Windshield JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2179 of 2490

Glass, Frames and Mechanisms - Glass, Frames and Mechanisms

Description and Operation

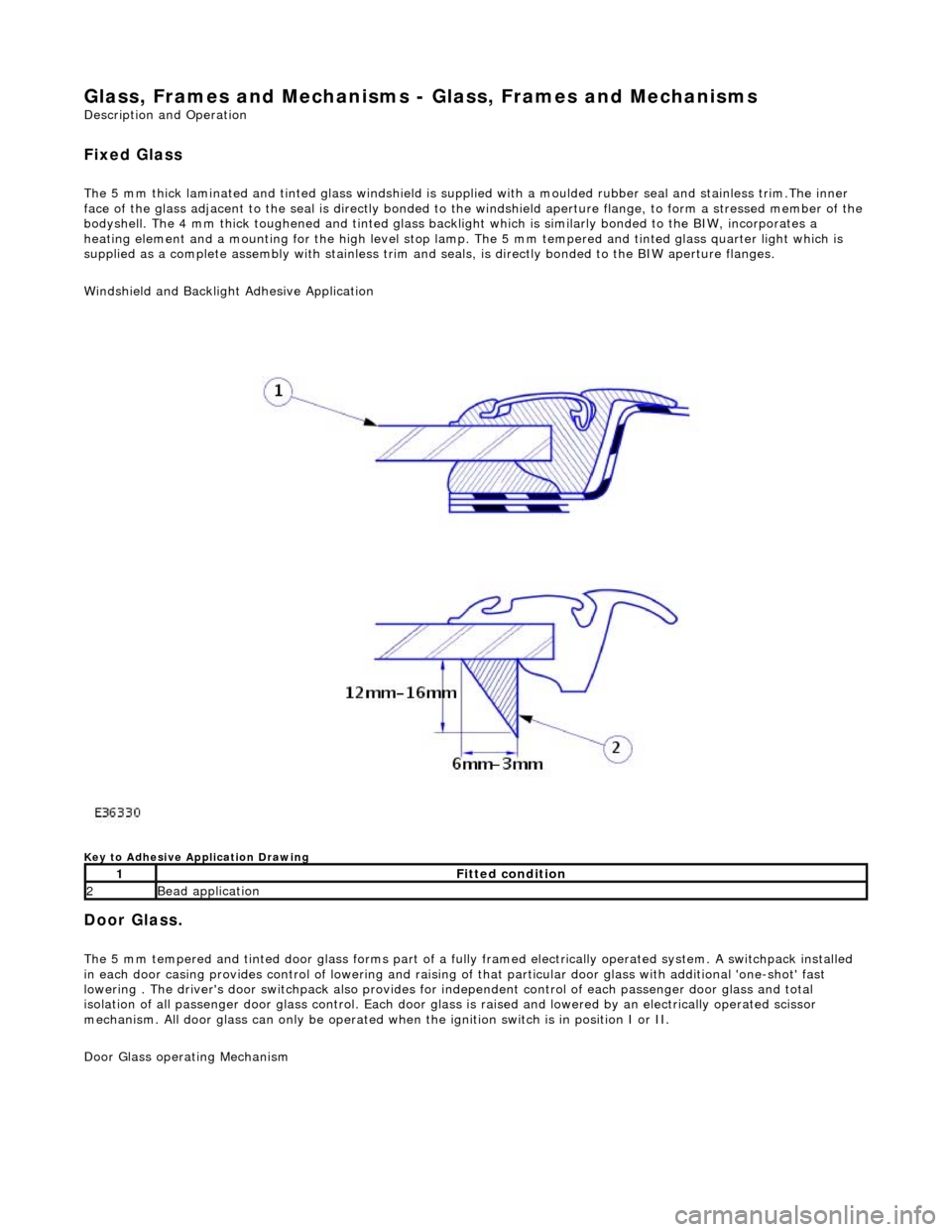

Fixed Glass

The 5 mm thick laminated and tinted glas s windshield is supplied with a moulded rubber seal and stainless trim.The inner

face of the glass adjacent to the seal is directly bonded to the windshield aperture flange, to form a stressed member of the

bodyshell. The 4 mm thick toughened and tinted glass backlight which is similarly bonded to the BIW, incorporates a

heating element and a mounting for the high level stop lamp. The 5 mm tempered and tinted glass quarter light which is

supplied as a complete assembly with stainless trim and seals, is directly bonded to the BIW aperture flanges.

