timing JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 576 of 2490

Engine - Crankshaft Inner Sprocket3.2L NA V8 - AJ26

In-vehic

le Repair

Remov

a

l

S

p

ecial Tool(s)

Camshaft setting

3

03-

530

T

i

ming chain tensioning

303-532

Wedges, primary ch ain

303-533

Cranksha

ft setting

303-531

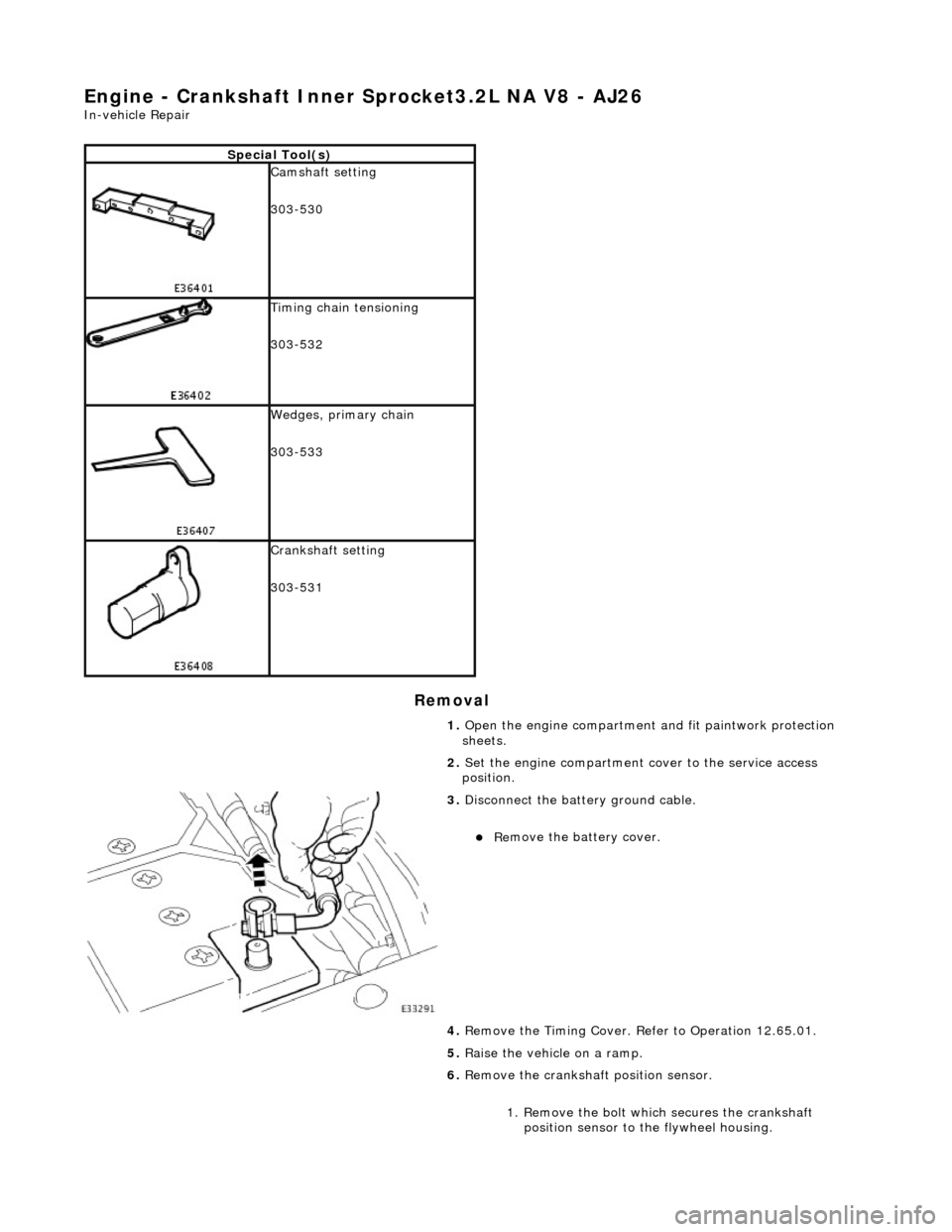

1. Open the engine compartment and fit paintwork protection

sheets.

