tow JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2041 of 2490

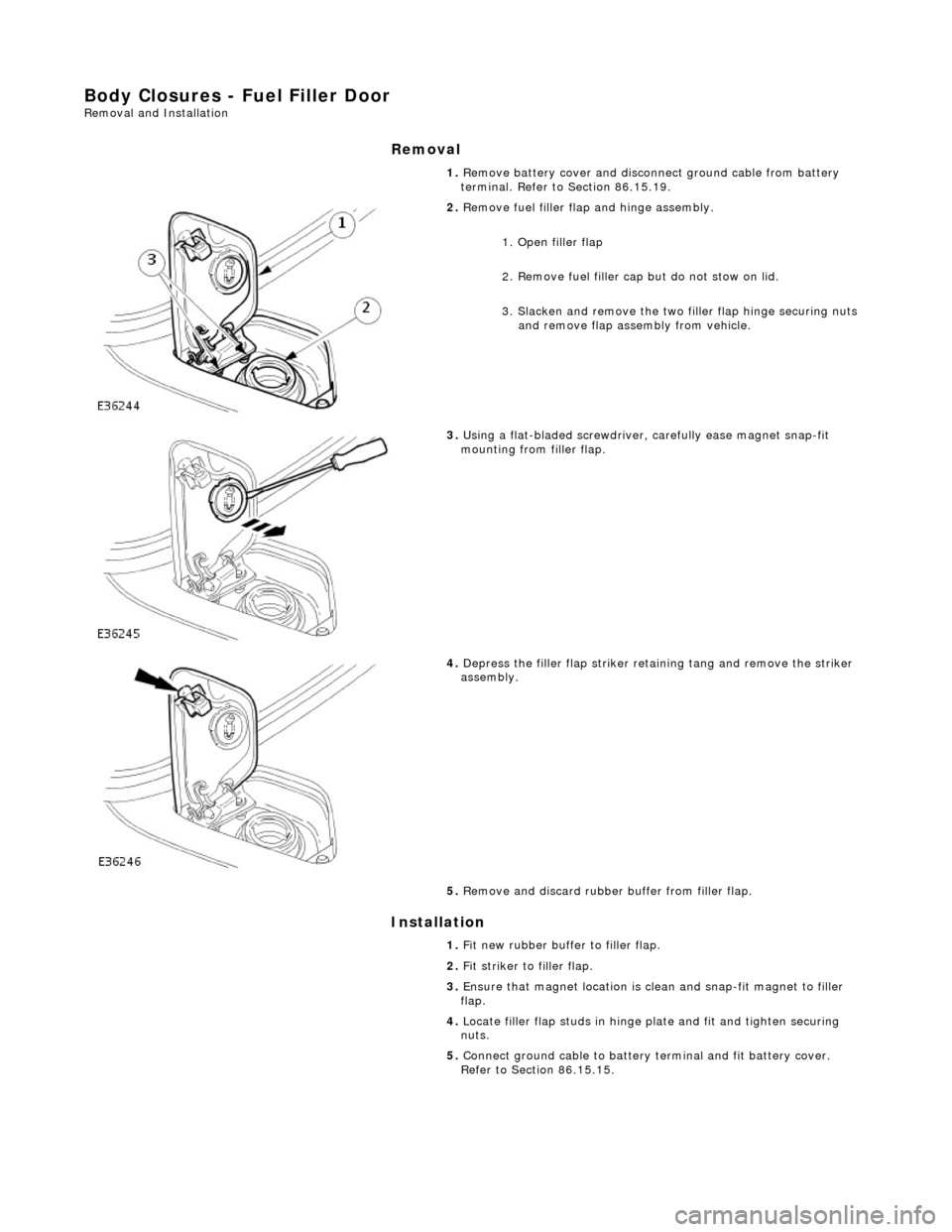

Body Closures - Fuel Filler Door Removal and Installation

Removal

Installation

1.

Remove battery cover and disconnect ground cable from battery

terminal. Refer to Section 86.15.19.

2. Remove fuel filler flap and hinge assembly.

1. Open filler flap

2. Remove fuel filler cap but do not stow on lid.

3. Slacken and remove the two filler flap hinge securing nuts and remove flap assembly from vehicle.

3. Using a flat-bladed screwdriver, carefully ease magnet snap-fit

mounting from filler flap.

