oil filter JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 849 of 2490

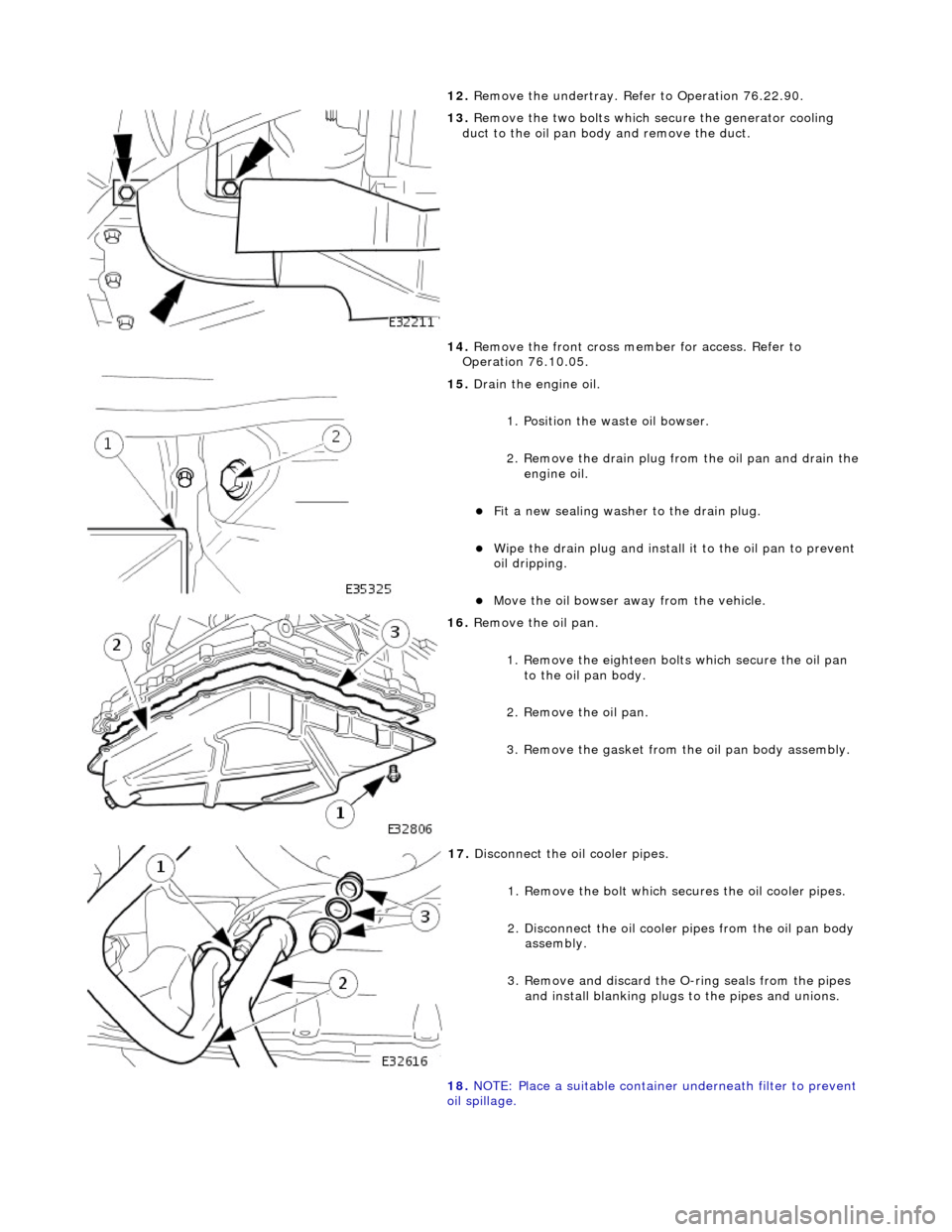

12. Remove the undertray. Re fer to Operation 76.22.90.

13. Remove the two bolts which se cure the generator cooling

duct to the oil pan body and remove the duct.

14. Remove the front cross member for access. Refer to

Operation 76.10.05.

15. Drain the engine oil.

1. Position the waste oil bowser.

2. Remove the drain plug from the oil pan and drain the engine oil.

Fit a new sealing washer to the drain plug.

Wipe the drain plug and install it to the oil pan to prevent

oil dripping.

Move the oil bowser away from the vehicle.

16. Remove the oil pan.

1. Remove the eighteen bolt s which secure the oil pan

to the oil pan body.

2. Remove the oil pan.

3. Remove the gasket from the oil pan body assembly.

17. Disconnect the oil cooler pipes.

1. Remove the bolt which secures the oil cooler pipes.

2. Disconnect the oil cooler pipes from the oil pan body

assembly.

3. Remove and discard the O-ring seals from the pipes

and install blanking plugs to the pipes and unions.

18. NOTE: Place a suitable container underneath filter to prevent

oil spillage.

Page 850 of 2490

Using the special tool, remove the oil filter.

19. Remove the oil pressure switch.

For additional information, refer to Oil Pressure Switch

- in this

section.

20. Remove the crankshaft position sensor.

1. Remove the bolt which secures the crankshaft position sensor to the flywheel housing.

2. Remove the access grommet from the housing.

Remove the sensor and allow it to hang free under the

engine.

Release the harness clips from the oil pan body.

21. Remove the bolt which secures the transmission cooler pipes

and remove the clamping bracket.

22. Release the air conditioning compressor.

Remove the lower securing bolts.

Loosen, but do not remove, th e upper securing bolts.

Release the compressor from the lower dowel.

23. Remove the four bolts (two each side) which secure the

exhaust downpipes to the oil pan body.

