tow JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2274 of 2490

Remote Central Locking Transmitter Unit

A four-button transmitter unit provides for remote controlled central locking of the vehicle.

The button bearing a red closed padlock sy mbol locks the vehicle and arms the security system. To remote 'single action'

lock, the transmitter is pointed towards the vehicle and this bu tton is pressed and released. To deadlock the vehicle, the

above operation is repeated with in three seconds. This function can also be used to remote close any windows. Completion

of deadlocking is indicated by an audible 'chirp' from the security system and a single flash from the direction indicators.

The vehicle is unlocked and the security system disarmed by pressing the button with the open padlock symbol.

The trunk lock can also be remotely released by op erating the button bearing the trunk lid open symbol.

The button with dipped headlamp symbol is for emergency us e. When depressed three times within three seconds, it

switches the headlamps on for 25 seconds and operates the vehicle alarm 5 times.

Page 2329 of 2490

Roof Opening Panel - Motor Synchronization

General Procedures

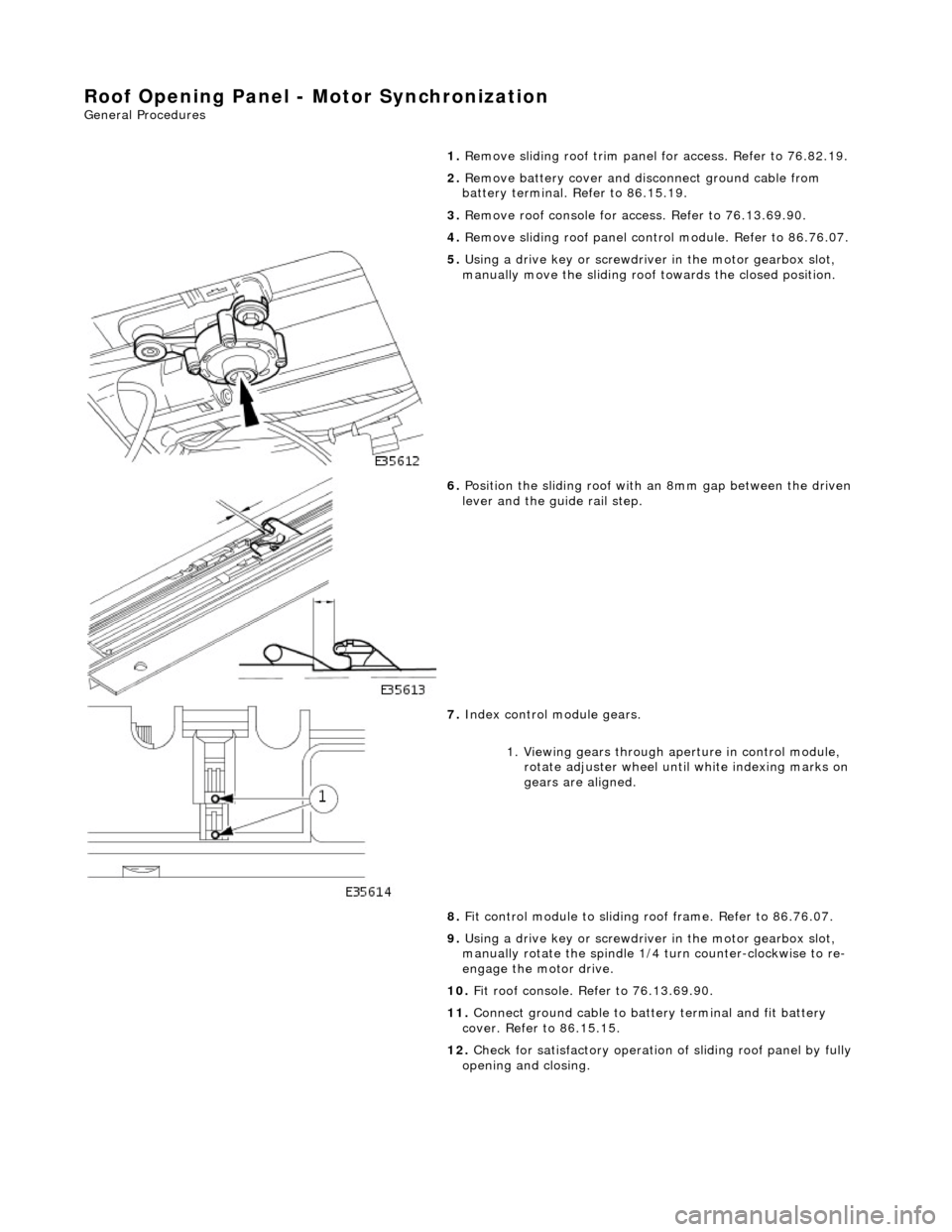

1.

Remove sliding roof trim panel for access. Refer to 76.82.19.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove roof console for ac cess. Refer to 76.13.69.90.

4. Remove sliding roof panel cont rol module. Refer to 86.76.07.

5. Using a drive key or screwdriver in the motor gearbox slot,

manually move the sliding roof towards the closed position.

6. Position the sliding roof with an 8mm gap between the driven

lever and the guide rail step.

7. Index control module gears.

1. Viewing gears through aperture in control module, rotate adjuster wheel until white indexing marks on

gears are aligned.

8. Fit control module to sliding r oof frame. Refer to 86.76.07.

9. Using a drive key or screwdriver in the motor gearbox slot,

manually rotate the spindle 1/4 turn counter-clockwise to re-

engage the motor drive.

10. Fit roof console. Refer to 76.13.69.90.

11. Connect ground cable to batt ery terminal and fit battery

cover. Refer to 86.15.15.

12. Check for satisfactory operation of sliding roof panel by fully

opening and closing.

