lower JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 988 of 2490

Engine Cooling - Radiator Lower Hose4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the thermostat cover.

3. Re

move the two screws which se

cure the radiator grille and

remove the grille for access.

4. Re

lease and reposition the spring

clip, and disconnect the hose

from the charge air cooler radiator.

5. Di

sconnect the bottom hose from the radiator.

1. Slacken the hose retaining clip and reposition the clip

along the hose.

2. Disconnect the hose from the radiator.

6. Disconnect the radiator bottom hose from the thermostat cover

and air charge cooler.

1. Release and reposition th e hose clip, and disconnect

the bottom hose from th e thermostat cover.

2. Release and reposition the hose clips, and disconnect the two sections of moulded hose from the air charge

cooler.

Page 1070 of 2490

Starting System - Starter Motor

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Disc

onnect the batt

ery ground cable.

Re

move the battery cover.

3. Place the vehicle on a ramp.

4. Working from below the vehicle, remove the power steering

rack for access. Refer to Operation 57.10.01.

5. Disc

onnect the starter motor main terminal.

1. Reposition the rubber b oot from the main terminal.

2. Remove the nut from the starter motor main terminal.

3. Disconnect the main cable from the terminal.

6. Di

sconnect the starter motor solenoid terminal.

1. Reposition the rubber boot from the terminal.

2. Remove the nut from the solenoid terminal.

3. Disconnect the cable from the terminal.

7. Remove the starter mo tor securing bolts.

1. Remove the upper securing bolt. Preferably, use a short 13 mm spanner or a Snap On Half Moon

spanner CMX1113 to initially loosen the bolt. (Refer

to the next step).