2. Set the engine compartment cover to the service access

position.

3. Disc

onnect the batt

ery ground cable.

пЃ¬Re

move the battery cover.

4. Remove the Timing Cover. Re fer to Operation 12.65.01.

5. Raise the vehicle on a ramp.

6. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

Page 577 of 2490

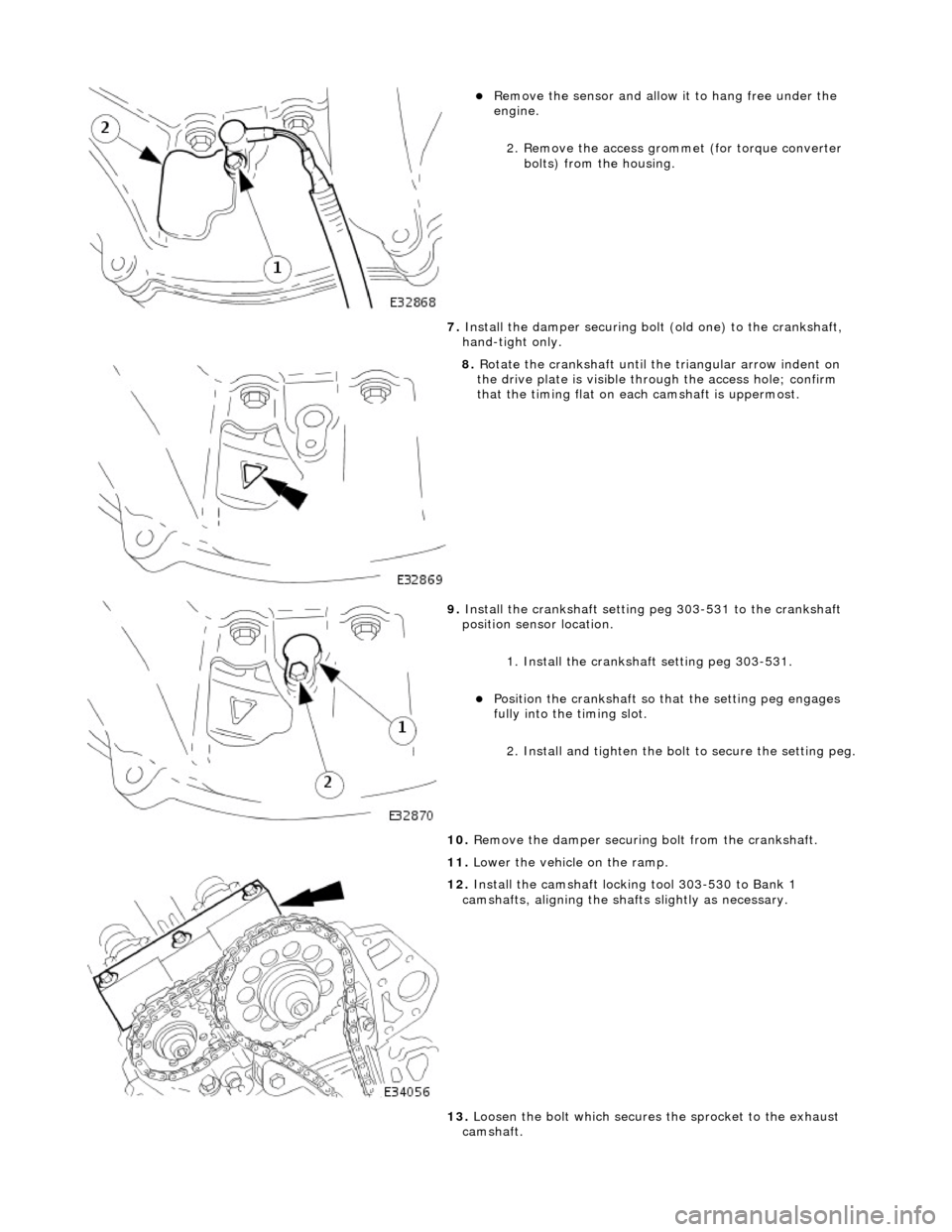

пЃ¬Remove the

sensor and allow

it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

7. Install the damper securing bolt (old one) to the crankshaft,

hand-tight only.

