timing JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 10 of 2490

В В В В В В В В В В В В В В В В В В В В

В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В Flexplate

В VehiclesВ With

out:В

SuperchargerВ (12.53.13)В

В В В В В В В В В В В В В В В В В В В В Flexplate

В VehiclesВ With:В Supercharger В (12.53.13) В

В В В В В В В В В В В В В В В В В В В В Intake

В Camshaft В LH В (12.13.16) В

В В В В В В В В В В В В В В В В В В В В Intake

В Camshaft В RH В (12.13.14) В

В В В В В В В В В В В В В В В В В В В В Intake

В Manifo

ldВ (30.15.01) В

В В В В В В В В В В В В В В В В В В В В Intake

В Manifold В Gaskets В (30.15.08) В

В В В В В В В В В В В В В В В В В В В В Intake

В Manifold В LHВ (18.50.26) В

В В В В В В В В В В В В В В В В В В В В Intake

В Manifold В RH В (18.50.25) В

В В В В В В В В В В В В В В В В В В В В Intake

В Manifold В Gasket В LHВ (18.50.28) В

В В В В В В В В В В В В В В В В В В В В Intake

В Manifold В Gasket В RH В (18.50.27) В

В В В В В В В В В В В В В В В В В В В В Oil

В Pan В (12.60.44) В

В В В В В В В В В В В В В В В В В В В В Oil

В Pan В Gasket В (12.60.38) В

В В В В В В В В В В В В В В В В В В В В Oil

В PressureВ SwitchВ (88.25.07) В

В В В В В В В В В В В В В В В В В В В В Oil

В Pump В VehiclesВ Without:В SuperchargerВ (12.60.26)В

В В В В В В В В В В В В В В В В В В В В Oil

В Pump В VehiclesВ With:В Supercharger В (12.60.26) В

В В В В В В В В В В В В В В В В В В В В Primary

В Timing В Chain В LHВ 4.0L, В VehiclesВ Wit

hout: В SuperchargerВ (12.65.67)В

В В В В В В В В В В В В В В В В В В В В Primary

В Timing В Chain В LHВ 3.2L/4.0L,В VehiclesВ With: В Supercharger В (12.65.67) В

В В В В В В В В В В В В В В В В В В В В Primary

В Timing В Chain В RH В (12.65.66) В

В В В В В В В В В В В В В В В В В В В В Primary

В Timing В Chain В InnerВ Guide В LHВ (12.65.58) В

В В В В В В В В В В В В В В В В В В В В Primary

В Timing В Chain В InnerВ Guide В RH В (12.65.60) В

В В В В В В В В В В В В В В В В В В В В Primary

В Timing В Chain В Outer В Guide В LHВ (12.65.61) В

В В В В В В В В В В В В В В В В В В В В Primary

В TimingВ Chain В Outer В Gu

ide В RH В (12.65.57) В

В В В В В В В В В В В В В В В В В В В В Primary

В Timing В Chain В Tensioner В LHВ (12.65.55) В

В В В В В В В В В В В В В В В В В В В В Primary

В Timing В Chain В Tensioner В RH В (12.65.54) В

В В В В В В В В В В В В В В В В В В В В Secondary

В Timing В Chain В LH В (12.65.69) В

В В В В В В В В В В В В В В В В В В В В Secondary

В Timing В Chain В RH В (12.65.68) В

В В В В В В В В В В В В В В В В В В В В Secondary

В Timing В Chain В Tensioner В LHВ 4.0L,В VehiclesВ Without: В Supercharger В В

В В В В В В В В В (12.65.64)

В

В В В В В В В В В В В В В В В В В В В В Secondary

В Timing В Chain В Tensioner В LHВ 3.2L/4.0L, В VehiclesВ With:В SuperchargerВ В

В В В В В В В В В (12.65.64)

В

В В В В В В В В В В В В В В В В В В В В Secondar

yВ Timing В Chain В Tensioner В RH В 4.0L,В VehiclesВ Without: В Supercharger В В

В В В В В В В В В (12.65.63)

В

В В В В В В В В В В В В В В В В

В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В

Secondar yВ Timing В Ch

ain

В Tensioner В RH В 3.2L/4.0L, В VehiclesВ With:В SuperchargerВ В

(12.65.63) В

Upper В Oil В Pan В 3.2L В (12.60.48) В

Upper В Oil В Pan В 4.0L, В VehiclesВ Without:В SuperchargerВ (12.60.48)В

Upper В Oil В Pan В 4.0L, В VehiclesВ With:В Supercharger В (12.60.48) В

Page 11 of 2490

В В В В В В В В В В В В В В В В В В В В В В В В В В В В В

В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В В Valve

В Co

verВ

LHВ (12.29.43) В

В В В В В В В В В В В В В В В В В В В В Valve

В CoverВ RHВ (12.29.44) В

В В В В В В В В В В В В В В В В В В В В Valve

В CoverВ Gasket В LHВ (12.29.40) В

В В В В В В В В В В В В В В В В В В В В Valve

В CoverВ Gasket В RH В (12.29.41) В

В В В В В В В В В В В В В В В В В В В В Valve

В SpringsВ LHВ

В В В В В В В В В В В В В В В В В В В В Valve

В SpringsВ RHВ

В В В В В В В В В В В В В В В В В В В В Variable

В Camshaft В Timing В Oil В Con

trolВ Unit В LHВ (12.65.71) В

В В В В В В В В В В В В В В В В В В В В Variable

В Camshaft В Timing В Oil В Control В Unit В RH В (12.65.70) В

В В В В В В В В В В В В В В В В В В В В Variable

В Camshaft В Timing В Oil В Control В Unit В Housing В LHВ (12.65.52) В

В В В В В В В В В В В В В В В В В В В В Variable

В Camshaft В Timing В Oil В Control В Unit В Housing В RH В (12.65.51) В

В

В В В В В В В В В В В В 303‐03A :В Engine В Cooling В

В В В В В В В В В В В В В В В В Descriptio

nВ and В Operation В

В В В В В В В В В В В В В В В В В В В В EngineВ Cooling В

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В EngineВ Cooling В

В В В В В В В В В В В В В В В В В В В В RelatedВ Faults В /В Codes В

В В В В В В В В В В В В В В В В В В В В DTCВ P0116 В ECT В circuit В rangeВ /В performanceВ problemВ

