seats JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 233 of 2490

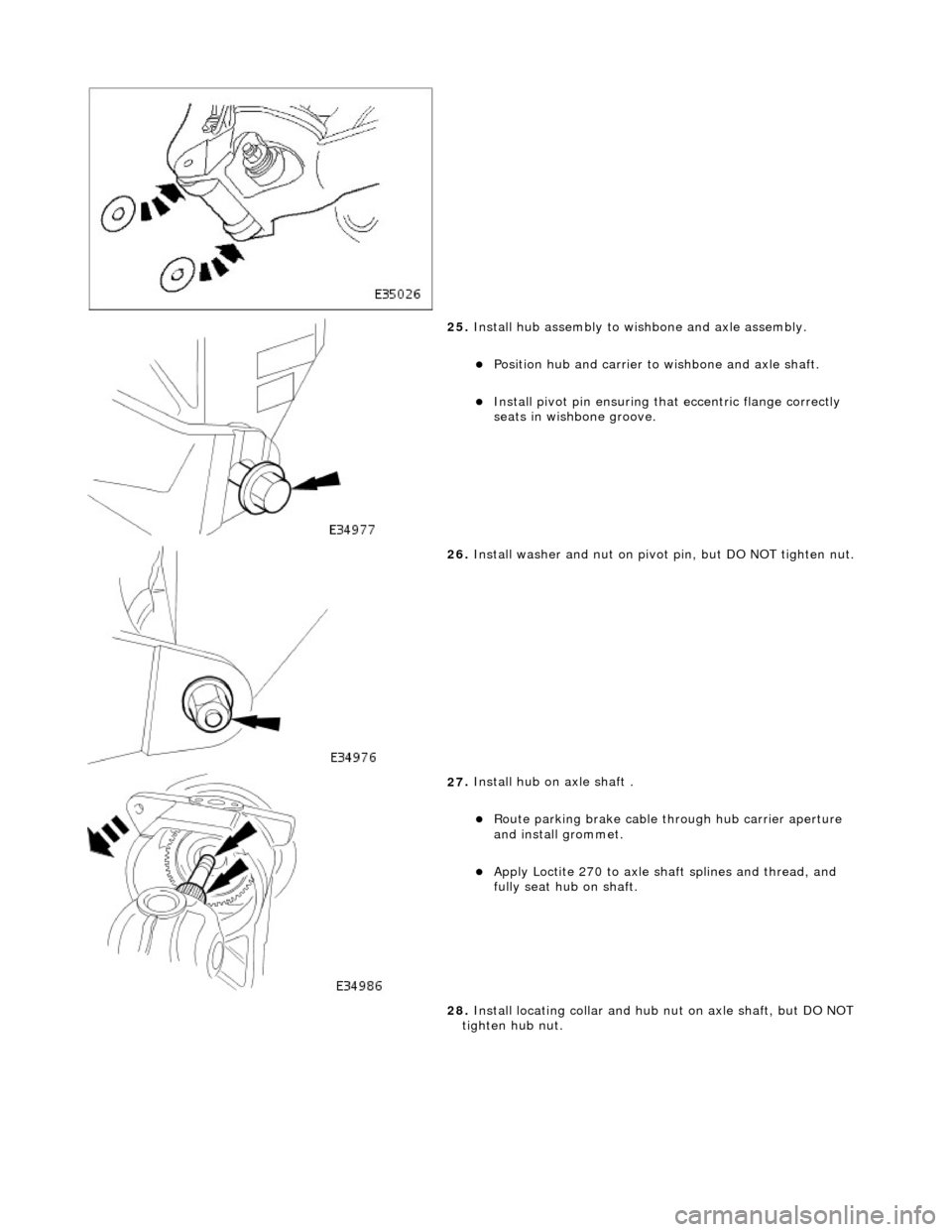

25

.

Install hub assembly to wi shbone and axle assembly.

Position hu

b and carrier to wishbone and axle shaft.

Install piv

ot pin ensuring that

eccentric flange correctly

seats in wishbone groove.

26

.

Install washer and nut on pivot pin, but DO NOT tighten nut.