2. Remove the lower securing bolt.

3. Carefully remove the starter motor.

Page 1071 of 2490

I

nstallation

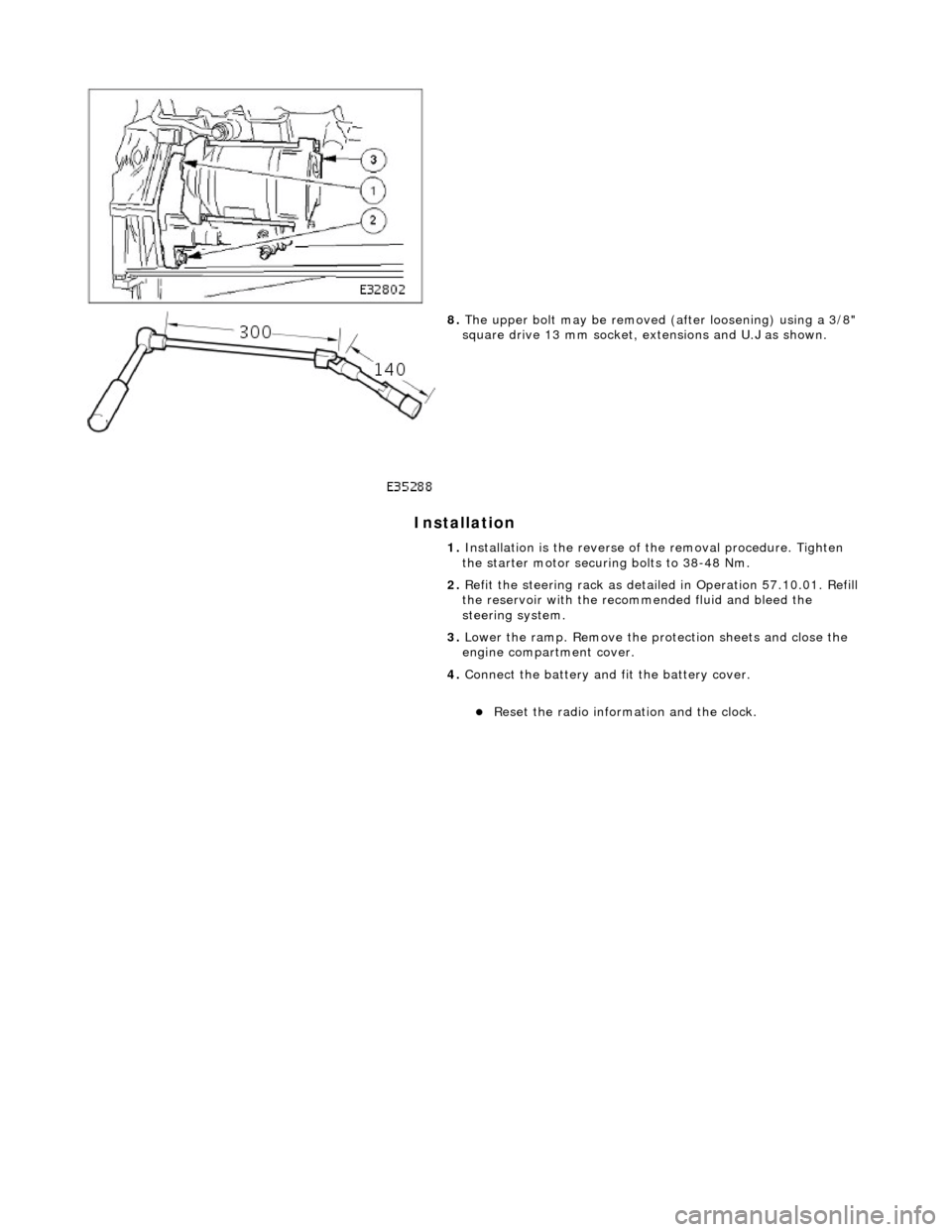

8.

The u

pper bolt may be removed (a

fter loosening) using a 3/8"

square drive 13 mm socket, ex tensions and U.J as shown.

1. Installation is the reverse of the removal procedure. Tighten

the starter motor securing bolts to 38-48 Nm.

2. Refit the steering rack as detail ed in Operation 57.10.01. Refill

the reservoir with the reco mmended fluid and bleed the

steering system.

3. Lower the ramp. Remove the protection sheets and close the

engine compartment cover.

4. Connect the battery and fit the battery cover.

R

eset the radio informat

ion and the clock.