4. Depress the filler flap striker retaining tang and remove the striker

assembly.

5. Remove and discard rubber buffer from filler flap.

1. Fit new rubber buffer to filler flap.

2. Fit striker to filler flap.

3. Ensure that magnet location is clean and snap-fit magnet to filler

flap.

4. Locate filler flap studs in hinge plate and fit and tighten securing

nuts.

5. Connect ground cable to battery terminal and fit battery cover.

Refer to Section 86.15.15.

Page 2072 of 2490

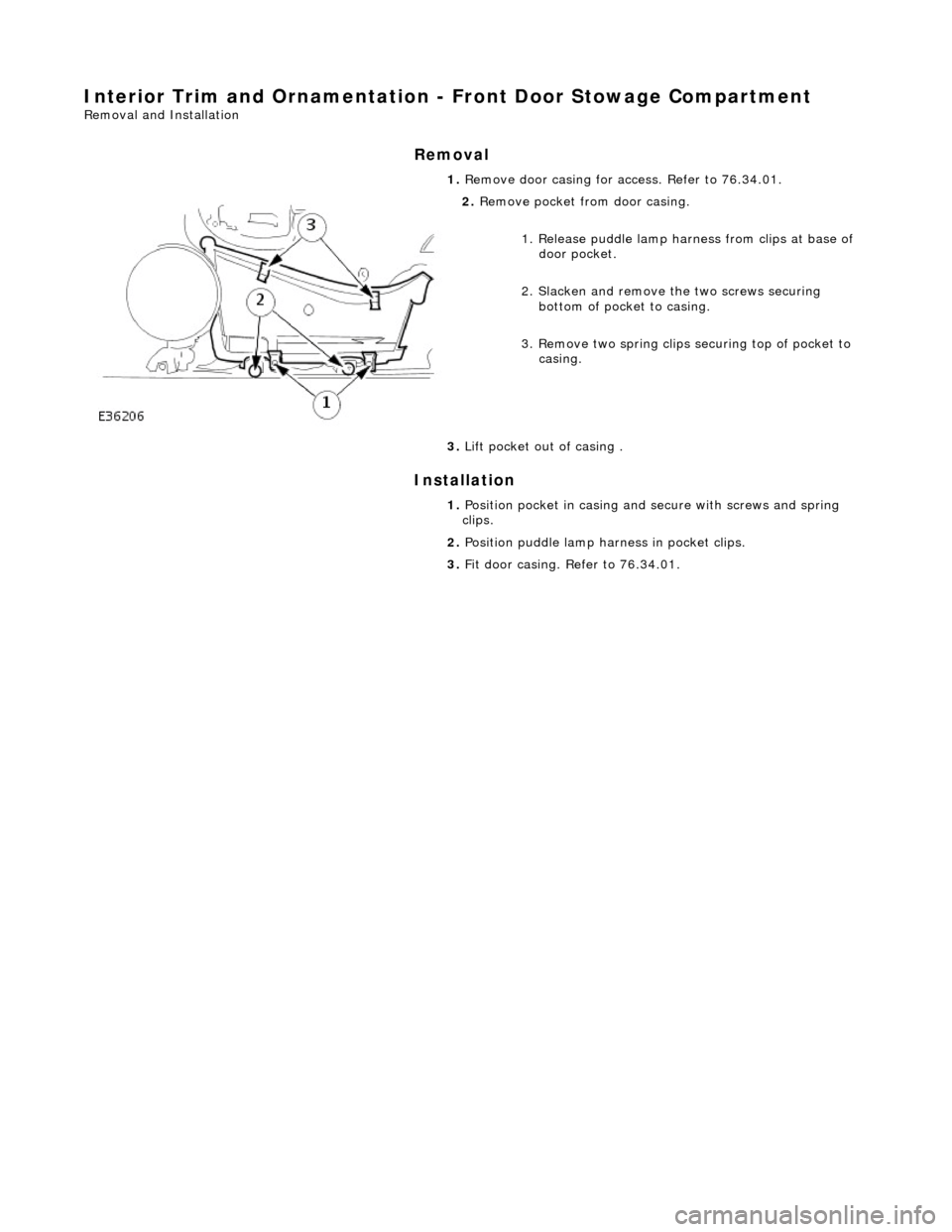

Interior Trim and Ornamentation - Front Door Stowage Compartment

Removal and Installation

Removal

Installation

1.