8. R

otate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

9. Inst

all the crankshaft setting peg 303-531 to the crankshaft

position sensor location.

1. Install the crankshaft setting peg 303-531.

пЃ¬Position the crankshaft so that the settin

g peg engages

fully into the timing slot.

2. Install and tighten the bolt to secure the setting peg.

10. Remove the damper securing bolt from the crankshaft.

11. Lower the vehicle on the ramp.

12

.

Install the camshaft locking tool 303-530 to Bank 1

camshafts, aligning the shafts slightly as necessary.

13. Loosen the bolt which secures the sprocket to the exhaust

camshaft.

Page 584 of 2490

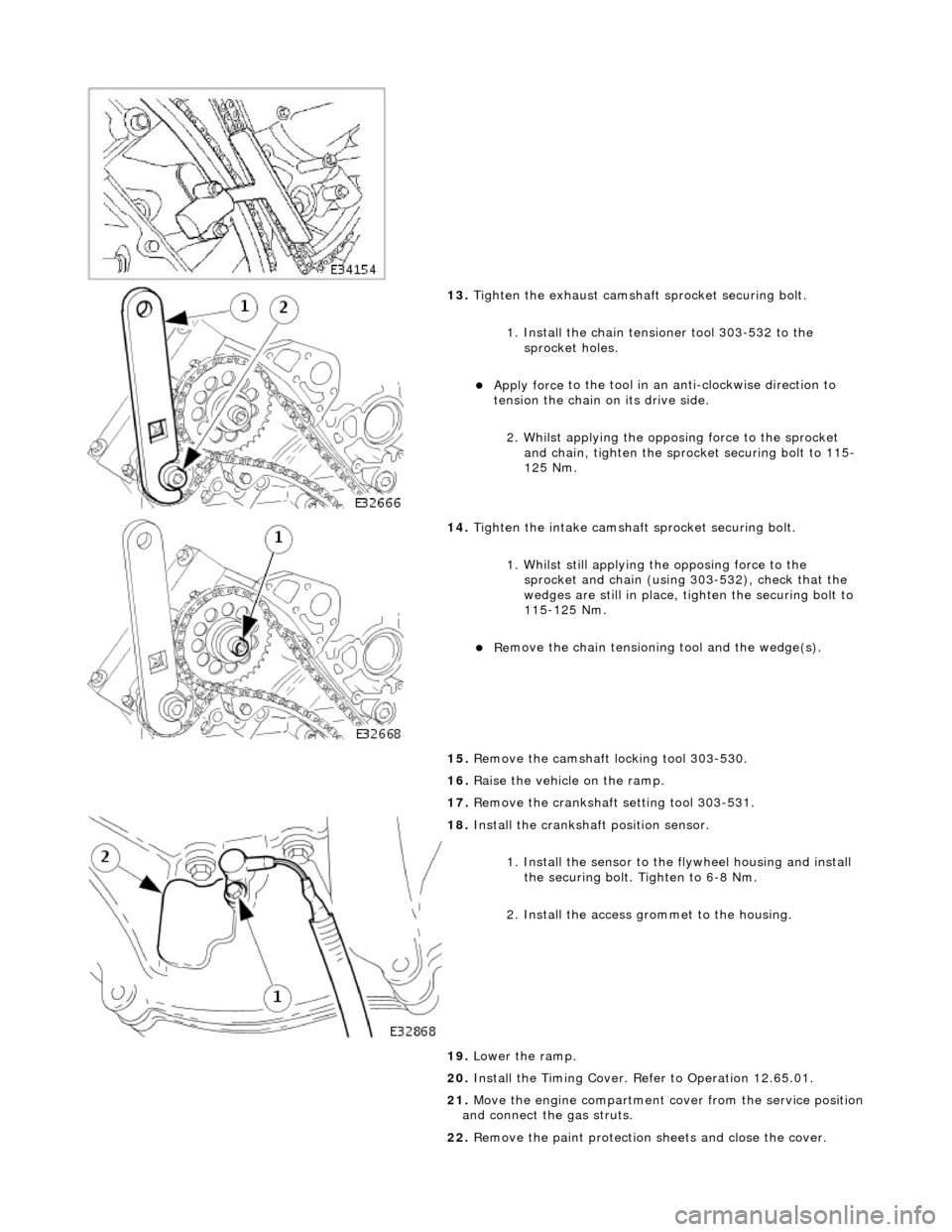

13. Tigh

ten the exhaust camshaft

sprocket securing bolt.

1. Install the chain tensioner tool 303-532 to the sprocket holes.

пЃ¬Appl y force

to the tool in an

anti-clockwise direction to

tension the chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprock et securing bolt to 115-

125 Nm.

14 .

Tigh

ten the intake camshaft

sprocket securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303-532), check that the

wedges are still in place, ti ghten the securing bolt to

115-125 Nm.

пЃ¬R e

move the chain tensioning

tool and the wedge(s).

15. Remove the camshaft locking tool 303-530.

16. Raise the vehicle on the ramp.

17. Remove the crankshaft setting tool 303-531.

18 . Inst

all the crankshaft position sensor.

1. Install the sensor to the flywheel housing and install

the securing bolt. Tighten to 6-8 Nm.

2. Install the access grommet to the housing.

19. Lower the ramp.

20. Install the Timing Cover. Refer to Operation 12.65.01.

21. Move the engine compartment cover from the service position

and connect the gas struts.

22. Remove the paint protection sheets and close the cover.

Page 586 of 2490

Engine - Crankshaft Outer

Sprocket

In-v

ehic

le Repair

Remov

a

l

S

p

ecial Tool(s)

Camshaft setting

3

03-

530

T

i

ming chain tensioning

303-532

Wedges, primary ch ain

303-533

Cranksha

ft setting

303-531

1. Open the engine compartment and fit paintwork protection

sheets.

2. Set the engine compartment cover to the service access

position.

3. Disc

onnect the batt

ery ground cable.

пЃ¬Re

move the battery cover.

4. Remove the Timing Co ver. Refer to Operation 12.65.01 in this

Section.

