timing JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 530 of 2490

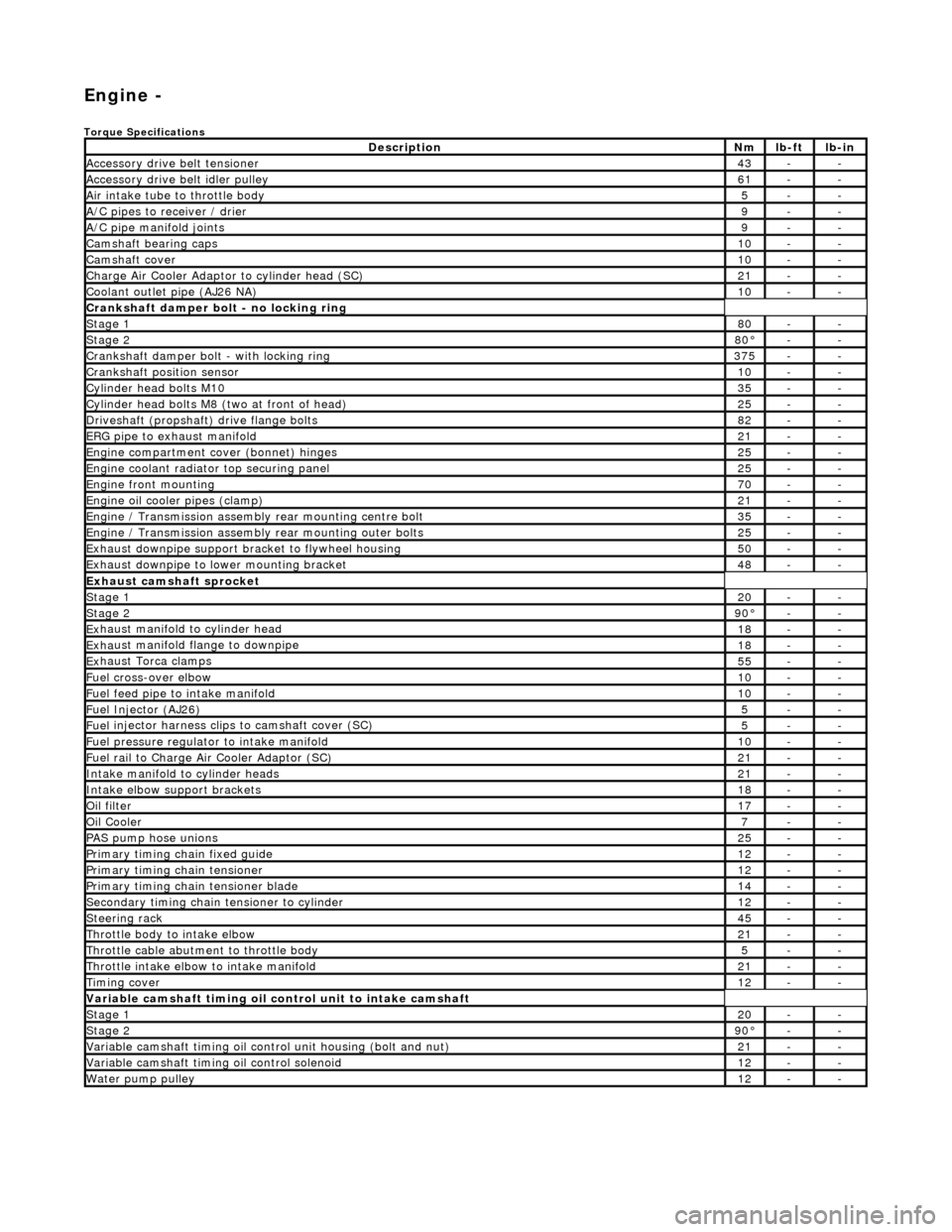

Engi

ne -

Torqu

e Specifications

De

s

cription

Nmlb

-

ft

lb

-

in

A

ccessory

drive belt tensioner

43--

A

ccessory

drive belt idler pulley

61--

Air in

ta

ke tube to throttle body

5--

A/C

pipes t

o receiver / drier

9--

A/C pipe m

anifold joints

9--

Camsh

aft bearin

g caps10--

Ca

msh

aft cove

r10--

Ch

arge Air Co

oler Adaptor to cylinder head (SC)

