tow JAGUAR X308 1998 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 517 of 2490

o

perating. If an indicator bulb fails, the warning

lamp and ticking operate at twice the normal rate.

Sidelam

ps and Headlamps

Thes

e are controlled by rotating the end of the column switch as follows.

In the OFF position:

пЃ¬All

exterior lamps are switched OFF.

In the sidelamp position:

пЃ¬The front

sidelamps, tail, license plate and any other la

mps required by local legislation are switched ON.

пЃ¬The

sidelamps tell-tale lamp illuminates.

In the headlamp position, with the ignition switch in position II:

пЃ¬The h

eadlamps are switched ON in addition to the lamps switched on in the sidelamp position.

If the ignition is switched to the OFF position with the column switch in the headlamp position, the sidelamps, tail and

license plate lamps will stay ON, but the headlamps will switch OFF.

In the AUTO position (where fitted), with the ignition switch in position II:

пЃ¬Th

e sensor mounted on the back of the interior rear view

mirror monitors exterior light levels and automatically

switches the sidelamps and di pped headlamps ON and OFF.

The sensitivity level can be adjusted by turn ing the sensor control knob on the back of the interior mirror, left to decrease or

right to increase. The sensor must not be covered and the windscreen must be kept clean.

Headlamp Main Bea

m Position

Wi

th the column switch in

the headlamp position:

пЃ¬Movin

g the switch stalk away fro

m the steering wheel switches the headlamps to main beam.

пЃ¬Movin

g the switch stalk towards the steering wheel switches the headlamps to dipped beam.

The main beam tell-tale lamp illuminates when the headlamps are switched to main beam.

Ma

in Beam Flash

Wi

th the ignition switch and column switch in any position:

пЃ¬Pulling the

switch stalk agains

t spring pressure towards th e steering wheel illuminates the headlamps on main beam

for as long as the switch is held.

The main beam tell-tale lamp illuminates while the headlamps are illuminated.

M

essage Center Functions

T

he message center functions:

пЃ¬Are se

lected by the button located at the end of the lighting switch stalk.

пЃ¬Are se

lected in turn, by repeatedly pressing the button,

from the odometer reading, through the trip computer data

in sequence, and back to th e odometer reading again.