Page 2

of 2

Page 1092 of 2490

Engine Ignition - Spark

Plugs

Re

mo

val and Installation

Remov

a

l

Installation

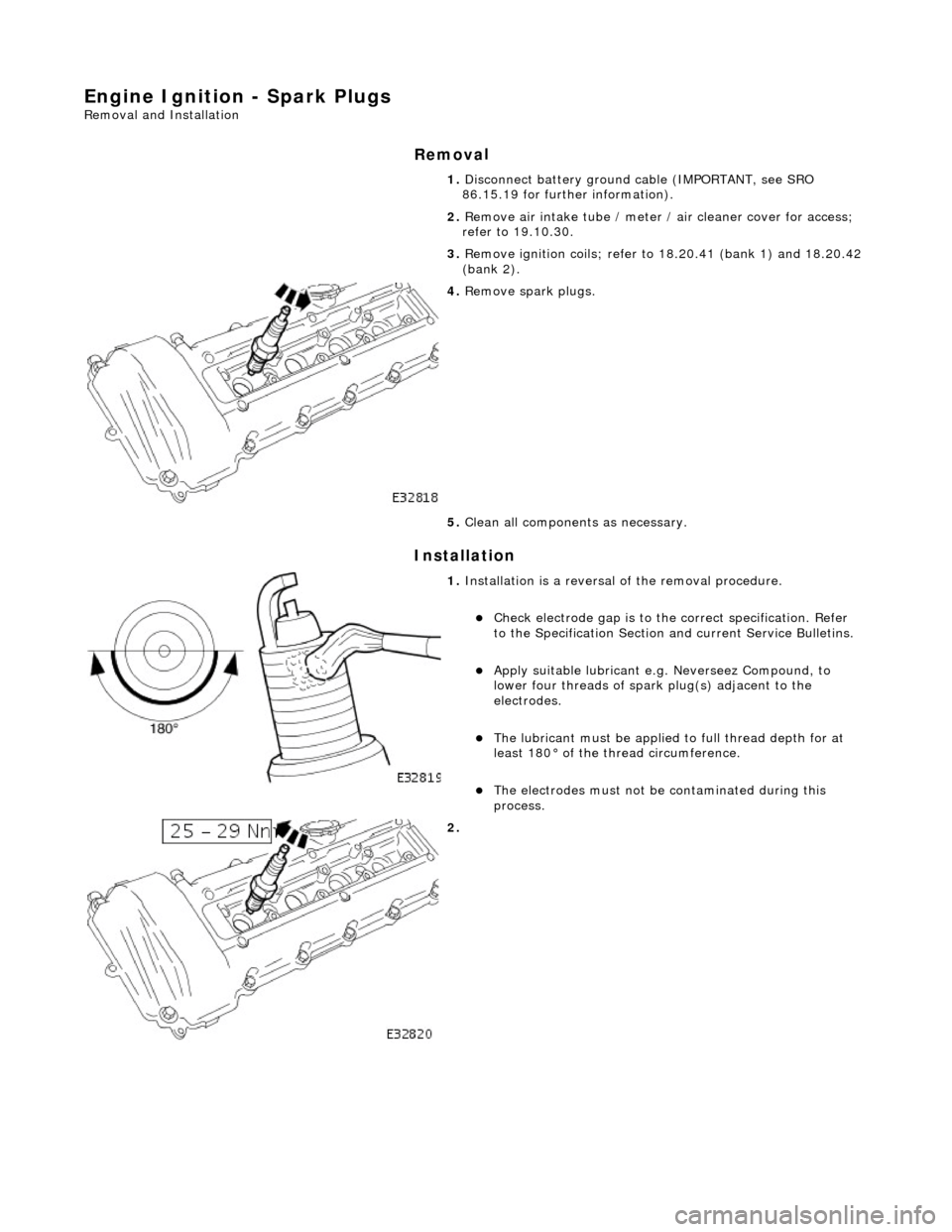

1.

Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Remove air intake tube / meter / air cleaner cover for access;

refer to 19.10.30.

3. Remove ignition coils; refer to 18.20.41 (bank 1) and 18.20.42

(bank 2).

4. Re

move spark plugs.

5. Clean all components as necessary.

1. Installation

is a reversal

of the removal procedure.

Check ele

ctrode gap is to the

correct specification. Refer

to the Specification Section and current Service Bulletins.

Apply su

itable lubricant e.

g. Neverseez Compound, to

lower four threads of spark plug(s) adjacent to the

electrodes.

The lubrican t must be applied

to full thread depth for at

least 180° of the thread circumference.

T h

e electrodes must not be

contaminated during this

process.

2.