В В В В В В В В В В В В В В В В В В В В DTCВ P0125 В Insufficient В coolantВ temperature В for В closed В loopВ fuelВ control В

В В В В В В В В В В В В В В В В В В В В DTCВ P0117 В ECT В circuit В low В input В

В В В В В В В В В В В В В В В В В В В В DTCВ P0118 В ECT В circuit В high В input В

В В В В В В В В В В В В В В В В В В В В DTCВ P1474 В Intercooler В coolant В pum

pВ relay В malfunction В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ A:В P0116, В P0125 В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ B:В P0117 В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ C:В P0118 В

В В В В В В В В В В В В В В В В В В В В PinpointВ testВ D:В P1474 В

В В В В В В В В В В В В В В В В GeneralВ Procedures В

В В В В В В В В В В В В В В В В В В В В CoolingВ System В Draining,В FillingВ and В Bleeding  ‐ 3.2L В NA В V8  ‐ AJ26/4.0L В NA В V8  – В

В В В В В В В В В В AJ27В

В В В В В В В В В В В В В В В В В В В В CoolingВ System В Draining,В FillingВ and В Bleeding  ‐ 4.0L В SC В V8  ‐ AJ26 В

В В В В В В В В В В В В В В В В В В В В CoolingВ Sy

stem В Draining В and В Vacuum В Filling В

В В В В В В В В В В В В В В В В RemovalВ and В Installation В

В

Removal

В

Engine  ‐ Re m

oval

В (12.41.01) В

Installation В

Engine  ‐ Installation В (12.41.01) В

Page 16 of 2490

В В В В В В В В В В В В В В В В В В В В KnockВ Sensor В (KS) В RH В (18.30.93) В

В В В В В В В В В В В В В В В В В В В В

VariableВ Camshaft В Timing В (VCT) В Oil В Co ntrol

В

Solenoid В (18.30.90) В

В

В В В В В В В В

307: В Automatic В Transmission/Transaxle В

В

В В В В В В В В В В В В 307‐01A :В Automatic В Transmission/Transaxle  ‐ 3.2L В NA В V8  ‐ AJ26/4.0LВ NAВ V8  ‐ AJ27 В

В В В В В В В В В В В В В В В В Specification В

В В В В В В В В В В В В В В В В Description В and В Operation В

В В В В В В В В В В В В В В В В В В В В TransmissionВ DescriptionВ

В В В В В В В В В В В В В В В В Diagnosis В and В Testing В

В В В В В В В В В В В В В В В В В В В В DiagnosticВ Strategy В

В В В В В В В В В В В В В В В В GeneralВ Procedures В

В В В В В В В В В В В В В В В В В В В В TransmissionВ FluidВ Drain В and В Refill В (44.24.02) В

In‐Ve

hicle В Repair В

В В В В В В В В В В В В В В В В В В В В ElectronicВ PressureВ ControlВ (EPC)В Solenoid В (44.15.51) В

В В В В В В В В В В В В В В В В В В В В ExtensionВ Housing В Seal В (44.20.18) В

В В В В В В В В В В В В В В В В В В В В ExtensionВ Housing В O ‐Ring В Seal В (44.20.19) В

В В В В В В В В В В В В В В В В В В В В MainВ ControlВ ValveВ BodyВ (44.40.01) В

В В В В В В В В В В В В В В В В В В В В OutputВ Shaft В Speed В (OSS) В Sensor В (44.15.41) В

В В В В В В В В В В В В В В В В В В В В ShiftВ Solenoids В (SS) В (44.15.50) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ ControlВ Module В (TCM) В (44.15.32) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ FluidВ Filter В (44.24.07) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ Fl

uid В Pan В (44.24.04) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ FluidВ Pan В Gasket В (44.24.05) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ InternalВ Wiring В Harness В (44.15.35) В

В В В В В В В В В В В В В В В В В В В В TransmissionВ InternalВ Wiring В Harness В Electrical В ConnectorВ O‐Ring В SealsВ В

В В В В В В В В В В (44.24.20)В

В В В В В В В В В В В В В В В В В В В В TransmissionВ RangeВ (TR)В Sensor В

В В В В В В В В В В В В В В В В В В В В TransmissionВ SupportВ InsulatorВ (12.45.04) В

В В В В В В В В В В В В В В В В В В В В TurbineВ Shaft В Speed В (TSS) В Sensor В (44.15.40) В

В В В В В В В В В В В В В В В В RemovalВ

В В В В В В В В В В В В В В В В В В В В TransmissionВ (44.20.01)В

В В В В В В В В В В В В В В В В Disassembly В and В AssemblyВ ofВ Subassemblies В

В В В В В В В В В В В В В В В В В В В В InputВ Sh

aft В Seal В (44.32.07) В

В В В В В В В В В В В В В В В В В В В В TorqueВ Converter В (44.17.07) В

В В В В В В В В В В В В В В В В Installation В

В В В В В В В В В В В В В В В В В В В В TransmissionВ (44.20.01)В

Mass

В

Airflow

В

Sen s

or

В

Knock

В Sensor

В (KS)

В LH

В (18.30.92)

