Engine system - general JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 979 of 2490

16

.

Refill the cooling system. Refer to the Refill procedure in

General Procedures.

17. Repressurise the climate cont rol system. Refer to Section

412-03 Observe all safety warnin gs and precautions stated in

that section.

18. Close the engine compartment cover.

19. Connect the battery and fit the battery cover. Reset the clock

and the radio.

Page 986 of 2490

16

. Re

fill the cooling system. Refer to the Refill procedure in

General Procedures.

17. Repressurise the climate cont rol system. Refer to Section

412-03 Observe all safety warnin gs and precautions stated in

that section.

18. Close the engine compartment cover.

19. Connect the battery and fit the battery cover. Reset the clock

and the radio.

Page 987 of 2490

Engine Cooling - Radiator Lo

wer Hose4.0L NA V8

- AJ27/3.2L NA V8 -

AJ26

Re

moval and Installation

Remov

al

Installation

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the thermostat cover.

3. Di

sconnect the radiator bott

om hose from the thermostat

cover.

1. Release and reposition th e hose clip, and disconnect

the bottom hose.

4. D

isconnect the bottom hose from the radiator.

1. Slacken the hose retaining clip and reposition the clip

along the hose.

2. Disconnect the hose from the radiator.

5. Remove the spring band clips from the hose.

1. Installation is th e reverse of the re moval procedure.

2. Refill the cooling system as de scribed in General Procedures.

Page 990 of 2490

Engine Cooling - Radiator Upper Hose4.0L NA V8 - AJ27/3.2L NA V8 -

AJ26

Re mo

val and Installation

Remova

l

Installation

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the hose.

3. Disc

onnect the top hose from the coolant outlet pipe.

1. Release and reposition th e hose clip, and disconnect

the top hose.

4. R

e

lease the top hose from the radiator.

1. Release the hose retaining clip and reposition the clip along the hose.

2. Disconnect the hose from the radiator.

пЃ¬Re move t

he hose clips from the top hose.

1. Installation is th e reverse of the re moval procedure.

2. Refill the cooling system as de scribed in General Procedures.

Page 991 of 2490

Engine Cooling - Radiator Upper Hose4.0L SC V8 - AJ26

Re

moval and Installation

Remov

al

Installation

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the hose.

3. Di

sconnect the top hose from the coolant outlet pipe.

1. Release and reposition th e hose clip, and disconnect

the top hose.

4. R

elease the top hose from the radiator.

1. Release the hose retaining clip and reposition the clip along the hose.

2. Disconnect the hose from the radiator.

пЃ¬Re

move the hose clips from the top hose.

1. Installation is th e reverse of the re moval procedure.

2. Refill the cooling system as de scribed in General Procedures.

Page 994 of 2490

Engine Cooling - Thermostat4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

Installation

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the outlet pipe.

3. Disc

onnect the bottom hose

from the coolant outlet pipe.

1. Release and reposi tion the hose clip.

2. Disconnect the bottom hose.

4. Re

move the thermostat from the outlet pipe.

1. Remove the three bolts which secure the thermostat cover to the outlet pipe.

2. Remove the thermostat cover, the thermostat and

the seal from the outlet pipe. Discard the seal.

1. Installation is th e reverse of the re moval procedure.

пЃ¬Use new seali

ng rings on th

e coolant outlet pipe and

thermostat housing.

пЃ¬The t he

rmostat ball valve must

locate in the recess in the

cover.

2. Tighten the thermostat cover bolts to 8-10 Nm.

3. Refill the cooling system as de scribed in General Procedures.

Page 997 of 2490

Engine Cooling - Thermostat Housing Cover4.

0L SC V8 - AJ26

Re

moval and Installation

Remov

al

Installation

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the outlet pipe.

3. Di

sconnect the bottom hose

from the coolant outlet pipe.

1. Release and reposi tion the hose clip.

2. Disconnect the bottom hose.

4. R

emove the thermostat from the outlet pipe.