5. Remove the VVT bush carrier.

1. Remove the three bolts which secure the carrier to the cylinder block.

Page 587 of 2490

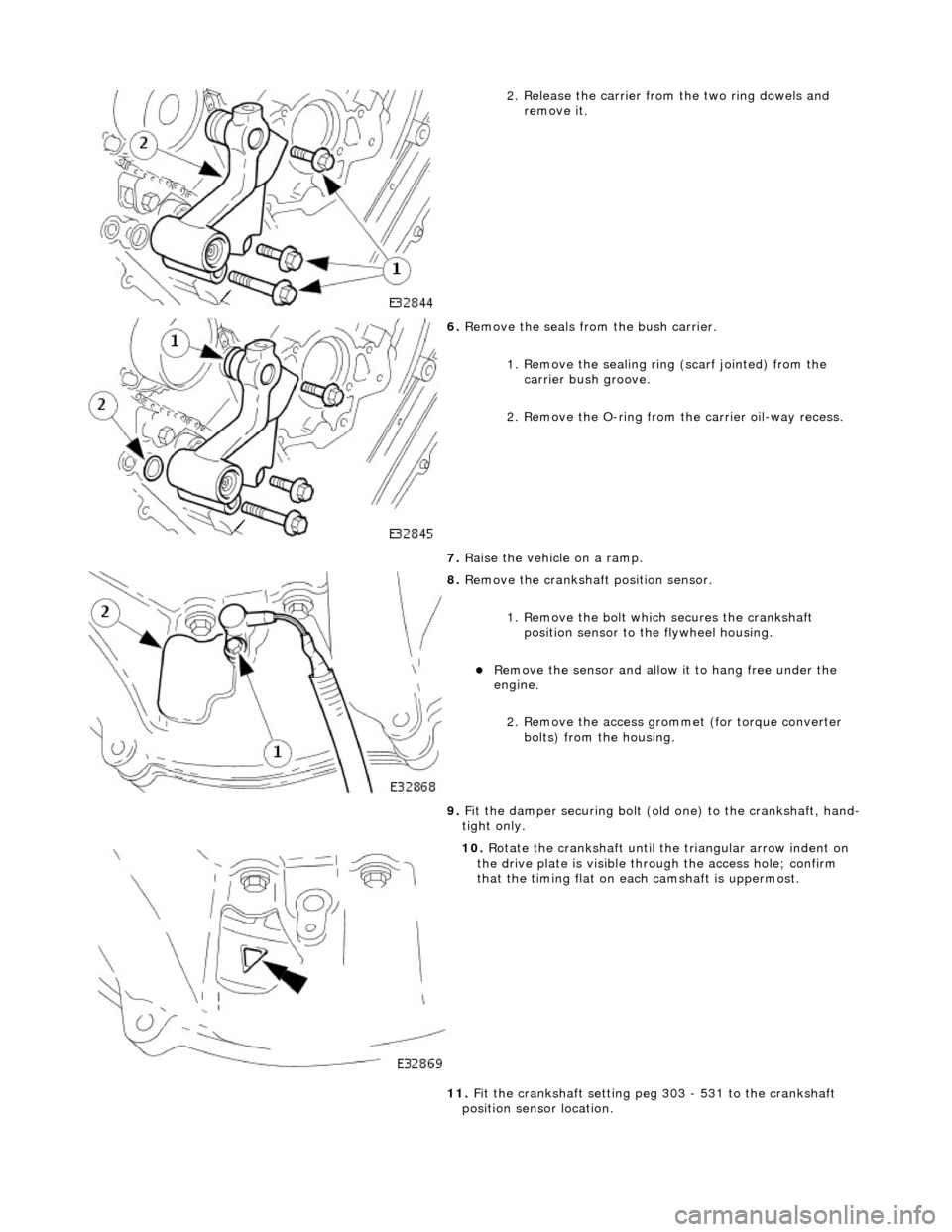

2

. Release the carrier from

the two ring dowels and

remove it.

6. R

emove the seals from the bush carrier.

1. Remove the sealing ring (scarf jointed) from the

carrier bush groove.

2. Remove the O-ring from the carrier oil-way recess.

7. Raise the vehicle on a ramp.

8. R

emove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

пЃ¬Remove the

sensor and allow

it to hang free under the

engine.

2. Remove the access grommet (for torque converter bolts) from the housing.

9. Fit the damper securing bolt (old one) to the crankshaft, hand-

tight only.

10

.

Rotate the crankshaft until the triangular arrow indent on

the drive plate is visible thro ugh the access hole; confirm

that the timing flat on ea ch camshaft is uppermost.

11. Fit the crankshaft setting peg 303 - 531 to the crankshaft

position sensor location.

Page 588 of 2490

1.

Fit the crankshaft setting peg 303 - 531.

пЃ¬Position the crankshaft so

that the setting

peg engages

fully into the timing slot.

2. Fit and tighten the bolt to secure the setting peg.

12. Remove the damper securing bolt from the crankshaft.

13. Lower the vehicle on the ramp.

14. F

it the camshaft locking tool 303 - 530 to the A-Bank

camshafts, aligning the shafts slightly as necessary.

