open hood JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2032 of 2490

Front End Body Panels - Radiator Grille Opening Panel Reinforcement Removal and Installation

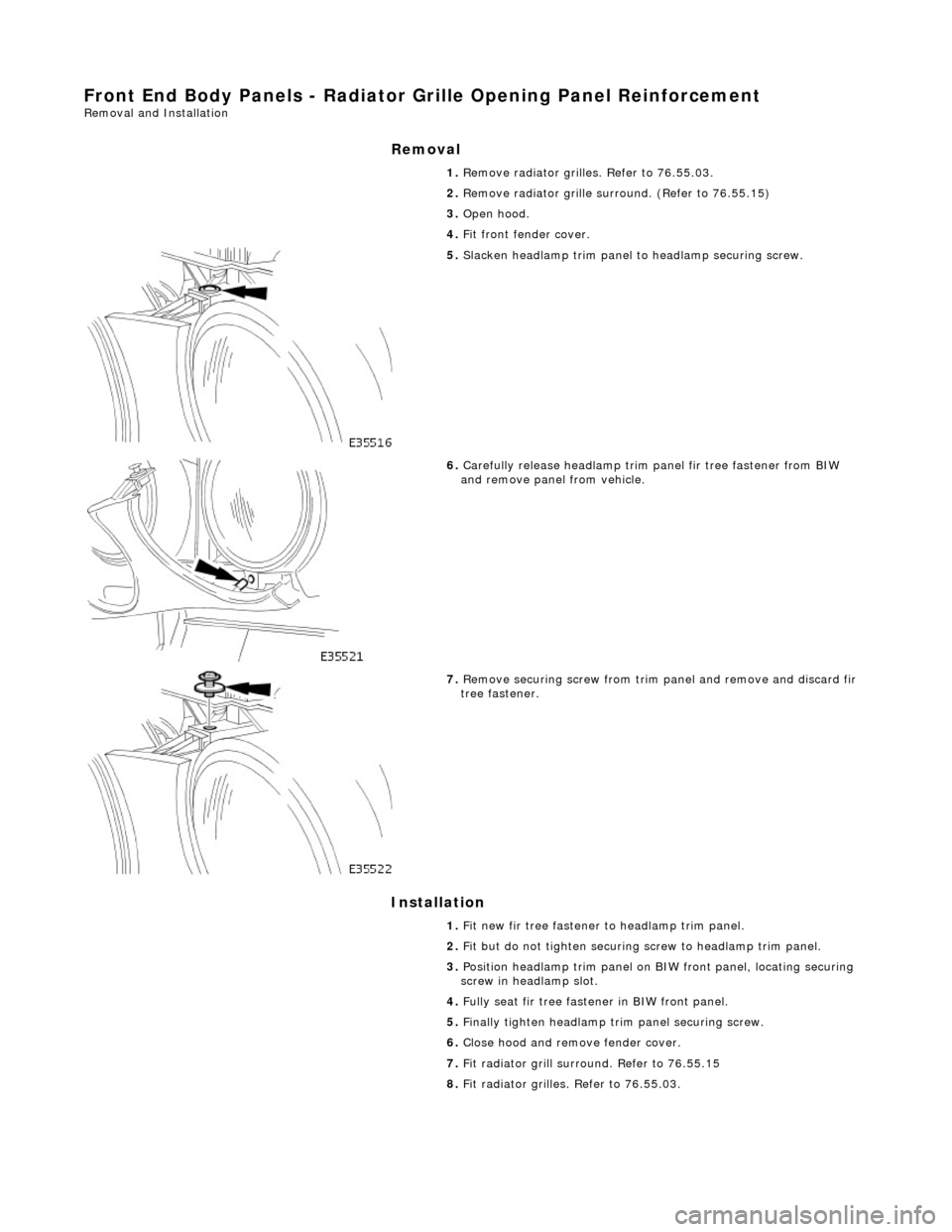

Removal

Installation

1.

Remove radiator grilles. Refer to 76.55.03.

2. Remove radiator grille surround. (Refer to 76.55.15)

3. Open hood.

4. Fit front fender cover.

5. Slacken headlamp trim panel to headlamp securing screw.

6. Carefully release headlamp trim panel fir tree fastener from BIW

and remove panel from vehicle.

7. Remove securing screw from trim panel and remove and discard fir

tree fastener.

1. Fit new fir tree fastener to headlamp trim panel.

2. Fit but do not tighten securing screw to headlamp trim panel.

3. Position headlamp trim panel on BIW front panel, locating securing

screw in headlamp slot.

4. Fully seat fir tree fastener in BIW front panel.

5. Finally tighten headlamp trim panel securing screw.

6. Close hood and remove fender cover.

7. Fit radiator grill surround. Refer to 76.55.15

8. Fit radiator grilles. Refer to 76.55.03.

Page 2035 of 2490

the BIW front upper crossmember. Two gas struts secured to the hood by pi vot pins and snap-on couplings, support the

hood in the open position. A full width insulating pad is secured by screws to the underside of the hood. A sponge rubber

tubular seal is mounted transversely to wards the front of the hood underside.