1. Remove the three bolts which secure the thermostat cover to the outlet pipe.

2. Remove the thermostat cover, the thermostat and

the seal from the outlet pipe. Discard the seal.

1. Installation is th e reverse of the re moval procedure.

пЃ¬Use new

sealing rings on th

e coolant outlet pipe and

thermostat housing.

пЃ¬The t

hermostat ball valve must

locate in the recess in the

cover.

2. Tighten the thermostat cover bolts to 8-10 Nm.

3. Refill the cooling system as de scribed in General Procedures.

Page 1000 of 2490

Engine Cooli

ng - Thermostat Housin

g Cover Seal4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

Installation

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the outlet pipe.

3. Disc

onnect the bottom hose

from the coolant outlet pipe.

1. Release and reposi tion the hose clip.

2. Disconnect the bottom hose.

4. Re

move the thermostat from the outlet pipe.

1. Remove the three bolts which secure the thermostat cover to the outlet pipe.

2. Remove the thermostat cover, the thermostat and

the seal from the outlet pipe. Discard the seal.

1. Installation is th e reverse of the re moval procedure.

пЃ¬Use new seali

ng rings on th

e coolant outlet pipe and

thermostat housing.

пЃ¬The t he

rmostat ball valve must

locate in the recess in the

cover.

2. Tighten the thermostat cover bolts to 8-10 Nm.

3. Refill the cooling system as de scribed in General Procedures.

Page 1026 of 2490

REFE

R to Section 310

-00

Fu

el

Sy

ste

m

- General

Information

.