Page 852 of 2490

Installation

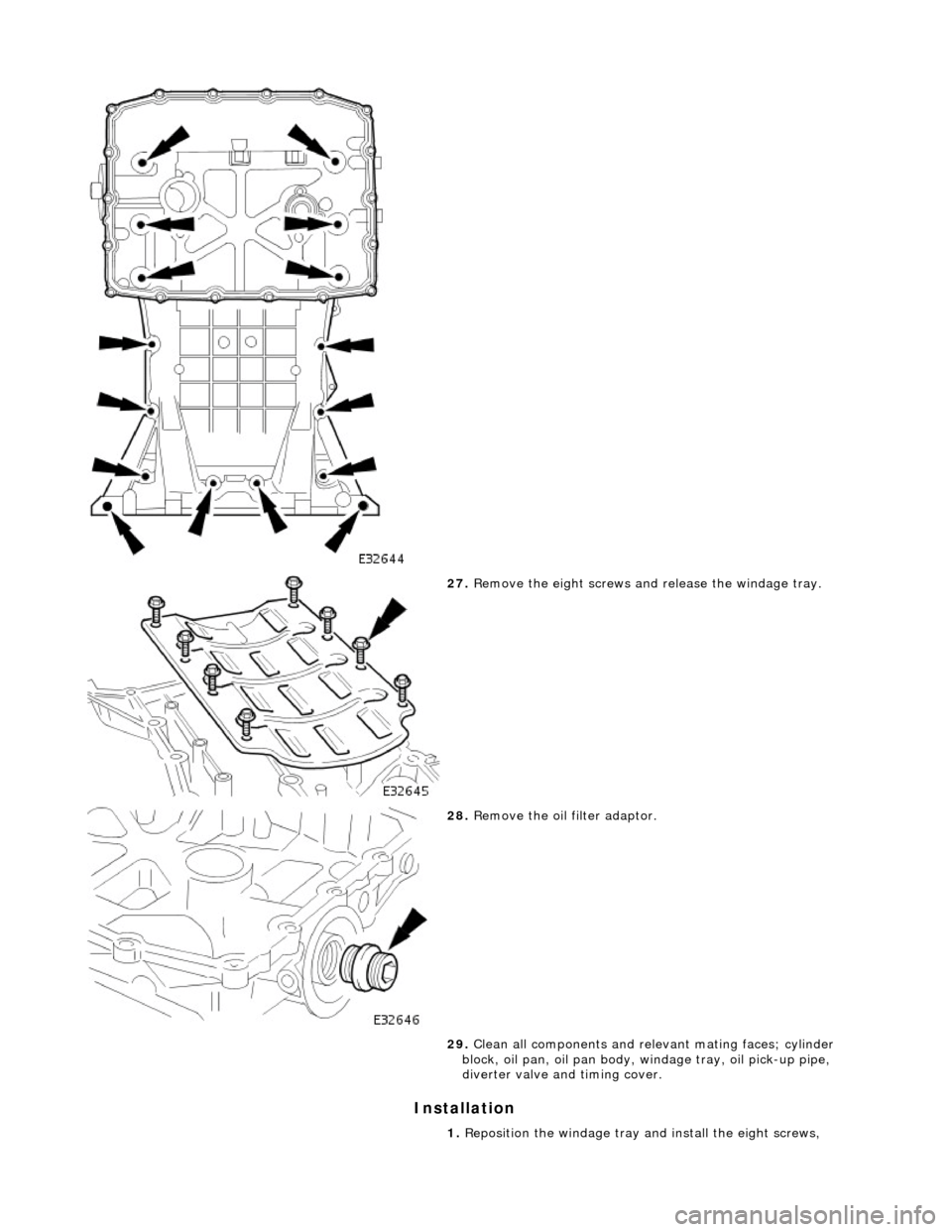

27. Remove the eight screws an d release the windage tray.

28. Remove the oil filter adaptor.

29. Clean all components and releva nt mating faces; cylinder

block, oil pan, oil pan body, windage tray, oil pick-up pipe,

diverter valve and timing cover.