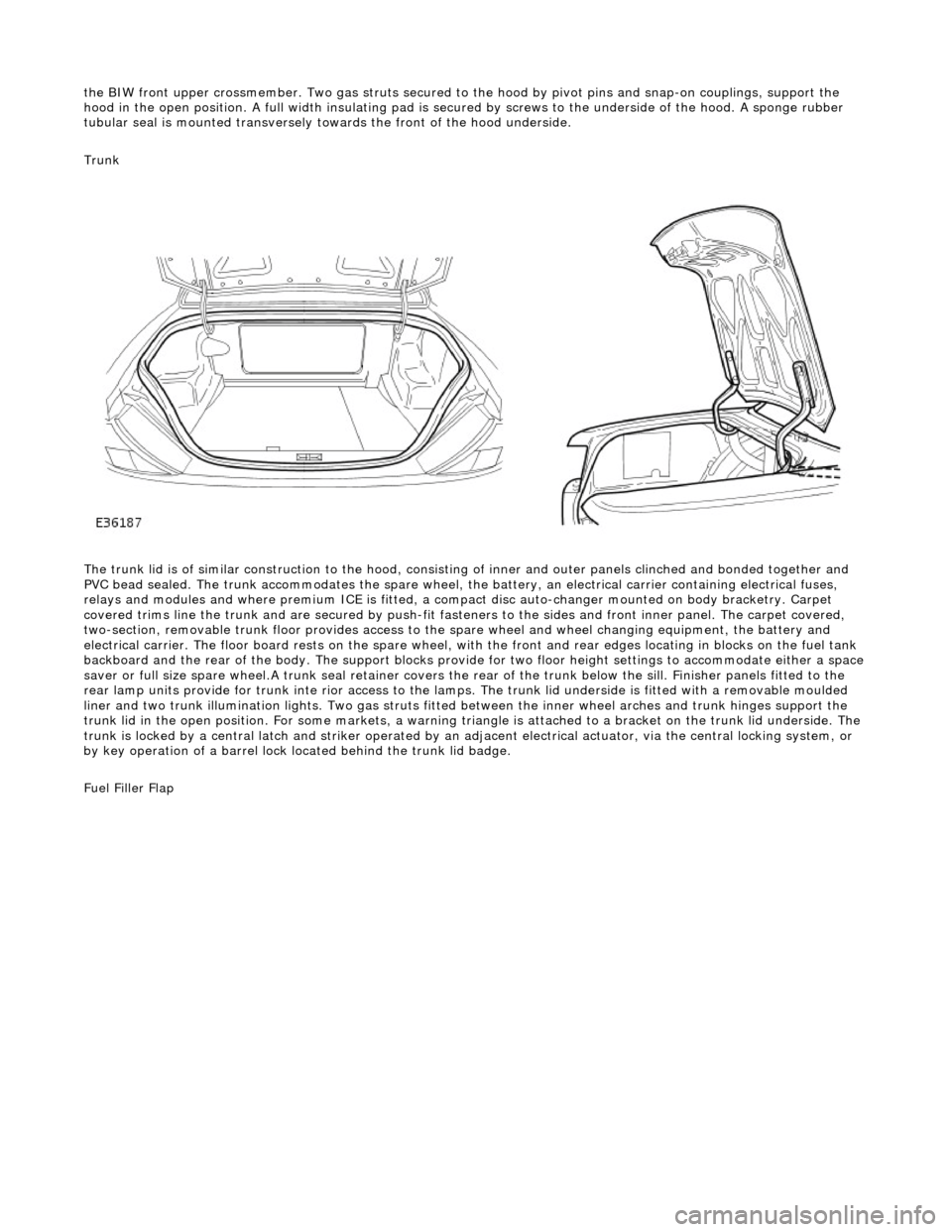

Trunk

The trunk lid is of similar construction to the hood, consisting of inner and outer panels clinched and bonded together and

PVC bead sealed. The trunk accommodates the spare wheel, the battery, an electrical carrier containing electrical fuses,

relays and modules and where premium ICE is fitted, a compac t disc auto-changer mounted on body bracketry. Carpet

covered trims line the trunk and are secured by push-fit fasten ers to the sides and front inner panel. The carpet covered,

two-section, removable trunk floor prov ides access to the spare wheel and wheel changing equipment, the battery and

electrical carrier. The floor board rests on the spare wheel, with the front and rear e dges locating in blocks on the fuel tank

backboard and the rear of the body. The support blocks provide for two floor height settings to accommodate either a space

saver or full size spare wheel.A trunk seal retainer covers the re ar of the trunk below the sill. Finisher panels fitted to the

rear lamp units provide for trunk inte rior access to the lamps. The trunk lid underside is fitted with a removable moulded

liner and two trunk illumination lights. Two gas struts fitted between the inner wheel arches and trunk hinges support the

trunk lid in the open position. For some markets, a warning triangle is attached to a bracket on the trunk lid underside. The

trunk is locked by a central latch and stri ker operated by an adjacent electrical actuator, via the central locking system, or

by key operation of a barrel lock located behind the trunk lid badge.