Check f o

r DTCs indicating a sensor

fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

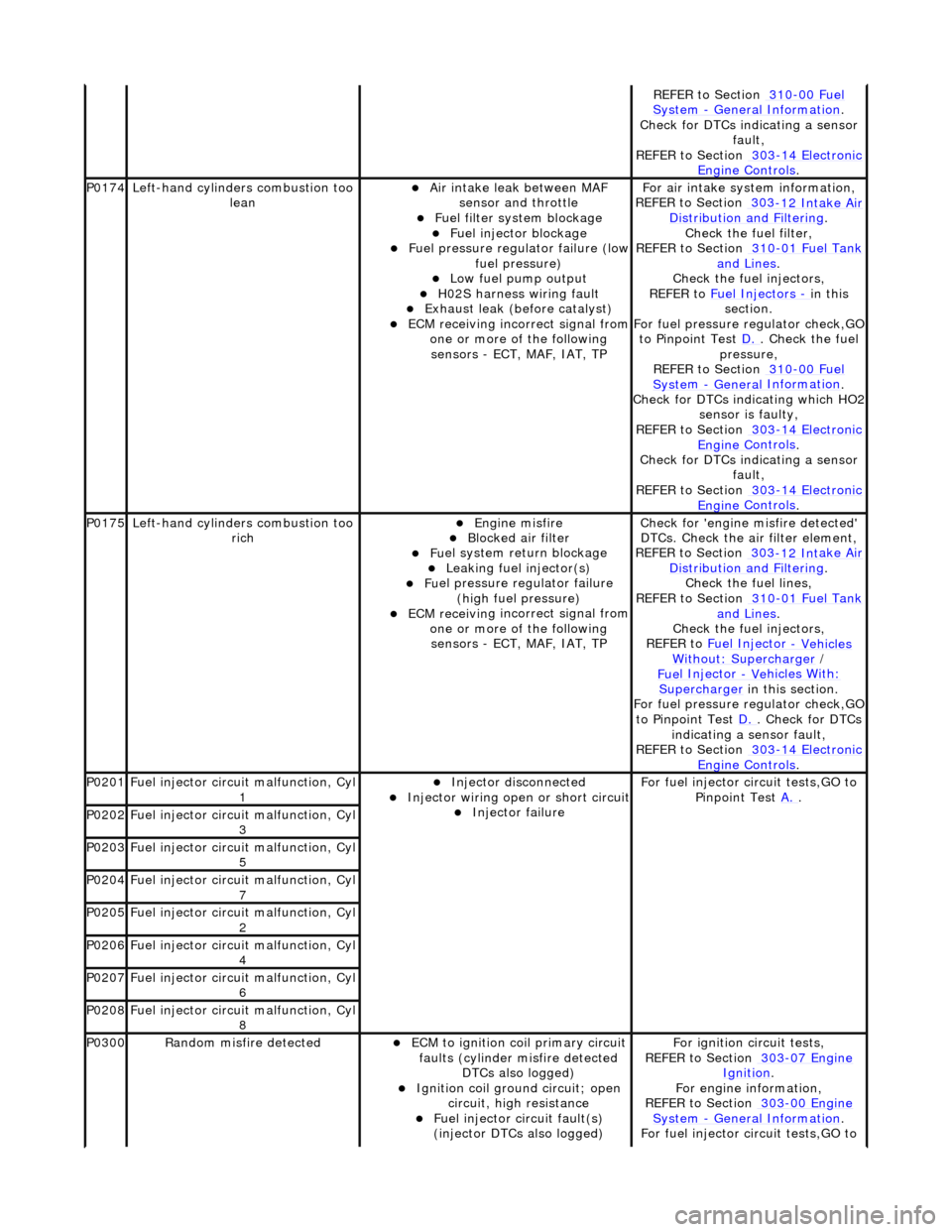

P0174

Left-hand cyl i

nders combustion too

lean

пЃ¬Air in

take leak between MAF

sensor and throttle

пЃ¬F u

el filter system blockage

пЃ¬F

u

el injector blockage

пЃ¬F

u

el pressure regulator failure (low

fuel pressure)

пЃ¬Low f u

el pump output

пЃ¬H0

2S harness wiri

ng fault

пЃ¬E

x

haust leak (before catalyst)

пЃ¬ECM receivi

n

g incorrect signal from

one or more of the following sensors - ECT, MAF, IAT, TP

F o

r air intake sy

stem information,

REFER to Section 303

-12 Int

ake Air

Distribu tion and Filterin

g

.

Check the fuel fi lter,

REF

ER to Section 310

-01

Fu

el Tank

and Lines.

Chec k the

fuel injectors,

REFER to Fuel Injectors

- in t h

is

section.

For fuel pressure regulator check,GO

to Pinpoint Test D.

. Ch

eck the fuel

pressure,

REFER to Section 310

-00 Fu

el

Sy

ste

m

- General

Information

.

Check f o

r DTCs indicating which HO2

sensor is faulty,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

Check f o

r DTCs indicating a sensor

fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

P0175Left-hand cyli

nders combustion too

rich

пЃ¬Engine m

isfire

пЃ¬Bl

ocked air

filter

пЃ¬F

u

el system return blockage

пЃ¬Leak

i

ng fuel injector(s)

пЃ¬F

u

el pressure regulator failure

(high fuel pressure)

пЃ¬ECM receivi n

g incorrect signal from

one or more of the following sensors - ECT, MAF, IAT, TP

Check for 'en

gine misfire detected'

DTCs. Check the air filter element,

REFER to Section 303

-12 Int

ake Air

Distribu tion and Filterin

g

.

Chec k the

fuel lines,

REFER to Section 310

-01 Fu

el Tank

and Lines.

Chec k the

fuel injectors,

REFER to Fuel Injector

- Vehicles Wi

thout: Supercharger

/

Fue

l Injector

- Ve

hicles With

:

Supercharger

in this

section.

For fuel pressure regulator check,GO

to Pinpoint Test D.

. Check for DT

Cs

indicating a sensor fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

P0201F

u

el injector circuit malfunction, Cyl

1

пЃ¬Injector discon n

ected

пЃ¬Inject

or wir

ing open or short circuit

пЃ¬Injector fail

ure

F

o

r fuel injector circuit tests,GO to

Pinpoint Test A.

.