Page 2335 of 2490

Roof Opening Panel - Roof Opening Panel Module

Removal and Installation

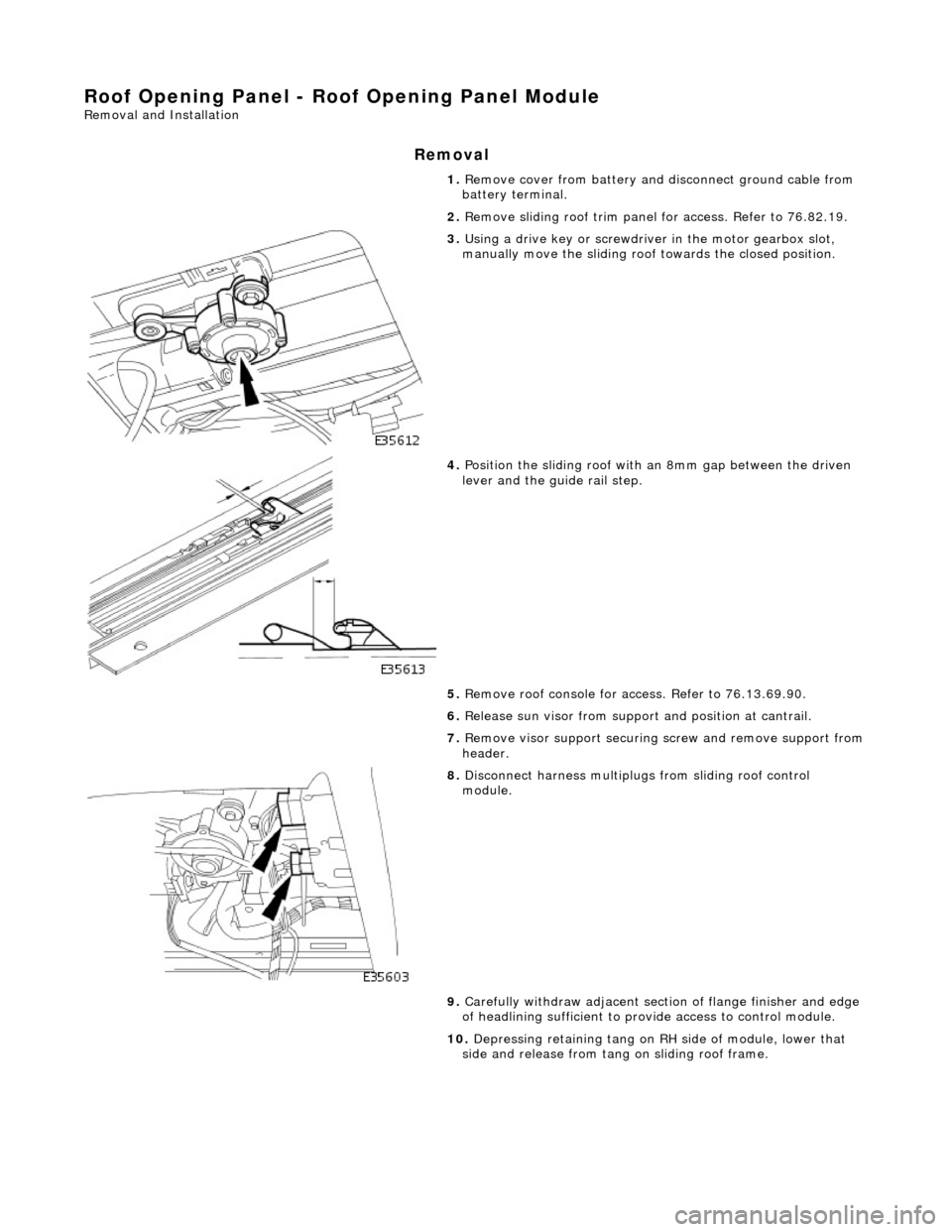

Removal

1. Remove cover from battery and disconnect ground cable from

battery terminal.

2. Remove sliding roof trim panel for access. Refer to 76.82.19.

3. Using a drive key or screwdriver in the motor gearbox slot,

manually move the sliding roof towards the closed position.

4. Position the sliding roof with an 8mm gap between the driven

lever and the guide rail step.

5. Remove roof console for ac cess. Refer to 76.13.69.90.

6. Release sun visor from support and position at cantrail.

7. Remove visor support securing screw and remove support from

header.

8. Disconnect harness multiplugs from sliding roof control

module.

9. Carefully withdraw adjacent sectio n of flange finisher and edge

of headlining sufficient to prov ide access to control module.

10. Depressing retaining tang on RH side of module, lower that

side and release from tang on sliding roof frame.