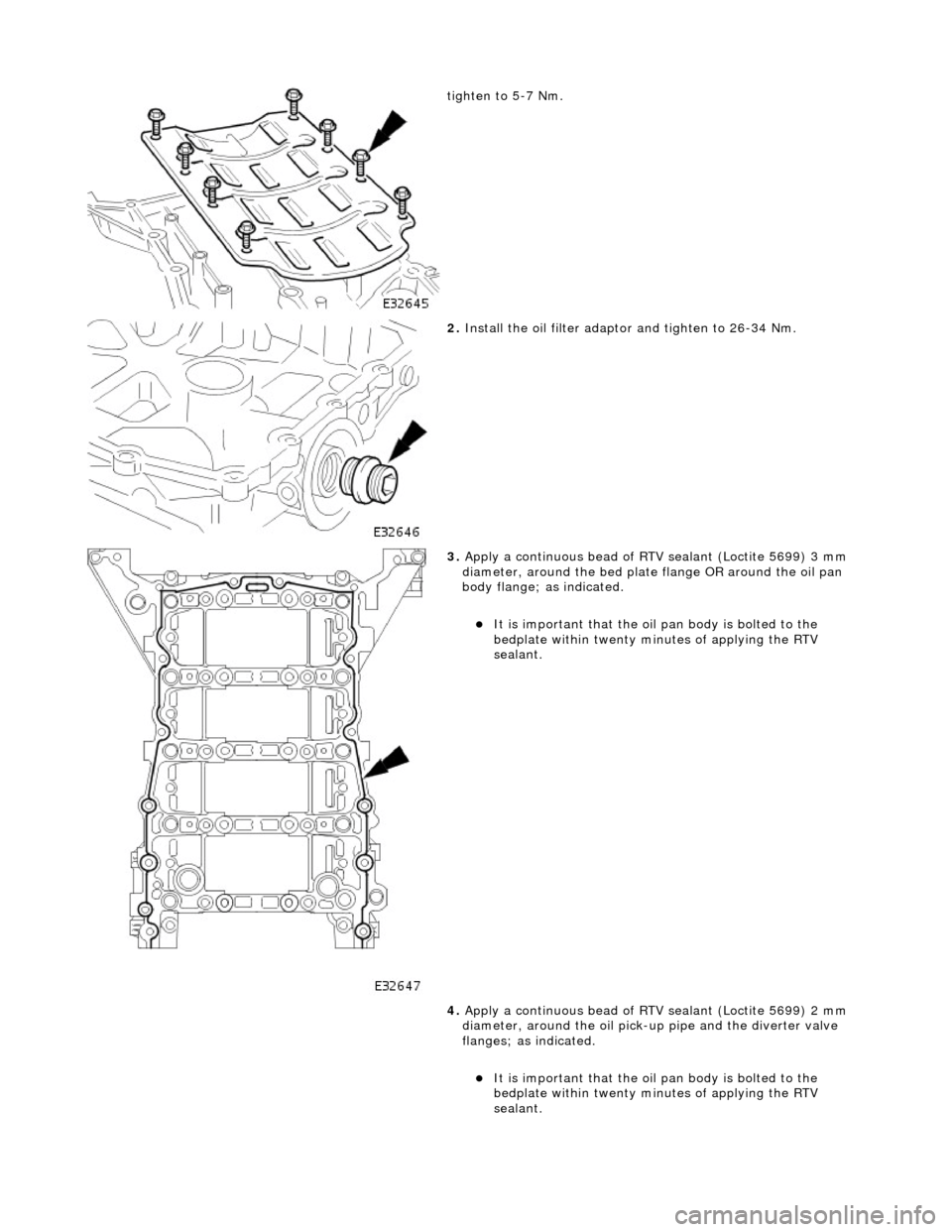

1. Reposition the windage tray and install the eight screws,

Page 853 of 2490

tighten to 5-7 Nm.

2. Install the oil filter adapto r and tighten to 26-34 Nm.

3. Apply a continuous bead of RTV sealant (Loctite 5699) 3 mm

diameter, around the bed plate flange OR around the oil pan

body flange; as indicated.

It is important that the oil pan body is bolted to the

bedplate within twenty minutes of applying the RTV

sealant.

4. Apply a continuous bead of RTV sealant (Loctite 5699) 2 mm

diameter, around the oil pick-u p pipe and the diverter valve

flanges; as indicated.

It is important that the oil pan body is bolted to the

bedplate within twenty minutes of applying the RTV

sealant.

Page 856 of 2490

11. Install the oil pressure switch.

For additional information, refer to Oil Pressure Switch - in this

section.

12. NOTE: Apply a suitable amount of clean engine oil to lubricate the oil filter O-ring seal.

Using the special tool, install the oil filter.

Tighten the oil filter to 15-18 Nm.

13. Install the crankshaft position sensor.

1. Install the sensor to the flywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

2. Install the access grommet to the housing.

14. Install the four bolts (two each side) which secure the

exhaust downpipes to the oil pan body.

15. Install the air conditioning compressor.

Locate the compressor onto the lower dowel.

Tighten the upper securing bolts.

Page 1026 of 2490

REFE

R to Section 310

-00

Fu

el

Sy

ste

m

- General

Information

.