P0202Fu

el injector circuit malfunction, Cyl

3

P0203F u

el injector circuit malfunction, Cyl

5

P0204F u

el injector circuit malfunction, Cyl

7

P0205Fu

el injector circuit malfunction, Cyl

2

P0206Fu

el injector circuit malfunction, Cyl

4

P0207F u

el injector circuit malfunction, Cyl

6

P0208F u

el injector circuit malfunction, Cyl

8

P0300Ran d

om misfire detected

пЃ¬ECM t

o

ignition coil primary circuit

faults (cylinder misfire detected DTCs also logged)

пЃ¬Ignition coil ground circuit; open

ci

rcuit, high resistance

пЃ¬F

u

el injector circuit fault(s)

(injector DTCs also logged)

F o

r ignition circuit tests,

REFER to Section 303

-07 En

gine

Ignition.

F or engi

ne information,

REFER to Section 303

-00 En

gine

Sy

ste

m

- General

Information

.

F o

r fuel injector circuit tests,GO to

Page 1027 of 2490

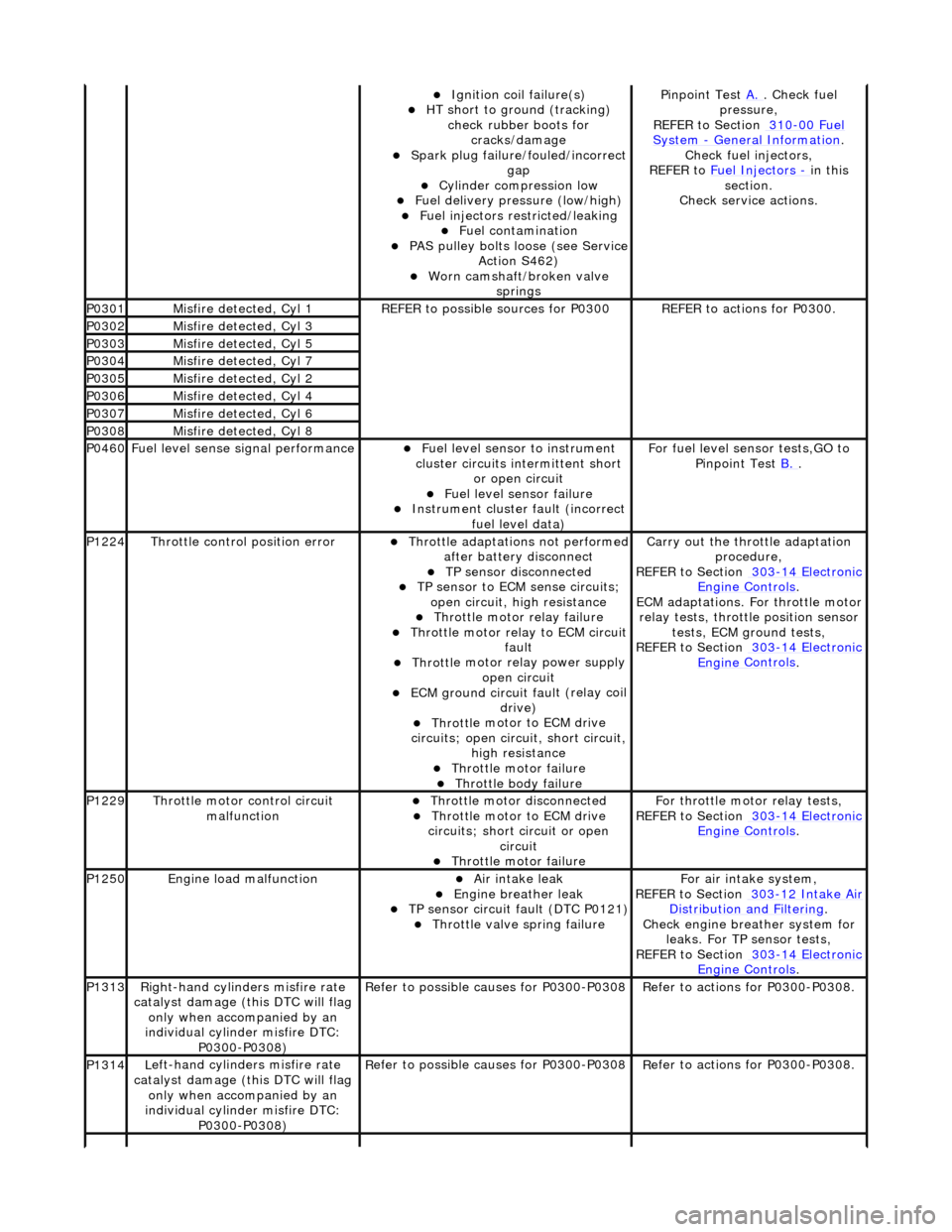

пЃ¬Ignition coil

failure(s)

пЃ¬HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

пЃ¬Spark plug

failure/fouled/incorrect

gap

пЃ¬Cy

linder compression low

пЃ¬F

uel delivery pressure (low/high)

пЃ¬F

uel injectors restricted/leaking

пЃ¬Fuel contamination

пЃ¬P

AS pulley bolts loose (see Service

Action S462)

пЃ¬W

orn camshaft/broken valve

springs

P

inpoint Test

A.

.

Check fuel

pressure,

REFER to Section 310

-00

Fuel

Sy

stem

- General

Information

.

Chec

k fuel injectors,

REFER to Fuel Injectors

- in t

his

section.

Check service actions.

P0301Misfire

detected, Cyl 1

R

EFER to possible sources for P0300

R

EFER to actions for P0300.

P0302Misfire

detected, Cyl 3

P0303Misfire

detected, Cyl 5

P0304Misfire

detected, Cyl 7

P0305Misfire

detected, Cyl 2

P0306Misfire

detected, Cyl 4

P0307Misfire

detected, Cyl 6

P0308Misfire

detected, Cyl 8

P0460F

uel level sense signal performance

пЃ¬Fue

l level sensor

to instrument

cluster circuits in termittent short

or open circuit

пЃ¬F