Remove door casing for access. Refer to 76.34.01.

2. Remove pocket from door casing.

1. Release puddle lamp harness from clips at base of door pocket.

2. Slacken and remove th e two screws securing

bottom of pocket to casing.

3. Remove two spring clips securing top of pocket to casing.

3. Lift pocket out of casing .

1. Position pocket in casing and secure with screws and spring

clips.

2. Position puddle lamp harn ess in pocket clips.

3. Fit door casing. Refer to 76.34.01.

Page 2219 of 2490

Instrument Panel and Console - Instrument Panel and Instrument Panel

Console

Description and Operation

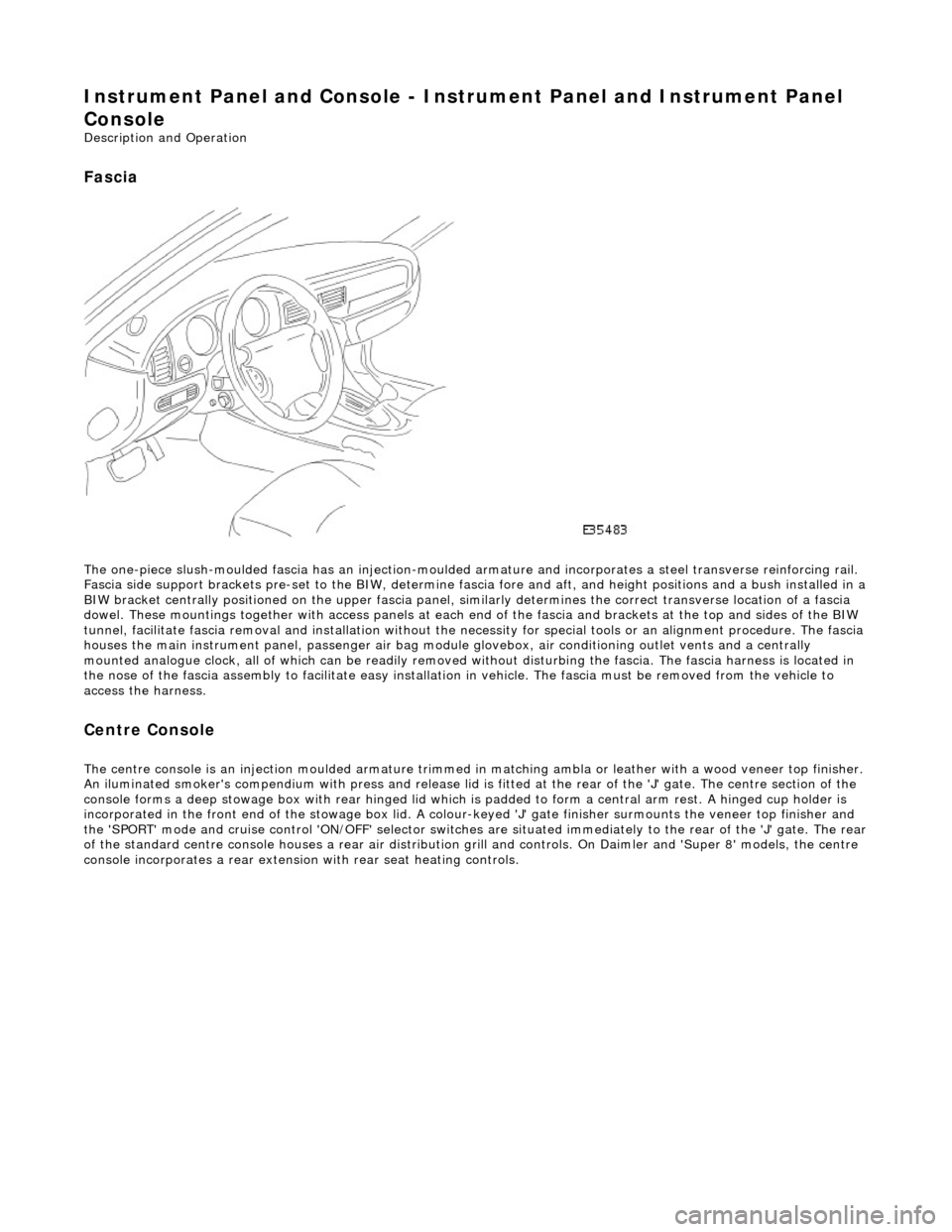

Fascia

The one-piece slush-moulded fascia has an injection-moulded ar mature and incorporates a steel transverse reinforcing rail.

Fascia side support brackets pre-set to th e BIW, determine fascia fore and aft, and height position s and a bush installed in a

BIW bracket centrally positioned on the upper fascia panel, similarly determines the correct transverse location of a fascia

dowel. These mountings together with access panels at each en d of the fascia and brackets at the top and sides of the BIW

tunnel, facilitate fascia removal and instal lation without the necessity for special tools or an alignment procedure. The fasci a

houses the main instrument panel, pass enger air bag module glovebox, air conditioning outlet vents and a centrally

mounted analogue clock, all of which can be readily removed wi thout disturbing the fascia. The fascia harness is located in

the nose of the fascia assembly to facilitate easy installati on in vehicle. The fascia must be removed from the vehicle to

access the harness.

Centre Console

The centre console is an injection moulded armature trimmed in matching ambla or leather with a wood veneer top finisher.

An iluminated smoker's compendium with pr ess and release lid is fitted at the rear of the 'J' gate. The centre section of the

console forms a deep stowage box with rear hinged lid which is padded to form a central arm rest. A hinged cup holder is

incorporated in the front end of the stowage box lid. A colour-keyed 'J' gate finisher surmounts the veneer top finisher and