21--

Co

olan

t outlet pipe (AJ26 NA)

10--

Cran

kshaft damper bolt - no lockin

g ring

St

ag

e 1

80--

Stag

e 2

80В°--

C

r

ankshaft damper bolt - with locking ring

37

5--

Cra

nkshaft position sensor

10--

Cy

li

nder head bolts M10

35--

Cy

lin

der head bolts M8 (two at front of head)

25--

Driv

es

haft (propshaft) drive flan

ge bo

l

ts

82--

ERG p

i

pe to exhaust manifold

21--

Engi

ne compartment cover (bonnet) hinges

25--

En

gine

coolant radiator top securing panel

25--

E

ng

ine front mounting

70--

En

gine

oil cooler pipes (clamp)

21--

En

gi

ne / Transmission assembly rear mounting centre bolt

35--

En

gi

ne / Transmission assembly rear mounting outer bolts

25--

Ex

ha

ust downpipe support bracket to flywheel housing

50--

Ex

ha

ust downpipe to lower mounting bracket

48--

E

x

haust camshaft sprocket

St

age 120--

Stage 290 В°--

Ex

haust manifold to cylinder head

18--

Ex

ha

ust manifold flange to downpipe

18--

E

x

haust Torca clamps

55--

Fuel cross-over elbo

w

10--

Fu

el f

eed pipe to intake manifold

10--

Fuel

Injector (AJ

26)

5--

Fuel

injector ha

rness clips to camshaft cover (SC)

5--

Fu

el p

ressure re

gu

l

ator to intake manifold

10--

F

u

el rail to Char

ge

A

ir Cooler Adaptor (SC)

21--

In

ta

ke manifold to cylinder heads

21--

Inta

ke elbow support brackets

18--

Oil f

i

lter

17--

Oil C

o

oler

7--

P

AS pu

mp hose unions

25--

P

r

imary timing chain fixed guide

12--

P

r

imary timing chain tensioner

12--

Pr

imary timing chain tensioner blade

14--

S

e

condary timing chain tensioner to cylinder

12--

S

t

eerin

g ra

ck45--

Thro

ttle body to intake elbow

21--

Th

ro

ttle cable abutment to throttle body

5--

Th

ro

ttle intake elbow to intake manifold

21--

Ti

mi

ng cover

12--

Variable camshaft t

i

ming oil control unit to intake camshaft

St

ag

e 1

20--

St

ag

e 2

90

В°--

Var

iable camshaft timing oil control unit housing (bolt and nut)