В

Page 43 of 2490

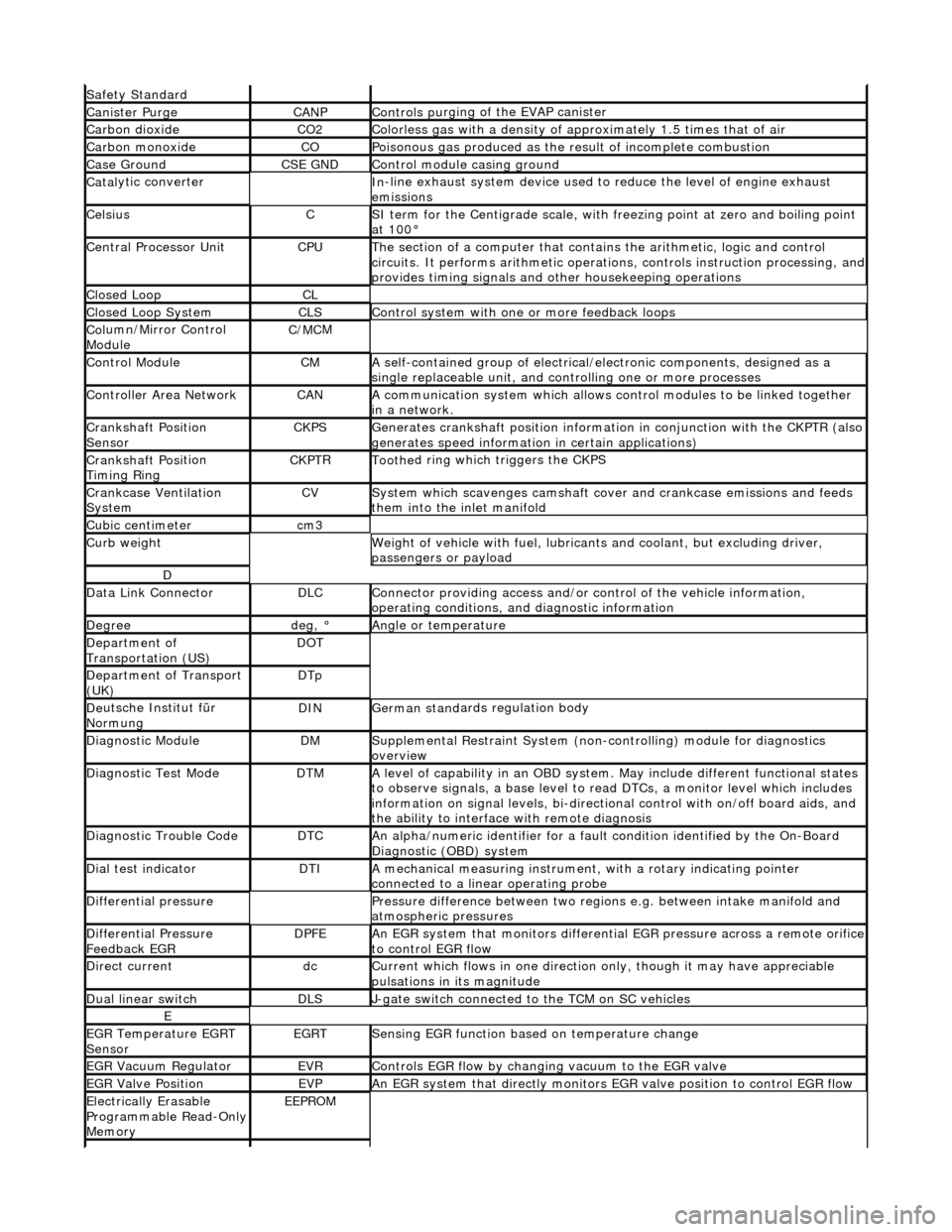

Safety Standard

Canister PurgeCANPControls pu

rging of the EVAP canister

Carbon dioxideCO2Colorless gas with

a density of a

pproximately 1.5 ti mes that of air

Carbon mon

oxide

COPoi

sonous gas produced as the re

sult of incomplete combustion

Case G

round

CSE GNDControl modu

le casing ground

Catal

ytic converter

In

-line exhaust system device used to reduce the level of engine exhaust

emissions

Ce

lsius

CSI ter

m for the Centigrade scale, with

freezing point at zero and boiling point

at 100В°

Central

Processor Unit

CPUTh

e section of a computer that contai

ns the arithmetic, logic and control

circuits. It performs arithm etic operations, controls instruction processing, and

provides timing signals and other housekeeping operations

Cl

osed Loop

CL

Cl

osed Loop System

CLSControl

system with one

or more feedback loops

Col

umn/Mirror Control

Module

C/MC

M

Control ModuleCMA

self-contained group of electrical/electronic components, designed as a

single replaceable un it, and controlling one or more processes

Controll

er Area Network

CANA

communication system which allows control modules to be linked together

in a network.

Crankshaft Posi

tion

Sensor

CKPSGenerates crankshaft positi on informa

tion in conjunct

ion with the CKPTR (also

generates speed information in certain applications)

Crankshaft Posi

tion

Timing Ring

CKPT

R

Toothe

d ring which

triggers the CKPS

Crankcase Ventila

tion

System

CVSys

tem which scavenges camshaft cover and crankcase emissions and feeds

them into the inlet manifold

Cubic ce nt

imeter

cm

3

Curb weightWe

ight of vehicle with fuel, lubrican

ts and coolant, but excluding driver,

passengers or payload

D

Dat

a Link Connector

DLCConne

ctor providing access and/or control of the vehicle information,

operating conditions, and diagnostic information

De

gree

deg, В°Angle or tempe

rature

D

epartment of

Transportation (US)

DO

T

D

epartment of Transport

(UK)

DTp

De

utsche In

stitut fГјr

Normung

DINGerman stand

ards regulation body

Di

agnostic Module

DMSuppl

emental Restraint System (non-c

ontrolling) module for diagnostics

overview

Di

agnostic Test Mode

DTMA le

vel of capability in an OBD system.