the 'SPORT' mode and cruise control 'ON/OFF' selector switches are situated immediately to the rear of the 'J' gate. The rear

of the standard centre console houses a re ar air distribution grill and controls. On Daimler and 'Super 8' models, the centre

console incorporates a rear extensio n with rear seat heating controls.

Page 2223 of 2490

Instrument Panel and Console - Coin Stowage Compartment

Removal and Installation

Removal

Installation

1.

Slacken and remove screw securing driver stowage

compartment to fascia.

2. Withdraw stowage compartment from fascia and remove from

vehicle.

1. Position driver stowage compartment in fascia recess.

2. Install stowage compartment to fascia securing screw.

Page 2232 of 2490

Instrument Panel and Console - Floor Console Stowage Compartment

Removal and Installation

Removal

Installation

1.

Open console gl ove box lid.

2. Slacken and remove the glove box lid stay securing screw and

remove lid stay.

3. Slacken and remove glove box latch securing screws and

remove latch assembly.

4. Slacken and remove glovebox liner rear securing screws.

5. Remove glovebox liner from vehicle.

1. Position glovebox liner in console.

2. Fit and tighten liner rear securing screws.

3. Position latch assembly on line r and fit and tighten securing

screws.

4. Fit and tighten check arm to lid securing screw.

5. Position lid to stay and fit and tighten securing screw.

6. Close glovebox lid.

Page 2233 of 2490

Instrument Panel and Console - Floor Console Stowage Compartment Lid

Removal and Installation

Removal

1. Open glovebox lid.

2. Slacken and remove lid stay se curing screw and remove stay from lid.

3. Slacken and remove glovebox latch securing screws and

remove latch from glovebox.

4. Slacken and remove glovebox li ner rear securing screws and

remove liner for access.

5. Slacken and remove remaining gl ovebox hinge securing screw.

Page 2242 of 2490

Instrument Panel and Console - Instrument Panel

Removal and Installation

Removal

1. Turn ignition switch to position II.

2. Motor driver and front passenger seats rearward.

3. Position steering wheel in stra ight ahead position and fully

lower and extend steering column.