Page 518 of 2490

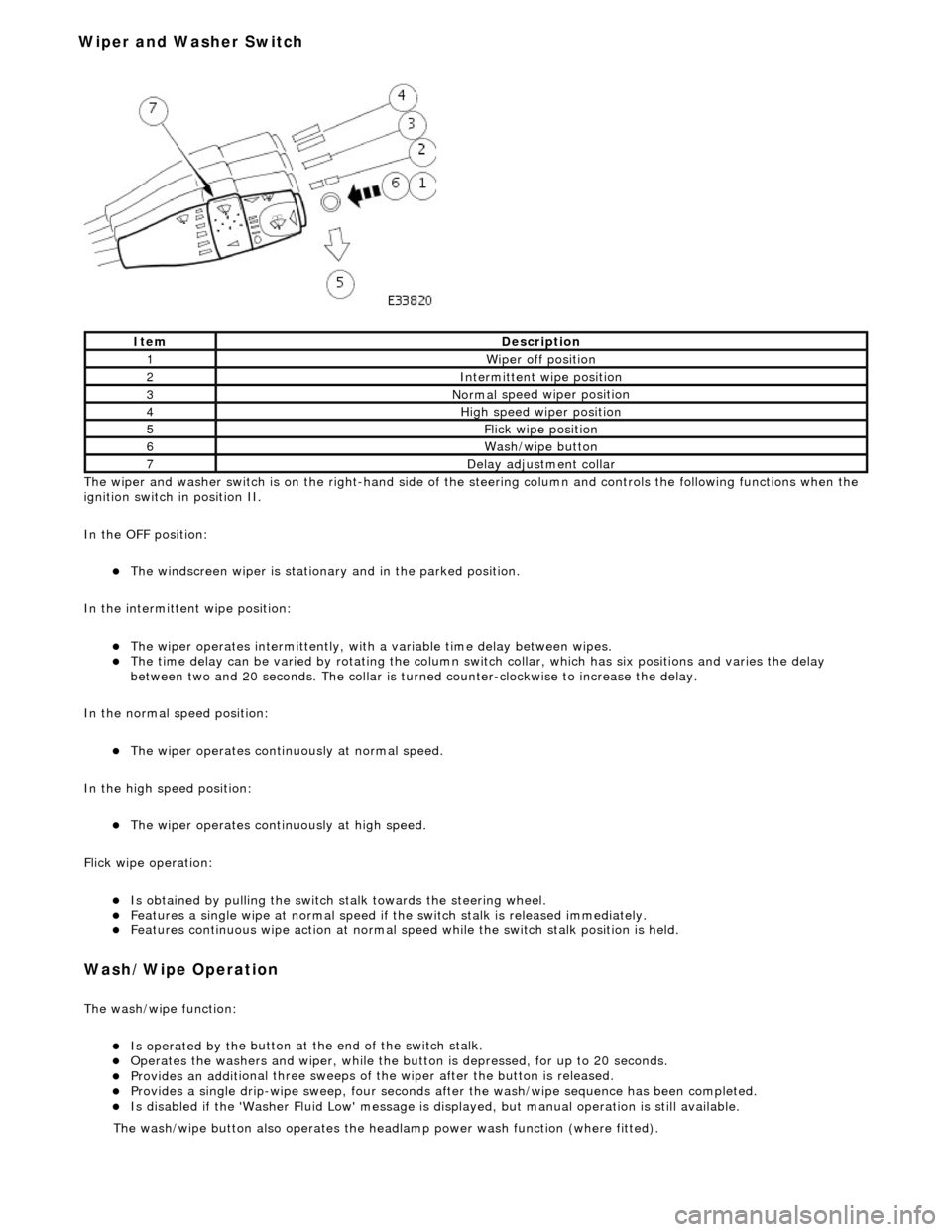

The wiper and washer switch i s

on the righ

t-hand side of the steering column and controls the fo llowing functions when the

ignition switch in position II.

In the OFF position:

пЃ¬The windscreen wiper is stationary and in the parked positio

n.

In the intermittent wipe position:

пЃ¬The wi per ope

rates intermittently, with

a variable time delay between wipes.

пЃ¬The time del

ay can be varied by rotating the column sw

itch collar, which has six positions and varies the delay

between two and 20 seconds. The collar is turned counter-clockwise to increase the delay.

In the normal speed position:

пЃ¬The wiper oper a

tes continuously at normal speed.

In the high speed position:

пЃ¬The wiper ope r

ates continuously at high speed.

Flick wipe operation:

пЃ¬Is obt

ained by pulling the switch

stalk towards the steering wheel.

пЃ¬F

e

atures a single wipe at normal speed if

the switch stalk is released immediately.

пЃ¬Fe

atures continuous wipe action

at normal speed while the swit ch stalk position is held.

Wash/W

ipe Operation

Th

e

wash/wipe function:

пЃ¬Is operat

ed by th

e button at the end of the switch stalk.

пЃ¬Op

erate

s the washers and wiper, while the butt

on is depressed, for up to 20 seconds.

пЃ¬Provides an addit

ional three sweeps of

the wiper after the button is released.

пЃ¬Provid

es a single drip-wipe sweep, four seconds af

ter the wash/wipe sequence has been completed.

пЃ¬Is disabled if the 'Washer Flu

id Low' message is di

splayed, but manual operat ion is still available.

Ite

m

De

scr

iption

1W

i

per off position

2Intermittent

wipe position

3Normal

speed wiper position

4High

speed wiper position

5Flick wipe position

6Wa

sh/wipe button

7D

e

lay adjustment collar

The was

h

/wipe button also operates the head

lamp power wash function (where fitted).