Windshield and Backlight Adhesive Application

Key to Adhesive Application Drawing

Door Glass.

The 5 mm tempered and tinted door glass forms part of a fully framed electrically operated system. A switchpack installed

in each door casing provides control of lowering and raising of that particular d oor glass with additional 'one-shot' fast

lowering . The driver's door switchpack also provides for independent control of each passenger door glass and total

isolation of all passenger door glass control. Each door glas s is raised and lowered by an electrically operated scissor

mechanism. All door glass can only be operated wh en the ignition switch is in position I or II.

Door Glass operating Mechanism

1Fitted condition

2Bead application

Page 2201 of 2490

Installation

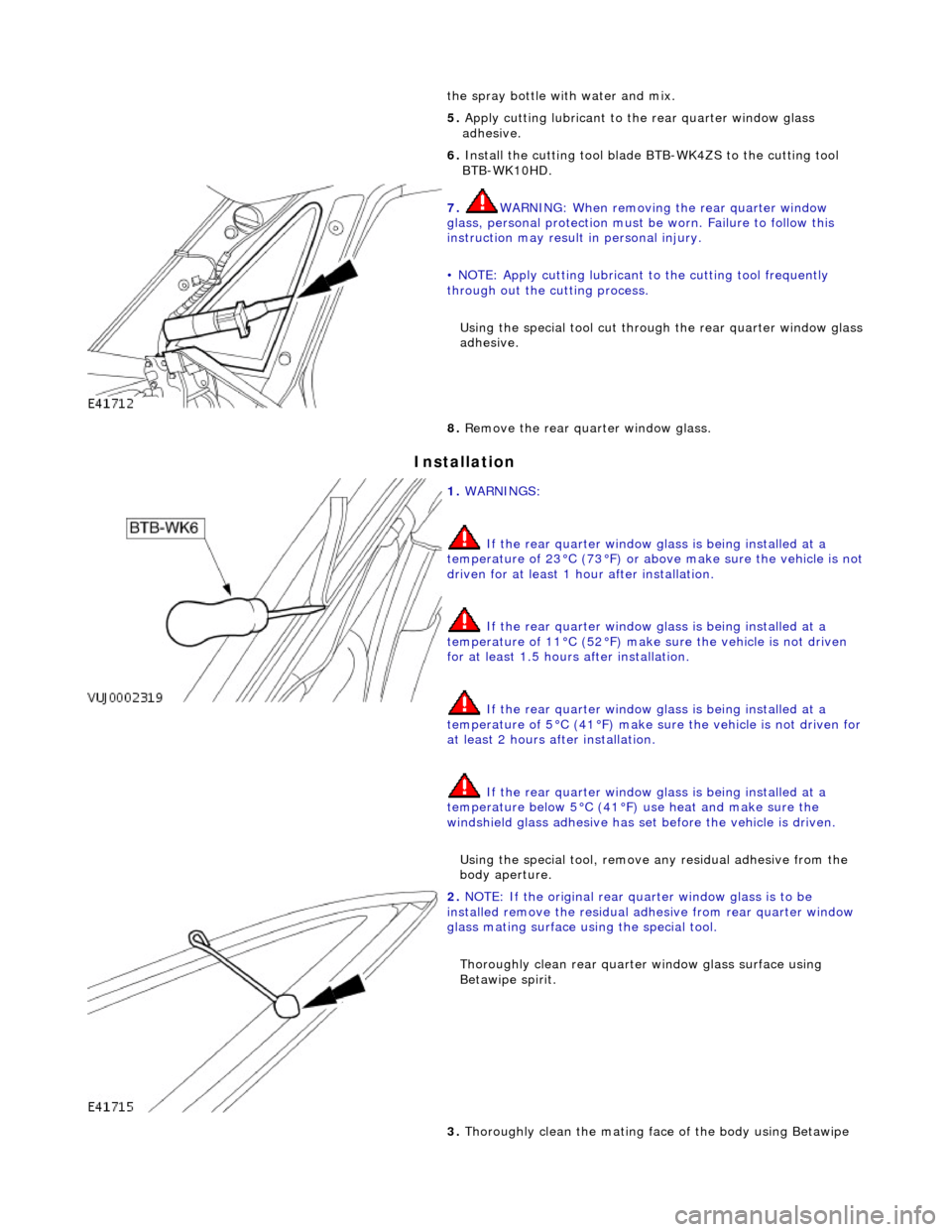

the spray bottle with water and mix.