4. Turn ignition switch to position O.

5. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

6. Remove 'J' gate finish er. Refer to 76.25.24.

7. Remove 'J' gate finisher retain ing panel. Refer to 76.25.26.

8. Remove centre console veneer panel. Refer to 76.47.26.

9. Disconnect and remove radio.

10. Remove centre console switch module. Refer to 86.80.32.

11. Remove centre console. Refer to 76.25.01.

12. Slacken and remove centre cons ole vent duct rear securing

screw and withdraw duct assemb ly from air conditioning unit

manifold.

13. WARNING: BEFORE ANY AIRBAG/SRS SERVICE IS

PERFORMED, AT LEAST ONE MINUTE MUST ELAPSE AFTER

DISCONNECTION OF THE BATTERY CABLE, TO ALLOW

DISSIPATION OF BACK-UP POWER SUPPLY ENERGY.

Remove driver airbag. Refer to 76.73.39.

14. Remove steering wheel. Refer to Section 211-04.

15. Remove steering column lo wer cowl. Refer to 76.46.03.

16. Remove steering column u pper cowl. Refer to 76.46.02.

17. Remove driver side unders cuttle. Refer to 76.46.11.

18. Remove combined windshield wiper/washer switch and

audible warning speaker assembly. Refer to 86.65.42.

19. Remove glovebox. Refer to 76.52.03.

20. Remove 'A' post lower trim pads. refer to 76.13.30.

21. Carefully withdraw driver stowage bin trim, remove bin

securing screw and remove bin from facia.

Page 2243 of 2490

22. Accessing via driver stowage bin aperture, disconnect facia

harness to centre console harness multiplugs.

23. Release driver side facia harness to passenger compartment

harness multiplug retaining le ver and disconnect multiplug.

24. From RH side footwell, remove nut securing facia harness

ground eyelet to tunnel front stud and disconnect eyelet from

stud.

25. Remove steering column reac h adjustment motor harness

multiplug (yellow) from retain ing bracket and disconnect

multiplug.

Page 2263 of 2490

64.

Position driver stowage bin in facia, install securing screw and fully seat trim.

65. Install trim pad on driver si de lower 'A' post. Refer to

76.13.30.

66. Install driver side unders cuttle. Refer to 76.46.11.

67. Install combined windshield wi per/washer switch and audible

warning speaker assembly. Refer to 86.65.42.