May include different functional states

to observe signals, a base level to re ad DTCs, a monitor level which includes

information on signal levels, bi-directional control with on /off board aids, and

the ability to interface with remote diagnosis

Diagnostic Trouble CodeDTCAn al

pha/numeric identifier for a fault

condition identified by the On-Board

Diagnostic (OBD) system

D

ial test indicator

DTIA mechan

ical measuring

instrument, with a rotary indicating pointer

connected to a linear operating probe

D

ifferential pressure

Pressure di

fference betwee

n two regions e.g. between intake manifold and

atmospheric pressures

D

ifferential Pressure

Feedback EGR

DP

FE

An

EGR system that monito

rs differential EGR pressure across a remote orifice

to control EGR flow

D

irect current

dcCurrent which f

lows in on

e direction only, though it may have appreciable

pulsations in its magnitude

Du

al linear switch

DLSJ

-gate switch connected to the TCM on SC vehicles

E

EGR

Temperature EGRT

Sensor

EGRTSens

ing EGR function based on temperature change

EGR Vacu

um Regulator

EVRControls EGR

flow by changi

ng vacuum to the EGR valve

EGR Valve

Position

EVPAn EGR

system that direct

ly monitors EGR valve position to control EGR flow

Electrically E

rasable

Programmable Read-Only

Memory

EEP

ROM

Page 45 of 2490

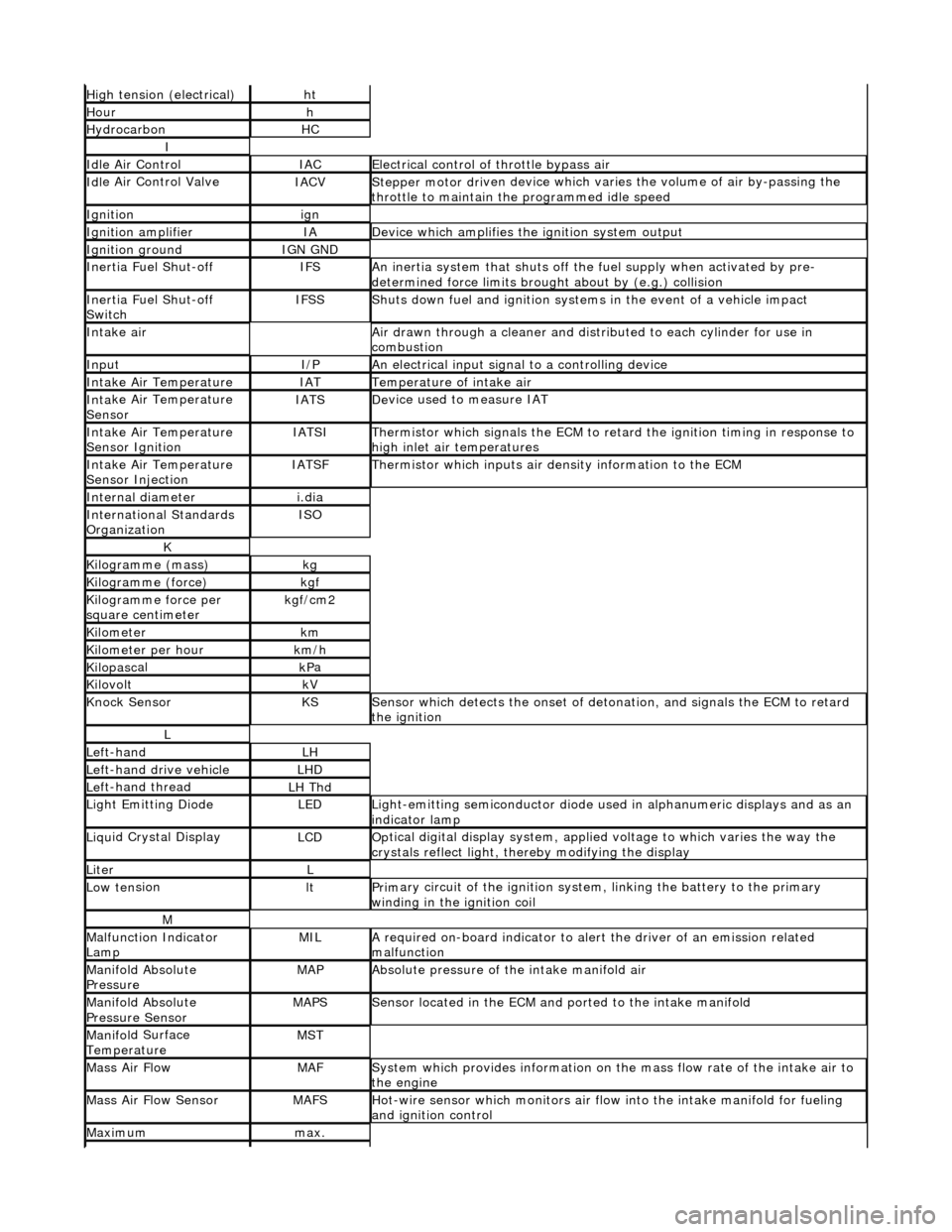

High

tension (electrical)

ht

Hourh

Hydro

carbon

HC

I

Idl

e Air Control

IACEl

ectrical control of throttle bypass air

Idl

e Air Control Valve

IACVStepper motor dri

ven device which vari

es the volume of air by-passing the

throttle to maintain the programmed idle speed

Ignitionign

Ignition am

plifier

IAD

evice which amplifies the i

gniti

on system output

Ignition groundIGN GND

In

ertia Fuel Shut-off

IFSAn

inertia system that shuts off the fuel supply when activated by pre-

determined force limits brough t about by (e.g.) collision

In

ertia Fuel Shut-off

Switch

IFSSShut

s down fuel and ignition systems in the event of a vehicle impact

Inta

ke air

Air drawn t

hrough a cleaner and distri

buted to each cylinder for use in

combustion

InputI/PAn

electrical input signal to a controlling device

Inta

ke Air Temperature

IATTem

perature of intake air

Inta

ke Air Temperature

Sensor

IATSDe

vice used to measure IAT

Inta

ke Air Temperature

Sensor Ignition

IATSITherm

istor which signals the ECM to retard

the ignition timing in response to

high inlet air temperatures

Inta

ke Air Temperature

Sensor Injection

IATSFTher

mistor which inputs air density information to the ECM

Internal diameteri.