15. L

oosen the bolt which secures

the sprocket to the camshaft.

16. Loosen

the bolt which secure

s VVT unit to the camshaft.

17. Remove the primary ch ain tensioner bolts.

Page 590 of 2490

пЃ¬The

teeth of the A-Bank and the B-Bank sprockets on the

crankshaft must be out of phas e with each other. If they

are in-phase after fitting, remo ve the sprocket, turn it on

its vertical axis and refit it.

2. Fi

t the chain tensioning tool 303 - 532 to the exhaust camshaft

sprocket.

пЃ¬Re po

sition the sprocket (and

the VVT unit) for the most

advantageous position for use of the tool.

пЃ¬R e

move the tool.

3. Re

fit the primary timing chain.

1. Fit the primary chain to position over the crankshaft sprocket and the VVT unit sprocket. There must be no

slack on the drive side of the primary chain and the

VVT unit must not be rotated on the camshaft.

4. Fit the primary chain tensioner

blade.

1. Position the tensioner blade to the cylinder block.

2. Fit the retaining / pivot bolt and tighten it to 12-16 Nm.

5. Refit the primary chain tensione r assembly. Refer to Operation

12.65.54 in this Section.

пЃ¬U s

e a wedge 303 - 533 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

Page 592 of 2490

2.

Fit a new O-ring to the carrier oil-way.

14. F

it the VVT bush carrier to the cylinder block.

пЃ¬Lubric

ate the seal (scarf

jointed) and the bush.

1. Fit the bush carrier assembly.

пЃ¬Check that th e seals are in pl ace an

d that the ring dowels

are engaged squarely. Fully locate the assembly as much

as possible by hand pressure.

2. Fit the three securing bolts. Tighten to 19-23 Nm.

15. Refit the Timing Cover. Refer to Operation 12.65.01 in this

Section.

16. Move the engine compartment cover from the service position

and connect the gas struts.

17. Remove the paint protection sheets and close the cover.

18. Connect the battery and fit the battery cover.

пЃ¬Refe

r to the Battery Reconnection Procedure in Section

414-01.

Page 595 of 2490

I

nstallation

11

.

Remove the crankshaft front seal.

1. Install and tighten the removal tool 303-541 to the crankshaft front seal.

2. Tighten the centre bolt of the tool to extract the seal.

пЃ¬R

emove the tool an

d seal assembly.

пЃ¬Separate the seal

from the tool.

12. Very carefully clean the thread s of the crankshaft, using a

plug tap M16x2, to remove all old cured sealant.

пЃ¬Kee

p the tap horizontal. Do not enlarge the crankshaft

thread - remove sealant only.

13. Clean all relevant parts and faces.

1. Loc

ate the new oil seal into the timing cover.

1. Remove the transit ring from the oil seal.

2. Position the seal to the timing cover.

2. Inst

all the new oil seal to the timing cover.

1. Install oil seal replacer tool 303-542 to the oil seal.

2. Use the nut and bolt provided with the tool, to fully seat the seal to the timing cover. Only tighten the nut

sufficiently to locate the seal and no more, or the

timing cover could become distorted.

пЃ¬All

ow the tool to stay in posi

tion against the seal for at

least five seconds.

пЃ¬R

emove the special tool from the seal.