5. Apply cutting lubricant to the rear quarter window glass

adhesive.

6. Install the cutting tool blade BTB-WK4ZS to the cutting tool

BTB-WK10HD.

7. WARNING: When removing the rear quarter window

glass, personal protec tion must be worn. Failure to follow this

instruction may result in personal injury.

• NOTE: Apply cutting lubricant to the cutting tool frequently

through out the cutting process.

Using the special tool cut throug h the rear quarter window glass

adhesive.

8. Remove the rear quarter window glass.

1. WARNINGS:

If the rear quarter window glass is being installed at a

temperature of 23°C (73°F) or abov e make sure the vehicle is not

driven for at least 1 hour after installation.

If the rear quarter window glass is being installed at a

temperature of 11°C (52°F) make sure the vehicle is not driven

for at least 1.5 hours after installation.

If the rear quarter window glass is being installed at a

temperature of 5°C (41°F) make su re the vehicle is not driven for

at least 2 hours after installation.

If the rear quarter window glass is being installed at a

temperature below 5°C (41°F) use heat and make sure the

windshield glass adhesive has set before the vehicle is driven.

Using the special tool, remove any residual adhe sive from the

body aperture.

2. NOTE: If the original rear qu arter window glass is to be

installed remove the residual ad hesive from rear quarter window

glass mating surface using the special tool.

Thoroughly clean rear quarte r window glass surface using

Betawipe spirit.

3. Thoroughly clean the mating face of the body using Betawipe

Page 2207 of 2490

12. Pass free end of cheese wire through penetration and install

second cutting handle.

13. WARNING: When removing the rear window glass,

personal protection must be worn. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Make sure the ch eese wire cannot contact the paintwork

while the the rear window glass ad hesive is being cut. Failure to

follow this instruction may result in damage to the vehicle.

When cutting, do not allow ch eese wire to contact edge of

window glass as this will crack the window glass.

• NOTE: Apply cutting lubricant to the cheese wire frequently

through out the cutting process.

With assistance and exercising care to avoid damaging the

paintwork, cut around the re ar window glass commencing

upwards and along the top.

14. Install the lifting handles to the windshield glass, and with

assistance carefully remove th e rear window glass from the

vehicle.