21--

Va

ria

ble camshaft timi

ng oil control solenoid

12--

Wa

ter pump pulley

12--

Page 552 of 2490

Engine - Connecting Rod Bearings

In-vehic

le Repair

Remov

a

l

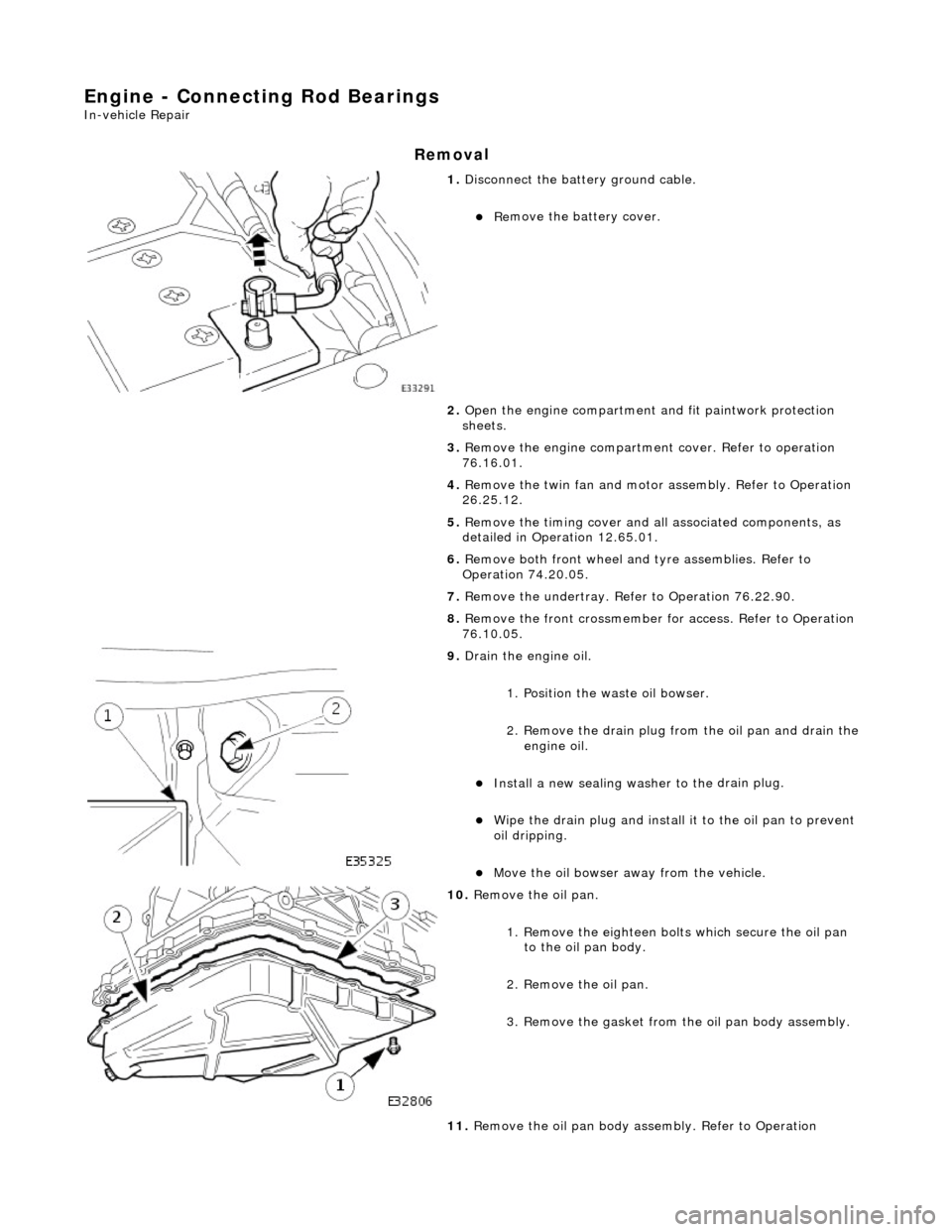

1.

Disc

onnect the batt

ery ground cable.

пЃ¬Re

move the battery cover.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Remove the engine compartmen t cover. Refer to operation

76.16.01.

4. Remove the twin fan and motor assembly. Refer to Operation

26.25.12.

5. Remove the timing cover and al l associated components, as

detailed in Operation 12.65.01.

6. Remove both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

7. Remove the undertray. Re fer to Operation 76.22.90.

8. Remove the front crossmember fo r access. Refer to Operation

76.10.05.

9. Drai

n the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

пЃ¬Install a new sealing wash er to the

drain plug.

пЃ¬Wipe the drain plug an

d

install

it to the oil pan to prevent

oil dripping.

пЃ¬Move the oil bowser away f

rom the vehicle.

10 . Re

move the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

11. Remove the oil pan body a ssembly. Refer to Operation

Page 556 of 2490

5.

Install the front cros smember. Refer to Operat

ion 76.10.05.