Fuel Filler Flap

Page 2037 of 2490

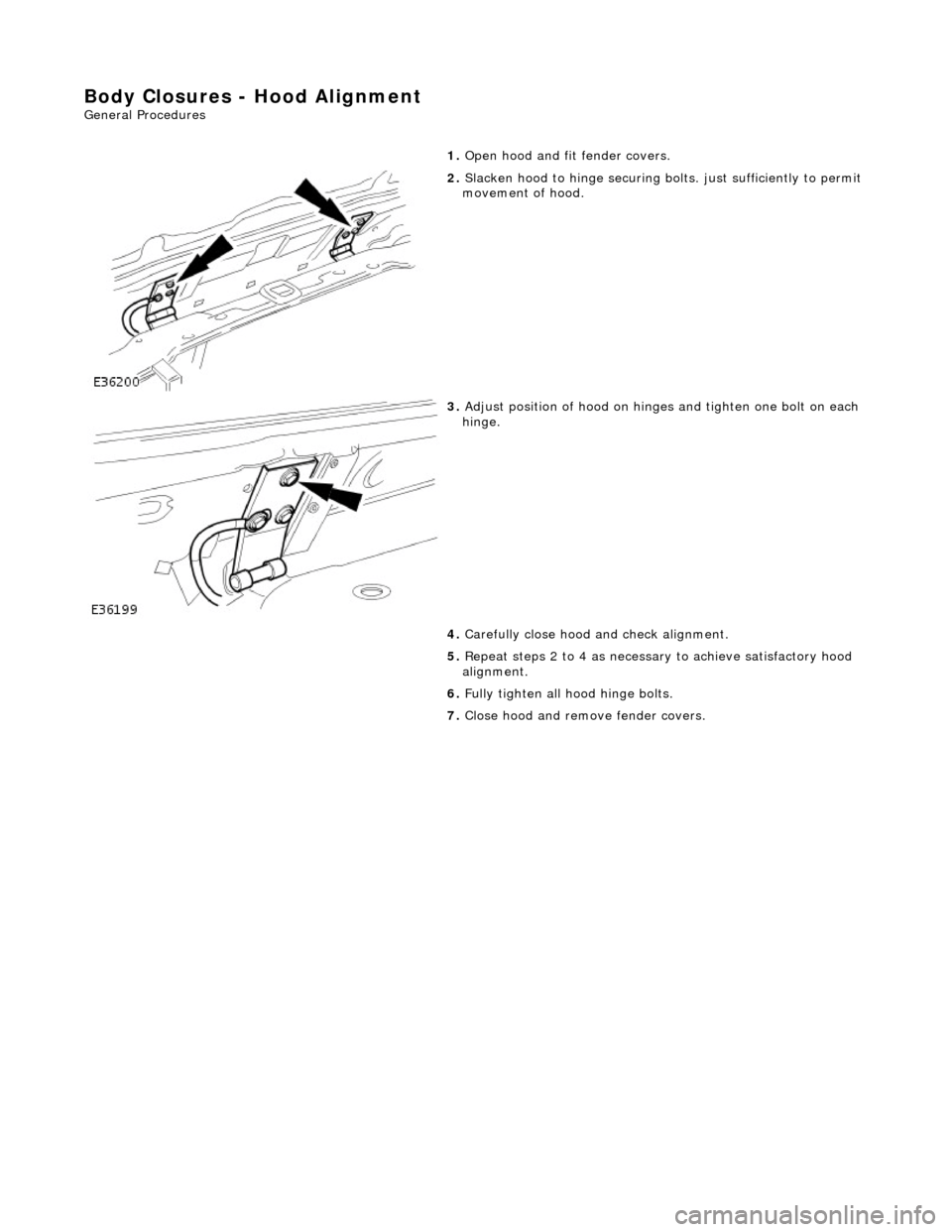

Body Closures - Hood Alignment

General Procedures

1.

Open hood and fit fender covers.

2. Slacken hood to hinge securing bo lts. just sufficiently to permit

movement of hood.

3. Adjust position of hood on hing es and tighten one bolt on each

hinge.

4. Carefully close hood and check alignment.

5. Repeat steps 2 to 4 as necessar y to achieve satisfactory hood

alignment.

6. Fully tighten all hood hinge bolts.

7. Close hood and remove fender covers.

Page 2042 of 2490

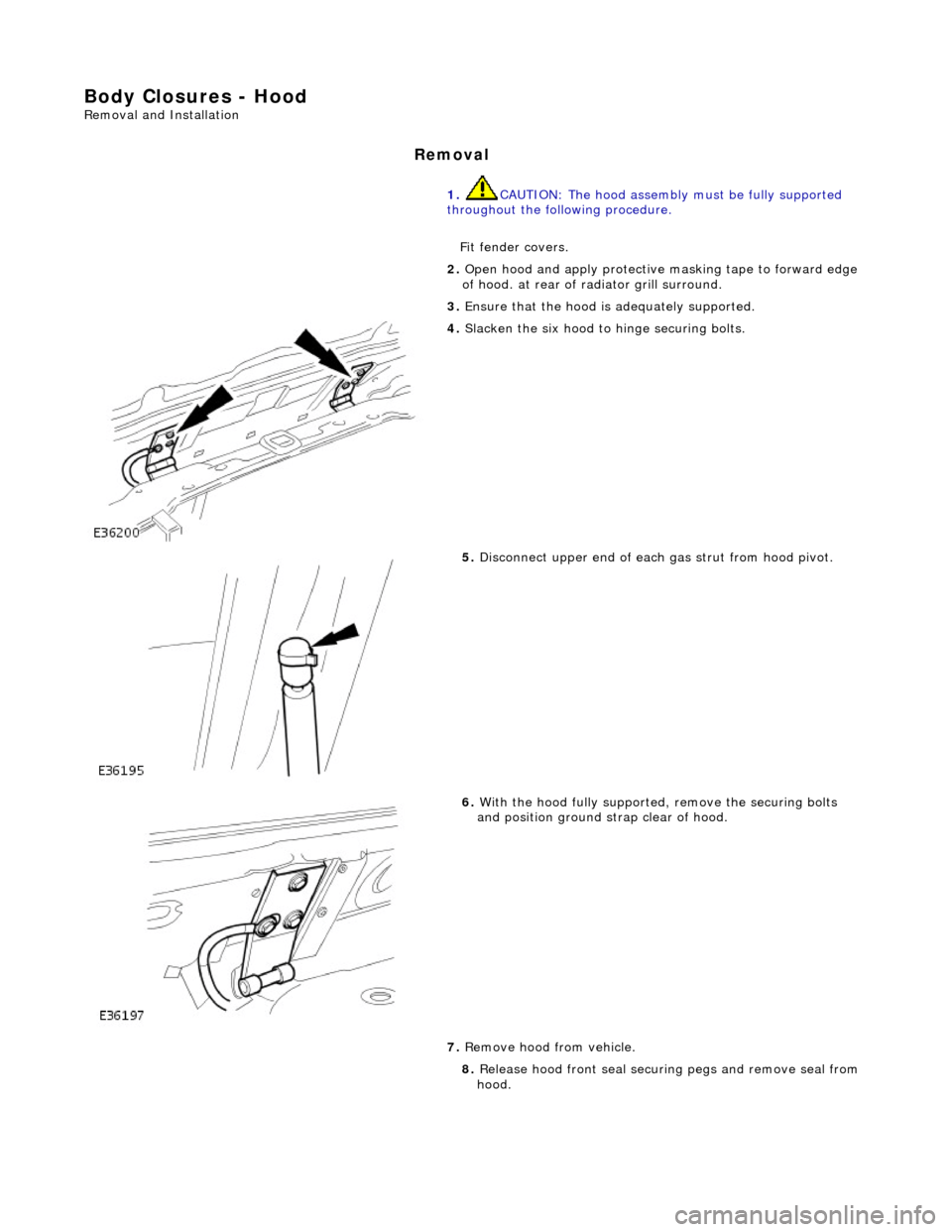

Body Closures - Hood

Removal and Installation

Removal

1. CAUTION: The hood assembly must be fully supported

throughout the following procedure.