dia

Inte

rnational Standards

Organization

ISO

K

Kilogramme (mass)kg

Kilogram

me (force)

kg

f

Ki

logramme force per

square centimeter

kg

f/cm2

Kilom

eter

km

Ki

lometer per hour

km

/h

Kilopasc

al

kP

a

KilovoltkV

Knock

Sensor

KSSens

or which detects the onset of detonation, and signals the ECM to retard

the ignition

L

Le

ft-hand

LH

Left-hand drive veh

icle

LHD

Le

ft-hand thread

LH Thd

Ligh

t Emitting Diode

LEDLigh

t-emitting semiconductor diode used

in alphanumeric displays and as an

indicator lamp

Liqu

id Crystal Display

LCDOp

tical digital display system, applied voltage to which varies the way the

crystals reflect light, thereby modifying the display

LiterL

Low ten

sion

ltPrim

ary circuit of the ignition system, linking the battery to the primary

winding in the ignition coil

M

Malfu

nction Indicator

Lamp

MILA

required on-board indicator to aler

t the driver of an emission related

malfunction

Mani

fold Absolute

Pressure

MAPAbsolute pressure o

f the intake manifold air

Mani

fold Absolute

Pressure Sensor

MAPSSensor loca

ted in the ECM and

ported to the intake manifold

Manifol

d Surface

Temperature

MST

Mass Ai

r Flow

MAFSy

stem which provides inform

ation on the mass flow rate of the intake air to

the engine

Mass Ai

r Flow Sensor

MAFSHot-wi

re sensor which monitors air flow

into the intake manifold for fueling

and ignition control

Maxim

um

max.