6. Install the undert ray. Refer to Operation 76.22.90.

7. Install both front wheel and tyre assemblies. Refer to

Operation 74.20.05.

8. Install the timing cover and al l associated components, as

detailed in Operation 12.65.01.

9. Install the twin fan and motor assembly. Refer to Operation

26.25.12.

10. NOTE: When the engine is star ted from cold and run for a

short period only, before being swit ched off, a quantity of oil will

be 'hung up' within the engine because it is not up to operating

temperature.

Should the oil level subsequently be topped-up, the level could

become too high, causing oil burning.

Typically, 0.875 L is hung up.

Refill the engine with the correct specification engine oil.

11. Connect the battery and in stall the battery cover.

пЃ¬Refe

r to the Battery Reconnection Procedure 86.15.15.

12. Check the oil level and start th e engine. Check for leaks and

that the engine runs correctly.

13. Install the engine compartmen t cover. Refer to operation

76.16.01.

14. Remove the paintwork protection sheets and close the engine

compartment cover.

Page 559 of 2490

I

nstallation

11

.

Remove the crankshaft front seal.

1. Install and tighten the removal tool 303-541 to the crankshaft front seal.

2. Tighten the centre bolt of the tool to extract the seal.

пЃ¬R

emove the tool an

d seal assembly.

пЃ¬Separate the seal

from the tool.

12. Very carefully clean the thread s of the crankshaft, using a

plug tap M16x2, to remove all old cured sealant.

пЃ¬Kee

p the tap horizontal. Do not enlarge the crankshaft

thread - remove sealant only.

13. Clean all relevant parts and faces.

1. Loc

ate the new oil seal into the timing cover.

1. Remove the transit ring from the oil seal.

2. Position the seal to the timing cover.

2. Inst

all the new oil seal to the timing cover.

1. Install oil seal replacer tool 303-542 to the oil seal.

2. Use the nut and bolt provided with the tool, to fully seat the seal to the timing cover. Only tighten the nut

sufficiently to locate the seal and no more, or the

timing cover could become distorted.

пЃ¬All

ow the tool to stay in posi

tion against the seal for at

least five seconds.

пЃ¬R

emove the special tool from the seal.

Page 563 of 2490

I

nstallation

12

.

Remove the crankshaft front seal.

1. Install and tighten the removal tool 303-541 to the crankshaft front seal.

2. Tighten the centre bolt of the tool to extract the seal.

пЃ¬R

emove the tool an

d seal assembly.

пЃ¬Separate the seal

from the tool.

13. Very carefully clean the thread s of the crankshaft, using a

plug tap M16x2, to remove all old cured sealant.

пЃ¬Kee

p the tap horizontal. Do not enlarge the crankshaft

thread - remove sealant only.

14. Clean all relevant parts and faces.

1. Loc

ate the new oil seal into the timing cover.

1. Remove the transit ring from the oil seal.

2. Position the seal to the timing cover.

2. Inst

all the new oil seal to the timing cover.

1. Install oil seal replacer tool 303-542 to the oil seal.

2. Use the nut and bolt provided with the tool, to fully seat the seal to the timing cover. Only tighten the nut

sufficiently to locate the seal and no more, or the

timing cover could become distorted.

пЃ¬All

ow the tool to stay in posi

tion against the seal for at

least five seconds.

пЃ¬R

emove the special tool from the seal.

Page 565 of 2490

Engine - Crankshaft

Inner Sp

rocket4.0L NA V8 - AJ27

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Camshaft setting

3

03 - 530

T

iming chain tensioning

303 - 532

Wedges, primary ch

ain

303 - 533

Cranksh

aft setting

303 - 531

1. Open the engine compartment and fit paintwork protection

sheets.

2. Set the engine compartment cover to the service access

position.

3. Di

sconnect the batt

ery ground cable.

пЃ¬R

emove the battery cover.

4. Remove the Timing Co ver. Refer to Operation 12.65.01 in this

Section.

