brake sensor JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 7 of 2490

206‐07: Powe r Brake Actuation

Specif

ication

Description and Operation

Brake Booster

Removal and Installation

Brake Booster (70.50.17)

Brake Booster and Brake Master Cylinder (70.50.18)

206‐09: Anti ‐Lock Control

Specification

Description and Operation

Anti‐Lock Control

Diagnosis and Testing

Anti‐Lock Control

Removal and Installation

Anti‐Lock Brake System (ABS) Module (70.60.02)

Front Wheel Speed Sensor (70.60.03)

Hydraulic Cont

rol Unit (HCU)

Rear Wheel Speed Sensor (70.60.04)

Wheel Speed Sensor Ring (70.60.25)

211: Steering System

211‐00: Steering System ‐ General Information

Specification

Description and Operation

Steering System

Diagnosis and Testing

Steering Sy

stem

General Procedures

Power Steering System Filling and Bleeding

Power Steering System Flushing (57.15.08)

Power Steering System Vacuum Filling and Bleeding

Steering Gear Centralizing

Page 42 of 2490

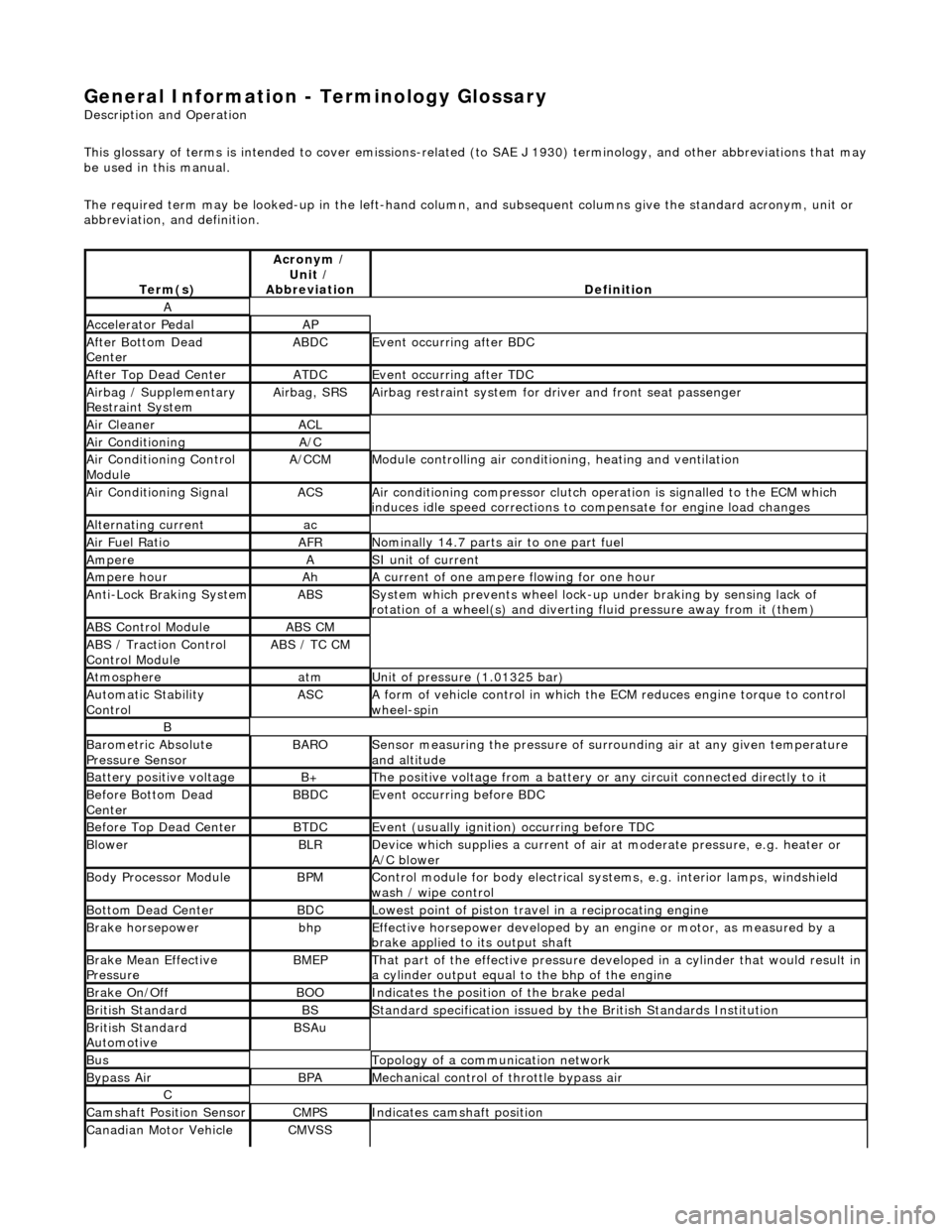

General Information - Terminology Glossary

Description an

d Operation

This glossary of terms is intended to cover emissions-related (to SAE J 1930) term inology, and other abbreviations that may

be used in this manual.