Fit fender covers.

2. Open hood and apply protective masking tape to forward edge

of hood. at rear of ra diator grill surround.

3. Ensure that the hood is adequately supported.

4. Slacken the six hood to hinge securing bolts.

5. Disconnect upper end of each gas strut from hood pivot.

6. With the hood fully supported , remove the securing bolts

and position ground strap clear of hood.

7. Remove hood from vehicle.

8. Release hood front seal securi ng pegs and remove seal from

hood.

Page 2045 of 2490

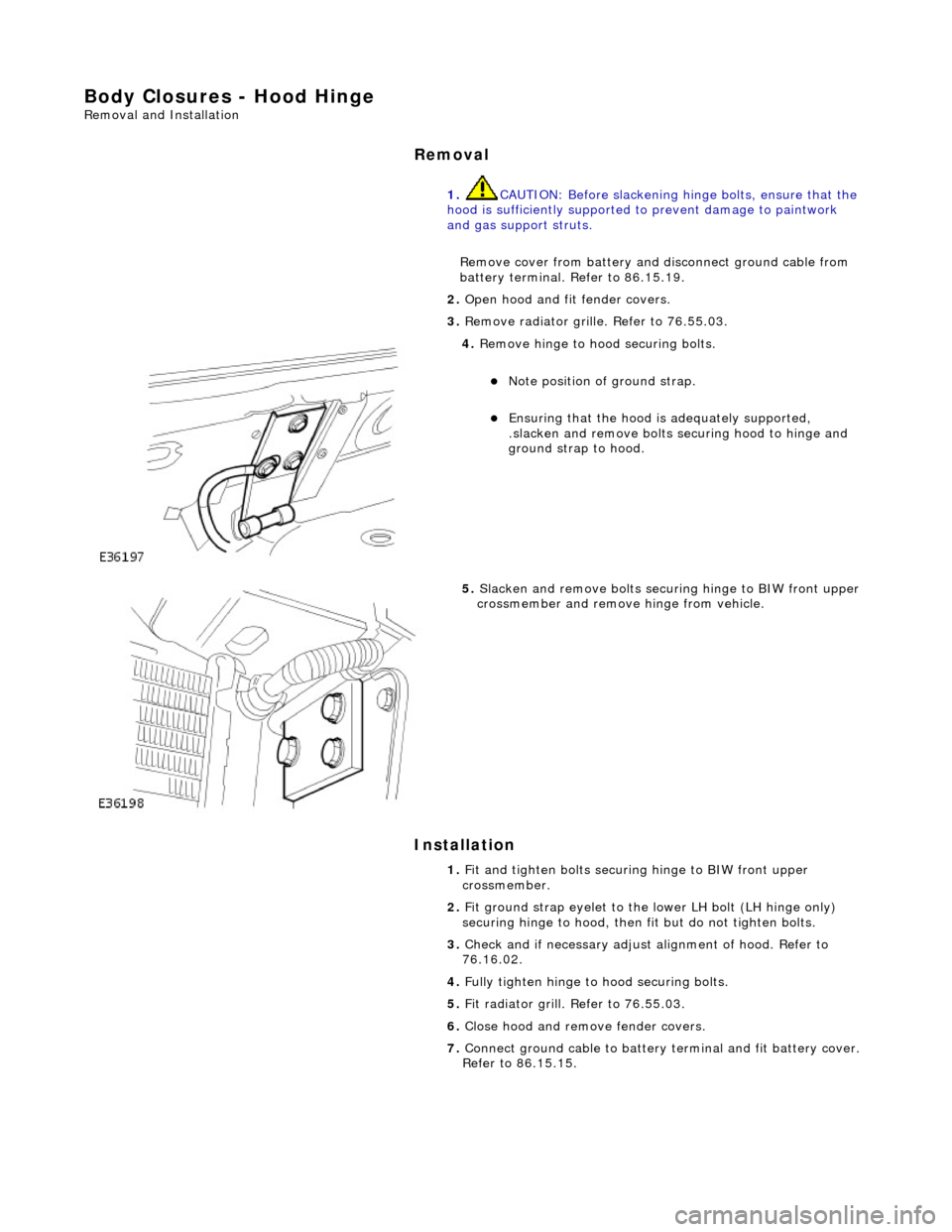

Body Closures - Hood Hinge

Removal and Installation

Removal

Installation

1.

CAUTION: Before slackening hi nge bolts, ensure that the

hood is sufficiently supported to prevent damage to paintwork

and gas support struts.

Remove cover from battery and disconnect ground cable from

battery terminal. Refer to 86.15.19.

2. Open hood and fit fender covers.

3. Remove radiator grille. Refer to 76.55.03.

4. Remove hinge to hood securing bolts.

Note position of ground strap.

Ensuring that the hood is adequately supported,

.slacken and remove bolts se curing hood to hinge and

ground strap to hood.

5. Slacken and remove bolts securi ng hinge to BIW front upper

crossmember and remove hinge from vehicle.

1. Fit and tighten bolts securing hinge to BIW front upper

crossmember.

2. Fit ground strap eyelet to the lower LH bolt (LH hinge only)

securing hinge to hood, then fit but do not tighten bolts.

3. Check and if necessary adjust alignment of hood. Refer to

76.16.02.