Page 1117 of 2490

I

nstallation

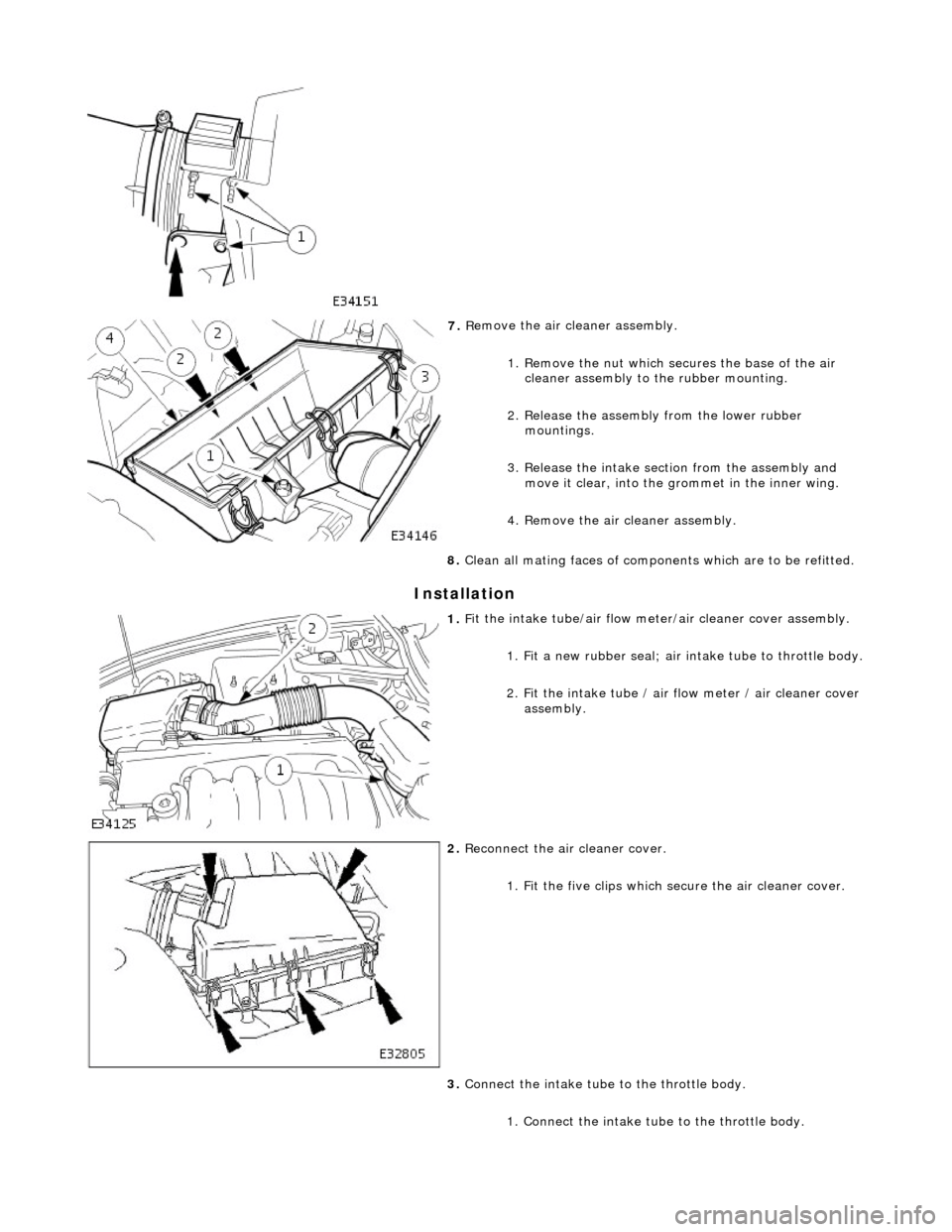

7.

R

emove the air cleaner assembly.

1. Remove the nut which se cures the base of the air

cleaner assembly to the rubber mounting.

2. Release the assembly from the lower rubber mountings.

3. Release the intake section from the assembly and move it clear, into the grommet in the inner wing.

4. Remove the air cleaner assembly.

8. Clean all mating faces of compon ents which are to be refitted.

1. F

it the intake tube/air flow meter/air cleaner cover assembly.

1. Fit a new rubber seal; air in take tube to throttle body.

2

. Fit the intake tube / air

flow meter / air cleaner cover

assembly.

2. R

econnect the air cleaner cover.