Page 48 of 2490

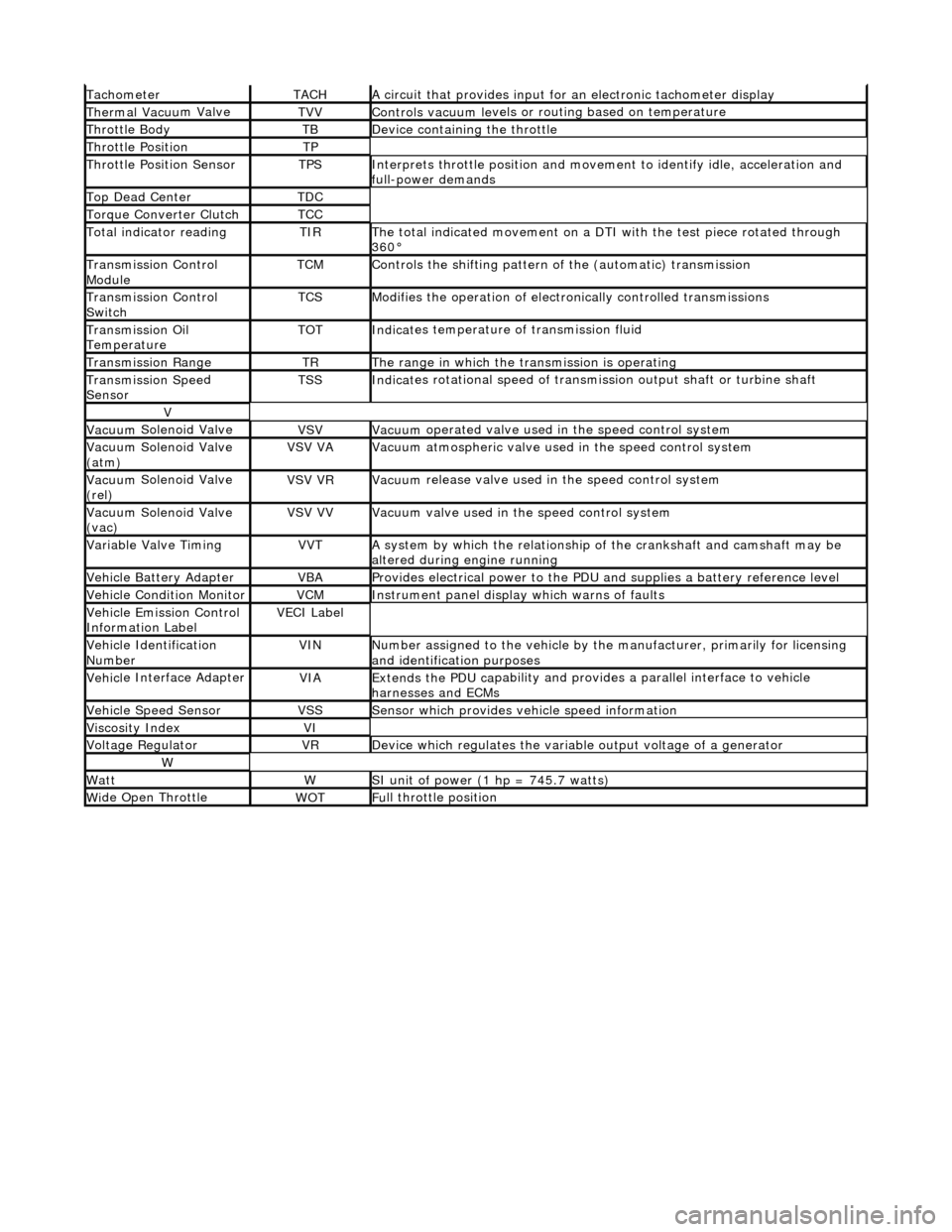

Tacho

meter

TACHA

ci

rcuit that provides input for

an electronic tachometer display

Thermal Vacuu

m Valve

TVVControls vacuum l

e

vels or

routing based on temperature

Throttle

Body

TBDe

vi

ce containing the throttle

Throttl

e

Position

TP

Throttl

e

Position Sensor

TPSInterprets throttl

e

position and movement to iden tify idle, acceleration and

full-power demands

Top Dead CenterTDC

Torque Converter C

lutch

TCC

To

tal

indicator reading

TIRThe t

o

tal indicated movement on a DTI with the test piece rotated through

360В°

Transm

ission Control

Module

TCMControls

the shifting pattern

of the (automatic) transmission

Transm

ission Control

Switch

TCSModifi es

the operation of electronically controlled transmissions

Transmission Oil

TemperatureTOTIndi

cat

es temperature of transmission fluid

Transmission RangeTRThe ran

g

e in which the transmission is operating

Transmission Spe

e

d

Sensor

TSSIndi cat

es rotational speed of transmission output shaft or turbine shaft

V

Vacuu

m

Solenoid Valve

VSVVacuu

m

operated valve used in the speed control system

Vacuu

m

Solenoid Valve

(atm)

VSV VAVacuu m

atmospheric valve used in the speed control system

Vacuu

m

Solenoid Valve

(rel)

VSV VRVacuu m

release valve used in the speed control system

Vacuu

m

Solenoid Valve

(vac)

VSV VVVacuu m

valve used in the speed control system

Variable Valve TimingVVTA

s

ystem by which the relationship of the crankshaft and camshaft may be

altered during engine running

Vehi cl

e Battery Adapter

VBAProvide

s

electrical power to the PDU

and supplies a battery reference level

Vehicl

e Condition Monitor

VCMInst

rum

ent panel display which warns of faults

Ve

hic

le Emission Control

Information Label

VECI Label

Vehi cl

e Identification

Number

VINN u

mber assigned to the vehicle by the manufacturer, primarily for licensing

and identification purposes

Vehi cl

e Interface Adapter

VIAExtends the

PDU ca

pability and provid

es a parallel interface to vehicle

harnesses and ECMs

Vehicle Spe e

d Sensor

VSSSens

or which provides ve

hicle speed information

Viscosity In

dexVI

Voltage RegulatorVRDe

vice which regulates the variable output voltage of a generator

W

Wat

tWSI unit of power (1 hp = 7

45.7 watts)