Check f o

r DTCs indicating a sensor

fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

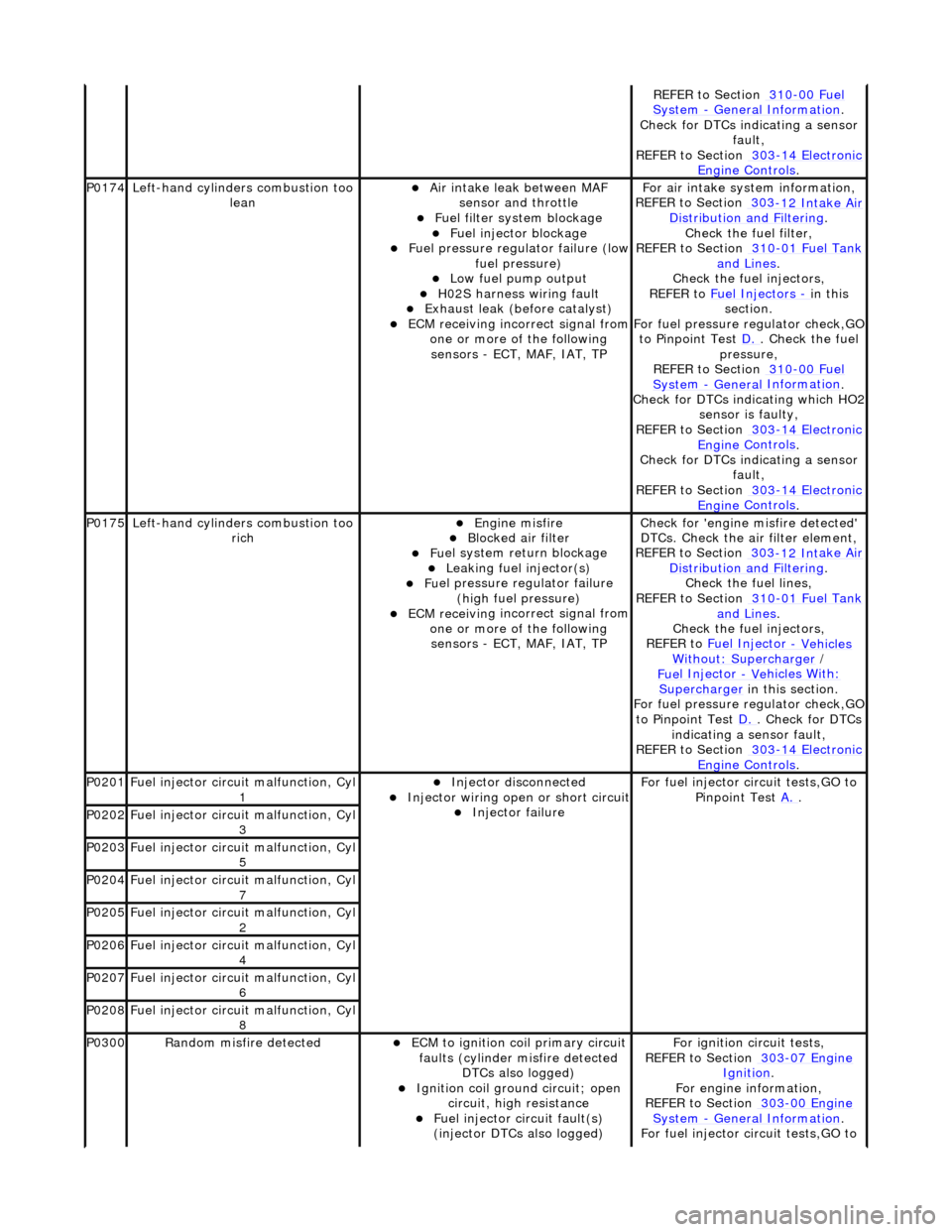

P0174

Left-hand cyl i

nders combustion too

lean

Air in

take leak between MAF

sensor and throttle

F u

el filter system blockage

F

u

el injector blockage

F

u

el pressure regulator failure (low

fuel pressure)

Low f u

el pump output

H0

2S harness wiri

ng fault

E

x

haust leak (before catalyst)

ECM receivi

n

g incorrect signal from

one or more of the following sensors - ECT, MAF, IAT, TP

F o

r air intake sy

stem information,

REFER to Section 303

-12 Int

ake Air

Distribu tion and Filterin

g

.

Check the fuel fi lter,

REF

ER to Section 310

-01

Fu

el Tank

and Lines.

Chec k the

fuel injectors,

REFER to Fuel Injectors

- in t h

is

section.

For fuel pressure regulator check,GO

to Pinpoint Test D.

. Ch

eck the fuel

pressure,

REFER to Section 310

-00 Fu

el

Sy

ste

m

- General

Information

.

Check f o

r DTCs indicating which HO2

sensor is faulty,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

Check f o

r DTCs indicating a sensor

fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

P0175Left-hand cyli

nders combustion too

rich

Engine m

isfire

Bl

ocked air

filter

F

u

el system return blockage

Leak

i

ng fuel injector(s)

F

u

el pressure regulator failure

(high fuel pressure)

ECM receivi n

g incorrect signal from

one or more of the following sensors - ECT, MAF, IAT, TP

Check for 'en

gine misfire detected'

DTCs. Check the air filter element,

REFER to Section 303

-12 Int

ake Air

Distribu tion and Filterin

g

.

Chec k the

fuel lines,

REFER to Section 310

-01 Fu

el Tank

and Lines.

Chec k the

fuel injectors,

REFER to Fuel Injector

- Vehicles Wi

thout: Supercharger

/

Fue

l Injector

- Ve

hicles With

:

Supercharger

in this

section.

For fuel pressure regulator check,GO

to Pinpoint Test D.

. Check for DT

Cs

indicating a sensor fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

P0201F

u

el injector circuit malfunction, Cyl

1

Injector discon n

ected

Inject

or wir

ing open or short circuit

Injector fail

ure

F

o

r fuel injector circuit tests,GO to

Pinpoint Test A.

.