27

.

Install hub on axle shaft .

Route parking brake cable throu

gh hub carrier aperture

and install grommet.

Appl

y Loctite 270 to axle shaft splines and thread, and

fully seat hub on shaft.

28. Install locating collar and hub nut on axle shaft, but DO NOT

tighten hub nut.

Page 244 of 2490

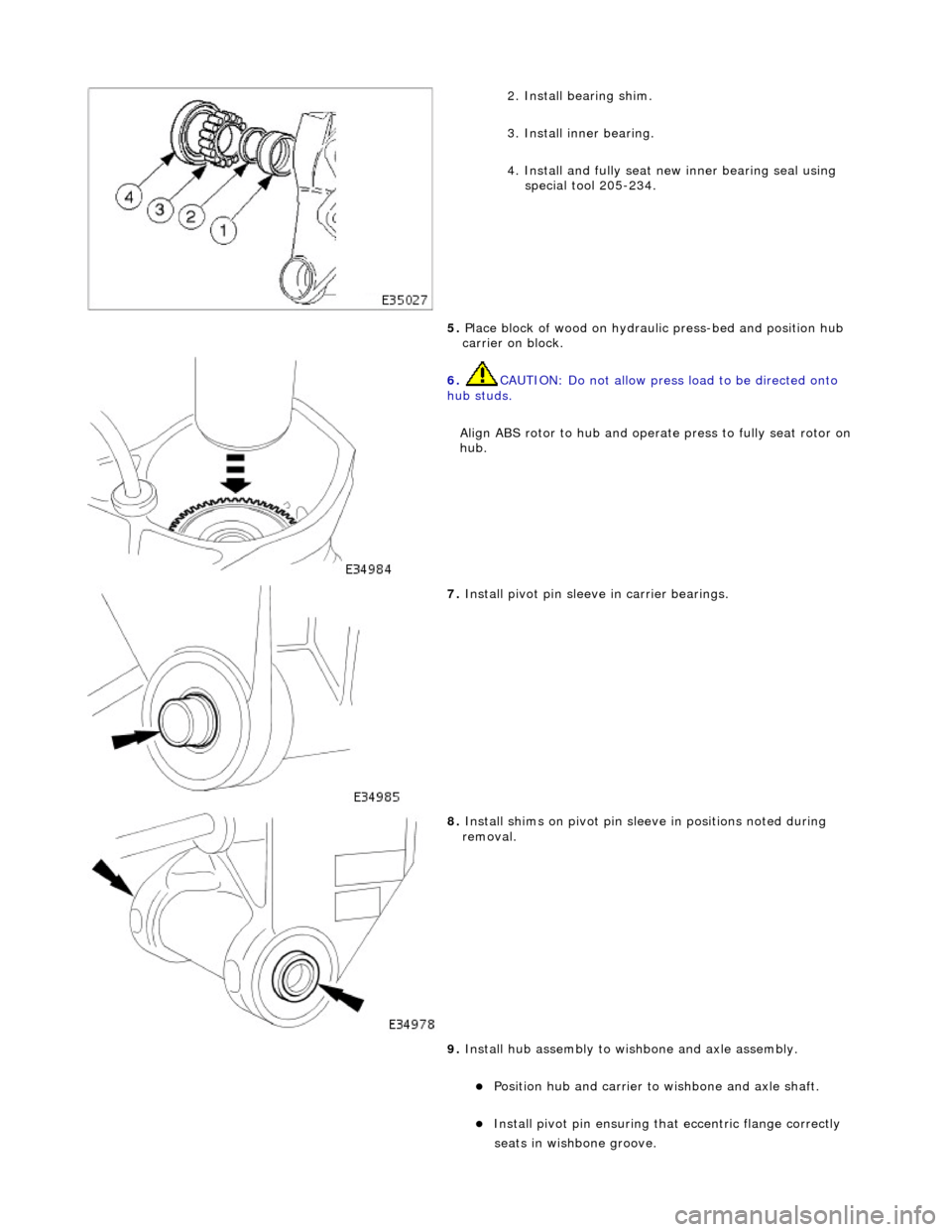

2.

