

35 . R

emove the cylinder head gasket.

1. Note how the gasket is installed and remove it.

2. Remove and discard the cloth, placed previously to absorb coolant spillage.

Wipe up any l e

aked coolant.

36. Remove the coolant drain tray from under the engine.

37. Remove and discard the gasket from the downpipe catalyst.

Page 617 of 2490

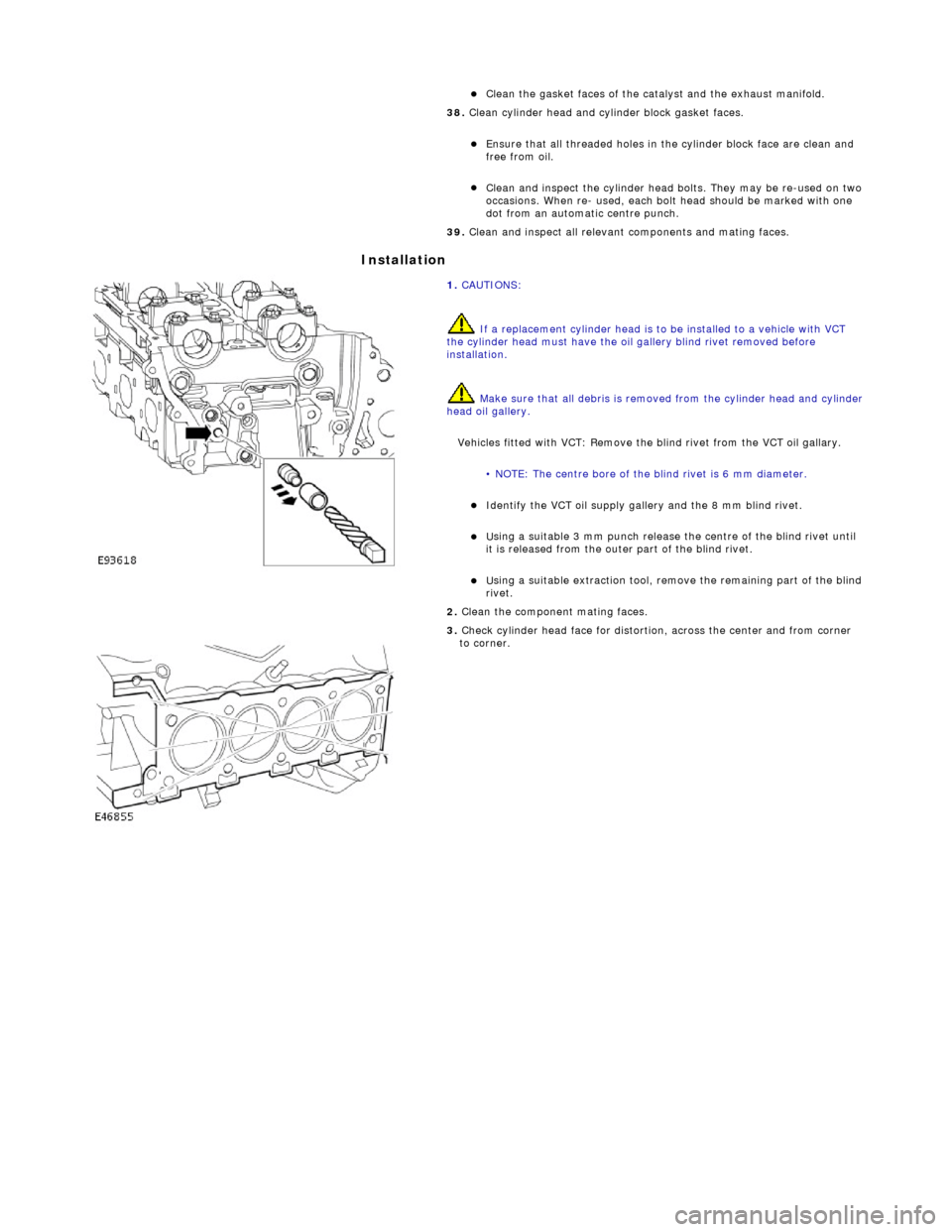

Inst

allation

Cl

ean the gasket faces of the catalyst and the exhaust manifold.

38. Clean cylinder head and cylinder block gasket faces.

E

nsure that all threaded holes in the cylinder block face are clean and

free from oil.

Cl

ean and inspect the cylinder head bolts. They may be re-used on two

occasions. When re- used, each bolt head should be marked with one

dot from an automatic centre punch.

39. Clean and inspect all relevant components and mating faces.

1.

CAUTIONS:

If a replacement cylinder head is to be installed to a vehicle with VCT

the cylinder head must have the oil gallery blind rivet removed before

installation.