P0202Fu

el injector circuit malfunction, Cyl

3

P0203F u

el injector circuit malfunction, Cyl

5

P0204F u

el injector circuit malfunction, Cyl

7

P0205Fu

el injector circuit malfunction, Cyl

2

P0206Fu

el injector circuit malfunction, Cyl

4

P0207F u

el injector circuit malfunction, Cyl

6

P0208F u

el injector circuit malfunction, Cyl

8

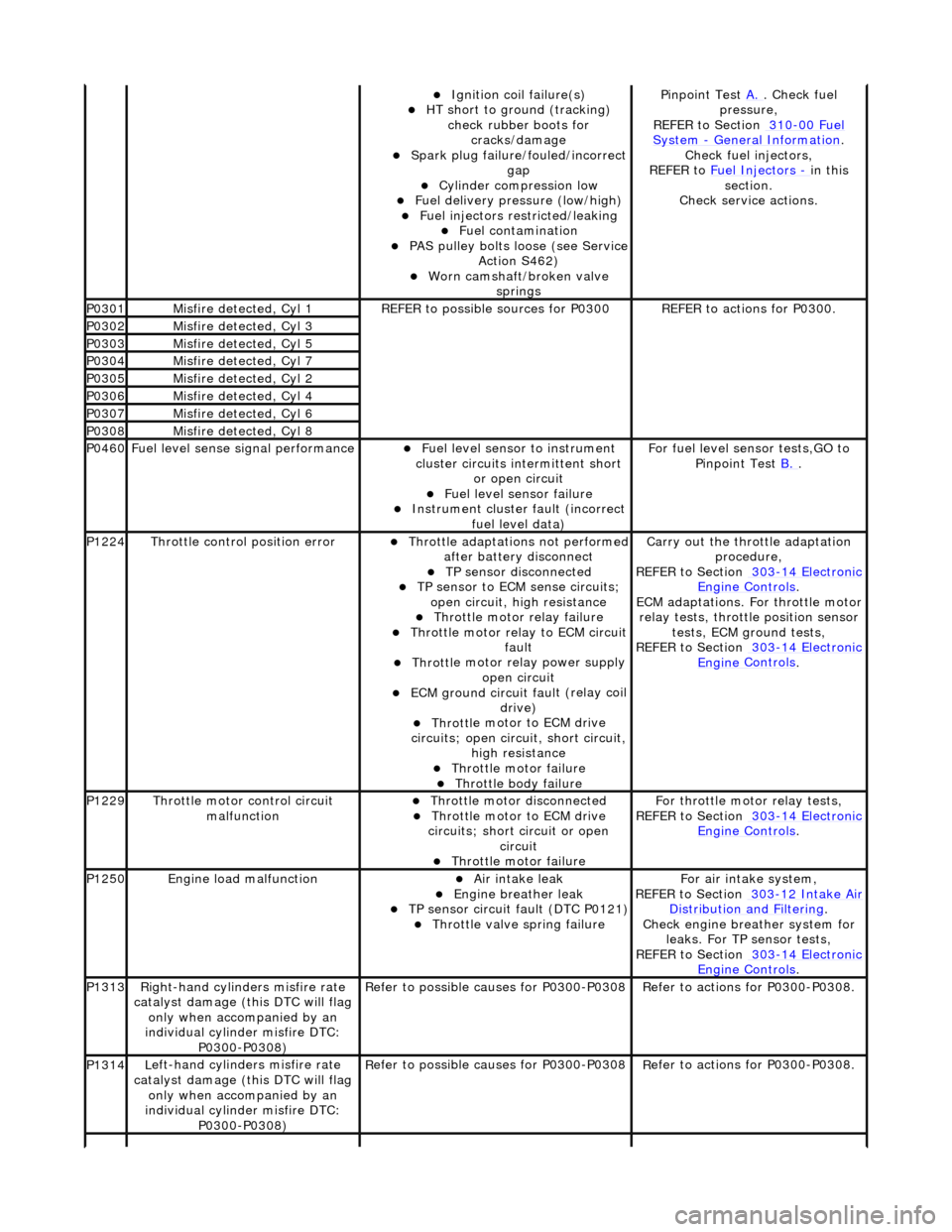

P0300Ran d

om misfire detected

ECM t

o

ignition coil primary circuit

faults (cylinder misfire detected DTCs also logged)

Ignition coil ground circuit; open

ci

rcuit, high resistance

F

u

el injector circuit fault(s)

(injector DTCs also logged)

F o

r ignition circuit tests,

REFER to Section 303

-07 En

gine

Ignition.

F or engi

ne information,

REFER to Section 303

-00 En

gine

Sy

ste

m

- General

Information

.

F o

r fuel injector circuit tests,GO to

Page 1027 of 2490

Ignition coil

failure(s)

HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

Spark plug

failure/fouled/incorrect

gap

Cy

linder compression low

F

uel delivery pressure (low/high)

F

uel injectors restricted/leaking

Fuel contamination

P

AS pulley bolts loose (see Service

Action S462)

W

orn camshaft/broken valve

springs

P

inpoint Test

A.

.

Check fuel

pressure,

REFER to Section 310

-00

Fuel

Sy

stem

- General

Information

.

Chec

k fuel injectors,

REFER to Fuel Injectors

- in t

his

section.

Check service actions.

P0301Misfire

detected, Cyl 1

R

EFER to possible sources for P0300

R

EFER to actions for P0300.

P0302Misfire

detected, Cyl 3

P0303Misfire

detected, Cyl 5

P0304Misfire

detected, Cyl 7

P0305Misfire

detected, Cyl 2

P0306Misfire

detected, Cyl 4

P0307Misfire

detected, Cyl 6

P0308Misfire

detected, Cyl 8

P0460F

uel level sense signal performance

Fue

l level sensor

to instrument

cluster circuits in termittent short

or open circuit

F

uel level sensor failure

Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor tests,GO to

Pinpoint Test B.

.

P1224Throttl

e control position error

Thro

ttle adaptations not performed

after battery disconnect

TP se

nsor disconnected

TP se

nsor to ECM sense circuits;

open circuit, hi gh resistance

Throttl

e motor relay failure

Th

rottle motor relay to ECM circuit

fault

Throttl

e motor relay power supply

open circuit

ECM ground circuit faul

t (relay coil

drive)

Throttl

e motor to ECM drive

circuits; open circuit, short circuit, high resistance

Throttl

e motor failure

Throttl

e body failure

Carry

out the throttle adaptation

procedure,

REFER to Section 303

-14

Electronic

Engine

Controls

.

ECM adaptations. For

throttle motor

relay tests, throttle position sensor tests, ECM ground tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1229Throttl

e motor control circuit

malfunction

Throttl

e motor disconnected

Throttl

e motor to ECM drive

circuits; short circuit or open circuit

Throttl

e motor failure

Fo

r throttle moto

r relay tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1250Engine

load malfunction

Air

intake leak

Engine

breather leak

TP se

nsor circuit fault (DTC P0121)

Throttl

e valve spring failure

F

or air intake system,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

Chec

k engine breather system for

leaks. For TP sensor tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1313Right-hand cylinders misfire rate

cat

alyst damage (this DTC will flag

only when accompanied by an

individual cylinder misfire DTC: P0300-P0308)

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

P1314L

eft-hand cylinders misfire rate

catalyst damage (this DTC will flag only when accompanied by an

individual cylinder misfire DTC: P0300-P0308)