Page 2386 of 2490

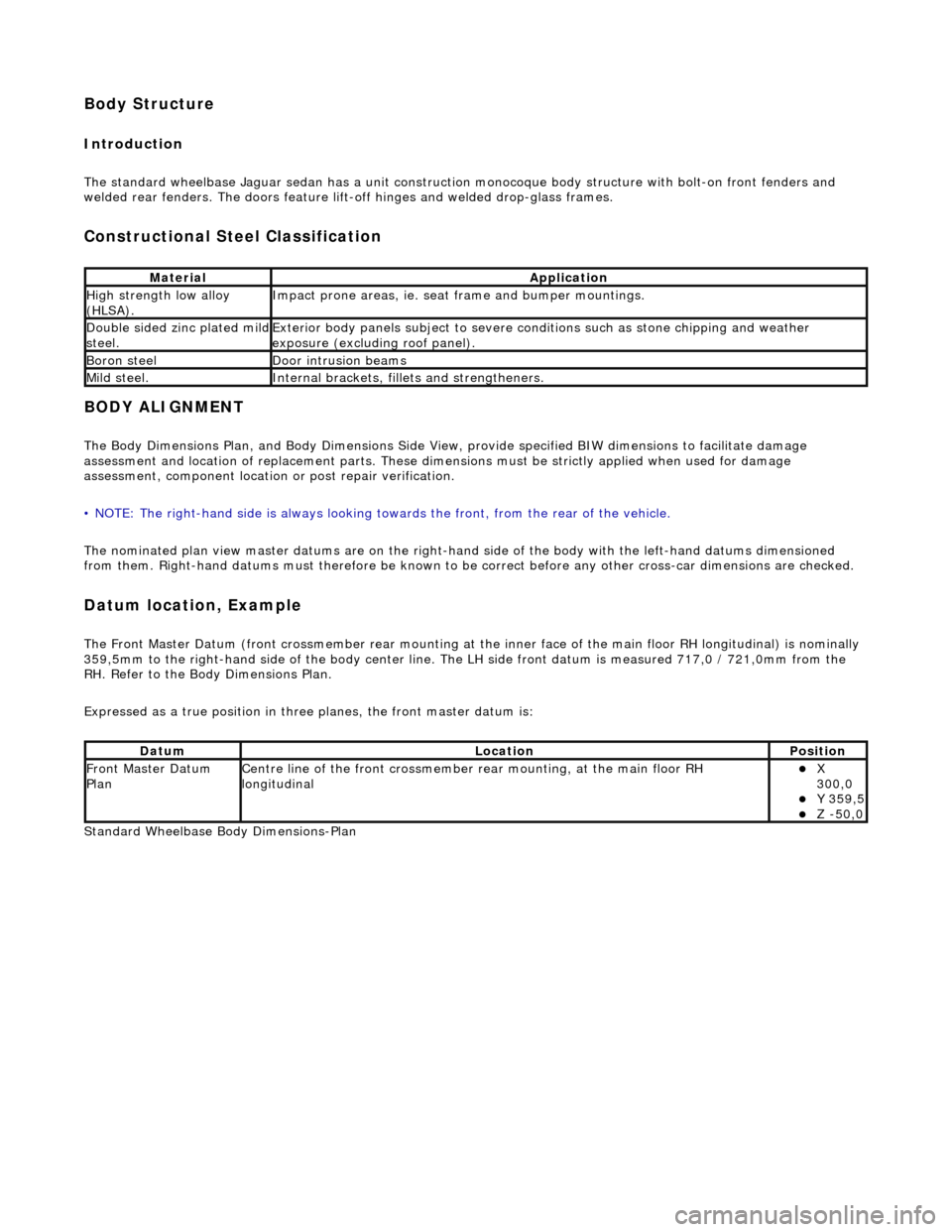

Body Structure

Introduction

The standard wheelbase Jaguar sedan has a unit construction monocoque body structure with bolt-on front fenders and

welded rear fenders. The doors feature lif t-off hinges and welded drop-glass frames.

Constructional Steel Classification

BODY ALIGNMENT

The Body Dimensions Plan, and Body Dimensions Side View, provide specified BIW dimensions to facilitate damage

assessment and location of replacemen t parts. These dimensions must be strictly applied when used for damage

assessment, component location or post repair verification.

• NOTE: The right-hand side is always looking towards the front, from the rear of the vehicle.

The nominated plan view master datums are on the right-hand side of the body with the left-hand datums dimensioned

from them. Right-hand datums must therefore be known to be correct before any other cross-car dimensions are checked.

Datum location, Example

The Front Master Datum (front crossmember rear mounting at the inner face of the main floor RH longitudinal) is nominally

359,5mm to the right-hand side of the body center line. The LH side fron t datum is measured 717,0 / 721,0mm from the

RH. Refer to the Body Dimensions Plan.

Expressed as a true posi tion in three planes, the front master datum is:

Standard Wheelbase Bo dy Dimensions-Plan

MaterialApplication

High strength low alloy

(HLSA).Impact prone areas, ie. seat frame and bumper mountings.

Double sided zinc plated mild steel.Exterior body panels subject to severe cond itions such as stone chipping and weather

exposure (excluding roof panel).

Boron steelDoor intrusion beams

Mild steel.Internal brackets, fill ets and strengtheners.

DatumLocationPosition

Front Master Datum

PlanCentre line of the front crossmember rear mounting, at the main floor RH

longitudinalпЃ¬X

300,0

пЃ¬Y 359,5 пЃ¬Z -50,0