Wiper and Washer Switch

Page 553 of 2490

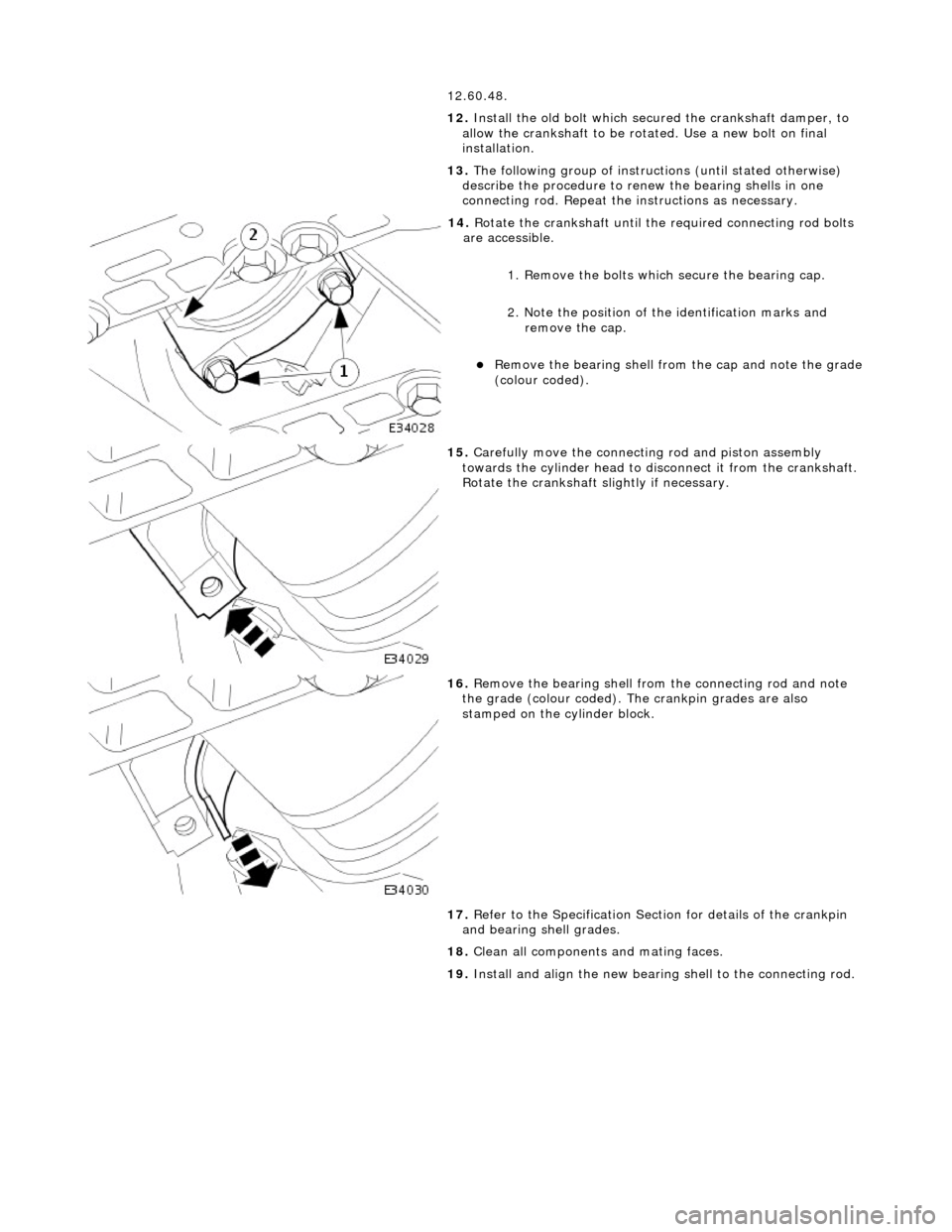

1

2.60.48.

12. Install the old bolt which secu red the crankshaft damper, to

allow the crankshaft to be rotated. Use a new bolt on final

installation.