uel level sensor failure

пЃ¬Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor tests,GO to

Pinpoint Test B.

.

P1224Throttl

e control position error

пЃ¬Thro

ttle adaptations not performed

after battery disconnect

пЃ¬TP se

nsor disconnected

пЃ¬TP se

nsor to ECM sense circuits;

open circuit, hi gh resistance

пЃ¬Throttl

e motor relay failure

пЃ¬Th

rottle motor relay to ECM circuit

fault

пЃ¬Throttl

e motor relay power supply

open circuit

пЃ¬ECM ground circuit faul

t (relay coil

drive)

пЃ¬Throttl

e motor to ECM drive

circuits; open circuit, short circuit, high resistance

пЃ¬Throttl

e motor failure

пЃ¬Throttl

e body failure

Carry

out the throttle adaptation

procedure,

REFER to Section 303

-14

Electronic

Engine

Controls

.

ECM adaptations. For

throttle motor

relay tests, throttle position sensor tests, ECM ground tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1229Throttl

e motor control circuit

malfunction

пЃ¬Throttl

e motor disconnected

пЃ¬Throttl

e motor to ECM drive

circuits; short circuit or open circuit

пЃ¬Throttl

e motor failure

Fo

r throttle moto

r relay tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1250Engine

load malfunction

пЃ¬Air

intake leak

пЃ¬Engine

breather leak

пЃ¬TP se

nsor circuit fault (DTC P0121)

пЃ¬Throttl

e valve spring failure

F

or air intake system,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

Chec

k engine breather system for

leaks. For TP sensor tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1313Right-hand cylinders misfire rate

cat

alyst damage (this DTC will flag

only when accompanied by an

individual cylinder misfire DTC: P0300-P0308)

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

P1314L

eft-hand cylinders misfire rate

catalyst damage (this DTC will flag only when accompanied by an

individual cylinder misfire DTC: P0300-P0308)

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.