Install bearing shim.

3. Install inner bearing.

4. Install and fully seat new inner bearing seal using special tool 205-234.

5. Place block of wood on hydrau lic press-bed and position hub

carrier on block.

6. CAUTIO

N: Do not allow press

load to be directed onto

hub studs.

Align ABS rotor to hub and operat e press to fully seat rotor on

hub.

7. Install piv o

t pin sleeve in carrier bearings.

8. Inst al

l shims on pivot pin slee

ve in positions noted during

removal.

9. Install hub assembly to wi shbone and axle assembly.

Position hub and carr

ier to wishbone and axle shaft.

Install pivo

t pin ensuring that

eccentric flange correctly

seats i

n wishbone groove.

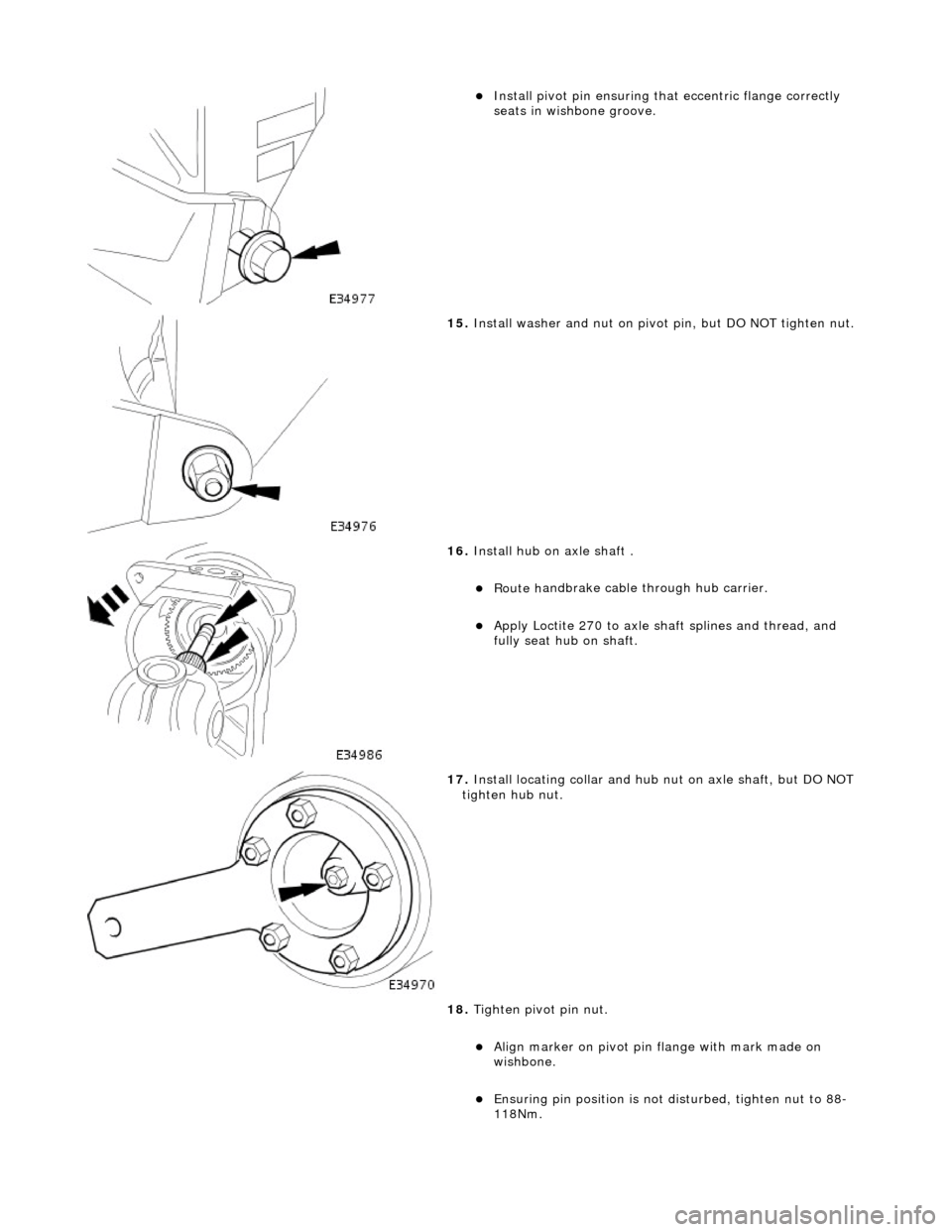

Page 256 of 2490

Install pivo

t pin ensuring that

eccentric flange correctly

seats in wishbone groove.