Make sure that all debris is removed from the cylinder head and cylinder

head oil gallery.

Vehicles fitted with VCT: Remove the blind rivet from the VCT oil gallary.

• NOTE: The centre bore of the blind rivet is 6 mm diameter.

I

dentify the VCT oil supply gallery and the 8 mm blind rivet.

U

sing a suitable 3 mm punch release the centre of the blind rivet until

it is released from the outer part of the blind rivet.

U

sing a suitable extraction tool, remo

ve the remaining part of the blind

rivet.

2.

Clean the component mating faces.

3.

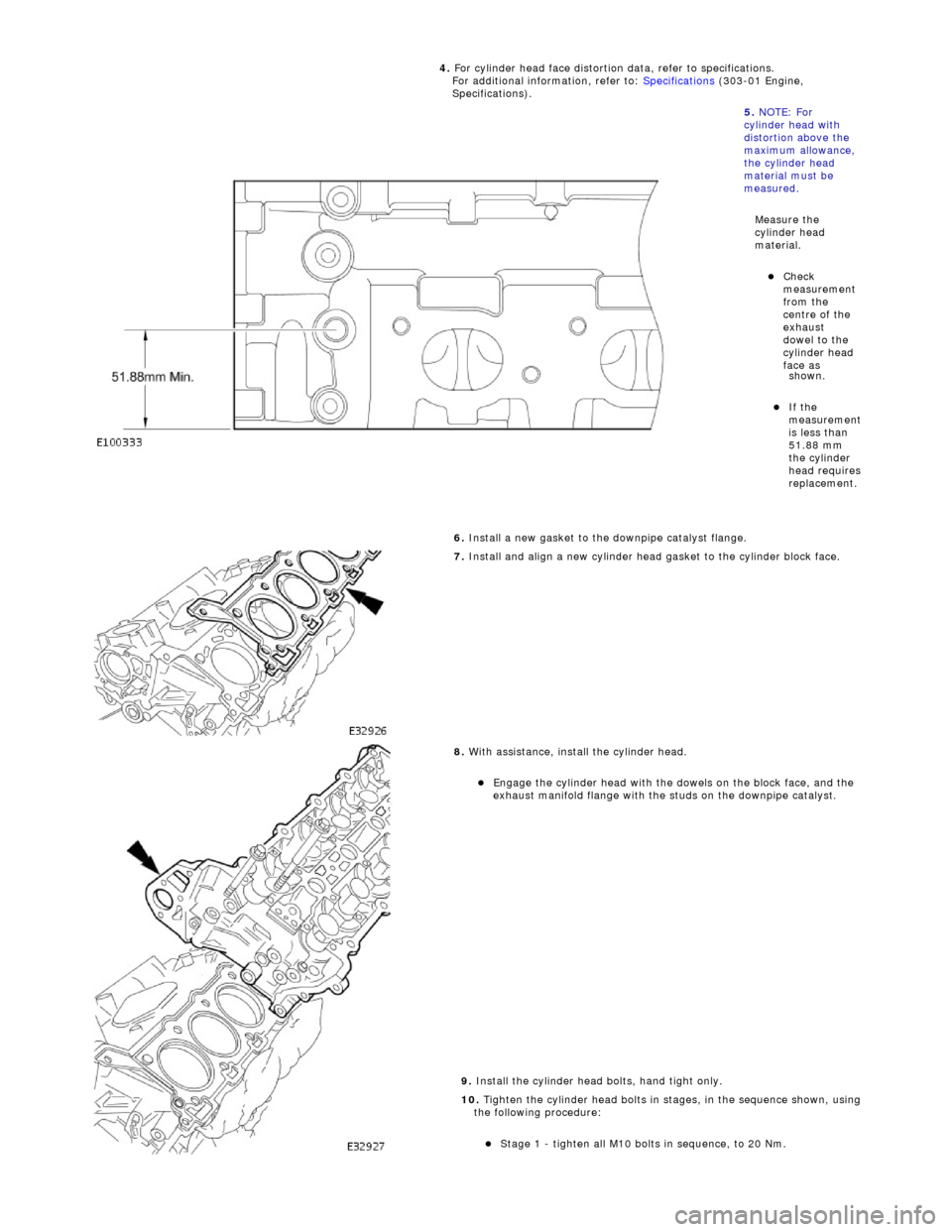

Check cylinder head face for distortio

n, across the center and from corner

to corner.

Page 618 of 2490

shown

.

If the

m

easurement

is less than

51.88 mm

the cylinder

head requires

replacement.

6.

Install a new gasket to the downpipe catalyst flange.

7.

Install and align a new cylinder head gasket to the cylinder block face.

8.

With assistance, install the cylinder head.