13. The following group of instructions (until stated otherwise)

describe the procedure to rene w the bearing shells in one

connecting rod. Repeat the instructions as necessary.

14

.

Rotate the crankshaft until th e required connecting rod bolts

are accessible.

1. Remove the bolts which secure the bearing cap.

2. Note the position of the identification marks and remove the cap.

пЃ¬Remove the

bearing shell from the cap and note the grade

(colour coded).

15

.

Carefully move the connecting rod and piston assembly

towards the cylinder head to di sconnect it from the crankshaft.

Rotate the crankshaft slightly if necessary.

16

.

Remove the bearing shell from the connecting rod and note

the grade (colour coded). The crankpin grades are also

stamped on the cylinder block.

17. Refer to the Specification Sectio n for details of the crankpin

and bearing shell grades.

18. Clean all components and mating faces.

19. Install and align the new bearing shell to the connecting rod.

Page 554 of 2490

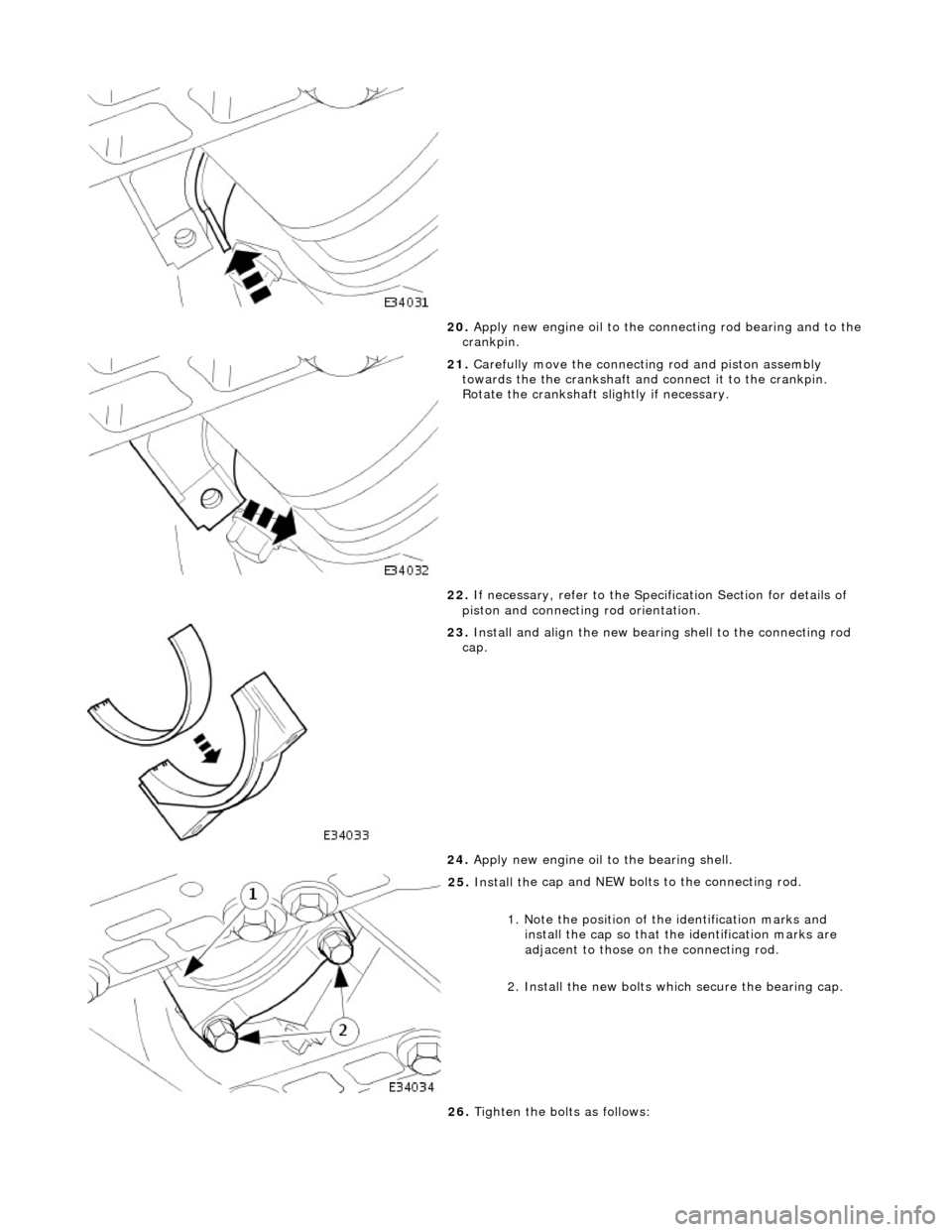

20. Apply new en

gine oil to the co

nnecting rod bearing and to the

crankpin.

21. Carefull

y move the connecting

rod and piston assembly

towards the the crankshaft and connect it to the crankpin.

Rotate the crankshaft slightly if necessary.

22. If necessary, refer to the Spec ification Section for details of

piston and connecting rod orientation.

23 . Install and alig

n the new bearin

g shell to the connecting rod

cap.

24. Apply new engine oil to the bearing shell.

25 . Install th

e cap and NEW bolts to the connecting rod.

1. Note the position of the identification marks and install the cap so that the identification marks are

adjacent to those on the connecting rod.

2. Install the new bolts whic h secure the bearing cap.

26. Tighten the bolts as follows:

Page 605 of 2490

Engine - Crankshaft

Rear Seal4.0L

NA V8 - AJ27/3.2 L NA V8 - AJ26

In-v

ehicle Repair

Remov

al

S

pecial Tool(s)

Crankshaft Rear Oi