5. Remove the VVT bush carrier from the A-Bank.

1. Remove the three bolts which secure the carrier to the cylinder block.

Page 567 of 2490

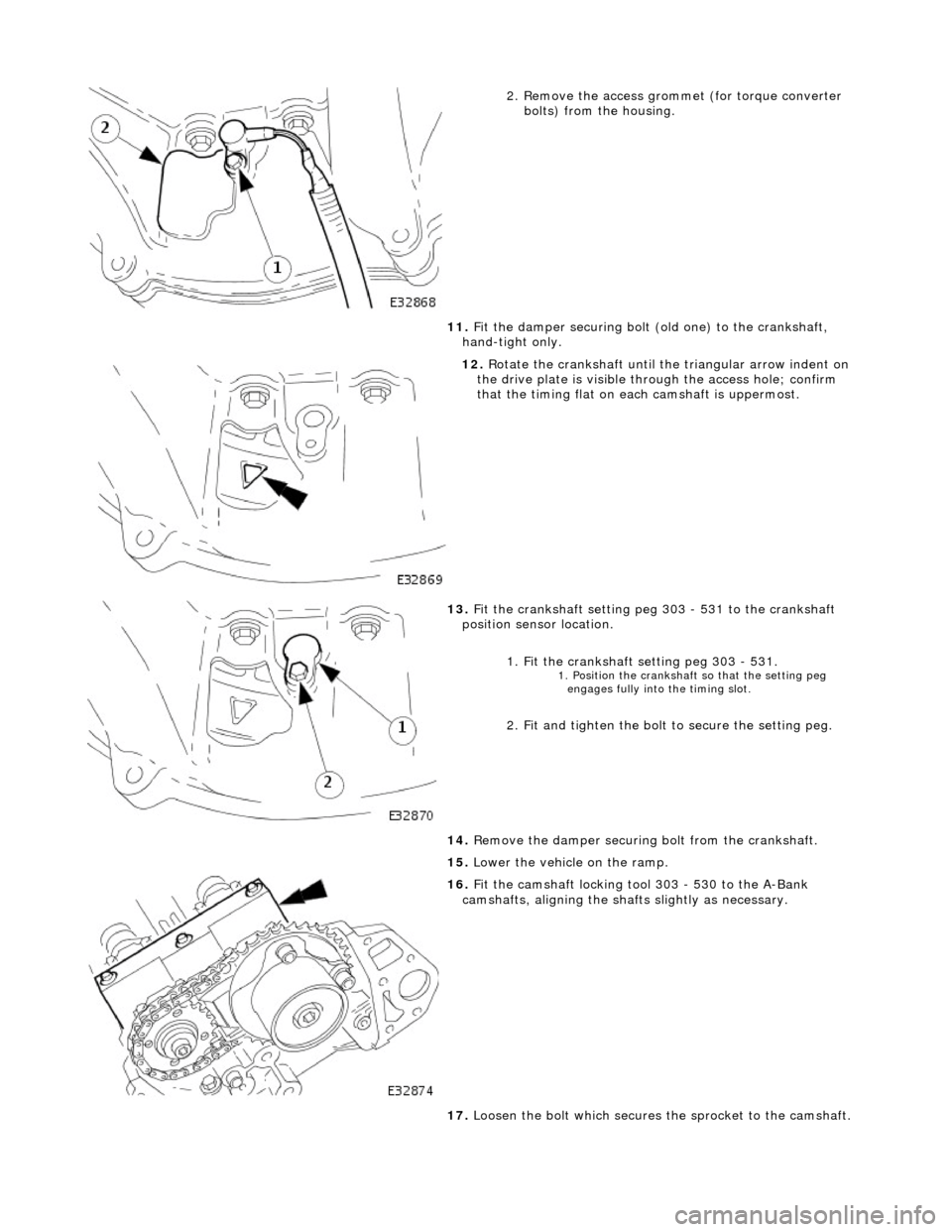

2

. Remove the access grommet (for torque converter

bolts) from the housing.