The required term may be looked-up in th e left-hand column, and subsequent columns give the standard acronym, unit or

abbreviation, and definition.

Te rm

(s)

Acr

ony

m /

Unit /

Abbreviation

De fi

nition

A

Accel

e

rator Pedal

AP

Af

ter Botto

m Dead

Center

ABDCEvent occurri ng after

BDC

Af

ter Top Dead CenterATDCEvent occurri ng after

TDC

Ai

rbag /

Supplementary

Restraint System

Airbag, SRSAi rbag restraint system for

dr

iver and front seat passenger

Air Cleane rACL

Air ConditioningA/C

Air Conditioning Con t

rol

Module

A/CCMModule c

ontrolling air conditioning, heating and ventilation

Air Conditioning SignalACSA

i

r conditioning compressor clutch operation is signalled to the ECM which

induces idle speed corrections to co mpensate for engine load changes

Alternating cu

rrent

ac

Ai

r Fuel R

atio

AFRN

omi

nally 14.7 parts air to one part fuel

Ampe

reASI unit of current

Ampere hourAhA current of one ampere

fl

owing for one hour

Anti-Lock Braking SystemABSS

y

stem which prevents wheel lock-up

under braking by sensing lack of

rotation of a wheel(s) and divertin g fluid pressure away from it (them)

ABS Control Mo

dule

ABS CM

ABS /

T

raction Control

Control Module

ABS / T

C CM

Atmosph

e

re

atmU

n

it of pressure (1.01325 bar)