15 . Inst

all washer and nut on pivot pin, but DO NOT tighten nut.

16 . Install hu

b on axle shaft .

Rout

e h

andbrake cable through hub carrier.

Appl

y Loct

ite 270 to axle shaft splines and thread, and

fully seat hub on shaft.

17 . Inst

all locating collar and hub nut on axle shaft, but DO NOT

tighten hub nut.

18. Tighten pivot pin nut.

Align mark

er on pivot pin flange with mark made on

wishbone.

Ensuri ng pi

n position is not

disturbed, tighten nut to 88-

118Nm.

Page 268 of 2490

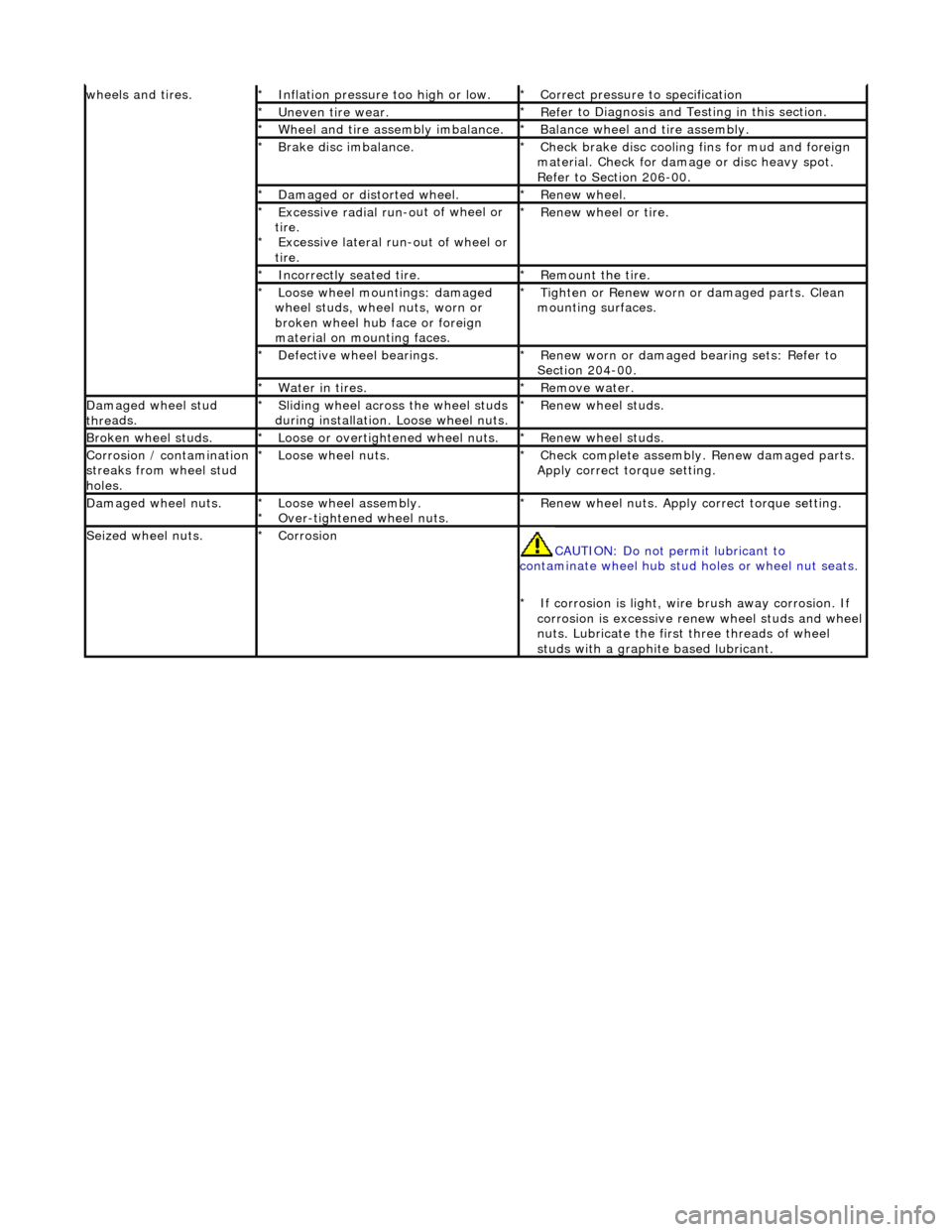

wheels

and tires.

Infl

atio

n pressure too high or low.

*

Cor r

ect pressure to specification

*

Uneven ti re wear.

*Re fe

r to Diagnosis and Testing in this section.

*

Wh ee

l and tire assembly imbalance.

*

Balance wheel an d tire assembly.

*

Brake disc imbalan c

e.

*

Check brak e disc co

oling fins for mud and foreign

material. Check for damage or disc heavy spot.

Refer to Section 206-00.

*

Damaged or distor

ted wh

eel.

*

Renew wh eel.

*

Excessive radial run-o

ut of wheel or

tire. Excessive lateral run-out of wheel or

tire.

*

*

Renew wh

eel or tire.

*

Incorrectl y

seated tire.

*

R e

mount the tire.

*

Loose wh eel mo