68. Install steering column upper cowl. Refer to 76.46.02.

69. Install steering column lower cowl. Refer to 76.46.03.

70. Install steering wheel. Refer to 211-04.

71. Install driver side airbag. Refer to 76.73.39.

Page 2273 of 2490

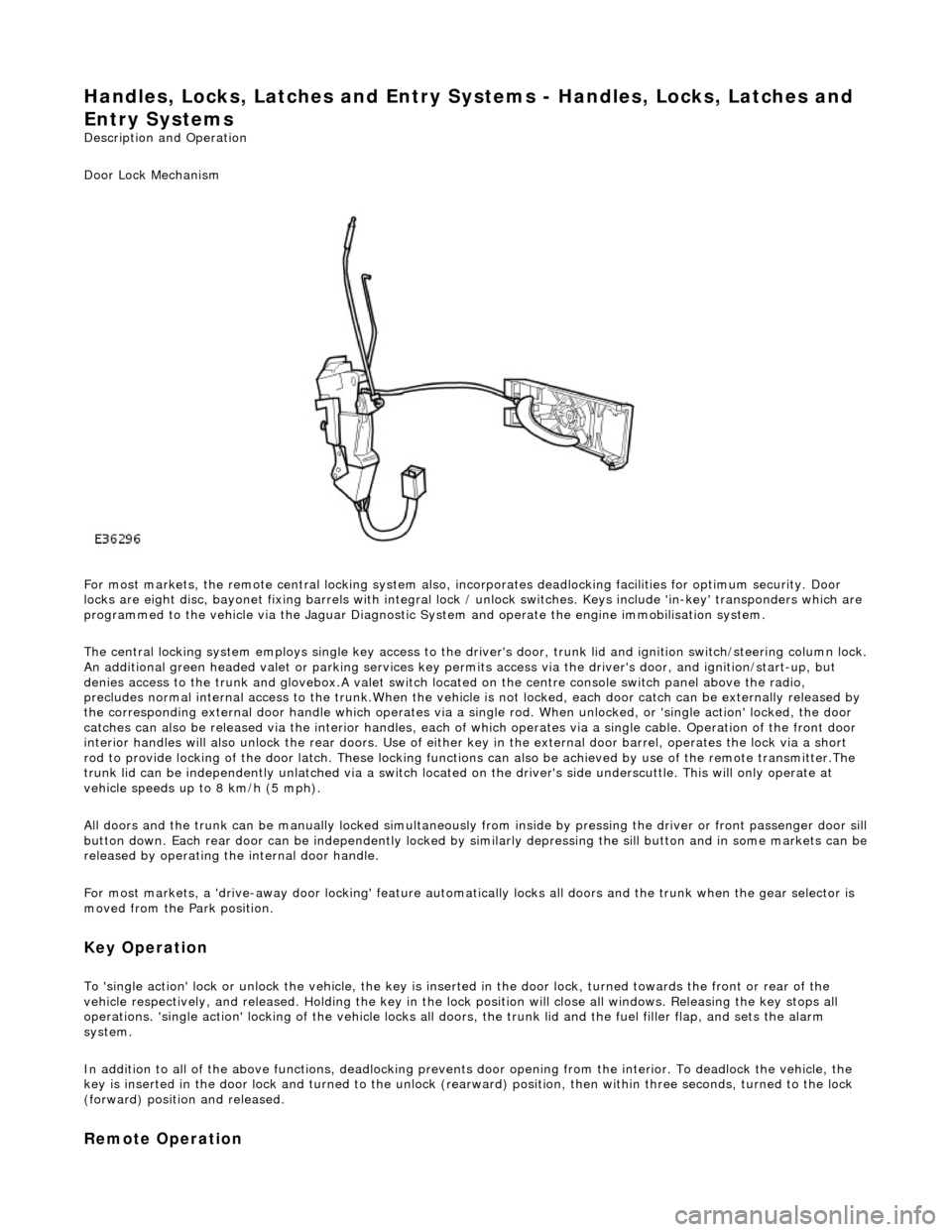

Handles, Locks, Latches and Entry Systems - Handles, Locks, Latches and

Entry Systems

Description and Operation

Door Lock Mechanism

For most markets, the remote central locking system also, in corporates deadlocking facilities for optimum security. Door

locks are eight disc, bayonet fixing barrels with integral lock / unlock switches. Keys include 'in-key' transponders which are

programmed to the vehicle via the Jaguar Diagnostic Sy stem and operate the engine immobilisation system.

The central locking system employs single key access to the driv er's door, trunk lid and ignition switch/steering column lock.

An additional green headed valet or park ing services key permits access via the driver's door, and ignition/start-up, but

denies access to the trunk and glovebox.A valet switch located on the centre console switch panel above the radio,

precludes normal internal access to the trunk.When the vehicle is not locked, each door catch can be externally released by

the corresponding external door handle which operates via a si ngle rod. When unlocked, or 'single action' locked, the door

catches can also be released via the interior handles, each of which operates via a single cable. Operation of the front door

interior handles will also unlock the rear doors. Use of either key in the external door barrel, operates the lock via a short

rod to provide locking of the door latch. These locking functions can also be achieved by use of the remote transmitter.The

trunk lid can be independently unlatched via a switch located on the driver's side underscuttle. This will only operate at

vehicle speeds up to 8 km/h (5 mph).

All doors and the trunk can be manually lock ed simultaneously from inside by pressing the driver or front passenger door sill

button down. Each rear door can be independently locked by si milarly depressing the sill button and in some markets can be released by operating the internal door handle.

For most markets, a 'drive-away door locking' feature automati cally locks all doors and the trunk when the gear selector is

moved from the Park position.

Key Operation

To 'single action' lock or unlock the vehicle, the key is inserted in the door lock , turned towards the front or rear of the

vehicle respectively, and released. Holding the key in the lock position will close all windows. Releasing the key stops all

operations. 'single action' locking of the vehicle locks all doors, the trunk lid and the fuel filler flap, and sets the alarm

system.

In addition to all of the above functions, deadlocking prevents door opening from th e interior. To deadlock the vehicle, the

key is inserted in the door lock and turned to the unlock (rearw ard) position, then within three seconds, turned to the lock

(forward) position and released.

Remote Operation