Au

to

matic Stability

Control

ASCA form of vehicle

control

in which the ECM reduces en gine torque to control

wheel-spin

B

Baro me

tric Absolute

Pressure Sensor

BAR OSensor measuring the pressure of surr ou

nding air at any given temperature

and altitude

Bat t

ery positive voltage

B+The posi

ti

ve voltage from a battery or

any circuit connected directly to it

Before Bottom Dead

CenterBBDCEvent occurri ng before BD

C

Before Top Dead

Center

BTD

CEvent (usual ly

ignition) occurring before TDC

Blowe

rBLRDe

vice which supplies a current of air at

moderate pressure, e.g. heater or

A/C blower

Body Processor M

odule

BPMControl modu

le

for body electrical systems, e.g. interior lamps, windshield

wash / wipe control

Bott om D

ead Center

BD

CLowest poin t of piston

travel in a reciprocating engine

Brake hors

epowe

r

bhpEffecti

ve horsepower devel

oped by an

engine or motor, as measured by a

brake applied to its output shaft

Brake Mean Effective

Pres sureBME PThat p

art of the effective

pressure developed in a cyli nder that would result in

a cylinder output equal to the bhp of the engine

Brake On/ O

ff

BOOIn

dic

ates the position of the brake pedal

Br

it

ish Standard

BSStan

dar

d specification issued by the British Standards Institution

Br

it

ish Standard

Automotive

BSAu

BusTopology of a commu n

ication network

Bypass

AirBPAMechanica l

control of throttle bypass air

C

Camshaft Posit

i

on Sensor

CMPSIndi

cat

es camshaft position

Canadian Motor

V

ehicle

CMVSS

Page 67 of 2490

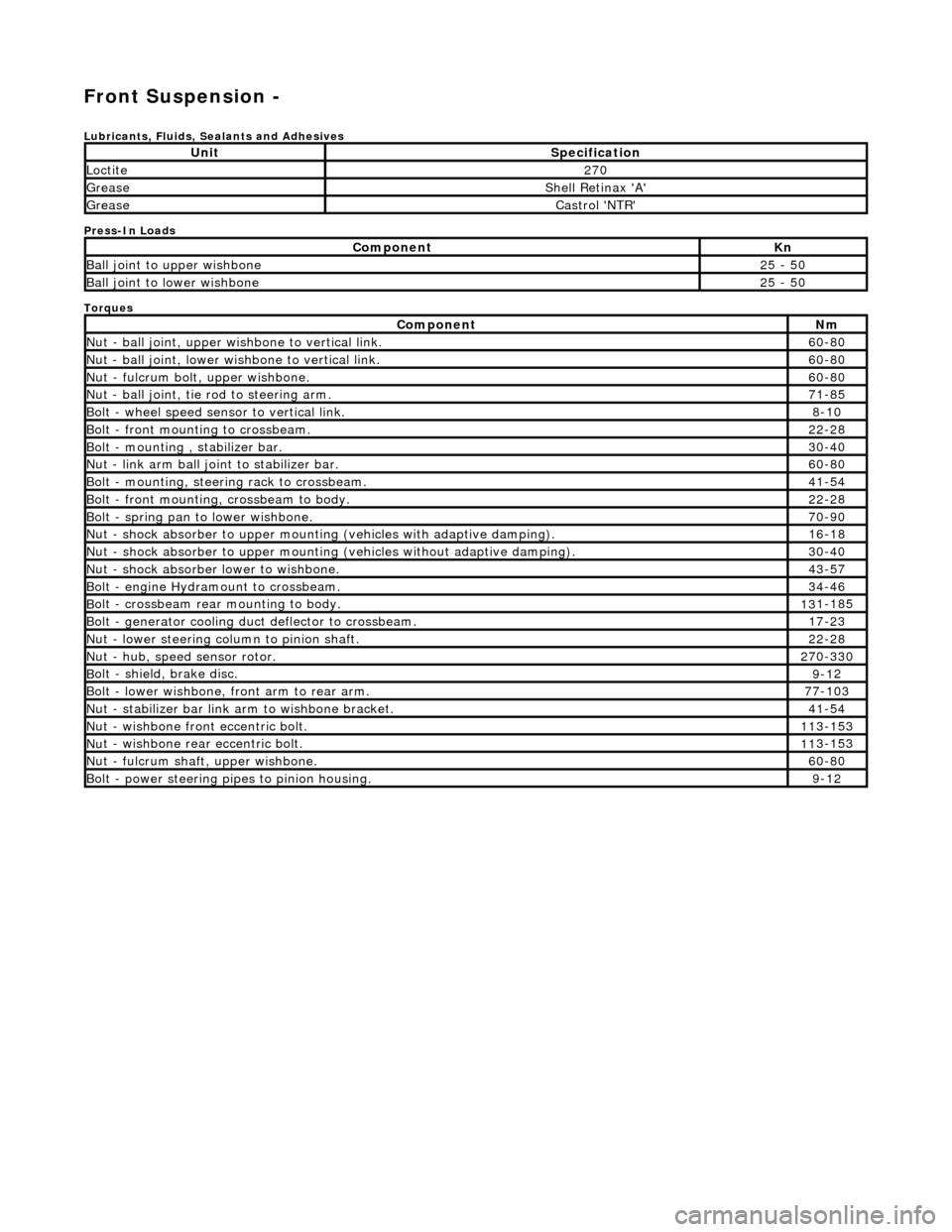

Front Suspension -

Lubri

cants, Fluids, Sealants and Adhesives

Press-In Loads

Torques

UnitS

pecification

Loctite27

0

Greas

e

Shell Retin

ax 'A'

Greas

e

Castro

l 'NTR'

Com

ponent

Kn

Ball join

t to upper wishbone

25

- 50

B

all joint to lower wishbone

25

- 50

Com

ponent

Nm

N

ut - ball joint, upper wishbone to vertical link.