untings: damaged

wheel studs, whee l nuts, worn or

broken wheel hub face or foreign

material on mounting faces.

*

Tigh

te

n or Renew worn or

damaged parts. Clean

mounting surfaces.

*

De

fe

ctive wheel bearings.

*

Renew worn

or damaged bearing sets: Refer to

Section 204-00.

*

W

a

ter in tires.

*

R e

move water.

*

Damaged wh eel stud

thre

ads.

Sli

d

ing wheel across the wheel studs

during installation. Loose wheel nuts.

*

Renew wh

eel studs.

*

Broken wh eel

studs.

Loose or overti

ght

ened wheel nuts.

*

Renew wh eel studs.

*

C o

rrosion / contamination

streaks from wheel stud

holes.

Loose wh eel

nuts.

*

Chec k com

plete assembly. Renew damaged parts.

Apply correct torque setting.

*

Damaged wh

eel nu

ts.

Loose wh

eel

assembly.

Over-tightened wheel nuts.

*

*

Renew wh

eel nu

ts. Apply correct torque setting.

*

Se ize

d wheel nuts.

Cor

rosion

*

CAUTI O

N: Do not permit lubricant to

contaminate wheel hub stud holes or wheel nut seats.

If corrosion is light, wire brush away corrosion. If

corrosion is excessive renew wheel studs and wheel

nuts. Lubricate th e first three threads of wheel

studs with a graphite based lubricant.