E

ngage t

he cylinder head with the dowels on the block face, and the

exhaust manifold flange with the studs on the downpipe catalyst.

9. Install the cylinder head bolts, hand tight only.

10. Tighten the cylinder head bolts in stages, in the sequence shown, using

the following procedure:

Stage 1 - ti

ghten all M10 bolt

s in sequence, to 20 Nm.

4.

For cylinder head face distortion

data, refer to specifications.

For additional information, refer to: Specifications

(303-01 Engi

ne,

Specifications).

5. NOTE: For

cylinder head with

distortion above the

maximum allowance,

the cylinder head

material must be

measured.

Measure the

cylinder head

material.

Che c

k

measurement

from the

centre of the

exhaust

dowel to the

cylinder head

face as

Page 620 of 2490

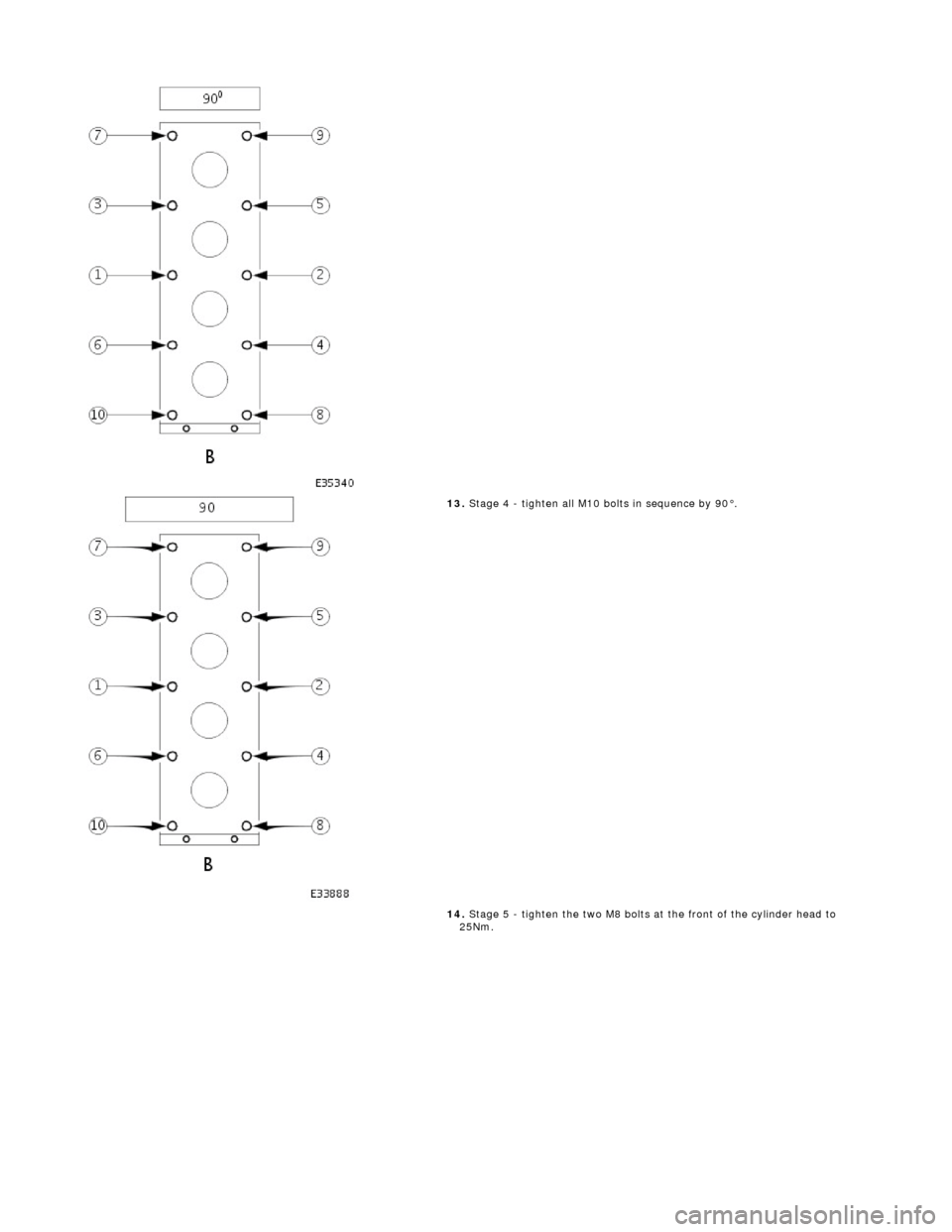

13. S

tage 4 - tighten all M10 bolts in sequence by 90°.

14. Stage 5 - tighten the two M8 bolts at the front of the cylinder head to

25Nm.