11. Fit the damper securing bolt (old one) to the crankshaft,

hand-tight only.

12

.

Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

13

.

Fit the crankshaft setting peg 303 - 531 to the crankshaft

position sensor location.

1. Fit the crankshaft setting peg 303 - 531.

1. P

osition the crankshaft so that the setting peg

engages fully into the timing slot.

2

. Fit and tighten the bolt to secure the setting peg.

14. Remove the damper securing bolt from the crankshaft.

15. Lower the vehicle on the ramp.

16

.

Fit the camshaft locking tool 303 - 530 to the A-Bank

camshafts, aligning the shafts slightly as necessary.

17. Loosen the bolt which secures the sprocket to the camshaft.

Page 571 of 2490

I

nstallation

32

.

Clean and inspect all relevant components.

1. F

it the sprockets to the crankshaft.

пЃ¬Th

e teeth of the A-Bank and the B-Bank sprockets on the

crankshaft must be out of phas e with each other. If they

are in-phase after fitting, remove the A-Bank sprocket,

turn it on its vertical axis and refit it.

2. F

it the chain tensioning tool 303 - 532 to the exhaust camshaft

sprocket, B-Bank.

пЃ¬Re

position the sprocket (and

the VVT unit) for the most

advantageous position for use of the tool.

пЃ¬R

emove the tool.

3. R

efit the primary timing chain, B-Bank.

1. Fit the primary chain over the crankshaft sprocket and the VVT unit sprocket. There must be no slack on

the drive side of the primary chain and the VVT unit

must not be rotate d on the camshaft.

пЃ¬Sl

ide the VVT and exhaust sprocket fully rearwards onto

the respective camshafts.

4. Fit the primary chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

Page 573 of 2490

9. F

it the chain tensioning tool 303 - 532 to the exhaust camshaft

sprocket, A-Bank.

пЃ¬Re

position the sprocket (and

the VVT unit) for the most

advantageous position for use of the tool.

пЃ¬R

emove the tool.

10

.

Refit the primary timing chain, A-Bank.

1. Fit the primary chain over the crankshaft sprocket and the VVT unit sprocket. There must be no slack on

the drive side of the primary chain and the VVT unit

must not be rotate d on the camshaft.

11

.

Fit the primary chain tensioner blade.

1. Position the tensioner blade to the cylinder block.

2. Fit the retaining / pivot bolt and tighten it to 12 - 16 Nm.

12. Refit the primary chain tens ioner assembly. Refer to

Operation 12.65.54 in this Section.

пЃ¬U

se a wedge 303 - 533 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

Page 575 of 2490

2

. Fit a new O-ring to the carrier oil-way.

21

.

NOTE: Lubricate the seal (s carf jointed) and the bush.

Fit the VVT bush carrier to the cylinder block.

1. Fit the bush carrier assembly.

1. C

heck that the seals are in place and that the ring

dowels are engaged squa rely. Fully locate the

assembly as much as possible by hand pressure.

2

. Fit the three securing bolts. Tighten to 19 - 23 Nm.

22

.

Fit new seals to the VVT bush carrier, B-Bank.

1. Fit the new sealing ring (scarf jointed) to the carrier bush groove.

2. Fit a new O-ring to the carrier oil-way.

23

.

NOTE: Lubricate the seal (s carf jointed) and the bush.

Fit the VVT bush carrier to the cylinder block. 1. Fit the bush carrier assembly.

1. C

heck that the seals are in place and that the ring

dowels are engaged squa rely. Fully locate the

assembly as much as possible by hand pressure.

2

. Fit the two securing bolts and one nut. Tighten to 19

- 23 Nm.

24. Refit the Timing Cover. Refer to Operation 12.65.01 in this

Section.

25. Move the engine compartment cover from the service position

and connect the gas struts.

26. Remove the paint protection sheets and close the cover.

27. Connect the battery and fit the battery cover.

пЃ¬Re

fer to the Battery Reconnection Procedure 86.15.15.