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

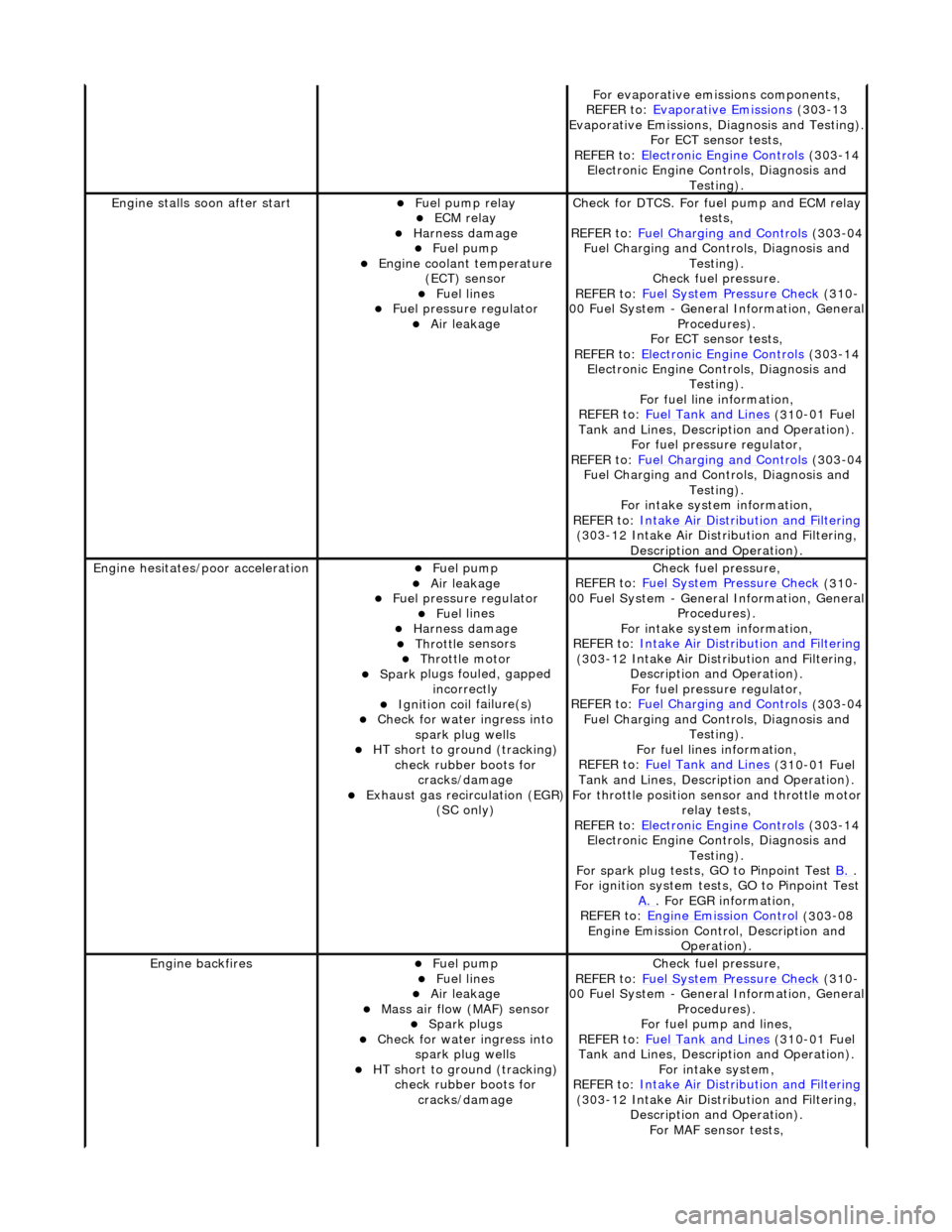

Page 1079 of 2490

F

or evaporative emissions components,

REFER to: Evaporative Emissions

(30

3-13

Evaporative Emissions, Diagnosis and Testing).

For ECT sensor tests,

REFER to: Electronic Engine Controls

(30

3-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

Engine stalls

soon after start

F

uel pump relay

ECM relay

Harness damage Fue

l pump

Engine coolan

t temperature

(ECT) sensor

Fue

l lines

F

uel pressure regulator

Air leakage

Check f

or DTCS. For fuel pump and ECM relay

tests,

REFER to: Fuel Charging and Controls

(30

3-04

Fuel Charging and Controls, Diagnosis and Testing).

Check fuel pressure.

REFER to: Fuel System Pressure Check

(31

0-

00 Fuel System - Genera l Information, General

Procedures).

For ECT sensor tests,

REFER to: Electronic Engine Controls

(30

3-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For fuel line information,

REFER to: Fuel Tank and Lines

(31

0-01 Fuel

Tank and Lines, Description and Operation).

For fuel pressure regulator,

REFER to: Fuel Charging and Controls

(30

3-04

Fuel Charging and Controls, Diagnosis and Testing).

For intake system information,

REFER to: Intake Air Distribution and Filtering

(30

3-12 Intake Air Distribution and Filtering,

Description and Operation).

Engine hesi

tates/poor acceleration

Fue

l pump

Air leakage

F

uel pressure regulator

Fue

l lines

Harness damage Throttl

e sensors

Throttl

e motor

Spark

plugs fouled, gapped

incorrectly

Ignition coil

failure(s)

Check f

or water ingress into

spark plug wells

HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

Exhaus

t gas recirculation (EGR)

(SC only)

Chec

k fuel pressure,

REFER to: Fuel System Pressure Check

(31

0-

00 Fuel System - Genera l Information, General

Procedures).

For intake system information,

REFER to: Intake Air Distribution and Filtering

(30

3-12 Intake Air Distribution and Filtering,

Description and Operation). For fuel pressure regulator,

REFER to: Fuel Charging and Controls

(30

3-04

Fuel Charging and Controls, Diagnosis and Testing).

For fuel lines information,

REFER to: Fuel Tank and Lines

(31

0-01 Fuel

Tank and Lines, Description and Operation).