W

i

de Open Throttle

WO

TFu

ll throttle position

Page 521 of 2490

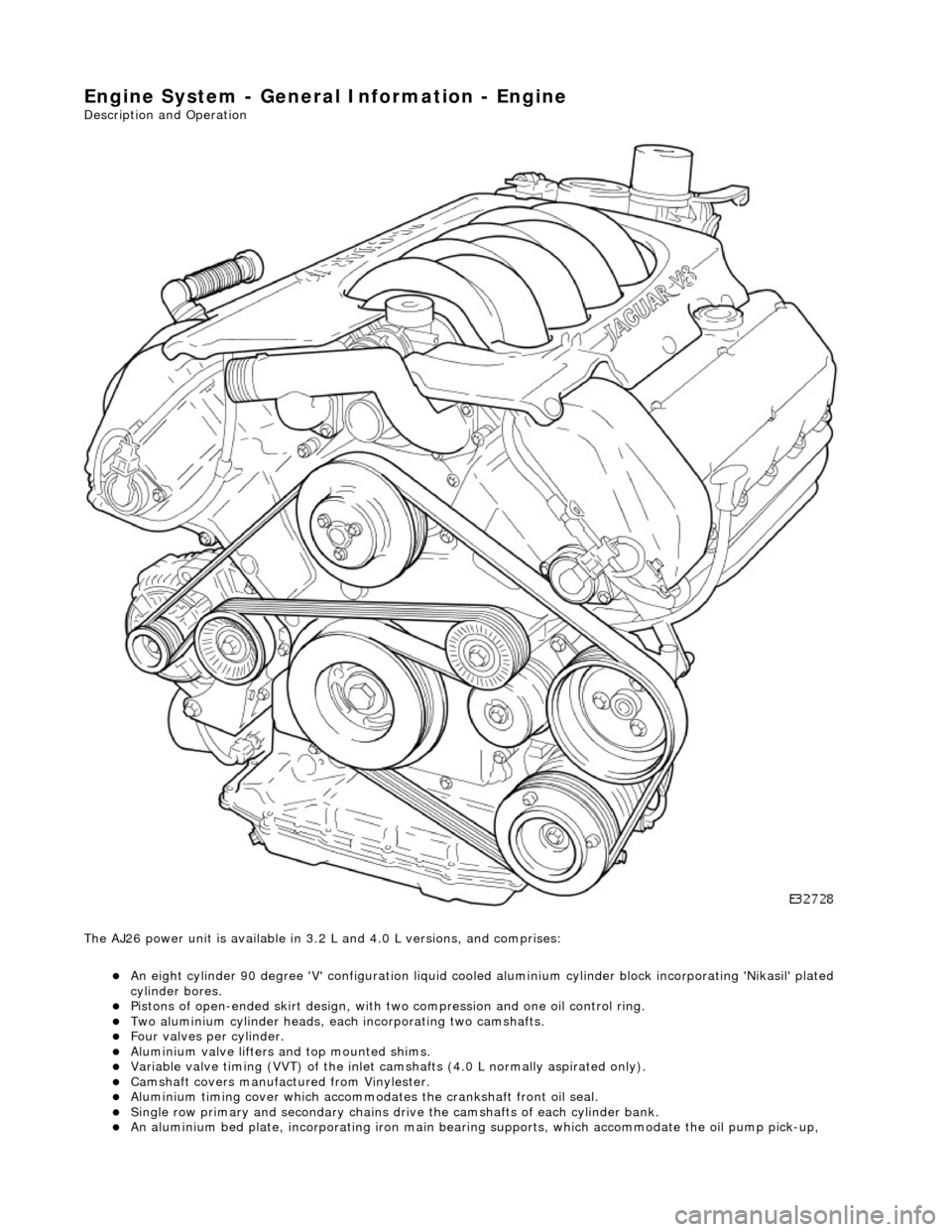

Engine System - General Infor

mation - Engine

Description an

d Operation

The AJ26 power unit is available in 3.2 L and 4.0 L versions, and comprises:

пЃ¬An eight cylinder 9

0 degree 'V' config

uration liquid cooled aluminium cylinder block incorporating 'Nikasil' plated

cylinder bores.

пЃ¬Pi

stons of open-ended skirt design, with

two compression and one oil control ring.

пЃ¬Two al

uminium cylinder heads, each

incorporating two camshafts.

пЃ¬F

our valves per cylinder.

пЃ¬Al

uminium valve lifters and top mounted shims.

пЃ¬Vari

able valve timing (VVT) of the inlet camshafts (4.0 L normally aspirated only).

пЃ¬Camshaft

covers manufactured from Vinylester.

пЃ¬Al

uminium timing cover which accommodat

es the crankshaft front oil seal.

пЃ¬Sin

gle row primary and secondary chains dr

ive the camshafts of each cylinder bank.

пЃ¬An alu

minium bed pl

ate, incorporating iron main bearing supports, which accomm odate the oil pump pick-up,

Page 527 of 2490

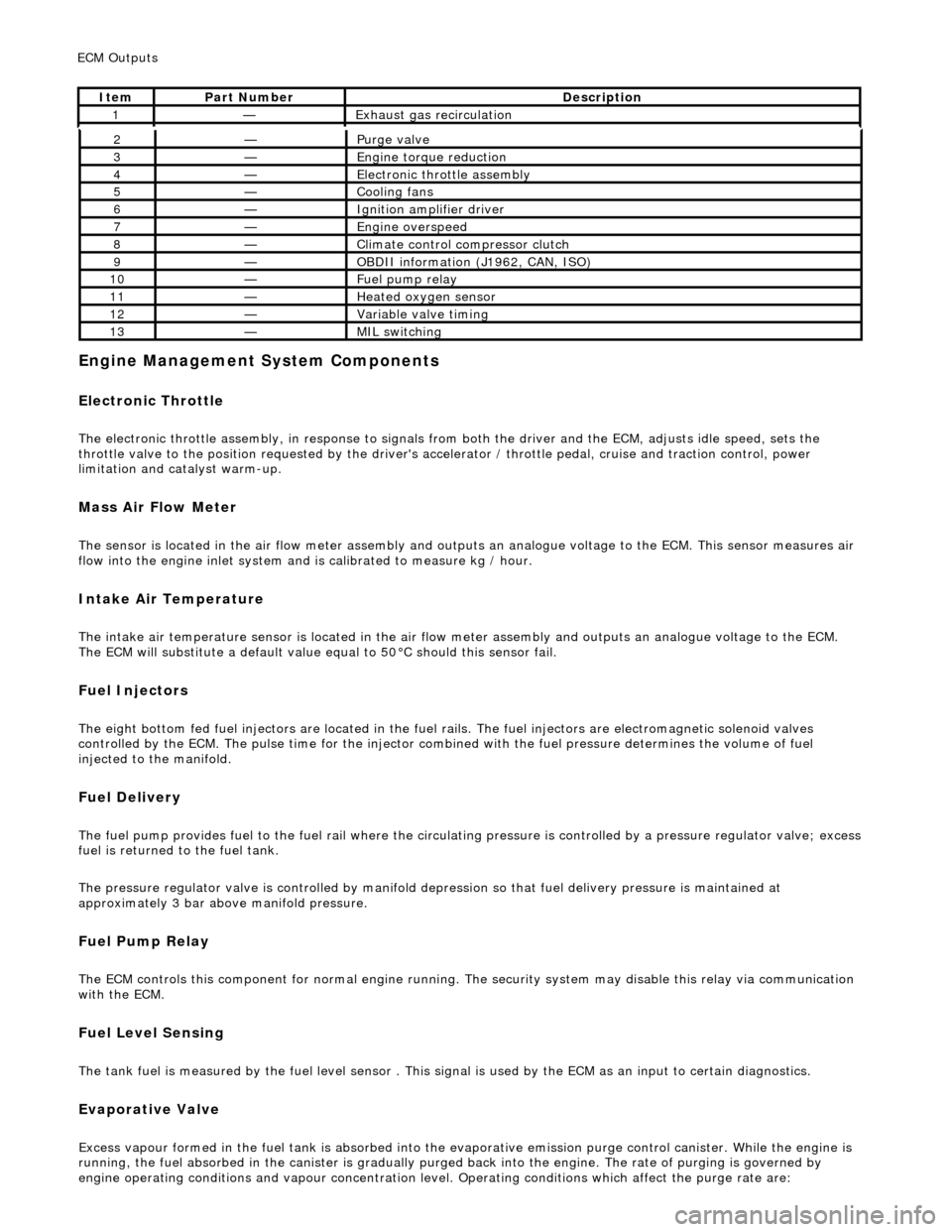

E

ngine Management System Components

Electronic Throt

tle

The

electronic throttle assembly, in resp

onse to signals from both the driver and the ECM, adjusts idle speed, sets the

throttle valve to the position requested by the driver's accelerator / throttle pedal, cruise and traction control, power

limitation and catalyst warm-up.