l Seal Remover /

Replacer.

303 - 538

1. Open the engine compartment and fit paint protection sheets.

2. Di

sconnect the batt

ery ground cable.

пЃ¬R

emove the battery cover.

3. Remove the transmission. Refer to Operation 44.20. 01 in

Section 307-01A.

4. Remove the drive plate. Refer to Operation 12.53.13.

5. F

it and align the seal removal tool 303 - 538 to the crankshaft.

1. Unscrew the two nuts towards the head of each bolt to allow the bolts to fit fully into the crankshaft.

2. Unscrew the center bolt until it is below the face of the main tool and position the tool to the rear of the

crankshaft.

3. Lightly tighten the two bolts so that they fully locate in the crankshaft.

6. Hold the tool against th

e cran

kshaft and lightly and evenly

tighten the two nuts to the face of the tool; to secure the tool

and to hold it parallel to the face of the crankshaft.

7. Secure the oil seal to the tool using the three self-tapping

Page 608 of 2490

Engine - Crankshaft Rear Seal4.0L SC V8 - AJ26

In-vehic

le Repair

Remov

a

l

S

p

ecial Tool(s)

Crankshaft Rear Oi

l Seal R

emover /

Replacer.

303 - 538

1. Open the engine compartment and fit paint protection sheets.

2. Disc

onnect the batt

ery ground cable.

пЃ¬Re

move the battery cover.

3. Remove the transmission. Refer to Operation 44.20. 01 in

Section 307-01B.

4. Remove the drive plat e. Refer to Operation (SC) 12.53.13.

5. Fi

t and align the seal removal tool 303 - 538 to the crankshaft.

1. Unscrew the two nuts towards the head of each bolt to allow the bolts to fit fully into the crankshaft.

2. Unscrew the center bolt until it is below the face of the main tool and position the tool to the rear of the

crankshaft.

3. Lightly tighten the two scre ws so that they fully locate

in the crankshaft.

6. Hold the tool against th e cr

an

kshaft and lightly and evenly

tighten the two nuts to the face of the tool; to secure the tool

and to hold it parallel to the face of the crankshaft.