For throttle position se nsor and throttle motor

relay tests,

REFER to: Electronic Engine Controls

(30

3-14

Electronic Engine Co ntrols, Diagnosis and

Testing).

For spark plug tests, GO to Pinpoint Test B.

.

For ign

ition system tests, GO to Pinpoint Test

A.

. F

or EGR information,

REFER to: Engine Emission Control

(30

3-08

Engine Emission Cont rol, Description and

Operation).

Engine ba

ckfires

Fue

l pump

Fue

l lines

Air leakage

Mass ai

r flow (MAF) sensor

Spark plugs

Check f

or water ingress into

spark plug wells

HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

Chec

k fuel pressure,

REFER to: Fuel System Pressure Check

(31

0-

00 Fuel System - Genera l Information, General

Procedures).

For fuel pump and lines,

REFER to: Fuel Tank and Lines

(31

0-01 Fuel

Tank and Lines, Description and Operation).

For intake system,

REFER to: Intake Air Distribution and Filtering

(30

3-12 Intake Air Distribution and Filtering,

Description and Operation). For MAF sensor tests,

Page 1095 of 2490

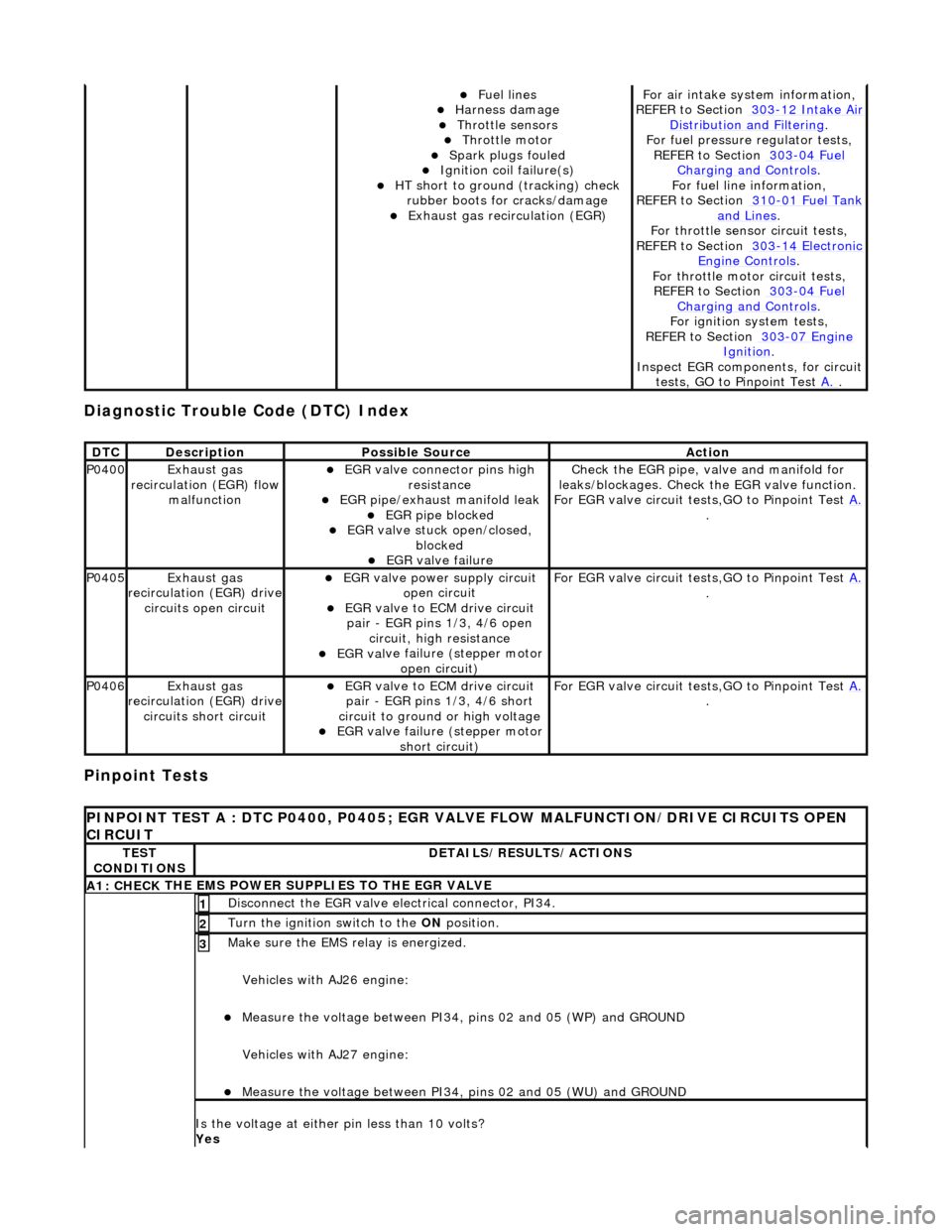

Diagnostic Trouble Code (D

TC) Index

Pinpoint Tests

Fue

l lines

Harness damage

Throttl

e sensors

Throttl

e motor

Spark plugs

fouled

Ignition coil

failure(s)

HT sho

rt to ground (tracking) check

rubber boots for cracks/damage

Exhaus

t gas recirculation (EGR)

F

or air intake syst

em information,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

F

or fuel pressure

regulator tests,

REF

ER to Section 303

-04

Fuel

Charging and Con

trols

.

F

or fuel line information,

REFER to Section 310

-01

Fuel Tank

and Lines.

F

or throttle sensor

circuit tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

Fo

r throttle motor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

For ign

ition system tests,

REFER to Section 303

-07

Engine

Ignition.

Inspe

ct EGR components, for circuit

tests, GO to Pinpoint Test A.