*

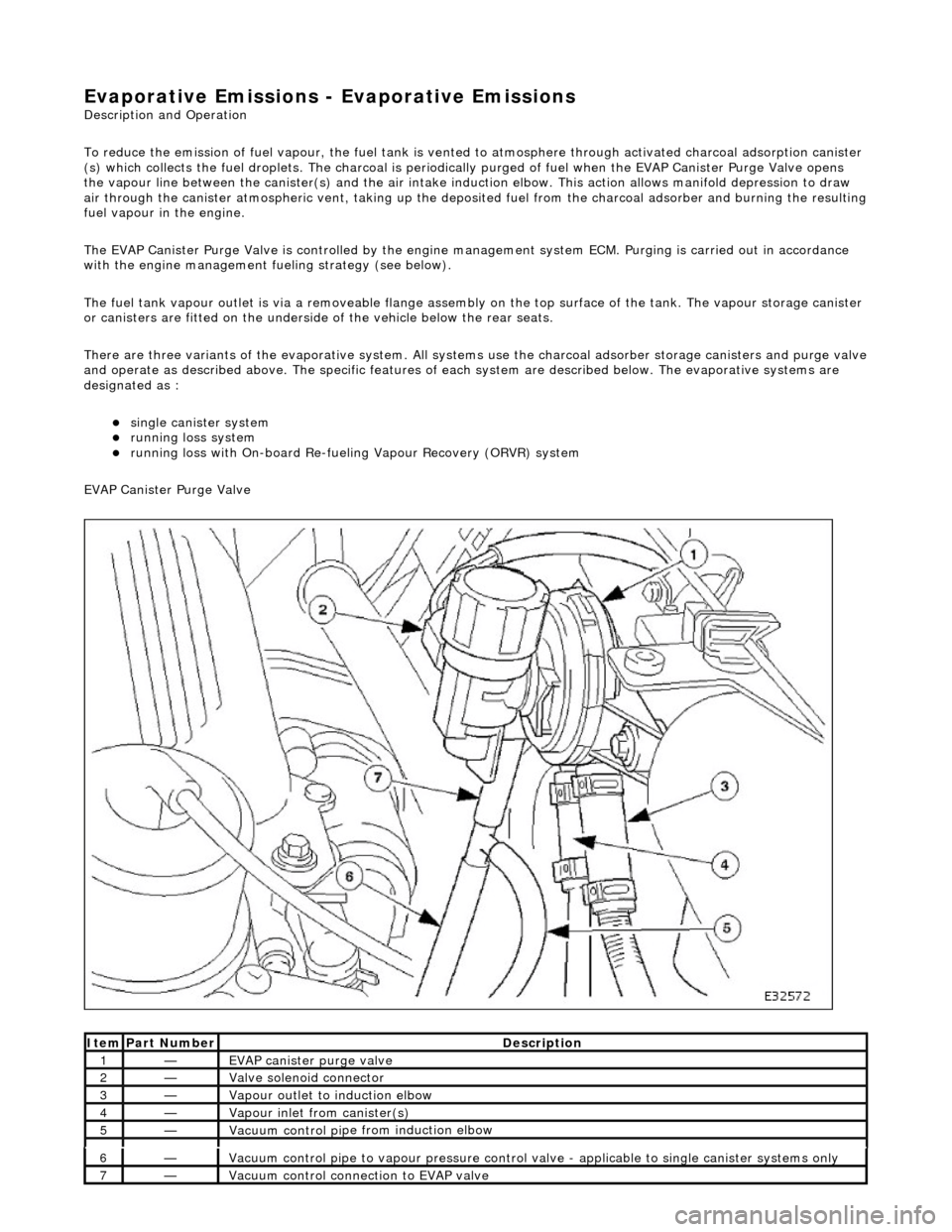

Page 1148 of 2490

Evaporative E

missions - Evaporative Emissions

Description an

d Operation

To reduce the emission of fuel vapour, th e fuel tank is vented to atmosphere through activated charcoal adsorption canister

(s) which collects the fuel droplets. The ch arcoal is periodically purged of fuel when the EVAP Canister Purge Valve opens

the vapour line between the canister(s) and the air intake induct ion elbow. This action allows manifold depression to draw

air through the canister atmospheric vent, taking up the deposited fuel from the charcoal adsorber and burning the resulting

fuel vapour in the engine.

The EVAP Canister Purge Valve is controlled by the engine management system ECM. Purging is carried out in accordance

with the engine management fu eling strategy (see below).

The fuel tank vapour outlet is via a removeable flange assemb ly on the top surface of the tank. The vapour storage canister

or canisters are fitted on the underside of the vehicle below the rear seats.