1. Fit the five clips which secure the air cleaner cover.

3. Connect the intake tube to the throttle body.

1. Connect the intake tube to the throttle body.

Page 1134 of 2490

Intake Air Distribution and Filtering - Thrott

le Body Elbow

Re

mo

val and Installation

Remov

a

l

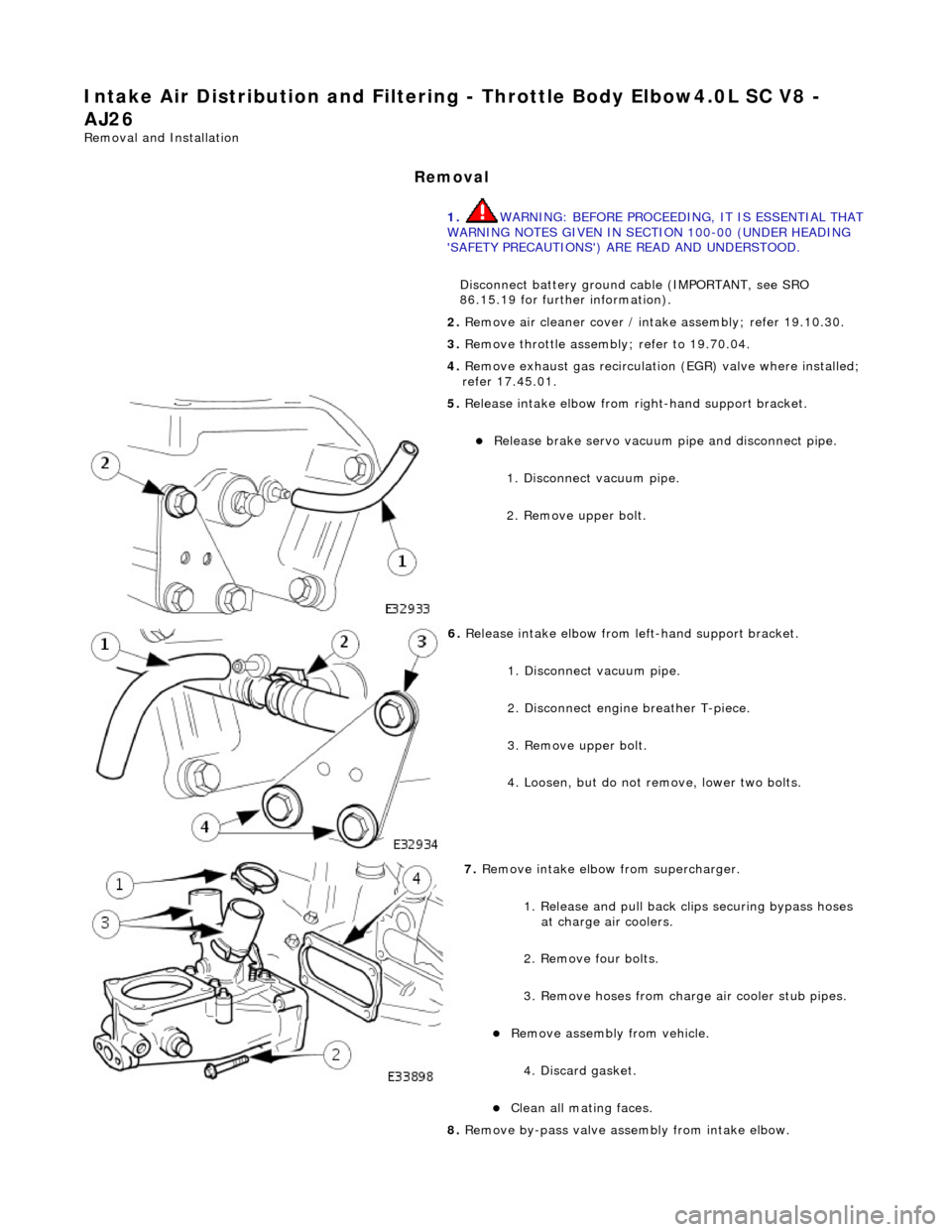

1.

WARNING: B E

FORE PROCEEDING, IT IS ESSENTIAL THAT

WARNING NOTES GIVEN IN SECTION 100-00 (UNDER HEADING

'SAFETY PRECAUTIONS') AR E READ AND UNDERSTOOD.

Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Re

move air cleaner cover / inta

ke assembly; refer 19.10.30.

3. Remove throttle assemb ly; refer to 19.70.04.

4. Remove exhaust gas recirculation (EGR) valve where installed;

refer 17.45.01.

5. Re

lease intake elbow from right-hand support bracket.

Re

lea

se brake servo vacuum pi

pe and disconnect pipe.

1. Disconnect vacuum pipe.

2. Remove upper bolt.

6. Relea

se intake elbow from le

ft-hand support bracket.

1. Disconnect vacuum pipe.

2. Disconnect engine breather T-piece.

3. Remove upper bolt.

4. Loosen, but do not remove, lower two bolts.

7. Re

move intake elbow from supercharger.

1. Release and pull back cl ips securing bypass hoses

at charge air coolers.

2. Remove four bolts.

3. Remove hoses from charge air cooler stub pipes.

Re move as

sembly from vehicle.

4. Discard gasket.

Cle a

n all mating faces.

8. Remove by-pass valve assembly from intake elbow.

Page 1142 of 2490

Intake Air Distribution and Filtering - Throttle B

ody Elbow4.0L SC V8 -

AJ26

Re mo

val and Installation

Remova

l

1.

WARNING: BE

FORE PROCEEDING, IT IS ESSENTIAL THAT

WARNING NOTES GIVEN IN SECTION 100-00 (UNDER HEADING

'SAFETY PRECAUTIONS') AR E READ AND UNDERSTOOD.

Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Re

move air cleaner cover / inta

ke assembly; refer 19.10.30.

3. Remove throttle assemb ly; refer to 19.70.04.

4. Remove exhaust gas recirculation (EGR) valve where installed;

refer 17.45.01.

5. Re

lease intake elbow from right-hand support bracket.

Re

lea

se brake servo vacuum pi

pe and disconnect pipe.

1. Disconnect vacuum pipe.

2. Remove upper bolt.

6. Relea

se intake elbow from le

ft-hand support bracket.

1. Disconnect vacuum pipe.

2. Disconnect engine breather T-piece.

3. Remove upper bolt.

4. Loosen, but do not remove, lower two bolts.

7. Re

move intake elbow from supercharger.