7. Secure the oil seal to the tool using the three self-tapping

Page 622 of 2490

2. In

stall the camshaft caps to their respective locations (inlet 0 to 4

and exhaust 5 to 9 from the front) and in the correct orientation

(arrow to front of engine).

3. Install and tighten the cap securing bolts. Tighten evenly, in stages, to 10 Nm.

19. Install the camshaft locking tool 303 - 530, align the camshafts as

necessary.

20 . Install the chain guide

.

пЃ¬The

c

hain guide must be installed so that the slotted hole is towards

the top, and the rais ed shoulder to the cylinder block.

1. Install the chain guide to the block and locate it onto the upper retaining pin.

2. Install the retaining bolt and tighten it to 12 Nm.

21. P

ush the secondary chain tensioner piston into the body to provide

clearance for installing the chain.

1. Insert a thin rigid wire through the hole in the end of the tensioner

piston to displace the ball from the non-return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

пЃ¬Rem

ove the wire.

22 . Ins

tall the secondary chain tensioner to the engine.

1. Fully seat the tensioner to the cylinder head.

2. Install the two bolts which secure the tensioner and tighten to 12 Nm.

23 . N

OTE: Assemble the VVT unit, the exhaust camshaft sprocket and the

secondary chain, in preparation for installing to the engine.

Install the VVT unit to the engine.

1. Install the above assembly to the camshafts with the chain correctly positioned over the tensioner; VVT unit to the inlet and

the sprocket to the exhaust.

2. Install, but do not tighten, each bolt which secures the VVT unit and the exhaust sprocket to the camshafts.

24. Install the chain tensioning tool 303 - 532 to the exhaust camshaft

sprocket.

Page 637 of 2490

пЃ¬To th

e upper face of each bearing surface (two places) in the cylinder

head.

пЃ¬To th

e upper face of each bearing surface (two places) in each bearing

cap.

пЃ¬On

the cam lobes ONLY, not on the base circle area.

17

.

Install the camshafts.

1. Install the camshafts to position in the cylinder head, with the timing flats uppermost.

2. Install the camshaft caps to their respective locations (inlet 0 to 4 and exhaust 5 to 9 from the front) and in the correct orientation

(arrow to front of engine).

3. Install and tighten the cap securing bolts. Tighten evenly, in stages, to 10 Nm.

18. Install the camshaft locking tool 303 - 530, align the camshafts as

necessary.

19

.

Install the chain guide.

• NOTE: The chain guide must be installed so that the slotted hole is

towards the top, and the raised shoulder to the cylinder block. 1. Install the chain guide to the block and locate it onto the upper retaining pin.

2. Install the retaining bolt and tighten it to 12 Nm.

20

.

Push the secondary chain tensioner piston into the body to provide

clearance for installing the chain.

1. Insert a thin rigid wire through the hole in the end of the tensioner

piston to displace the ball from the non-return valve seat.

2. With the wire in position, press the piston fully into the tensioner body.

пЃ¬Re

move the wire.

21

.

Install the secondary chain tensioner to the engine.