Page 2212 of 2490

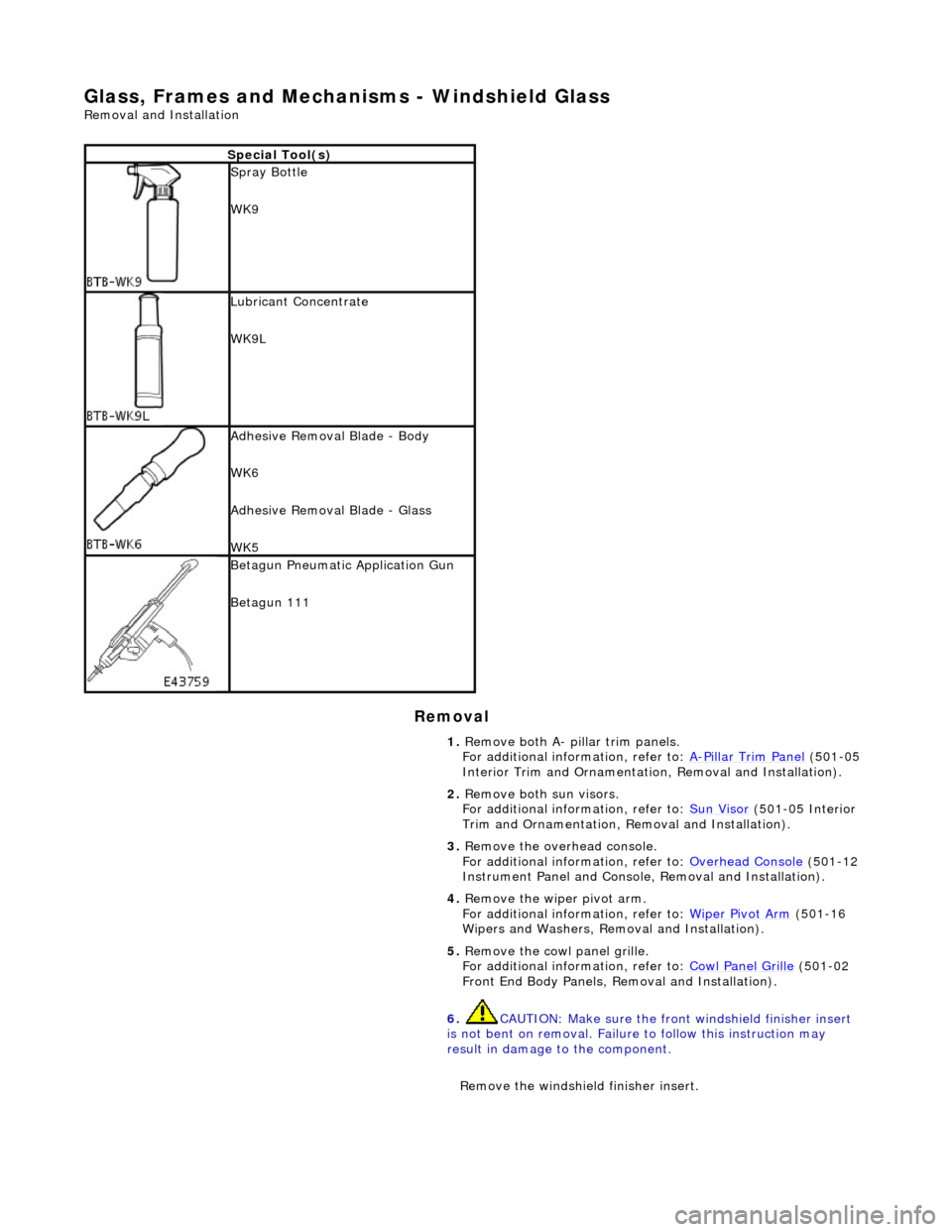

Glass, Frames and Mechanisms - Windshield Glass

Removal and Installation

Removal

Special Tool(s)

Spray Bottle

WK9

Lubricant Concentrate

WK9L

Adhesive Removal Blade - Body

WK6

Adhesive Removal Blade - Glass

WK5

Betagun Pneumatic Application Gun

Betagun 111

1. Remove both A- pill ar trim panels.

For additional information, refer to: A

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

2. Remove both sun visors.

For additional information, refer to: Sun Visor

(501-05 Interior

Trim and Ornamentation, Re moval and Installation).

3. Remove the overhead console.

For additional information, refer to: Overhead Console

(501-12

Instrument Panel and Console, Removal and Installation).

4. Remove the wiper pivot arm.

For additional information, refer to: Wiper Pivot Arm

(501-16

Wipers and Washers, Remo val and Installation).

5. Remove the cowl panel grille.

For additional information, refer to: Cowl Panel Grille

(501-02

Front End Body Panels, Removal and Installation).

6. CAUTION: Make sure the front windshield finisher insert

is not bent on removal. Failure to follow this instruction may

result in damage to the component.

Remove the windshield finisher insert.

Page 2213 of 2490

7. Remove the windshield finisher.

8. Apply a suitable protective ta pe around windshield glass

aperture to protect paintwork.

9. NOTE: Left-hand shown, right-hand similar

Apply a suitable protec tive tape to leading edge of headlining.

10. Place a suitable prot ective sheet over fascia and place a

protecting boar d over sheet

11. Prepare the cheese wire and cutting handle.

Position cutting handle cent ral tube fully upwards in

handle.

Page 2214 of 2490

Cut a suitable length of cheese wire and pass one end

through handle tube and locating aperture.

Move cutting handle central tube downwards to secure

cheese wire.

12. Using a suitable long bladed tool, penetrate Betaseal

approximately 150mm from the top of one A pillar.

13. Pass free end of cheese wire through penetration and install

second cutting handle.

14. WARNING: When removing the windshield glass,

personal protection must be worn. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Make sure the ch eese wire cannot contact the paintwork

while the the windshield adhesive is being cut. Failure to follow

this instruction may result in damage to the vehicle.