4. Fully tighten hinge to hood securing bolts.

5. Fit radiator grill. Refer to 76.55.03.

6. Close hood and remove fender covers.

7. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 2047 of 2490

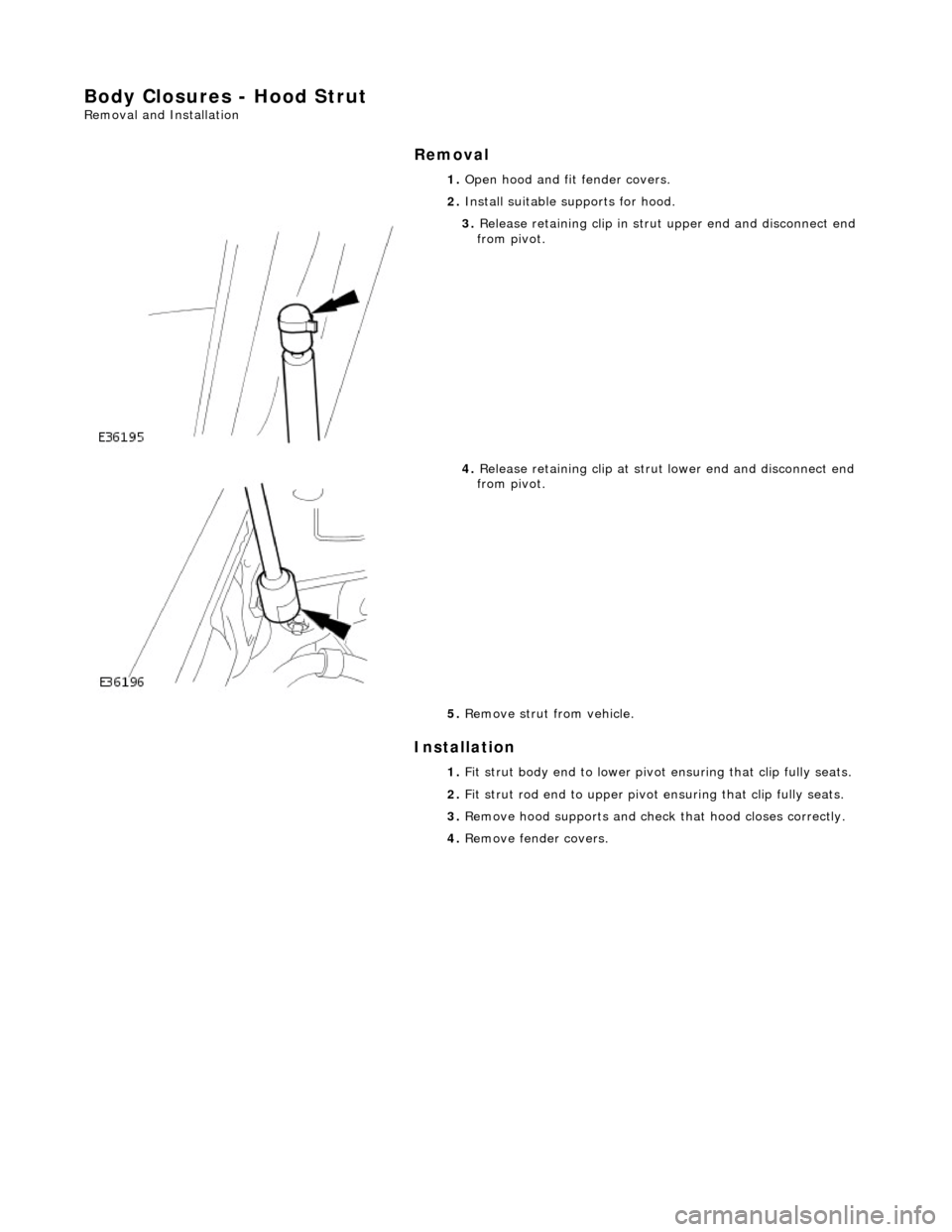

Body Closures - Hood Strut

Removal and Installation

Removal

Installation

1.

Open hood and fit fender covers.

2. Install suitable supports for hood.

3. Release retaining clip in stru t upper end and disconnect end

from pivot.

4. Release retaining clip at stru t lower end and disconnect end

from pivot.