Page 602 of 2490

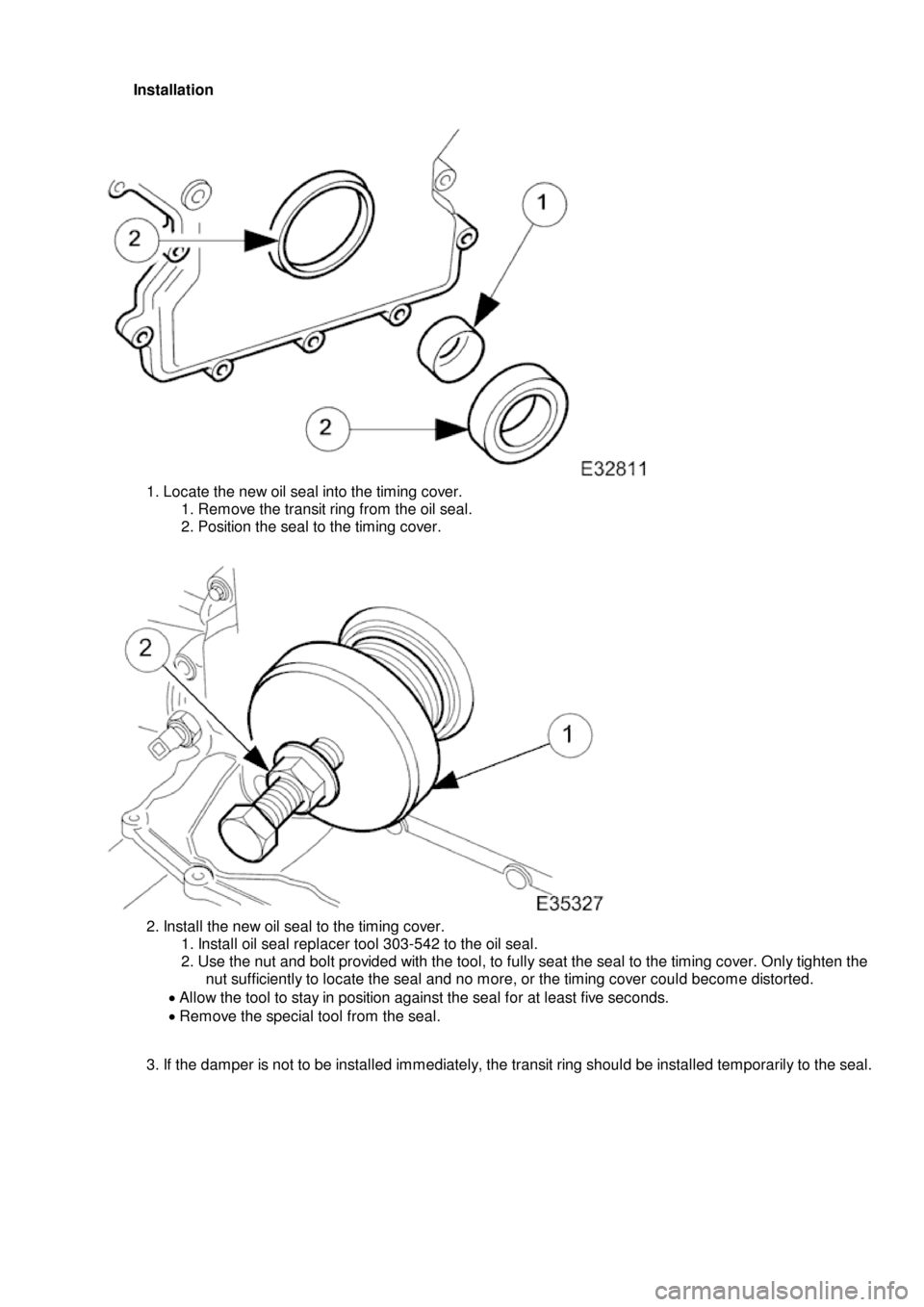

1.

Locate the new oil seal into the timing cover.

1. Remove the transit ring from the oil seal.

2. Position the seal to the timing cover.

2.

Install the new oil seal to the timing cover.

1. Install oil seal replacer tool 303-542 to the oil seal.

2. Use the nut and bolt provided with the tool, to fully seat the seal to the timing cover. Only tighten the nut sufficiently to locate the seal and no more, or the timing cover could become distorted.

п‚·пЂ Allow the tool to stay in position against the seal for at least five seconds.

п‚·пЂ Remove the special tool from the seal.

3. If the damper is not to be installed immediately, the transit ring should be installed temporarily to the seal.

Installation