60

-80

N

ut - ball joint, lower wishbone to vertical link.

60

-80

Nu

t - fulcrum bolt, upper wishbone.

60

-80

N

ut - ball joint, tie rod to steering arm.

71

-85

Bol

t - wheel speed sensor to vertical link.

8-1

0

Bol

t - front mounting to crossbeam.

22

-28

Bolt

- mounting , stabilizer bar.

30

-40

N

ut - link arm ball joint to stabilizer bar.

60

-80

Bolt

- mounting, steering rack to crossbeam.

41

-54

B

olt - front mounting, crossbeam to body.

22

-28

Bol

t - spring pan to lower wishbone.

70

-90

N

ut - shock absorber to upper mounting

(vehicles with adaptive damping).

16

-18

Nu

t - shock absorber to upper mounting (vehicles without adaptive damping).

30

-40

N

ut - shock absorber lower to wishbone.

43

-57

B

olt - engine Hydramount to crossbeam.

34

-46

B

olt - crossbeam rear mounting to body.

13

1-185

Bol

t - generator cooling du

ct deflector to crossbeam.

17

-23

N

ut - lower steering column to pinion shaft.

22

-28

N

ut - hub, speed sensor rotor.

27

0-330

B

olt - shield, brake disc.

9-1

2

Bol

t - lower wishbone, front arm to rear arm.

77

-103

Nu

t - stabilizer bar link arm to wishbone bracket.

41

-54

N

ut - wishbone front

eccentric bolt.

11

3-153

Nu

t - wishbone rear

eccentric bolt.

11

3-153

N

ut - fulcrum shaft, upper wishbone.

60

-80

Bolt -

power steering pi

pes to pinion housing.

9-1

2

Page 89 of 2490

Inst

all sensor bolt an

d tighten to 8-10Nm.

22

.

Connect wheel speed sensor harness.

1. Connect wheel speed sensor harness to sensor.

2. Using new tiestraps secure wheel speed sensor harness to upper wishbone.

23

.

Install brake calipers.

R

emove tie supporting brake caliper.

1. Install caliper on carrier.

2. Install guide pins.

3. Install guide pin dust caps.

4. Install caliper spring clip.

24. Install road wheel. Re fer to Section 100-02.

25. Raise vehicle, remove stands and lower vehicle onto road

wheels.

26

.

Ensuring graduation mark remains aligned, finally tighten

wishbone rear eccentric bolt to 113-153Nm.

27. Check wheel alignment and if necessary adjust. Refer to

57.65.01.

Page 103 of 2490

2.

Using new tiestraps secure wheel speed sensor

harness to upper wishbone.

25

.

Install brake calipers.

R

emove tie supporting brake caliper.

1. Install caliper on carrier.

2. Install guide pins and tighten to 25-30Nm.

3. Install guide pin dust caps.

4. Install caliper spring clip.

26

.

Position and partially tighten wishbone rear eccentric bolt.

R

otate eccentric bolt to align large graduation with mark

made during removal.

27

.

Position and partially tighten wishbone front eccentric bolt.

R

otate eccentric bolt to align large graduation with mark

made during removal.

P

artially tighten bolt.

28. Fit road wheel. Refer to Section 100-02.

29. Raise vehicle, remove stands and lower vehicle onto road

wheels.

30. Ensuring graduation mark remains aligned, finally tighten

wishbone rear eccentric bolt to 113-153Nm.

Page 171 of 2490

Rear

Suspension - Rear Susp

ension and Axle Assembly

Re

moval and Installation

Remov

al

1.

CAUTI

ON: Replacement of nuts and bolts: Various

thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt

can be used.