1. Fully seat the tensioner to the cylinder head.

2. Install the two bolts which secure the tensioner and tighten to 12 Nm.

22. Install the VVT unit to the engine.

пЃ¬A

ssemble the VVT unit, the exhaust camshaft sprocket and the

Page 645 of 2490

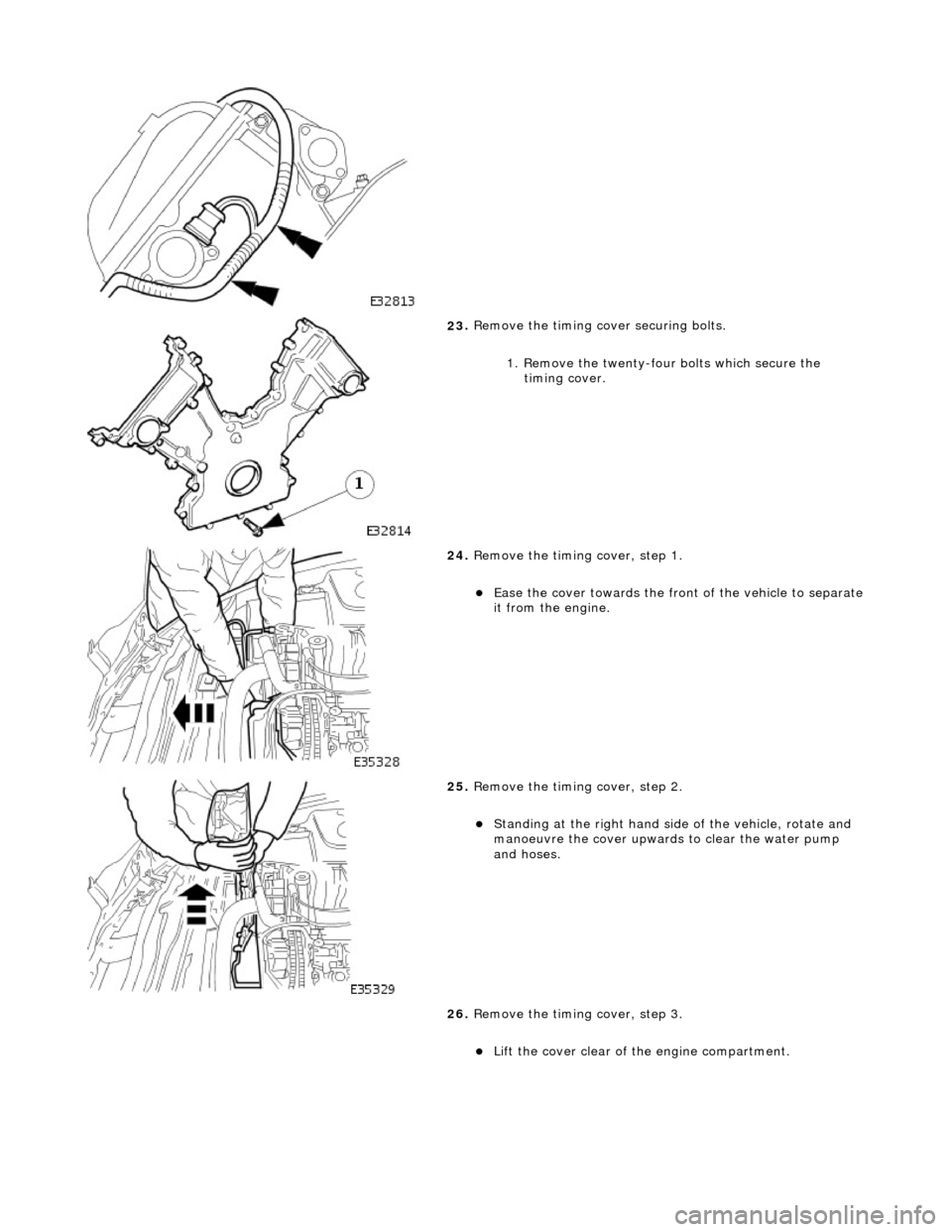

23

.

Remove the timing cover securing bolts.

1. Remove the twenty-fou r bolts which secure the

timing cover.

24

.

Remove the timing cover, step 1.

пЃ¬Ease the cover towards the front of

the vehicle to separate

it from the engine.

25

.

Remove the timing cover, step 2.

пЃ¬Stan

ding at the right hand side

of the vehicle, rotate and

manoeuvre the cover upwards to clear the water pump

and hoses.

26. Remove the timing cover, step 3.

пЃ¬Li

ft the cover clear of th

e engine compartment.

Page 647 of 2490

and hoses.

5. R

efit the timing cover, step 3.

пЃ¬Ease

the cover towards the engi

ne and locate it directly

onto the dowels so that th e gaskets or sealant are not

smeared.

6. F

it and tighten the securing bolt

s in the correct order. Tighten

to 11-13 Nm.

7. Reposition and secure the engine harness clips to the timing

cover.