1. Release and pull back cl ips securing bypass hoses

at charge air coolers.

2. Remove four bolts.

3. Remove hoses from charge air cooler stub pipes.

Re move as

sembly from vehicle.

4. Discard gasket.

Cle a

n all mating faces.

8. Remove by-pass valve assembly from intake elbow.

Page 1157 of 2490

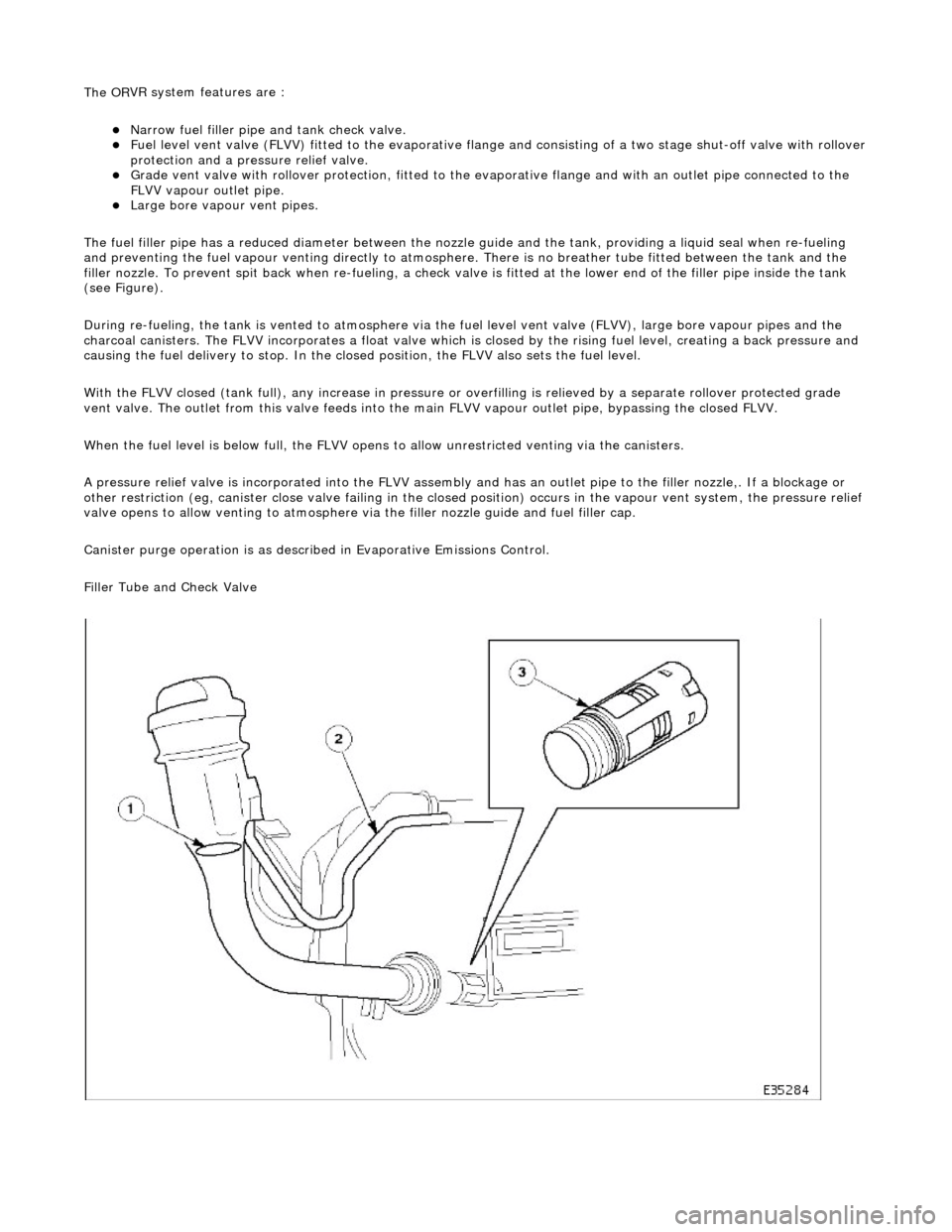

The OR

VR system features are :

N

arrow fuel filler pipe and tank check valve.

Fue

l level vent valve (FLVV) fitted to the evaporative flan

ge and consisting of a two stage shut-off valve with rollover

protection and a pressure relief valve.