Make sure the cheese wire cannot contact the instrument

panel while the the windshield adhesive is being cut. Failure to

follow this instruction may result in damage to the vehicle.

Make sure the cheese wire passes the Vehicle Identification

Number (VIN) plate on the correct side. Failure to follow this

instruction may result in damage to the component.

When cutting, do not allow ch eese wire to contact edge of

windshield glass as this will crack the windshield glass.

• NOTE: Apply cutting lubricant to the cheese wire frequently

through out the cutting process.

With assistance and exercising care at the corners to avoid

damaging paintwork, cut around the windshield glass

Page 2215 of 2490

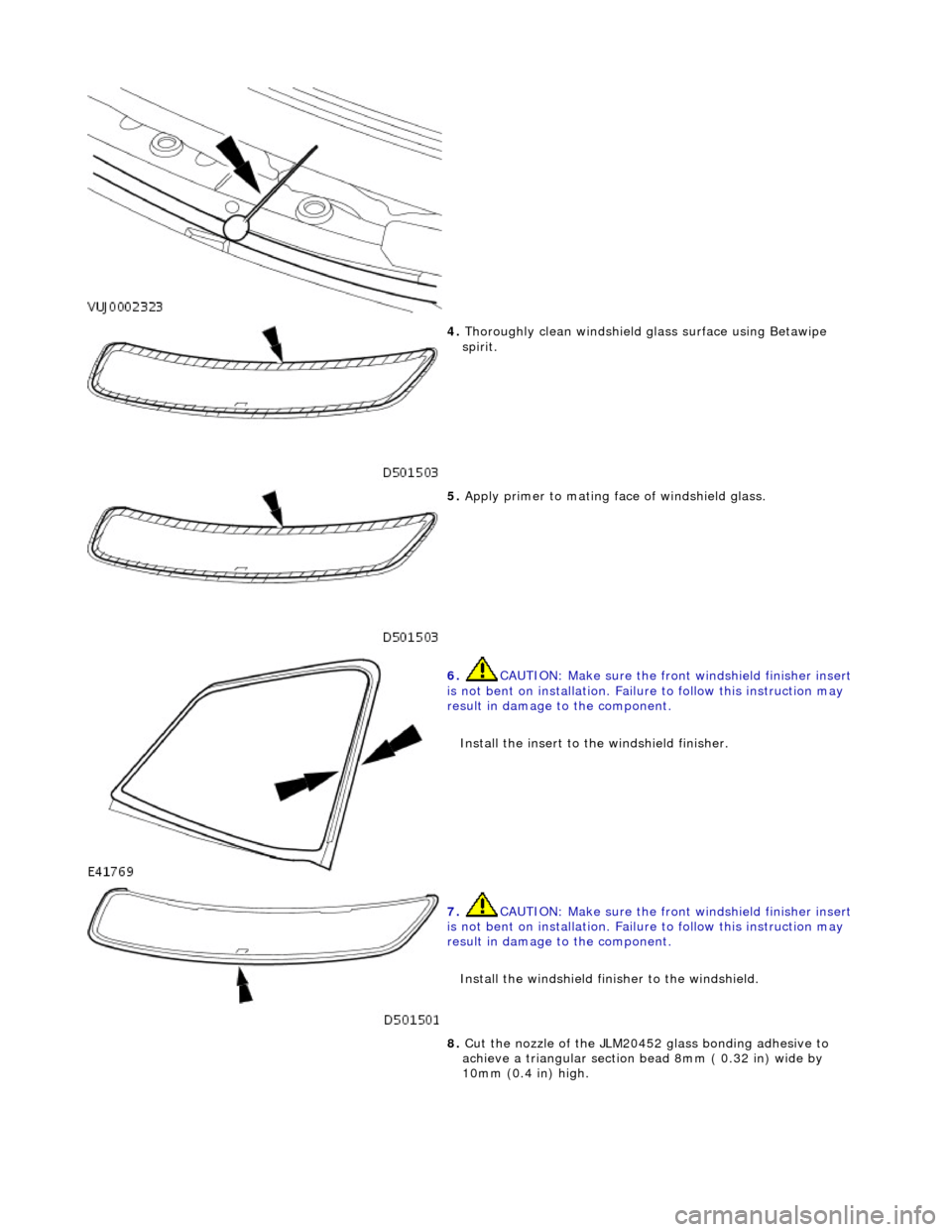

Installation

commencing downwards and along the bottom.