5. Remove strut from vehicle.

1. Fit strut body end to lower pivot ensuring that clip fully seats.

2. Fit strut rod end to upper pivot en suring that clip fully seats.

3. Remove hood supports and check that hood closes correctly.

4. Remove fender covers.

Page 2311 of 2490

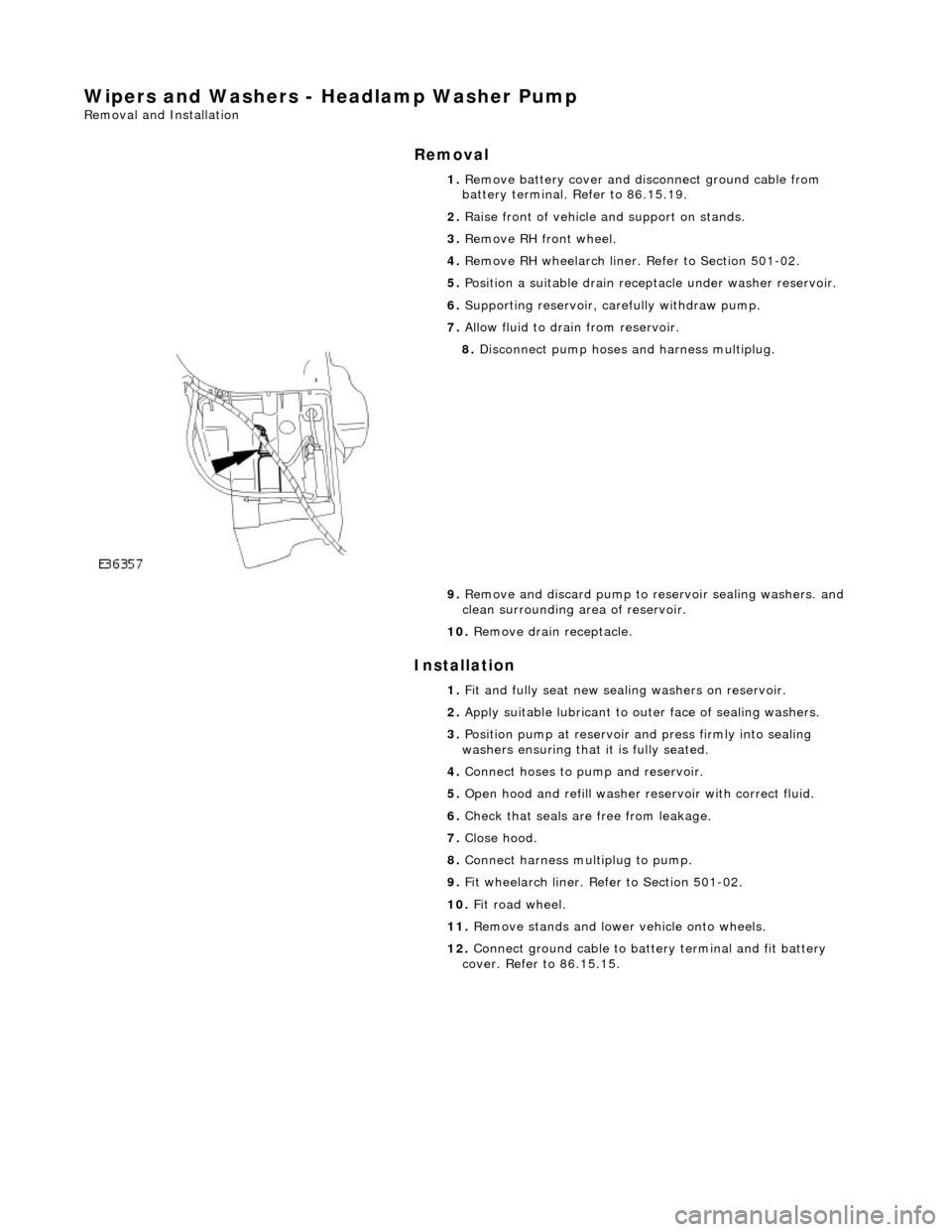

Wipers and Washers - Headlamp Washer Pump

Removal and Installation

Removal

Installation

1.

Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Raise front of vehicle and support on stands.

3. Remove RH front wheel.

4. Remove RH wheelarch liner. Refer to Section 501-02.

5. Position a suitable drain recept acle under washer reservoir.

6. Supporting reservoir, ca refully withdraw pump.

7. Allow fluid to drain from reservoir.

8. Disconnect pump hoses and harness multiplug.

9. Remove and discard pump to re servoir sealing washers. and

clean surrounding area of reservoir.

10. Remove drain receptacle.

1. Fit and fully seat new sealing washers on reservoir.

2. Apply suitable lubricant to outer face of sealing washers.

3. Position pump at reservoir and press firmly into sealing

washers ensuring that it is fully seated.

4. Connect hoses to pump and reservoir.

5. Open hood and refill washer re servoir with correct fluid.

6. Check that seals are free from leakage.

7. Close hood.

8. Connect harness multiplug to pump.

9. Fit wheelarch liner. Refe r to Section 501-02.

10. Fit road wheel.

11. Remove stands and lowe r vehicle onto wheels.

12. Connect ground cable to batt ery terminal and fit battery

cover. Refer to 86.15.15.