For additional informat ion, refer to Section 100

-0

0 General

Informati

on

.

R

aise the rear of the vehicle

and support on axle stands.

For additional informat ion, refer to Section 100

-0

2 Jacking and

Liftin

g

.

2.

R

emove the rear wheels.

For additional informat ion, refer to Section 204

-04

Wheels and

Tire

s

.

3. CAUTI

ON: Do not suspend the caliper from the brake

hose as this will damage the hose.

• NOTE: Right-hand shown, left-hand similar

Remove the brake calipers from the carriers.

1. Remove the caliper spring clip.

2. Remove the guide pin dust caps.

3. Slacken and withdr aw the guide pins.

4. Remove the caliper from the carrier and secure to the suspension mounting bracket using a tie strap.

4. NOTE

: Right-hand shown, left-hand similar

Disconnect the wheel speed sensor electrical connectors.

5. NOTE: Right-hand shown, left-hand similar

Remove and discard th e tie straps securing the wheel speed

sensor harnesses to the brake hose clips.

Page 179 of 2490

18

.

Install the brake caliper on to the carrier.

1. Position the caliper asse mbly on to the carrier.

2. Install the guide pins and tighten to 25-30 Nm.

3. Install the dust caps.

4. Install the brake caliper spring clip.

19

.

Connect the wheel speed sensor electrical connector.

20

.

Using a new tie strap, secure the wheel speed sensor harness

to the brake hose clip.

21. Install the rear wheels.

For additional informat ion, refer to Section 204

-04

Wheels and

Tire

s

.

22

.

Remove the axle stands and lower the vehicle.

For additional informat ion, refer to Section 100

-0

2 Jacking and

Liftin

g

.

23

.

Check and adjust the rear whee l alignment as necessary.

For additional informat ion, refer to Section 204

-00

Suspension

Sy

stem

- General

Information

.

Page 180 of 2490

Rear Su

spension - Rear Shock Absorber

Re

mo

val and Installation

Remov

a

l

S

p

ecial Tool(s)

Spri

ng C

ompressors

204-179 (JD 199)

Spri ng Re

taining straps

204-179-1 (JD 199-1)

1. CAUTION: Replacement of nuts and bolts: Various

thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt

can be used.

For additional informat ion, refer to Section 100

-00

General

Informati

o

n

.

R a

ise the rear of the vehicle

and support on axle stands.

For additional informat ion, refer to Section 100

-02

Jacking and

Liftin

g.

2. Re

move the relevant rear wheel.

For additional informat ion, refer to Section 204

-04 W

heels and

Tire

s.

3. CAUTIO

N: Do not suspend the caliper from the brake

hose as this will damage the hose.

Remove the brake caliper from the carrier.

1. Remove the caliper spring clip.

2. Remove the guide pin dust caps.

3. Slacken and withdr aw the guide pins.

4. Remove the caliper from the carrier and secure to the suspension mounting bracket using a tie strap.

4. Disc

onnect the wheel speed sensor electrical connector.