15. With assistance and exercising care, remove the windshield

glass.

1. Attach lifting handles to windshield glass.

2. Remove the windshield glass.

16. Remove lifting handles from windshield glass.

17. Remove cheese wire cutter fro m windshield glass aperture,

remove cutting handles and discard cheese wire.

1. WARNINGS:

If the windshield glass is being installed at a temperature of 23°C (73°F) or above make sure the vehicle is not driven for at

least 1 hour after installation.

If the windshield glass is being installed at a temperature of

11°C (52°F) make sure the vehicl e is not driven for at least 1.5

hours after installation.

If the windshield glass is being installed at a temperature of 5°C (41°F) make sure the vehicle is not driven for at least 2

hours after installation.

If the windshield glass is being installed at a temperature

below 5°C (41°F) use heat and ma ke sure the windshield glass

adhesive has set before the vehicle is driven.

• NOTE: If the original windshield glass is to be installed remove

the residual adhesive from windsh ield glass mating surface using

the special tool.

Using the special tool, remove any residual adhe sive from the

body.

2. Remove the protective tape from around windshield glass

aperture.

3. Apply glass primer to the mating face of the body flange.

Page 2216 of 2490

4. Thoroughly clean windshield glass surface using Betawipe

spirit.

5. Apply primer to mating fa ce of windshield glass.

6. CAUTION: Make sure the front windshield finisher insert

is not bent on installation. Failure to follow this instruction may

result in damage to the component.

Install the insert to the windshield finisher.

7. CAUTION: Make sure the front windshield finisher insert

is not bent on installation. Failure to follow this instruction may

result in damage to the component.

Install the windshield finisher to the windshield.

8. Cut the nozzle of the JLM20452 glass bonding adhesive to

achieve a triangular section bead 8mm ( 0.32 in) wide by

10mm (0.4 in) high.