There are three variants of the evaporativ e system. All systems use the charcoal adsorber storage canisters and purge valve

and operate as described above. The specific features of each system are described below. The evaporative systems are

designated as :

sin g

le canister system

ru

nn

ing loss system

ru

nn

ing loss with On-board Re-fueling Vapour Recovery (ORVR) system

EVAP Canister Purge Valve

Ite

m

Par

t

Number

De

scr

iption

1—EVAP canister purge v

alve

2—Valve s

olenoid connector

3—Vapour outlet to indu

ction elbow

4—Vapour

inlet from canister(s)

5—Vacuum contro

l pi

pe from induction elbow

6—Vacuum contro

l pi

pe to vapour pressure control va

lve - applicable to single canister systems only

7—Vacuum

control connection to EVAP valve

Page 1937 of 2490

Exterior Lighting - High Beam Headlamp

Removal and Installation

Removal

Installation

1. Remove headlamp assembly fo r access. Refer to 86.41.33.

2. Release bulb holder securing tangs and position holder for

access.

3. Rotate pilot bulb holder 1/4 turn and withdraw holder.

4. Invert headlamp assembly.

5. Release headlamp unit adju sting screws and pivot.

1. Install headlamp unit on adjusting screw and pivot seats.

Page 1945 of 2490

Exterior

Lighting - License Plate Lamp

Rem

oval and Installation

Remov

al

Installation

1.

Remove battery cover and disconnect ground cable from battery

terminal. Refer to 86.15.19.

2. Remove trunk lamp assemblies. Refer to 86.45.16

3. Remove trunk lid upper trim finisher. Refer to 76.43.79.

4.

From inside trunk lid, press tang at each side of lamp and push

lamp outwards.

5.

Withdraw number plate lamp from trunk lid for access and

disconnect lamp harness multiplug.

6.

Remove and discard foam seal from lamp.

1. Install new foam seal to number plate lamp.

2. Position number plate lamp at trunk lid and connect harness

multiplug.

3. Install number plate lamp in trunk lid aperture ensuring that seal

seats correctly.

4. Install trunk upper trim finisher. Refer to 76.43.79.

5. Install trunk lamp assemb lies. Refer to 86.45.16.

6. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 1947 of 2490

Exterior Lighting - Low Beam HeadlampVehicles Without: Headlamp

Leveling

Removal and Installation

Removal

Installation

1. Remove headlamp assembly fo r access. Refer to 86.41.33.

2. Release bulb holder securing tangs and withdraw holder for

access.

3. Invert headlamp assembly.

4. Release headlamp unit adju sting screws and pivot.

1. Install headlamp unit adjusting screws and pivot in locating

seats.

2. Invert headlamp assembly.

3. Install headlamp assembly bulb holder.

Page 1949 of 2490

Exterior Lighting - Low Beam HeadlampVehicles With: Headlamp Leveling

Removal and Installation

Removal

Installation

1.

Remove headlamp assembly for access. Refer to 86.41.33.

2. Release bulb holder securing tangs and withdraw holder for

access.

3. Invert headlamp assembly.

4. Release headlamp unit adjusting screws and pivot.

5. Remove actuator.

1. Release headlamp unit from leveling actuator adjusting screw.

2. Rotate actuator 1/4 turn inward, tilt forward end

downward and withdraw assembly from headlamp.

1. Install headlamp unit adjusting screws and pivot in locating

seats.

2. Invert headlamp assembly and install bulb holder.

3. With forward end tilted downward, position actuator assembly on

headlamp mounting.

4. Align actuator with headlamp and rotate it 1/4 turn outwards to

engage and fully seat in mounting.

5. Install headlamp assembly. Refer to 86.41.33.

6. Align headlamp beams.

Page 2022 of 2490

Body closures

Each front and rear door consists of a welded, mild steel inner frame and an outer panel. The outer panel is welded to the

waist rail and cheater of the inner frame, then bonded and clinched to fo rm the door assembly. Cosmetic PVC bead is

applied to all clinch joints. Sp onge rubber seals are mounted on the doors. Inte rnal insulation is provided by a foam water

shedder attached to the door by double-sided adhesive tape.

The door aperture B/C posts are reinforced over their full height to fully satisfy all forthcoming European and Federal side

impact legislation. The hood consists of one piece inner and outer panels clinched and bonded together, with cosmetic bead

PVC sealant applied to all clinch joints. Th e hood pivots at the front on two hinges each secured by bolts to the hood front

underside and the BIW front upper crossmem ber. Two gas struts secured to the hood by pivot pins and snap-on couplings,

support the hood in the open position. A full width insulating pad is secured by screws to the underside of the hood. A

sponge rubber tubular seal is mounted tran sversely towards the front of the hood underside. The trunk lid is of similar

construction to the hood, consisting of inner and outer pa nels clinched and bonded together and PVC bead sealed.