Page 181 of 2490

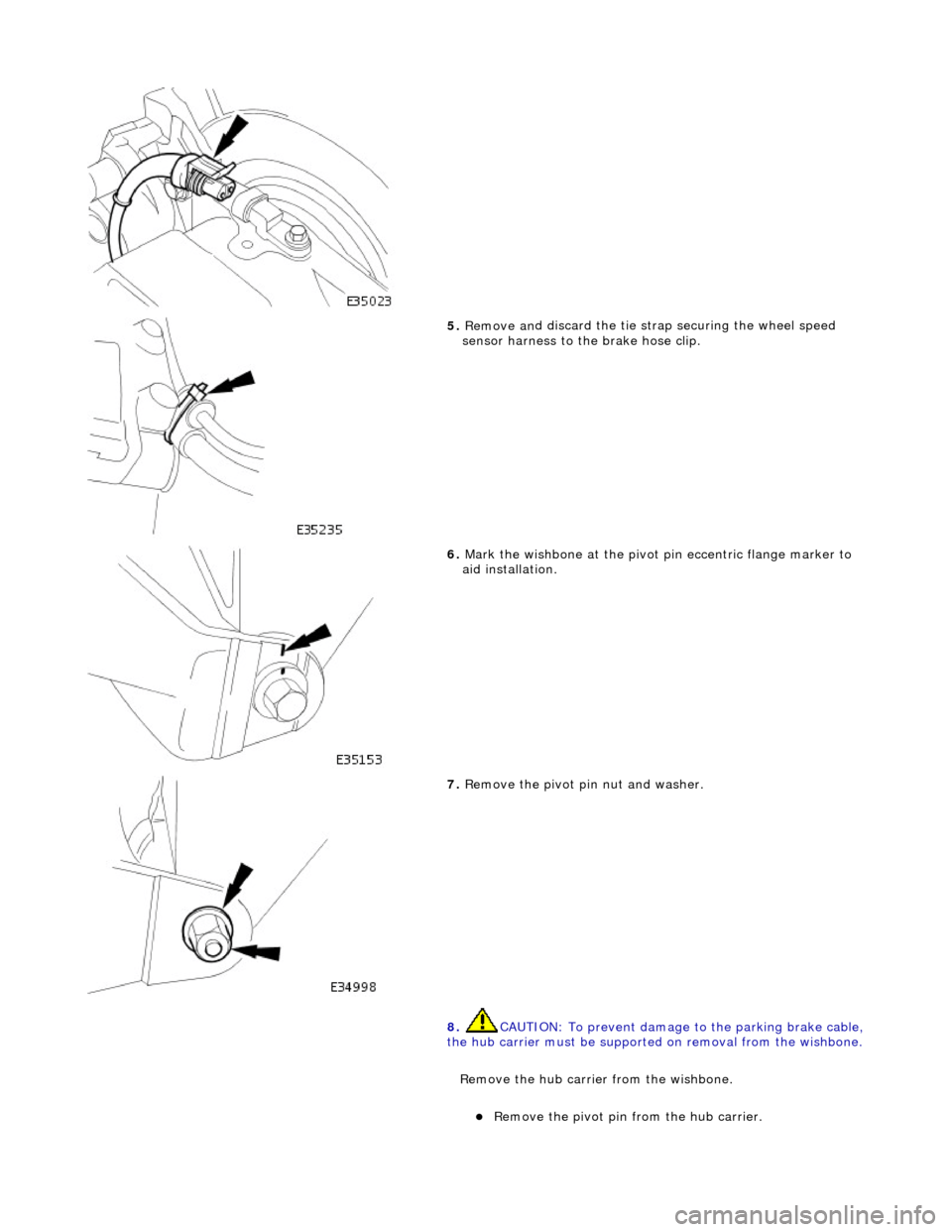

5. Remove an

d discard the tie st

rap securing the wheel speed

sensor harness to the brake hose clip.

6. Mark the wi

shbone at the pivot

pin eccentric flange marker to

aid installation.

7. Remove the

pivot pin nut and washer.

8. CAUTION: To prevent damage to the parking brake cable,

the hub carrier must be supported on removal from the wishbone.

R

emove the hub carrie

r from the wishbone.

R

emove the pivot pin from the hub carrier.

Page 190 of 2490

22. R

elease the tie strap securing the brake caliper to the

suspension mounting bracket.

23 . Install

the brake caliper on to the carrier.

1. Position the caliper asse mbly on to the carrier.

2. Install the guide pins and tighten to 25-30 Nm.

3. Install the dust caps.

4. Install the brake caliper spring clip.

24 . Conne

ct the wheel speed sensor electrical connector.

25 . U

sing a new tie strap, secure the wheel speed sensor harness

to the brake hose clip.

26. Install the rear wheel.

For additional informat ion, refer to Section 204

-04 W

heels and

Tire

s.

27 .

Remove the

axle stands

and lower the vehicle.

For additional informat ion, refer to Section 100

-02

Jacking and

Liftin

g.