Page 2217 of 2490

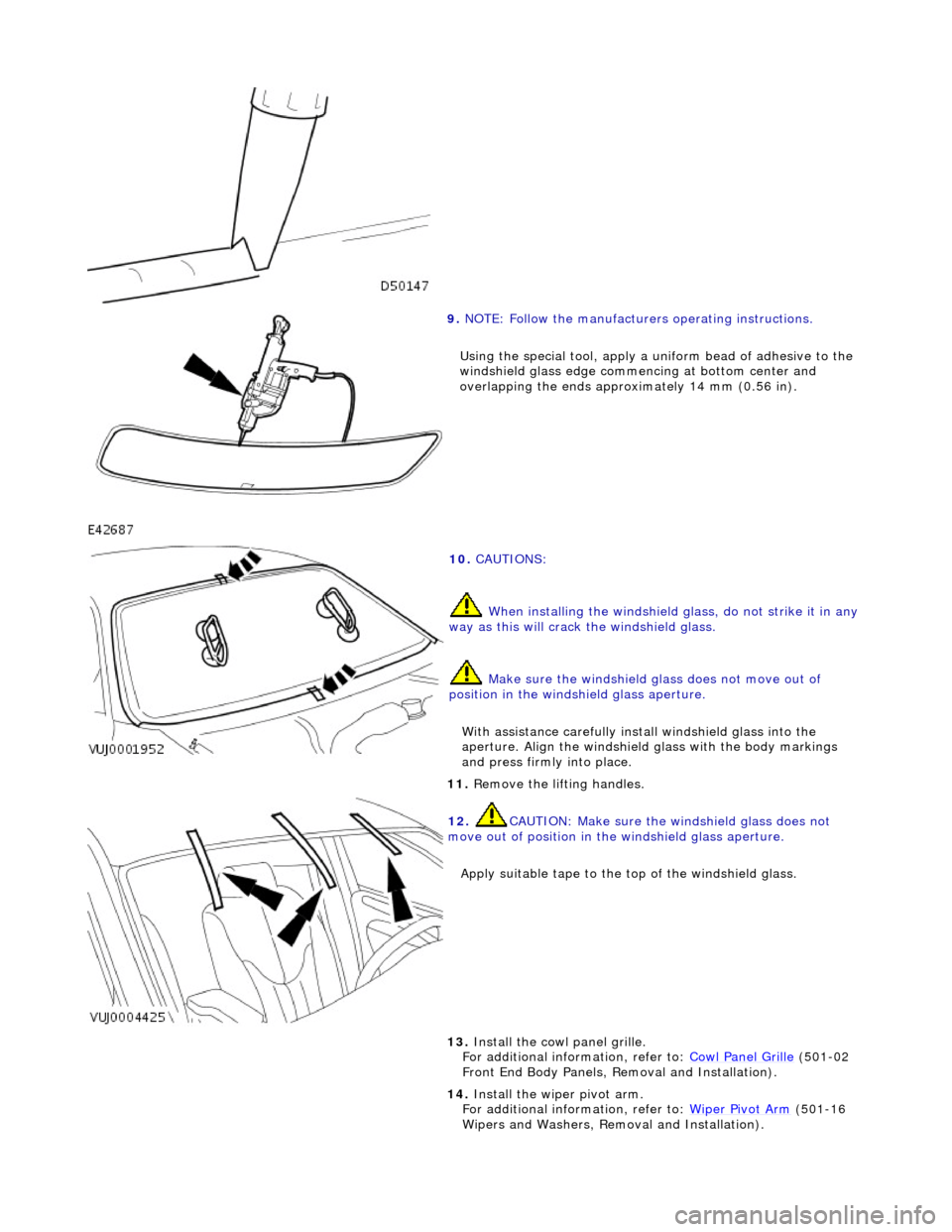

9. NOTE: Follow the manufacturers operating instructions.

Using the special tool, apply a uni form bead of adhesive to the

windshield glass edge commenc ing at bottom center and

overlapping the ends approximately 14 mm (0.56 in).

10. CAUTIONS:

When installing the windshield glass, do not strike it in any

way as this will crack the windshield glass.

Make sure the windshield glass does not move out of

position in the windshield glass aperture.

With assistance carefully install windshield glass into the

aperture. Align the windshield glass with the body markings

and press firmly into place.

11. Remove the lifting handles.

12. CAUTION: Make sure the windshield glass does not

move out of position in the windshield glass aperture.

Apply suitable tape to the to p of the windshield glass.

13. Install the cowl panel grille.

For additional information, refer to: Cowl Panel Grille (501-02

Front End Body Panels, Removal and Installation).

14. Install the wiper pivot arm.

For additional information, refer to: Wiper Pivot Arm

(501-16

Wipers and Washers, Remo val and Installation).

Page 2242 of 2490

Instrument Panel and Console - Instrument Panel

Removal and Installation

Removal

1. Turn ignition switch to position II.

2. Motor driver and front passenger seats rearward.

3. Position steering wheel in stra ight ahead position and fully

lower and extend steering column.

4. Turn ignition switch to position O.

5. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

6. Remove 'J' gate finish er. Refer to 76.25.24.

7. Remove 'J' gate finisher retain ing panel. Refer to 76.25.26.

8. Remove centre console veneer panel. Refer to 76.47.26.

9. Disconnect and remove radio.

10. Remove centre console switch module. Refer to 86.80.32.

11. Remove centre console. Refer to 76.25.01.

12. Slacken and remove centre cons ole vent duct rear securing

screw and withdraw duct assemb ly from air conditioning unit

manifold.

13. WARNING: BEFORE ANY AIRBAG/SRS SERVICE IS

PERFORMED, AT LEAST ONE MINUTE MUST ELAPSE AFTER

DISCONNECTION OF THE BATTERY CABLE, TO ALLOW

DISSIPATION OF BACK-UP POWER SUPPLY ENERGY.

Remove driver airbag. Refer to 76.73.39.

14. Remove steering wheel. Refer to Section 211-04.

15. Remove steering column lo wer cowl. Refer to 76.46.03.

16. Remove steering column u pper cowl. Refer to 76.46.02.

17. Remove driver side unders cuttle. Refer to 76.46.11.

18. Remove combined windshield wiper/washer switch and

audible warning speaker assembly. Refer to 86.65.42.

19. Remove glovebox. Refer to 76.52.03.

20. Remove 'A' post lower trim pads. refer to 76.13.30.

21. Carefully withdraw driver stowage bin trim, remove bin

securing screw and remove bin from facia.