Page 2314 of 2490

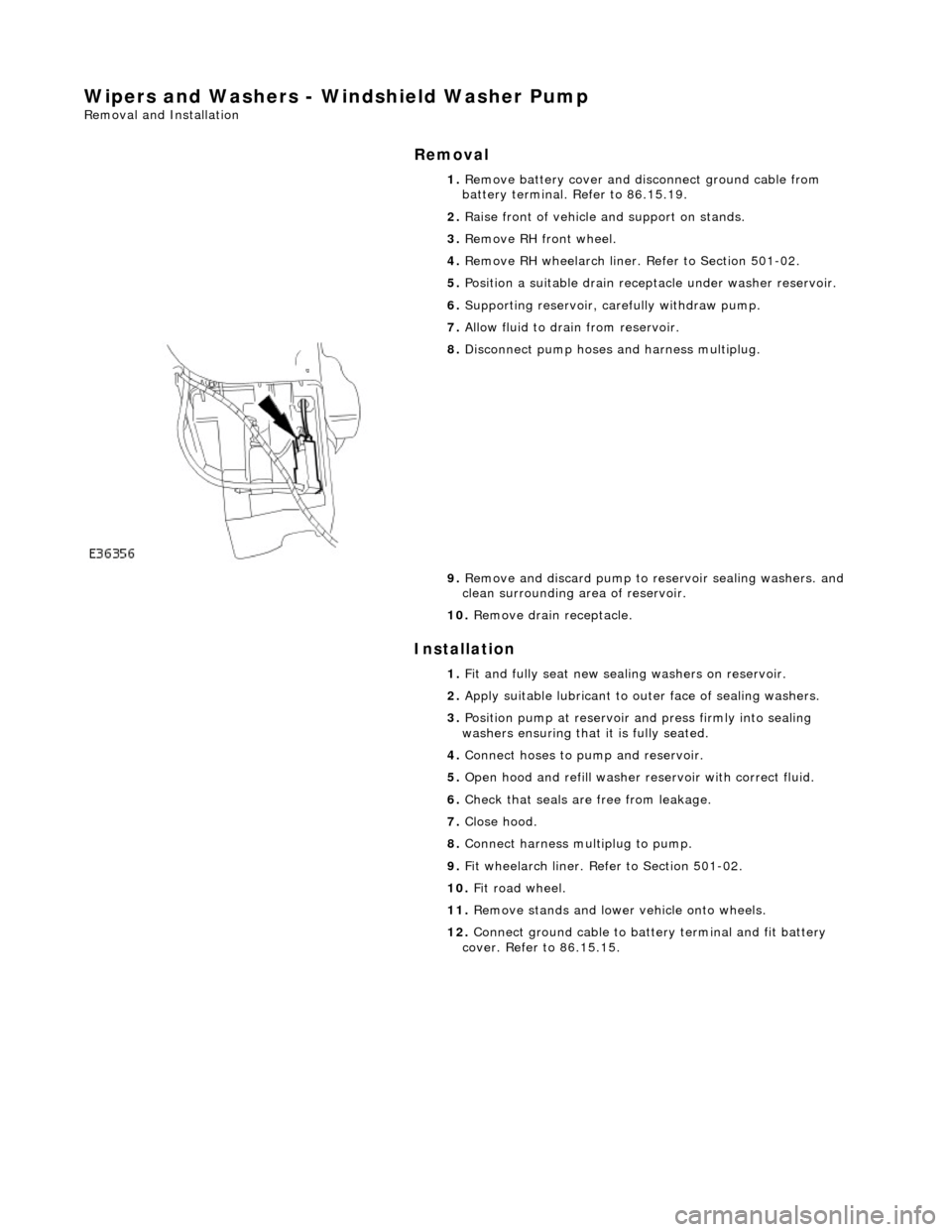

Wipers and Washers - Windshield Washer Pump

Removal and Installation

Removal

Installation

1.

Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Raise front of vehicle and support on stands.

3. Remove RH front wheel.

4. Remove RH wheelarch liner. Refer to Section 501-02.

5. Position a suitable drain recept acle under washer reservoir.

6. Supporting reservoir, ca refully withdraw pump.

7. Allow fluid to drain from reservoir.

8. Disconnect pump hoses and harness multiplug.

9. Remove and discard pump to re servoir sealing washers. and

clean surrounding area of reservoir.

10. Remove drain receptacle.

1. Fit and fully seat new sealing washers on reservoir.

2. Apply suitable lubricant to outer face of sealing washers.

3. Position pump at reservoir and press firmly into sealing

washers ensuring that it is fully seated.

4. Connect hoses to pump and reservoir.

5. Open hood and refill washer re servoir with correct fluid.

6. Check that seals are free from leakage.

7. Close hood.

8. Connect harness multiplug to pump.

9. Fit wheelarch liner. Refe r to Section 501-02.

10. Fit road wheel.

11. Remove stands and lowe r vehicle onto wheels.

12. Connect ground cable to batt ery terminal and fit battery

cover. Refer to 86.15.15.

Page 2315 of 2490

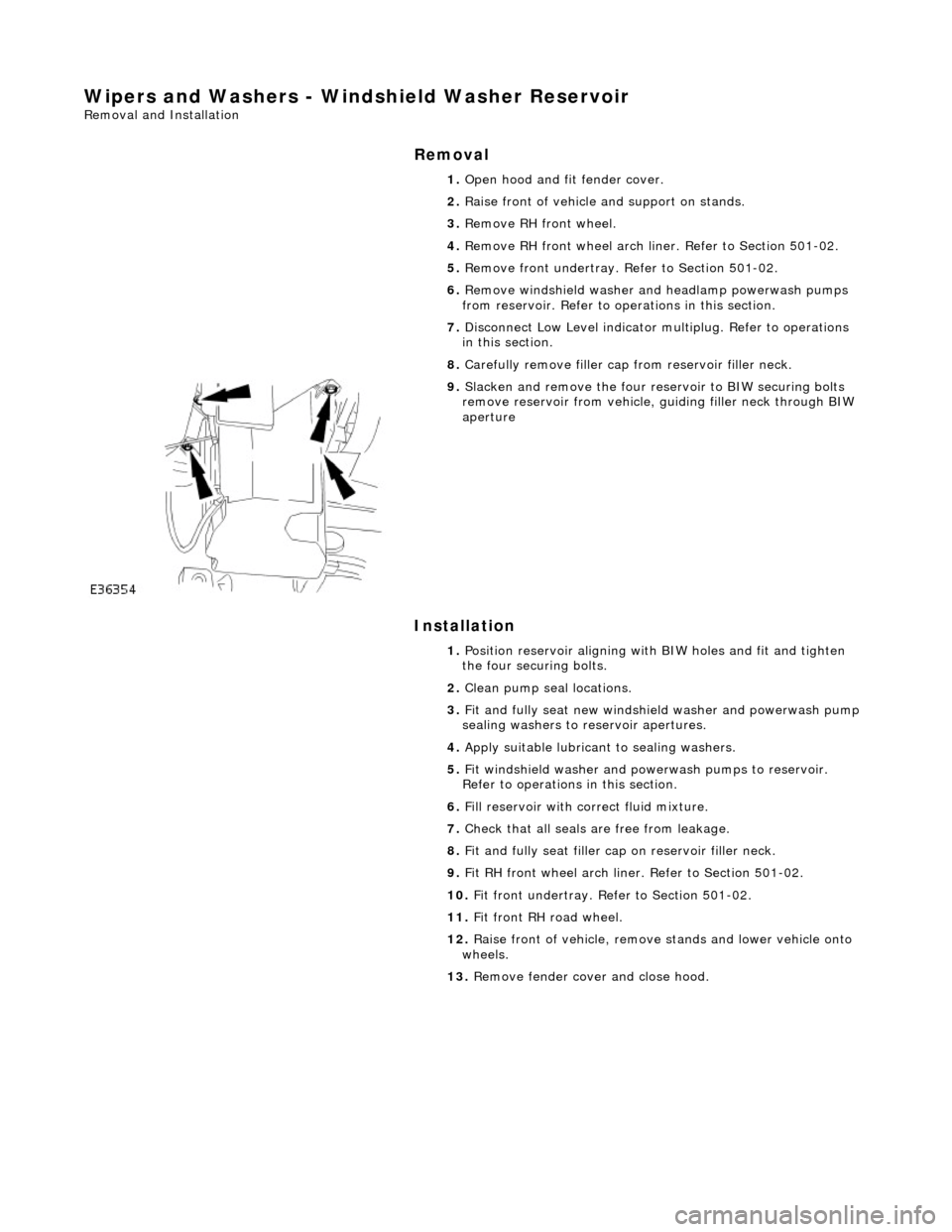

Wipers and Washers - Windshield Washer Reservoir

Removal and Installation

Removal

Installation

1.