Incorporating a removable moulded liner and two trunk illuminati on lights, the trunk lid is supported when open, by two gas

struts, each secured to the inner wheel arch and trunk hinge by snap fittin gs. For some markets, a warning triangle is

attached to a bracket on the trunk lid underside and is retained in the open position by a rubber block.

Fascia

One-piece slush-moulded fascia on inject ion moulded armature and steel cross-rail reinforcement. Fascia support brackets

set with BIW to achieve close tolerance fit of fascia to bo dy eliminate necessity for adjustment following removal and

installation..

Fuel Filler Flap

The fuel filler comprising a hinged flap attached to the body decking panel by tw o nuts, incorporates a rubber buffer, snap-

in striker, hinge spring and fuel cap stowage magnet. The rubber fuel bowl moulding is attached via a steel armature to the

body reinforcement panel by five M5 nuts and is retained at the filler neck by a clip. The mating drain tube is fitted with an

internal filter. The fuel filler flap latch mechanism attached to the fuel bowl armatu re by two M5 nuts, includes a locking pin

and actuator which are both se rviceable items. The latch actuator operates independently from the central locking system;

it is driven directly by the se curity and locking control module. Locking of the fuel filler flap is achi eved only by operation of

the key or by the remote rf transmitter.

Seating

All front seats are equipped with electric height adjustment. In addition, both seats are available with manual or power

forward and rearward adjustment, manual or power operated headrest adjustment, 12 way electric adjustment, memory

controlled 12 way seat adjustment and integral seat heating. A side air bag module is installe d in the outboard squab wing

of each front seat. Each front seat has a non-handed, one-piece frame incorporatin g cushion and squab frames, side air bag

support bracket and seat adjuster mechanis ms. Seat switchpacks are installed on the outboard side of driver and passenger

seats and control modules are installed in the base of each seat . The standard rear seat is of fixed, bench type with full

width removable cushion. For certain mark ets, two individual rear seats are available as an option on long wheelbase

models. Both type s of rear seat are available with th ermostatically controlled heating of the cushion and sq uab. Individual

rear seats are electrically adjustable fo r squab re cline (via cushion fore and af t movement), head restraint height and

lumbar support. Separate motors provide ad justment of each seat cushion and head restraint and an electrically driven air

compressor provides variation of lumbar support. Seat adjustment is controlled via switches installed on a panel in an

extension to the centre console.Both the driver and front pass enger seat are secured to the vehicle floor at four points.

Interior Trim

The one-piece door casings are trimmed in UEV to match the seating, with wood veneer at the waistline and a carpet insert

at the front lower corner. Each casing is secured to the door inner panel by fir tree fastener s along the lower section, two

armrest fixings at the centre and veneer panel dowels and fixings at the top. The armrests which are common to front and

rear doors, are trimmed in matc hing leather or UEV according to specification. Switchpacks dedicated to driver and front or

rear passenger, are incorporated in the ar mrests. A speaker is installed in the lower section of each door and a tweeter is

incorporated behind each interior door handle escutcheon. where premium ICE is fitted, the front tweeters are installed in

the upper A posts. On each side, a graine d UEV finisher trimmed to match the head lining is secured to the 'A' post and

cantrail by fir tree fasteners locating in BIW apertures. Th e upper 'D' post finisher is trimmed and secured in the same

manner. The single piece'B' post finishers, also finished in grained matching UEV, each have a front seat belt exit aperture

and are secured to the BIW by four spring clips and two fir tree fasteners. The one-piece headlining consists of a 6mm thick

polyurethane foam membrane covered with suede effect knitted polyester. The headlining is secured to the BIW roof by

body tangs, the roof console, sun visors, combined grab handles and coat hooks, th e cantrail finishers and where fitted, the