Mass

Air Flow Meter

The sensor i

s located in the air flow mete

r assembly and outputs an analogue voltag e to the ECM. This sensor measures air

flow into the engine inlet system and is calibrated to measure kg / hour.

In

take Air Temperature

Th

e intake air temperature sensor is loca

ted in the air flow meter assembly and outputs an analogue voltage to the ECM.

The ECM will substitute a default value eq ual to 50В°C should this sensor fail.

Fuel Injectors

The eigh

t bottom fed fuel injectors are located in the fuel rails. Th

e fuel injectors are electromagnetic solenoid valves

controlled by the ECM. The pulse time for the injector combined with the fuel pr essure determines the volume of fuel

injected to the manifold.

Fue

l Delivery

The fu

el pump provides fuel to the fuel rail where the circulat

ing pressure is controlled by a pressure regulator valve; excess

fuel is returned to the fuel tank.

The pressure regulator valve is controlled by manifold depression so that fuel delivery pressure is maintained at

approximately 3 bar above manifold pressure.

Fuel Pump

Relay

The ECM controls thi

s component for normal

engine running. The security system may disable this relay via communication

with the ECM.

Fuel Lev

el Sensing

The tank fuel

is measured by the fuel le

vel sensor . This signal is used by the ECM as an in put to certain diagnostics.

Eva

porative Valve

Excess vapour

formed in the fuel tank is

absorbed into the evaporative emission pu rge control canister. While the engine is

running, the fuel absorbed in the canister is gradually purged back into the engine. The rate of purging is governed by

engine operating conditions and vapour concentration level. Operating conditions which affect the purge rate are:

2—Purge

valve

3—Engine

torque reduction

4—E

lectronic throttle assembly

5—Coo

ling fans

6—Ignition amplifier driver

7—Engine overspeed

8—Cli

mate control compressor clutch

9—O

BDII information (J1962, CAN, ISO)

10—F

uel pump relay

11—Heat

ed oxygen sensor

12—Vari

able valve timing

13—MIL sw

itching

ECM Out

puts

It

em

Par

t Number

De

scription

1—Exhaus

t gas recirculation

Page 528 of 2490

пЃ¬Speed an

d load

пЃ¬Coo

l

ant temperature

пЃ¬Ti

me el

apsed from start up

пЃ¬Cl

osed l

oop fuelling

Determination of the vapour concentration is made by stepped opening of the EVAP valve and subsequent monitoring of the

fuelling correction. This function is performed prior to purging, so that at the onse t of purging the EVAP valve can be set to

the optimum position. Should the ECM be unable to determine the concentration before purging, a default value is

employed, which is then modified whilst purging is in progress.

When the purging process is operational th e ECM modifies the basic fuelling calculation to maintain the correct air / fuel

ratio.

Purging is inhibited during fuel cut-off and stability / traction control intervention.

Coolant Temperature Sen

sor

Th

e

sensor outputs a voltage to the ECM which decreases as temperature increases.

Cooling Fans

In response to engi

ne coolant temperat

u

re and climate control system demand, the ECM will energize the cooling fans.

Climate Control Compressor

The E

C

M will allow the compressor clutch to be engaged if th

e engine temperature and load demand are normal. Should the

driver require maximum engine powe r or the coolant temperature be high, the request will be denied.

Cranking Signal

The ECM reacts to a signal fr

om th

e Body Processor Module (BPM) when the starter motor relay is energi

zed. This signal is

used to trigger starting, fu el and ignition strategies.

Engine Speed and Cranksh

aft Position

Engine

speed and cran

k position are moni

tored by a sensor which is mounted on the cylinder block (flywheel housing)

behind the crankshaft drive plat e. It indicates rotational speed to the ECM in the form of 12 pulses per crank revolution.

Engine speed is used for synchronization of fuel an d ignition systems, as well as other functions.

Camshaft Position

The ca

mshaft position sensor is mounted at

the rear of Bank 2 cylinder head on the inlet side and provides one signal every

720 degrees of crankshaft rotation. The signal, in conjunction with the signal from the crankshaft position sensor, indicates

to the ECM that the piston of cylinder 1A is approaching TDC on the compression stroke.

Variable Valve

Timing (Where Fitted)

By energi

si

ng a solenoid to allow the pass

age of pressurized oil on each of the inle t camshaft drives, the ECM can vary by a

single stepped amount, the relati ve timing of the inlet valves.

Ign

ition

Ignit

i

on spark is produced by

individual on-plug coil units.

There are two ignition amplifiers; module #1 drives coils 1A, 2B, 3B and 4A, whilst module #2 drives coils 1B, 2A, 3A and

4B. The ECM controls the amplifiers.

Page 529 of 2490

Thi

s sensor uses a piezo-electric sensing element to detect kn

ock which may occur under acceleration at critical conditions.

Should detonation be present the ECM will retard ignition timing of individual cylinders.

Exhaust G

as Recirculation

The EGR

valve (where fitted) reduces NOx

emissions by recirculating a portion of the exhaust gases back into the inlet

manifold.

Heated Oxyg

en Sensors

The h

eated oxygen sensors, one per bank, are situated upstream of the catalysts. Integral

to the sensors are heaters

(under ECM control) which allow the sensor s to reach their operating temperature as soon as possible after engine start. A

comparison between the level of oxygen in the exhaust gas to that in the atmosphere produces an output signal. This signal

is used by the engine closed loop fuel strategy to make fuelling corrections and so control overall emission levels.

Oxygen Sensors

Thes

e sensors, one per bank, are situated downstream of the

catalyst. The comparison of upstream and downstream signals

allows determination of cata lyst conversion efficiency.

Knock Sensor