Grade ven

t valve with rollover protection, fitted to the ev

aporative flange and with an outlet pipe connected to the

FLVV vapour outlet pipe.

Large bore vapour vent pipes.

The fuel filler pipe has a reduced diameter between the nozzle guide and the tank, providing a liquid seal when re-fueling

and preventing the fuel vapour venting directly to atmosphere. There is no breather tube fitted between the tank and the

filler nozzle. To prevent spit back when re-fueling, a check valv e is fitted at the lower end of the filler pipe inside the tank

(see Figure).

During re-fueling, the tank is vented to atmosphere via the fuel level vent valv e (FLVV), large bore vapour pipes and the

charcoal canisters. The FLVV incorp orates a float valve which is closed by the rising fuel level, creating a back pressure and

causing the fuel delivery to stop. In the closed position, the FLVV also sets the fuel level.

With the FLVV closed (tank full), any increase in pressure or overfilling is relieved by a separate rollover protected grade

vent valve. The outlet from this valve feeds into the main FLVV vapour outlet pipe, bypassing the closed FLVV.

When the fuel level is below full, the FLVV opens to allow unrestricted venting via the canisters.

A pressure relief valve is incorp orated into the FLVV assembly and has an outlet pipe to the filler nozzle,. If a blockage or

other restriction (eg, canister close valve failing in the closed position) occurs in the vapour vent system, the pressure reli ef

valve opens to allow venting to atmosphere via the filler nozzle guide and fuel filler cap.

Canister purge operation is as described in Evaporative Emissions Control.