Open hood and fit fender cover.

2. Raise front of vehicle and support on stands.

3. Remove RH front wheel.

4. Remove RH front wheel arch li ner. Refer to Section 501-02.

5. Remove front undertray. Refer to Section 501-02.

6. Remove windshield washer and headlamp powerwash pumps

from reservoir. Refer to op erations in this section.

7. Disconnect Low Level indicator mu ltiplug. Refer to operations

in this section.

8. Carefully remove filler cap from reservoir filler neck.

9. Slacken and remove the four re servoir to BIW securing bolts

remove reservoir from vehicle, guiding filler neck through BIW

aperture

1. Position reservoir aligning with BIW holes and fit and tighten

the four securing bolts.

2. Clean pump seal locations.

3. Fit and fully seat new windshie ld washer and powerwash pump

sealing washers to reservoir apertures.

4. Apply suitable lubricant to sealing washers.

5. Fit windshield washer and powerwash pumps to reservoir.

Refer to operations in this section.

6. Fill reservoir with correct fluid mixture.

7. Check that all seals are free from leakage.

8. Fit and fully seat filler cap on reservoir filler neck.

9. Fit RH front wheel arch liner. Refer to Section 501-02.

10. Fit front undertray. Refer to Section 501-02.

11. Fit front RH road wheel.

12. Raise front of vehicle, remove stands and lower vehicle onto

wheels.

13. Remove fender cover and close hood.

Page 2421 of 2490

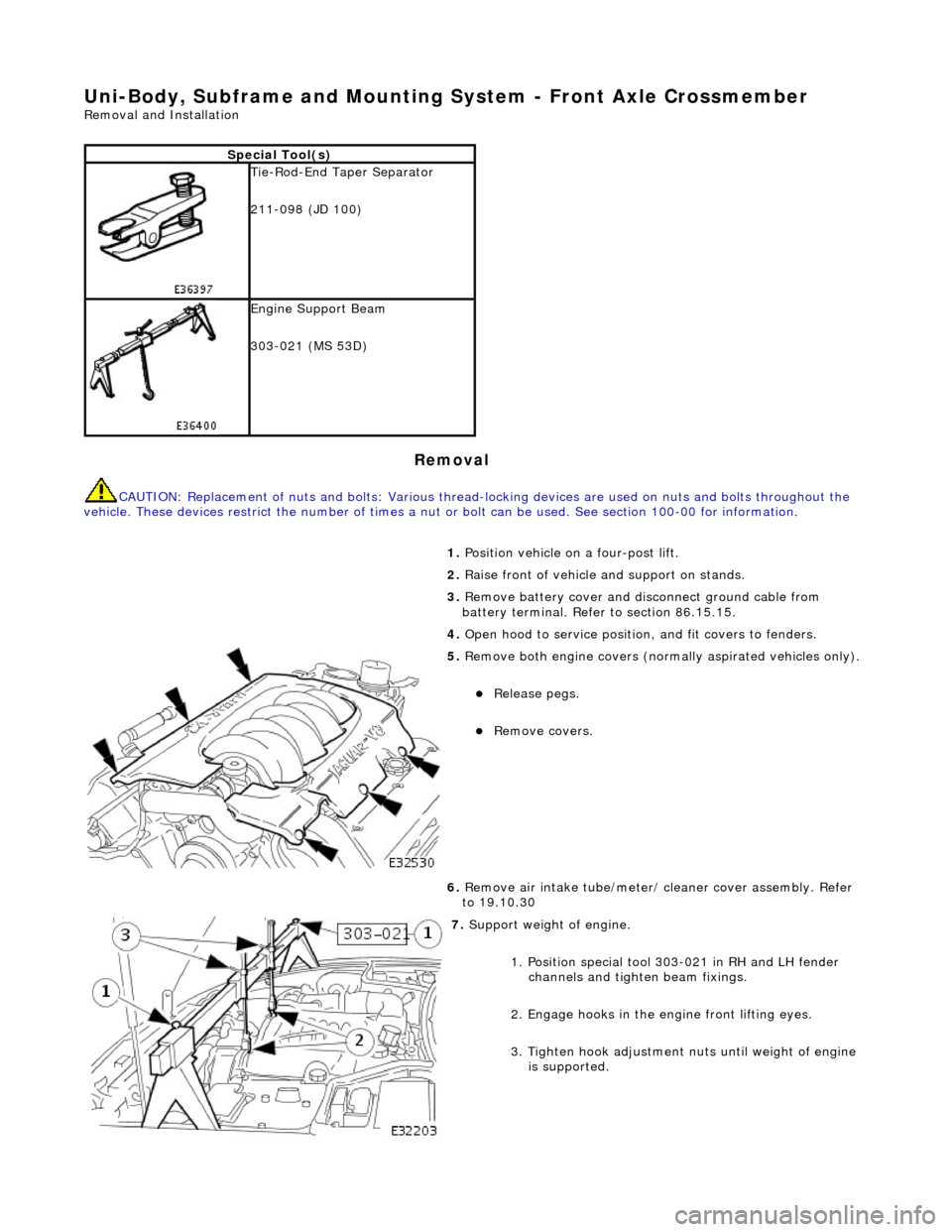

Uni-Body, Subframe and Mounting System - Front Axle Crossmember

Removal and Installation

Removal

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Special Tool(s)

Tie-Rod-End Taper Separator

211-098 (JD 100)

Engine Support Beam

303-021 (MS 53D)

1. Position vehicle on a four-post lift.

2. Raise front of vehicle and support on stands.

3. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to section 86.15.15.

4. Open hood to service position, and fit covers to fenders.

5. Remove both engine covers (nor mally aspirated vehicles only).

Release pegs.

Remove covers.

6. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

7. Support weight of engine.

1. Position special tool 303-021 in RH and LH fender channels and tighte n beam fixings.

2. Engage hooks in the en gine front lifting eyes.

3. Tighten hook adjustment nuts until weight of engine is supported.