Filler Tube and Check Valve

Page 1169 of 2490

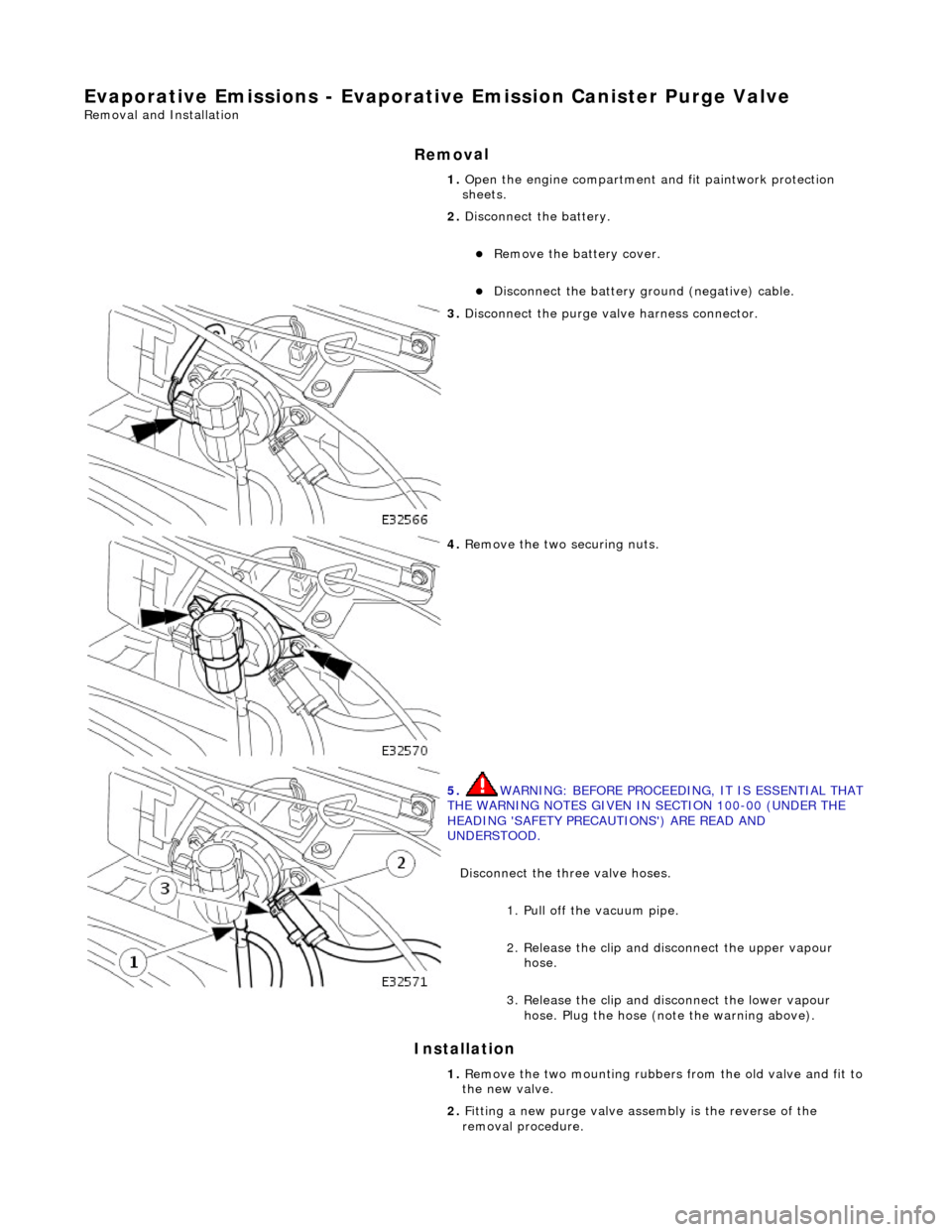

Evaporative Emissions - Evaporative Emission Canister Purg

e Valve

Re

moval and Installation

Remov

al

Installation

1. O

pen the engine compartment and fit paintwork protection

sheets.

2. Disconnect the battery.

R

emove the battery cover.

Di

sconnect the battery ground (negative) cable.

3. Di

sconnect the purge valve harness connector.

4. R

emove the two securing nuts.

5. WARNING: B

EFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Disconnect the three valve hoses.

1. Pull off the vacuum pipe.

2. Release the clip and di sconnect the upper vapour

hose.

3. Release the clip and disconnect the lower vapour hose. Plug the hose (note the warning above).

1. R

emove the two mounting rubbers from the old valve and fit to

the new valve.

2. Fitting a new purge valve asse mbly is the reverse of the

removal procedure.

Page 1201 of 2490

leak

/blockage

EVAP valve failure

P0444Evaporati

ve emissions system

(EVAP) valve circuit open circuit

EVAP t

o ECM drive circuit open

circuit or high resistance

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0445Evaporati

ve emissions system

(EVAP) valve circuit short circuit

E

VAP to ECM drive circuit short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0447Cani

ster close valve (CCV) circuit

open circuit

CCV to ECM

drive circuit open

circuit, high resi stance or short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0448Cani

ster close valve (CCV) circuit

short circuit

CCV to

ECM drive circuit short

circuit to high voltage

CCV failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0452F

uel tank pressure (FTP) sensor

circuit low voltage

FTP

sensor disconnected

FTP

sensor to ECM sense circuit

open circuit or short circuit to

ground

FTP sen

sor to ECM power supply

circuit open circuit or short circuit

to ground

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0453F

uel tank pressure (FTP) sensor

circuit high voltage

FTP

sensor to ECM signal ground

circuit open circuit

F

TP sensor to ECM wiring (supply,

sense, signal, ground) short circuit

to each other

FTP

sensor to ECM sense circuit

short circuit to high voltage

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0460Fue

l level sense signal

performance

Fue

l level sensor

to instrument

cluster circuits in termittent short or

open circuit

F

uel level sensor failure

Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0506Idl

e rpm lower than expected

Ai

r intake blockage

Acce

ssory drive overload

(defective/siezed component)

Thr

ottle valve stuck closed

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check t

he accessory drive

components,

REFER to Section 303

-0

5 Accessory

Dr

ive

.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0507Idle rpm

higher than expected

Inta

ke air leak between MAF

sensor and throttle

Inta

ke air leak between throttle

and engine

Engine

breather leak

Cruis

e (speed) control vacuum

failure

Thr

ottle valve stuck open

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Chec

k the engine breather system,

REFER to Section 303

-08

Engine

Emissi

on Control

.

F

or cruise (speed) control information,

REFER to Section 310

-03

Speed

Control.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0560Vehicle voltage

malfunction

ECM battery

power supply open

circuit, high resistance

F

or ECM power supply circuit tests,

GO to Pinpoint Test AD.

.

P0566Cruise (speed) contr

ol

CANCEL

switch ON fault

Cru

ise (speed) control switches

internal steering wheel short circuit

to ground

For cru

ise (speed) control circuit tests,

REFER to Section 310

-03

Speed