.

DT

C

De

scription

Possib

le Source

Acti

on

P0400Exhaus

t gas

recirculation (EGR) flow malfunction

EGR

valve connector pins high

resistance

EGR pipe/exhaust manifold leak EGR pipe block

ed

EGR val

ve stuck open/closed,

blocked

EGR

valve failure

Check the EGR pi

pe, valve and manifold for

leaks/blockages. Check the EGR valve function.

For EGR valve circuit tests,GO to Pinpoint Test A.

.

P0405Exhaus

t gas

recirculation (EGR) drive

circuits open circuit

EGR valve power supply circuit o

pen circuit

EGR valve t

o ECM drive circuit

pair - EGR pins 1/3, 4/6 open circuit, high resistance

EGR val

ve failure (stepper motor

open circuit)

F

or EGR valve circuit tests,GO to Pinpoint Test

A.

.

P0406Exhaus

t gas

recirculation (EGR) drive

circuits short circuit

EGR valve t

o ECM drive circuit

pair - EGR pins 1/3, 4/6 short

circuit to ground or high voltage

EGR val

ve failure (stepper motor

short circuit)

F

or EGR valve circuit tests,GO to Pinpoint Test

A.

.

P

INPOINT TEST A : DTC P0400, P0405; EGR VALV

E FLOW MALFUNCTION/DRIVE CIRCUITS OPEN

CIRCUIT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE EMS POWER SU

PPLIES TO THE EGR VALVE

D

isconnect the EGR valve electrical connector, PI34.

1

Turn the ignition swi

tch to the ON

position.

2

Make sure the EMS re lay i

s energized.

Vehicles with AJ26 engine:

Me

asure the voltage between PI34, pins 02 and 05 (WP) and GROUND

Vehicles with AJ27 engine:

Me

asure the voltage between PI34, pins 02 and 05 (WU) and GROUND

3

Is th

e voltage at either pin less than 10 volts?

Yes

Page 1204 of 2490

op

en circuit

ECM ground circuit faul

t (relay coil

drive)

P1235Vacuu m

switching valve (VSV) 1

circuit range/ performance

(mechanical guard position)

Vac u

um leak/blockage between the

throttle elbow and the throttle

vacuum actuator

Vacuu m

actuator failure

Mechanica

l

guard actuator

seized/spring broken

Carr y out mechanical checks

for

vacuum leak/blockag e, failed vacuum

actuator, and broken /siezed actuator

spring.

P1236Vacuu m

switching valve (VSV) 1

(vacuum) circuit failure

VSV 1 disconne cted

VSV 1 to ECM drive circu

i

t high

resistance, open circuit or short

circuit

VSV 1 powe r supply open

circuit

VSV 1 failu

r

e

For VSV tests,

REF

ER to Section 310

-03

Sp

eed

Control.

P1237Vacuu

m

switching valve (VSV) 2

(atmosphere) circuit failure

VSV 2 disconne cted

VSV 2 to ECM drive circu

i

t high

resistance, open circuit or short

circuit

VSV 2 power supply open

circuit

VSV 2 failu

r

e

For VSV tests,

REF

ER to Section 310

-03

Sp

eed

Control.

P1238Vacuu

m

switching valve (VSV) 3

(release) circuit failure

VSV 3 disconne cted

VSV 3 to ECM drive circu

i

t high

resistance, open circuit or short

circuit

VSV 3 powe r supply open

circuit

VSV 3 failu

r

e

For VSV tests,

REF

ER to Section 310

-03

Sp

eed

Control.

P1240Sensor r

e

fere

nce voltage

malfunction (throttle sensors, fuel

tank pressure se nsor) (ECM pins

EM10-21; EM11-8)

ECM t o

sensors reference voltage

short circuit to ground, short circuit

to high voltage, op en circuit, high

resistance

TP sensor , pedal position and

mechan

ical guard sensor(s), fuel

tank pressure sens or failure(s)

Fo

r sensor reference voltage circuit

tests,GO to Pinpoint Test V.

.

P1241Sensor re

ferenc

e voltage low

(throttle sensors, fuel tank

pressure sensor) (ECM pins EM10-

21; EM11-8)

ECM t o

sensors reference voltage

short circuit to ground

TP sensor , APP

and mechanical

guard sensor(s), fuel tank pressure

sensor failure(s)

F o

r sensor reference voltage circuit

tests,GO to Pinpoint Test V.

.

P1242Sensor re

ferenc

e voltage high

(throttle sensors, fuel tank

pressure sensor) (ECM pins EM10-

21; EM11-8)

ECM t o

sensors reference voltage

circuit open circuit, high resistance,

short circuit to high voltage

TP sensor , APP

and mechanical

guard sensor(s), fuel tank pressure

sensor failure(s)

F o

r sensor reference voltage circuit

tests,GO to Pinpoint Test V.

.

P1243Sensor re

ference ground

malfunction (throttle sensors, fuel

tank pressure sensor, ECT sensor,

IAT sensor, IAT sensor 2) (ECM

pins EM10-20; EM11-12)

ECM t o

sensors reference ground

circuit open circuit, high resistance

Throttle sensors, fuel

tank pressure

sensor, ECT sensor, IAT sensor,

IAT sensor 2 failures

F o

r sensor reference ground circuit

tests,GO to Pinpoint Test W.

.

P1245Engine crank signal low voltage Starter relay coi

l to ECM/BPM

circuit open circuit

For en gin

e crank circuit tests,GO to

Pinpoint Test X.

.

P1246Engine crank signal high voltage Starter relay coi

l to ECM/BPM

circuit short circuit to B+ voltage

B P

M failure

For en

gin

e crank circuit tests,GO to

Pinpoint Test X.

.

P1250Engine load

malfunction

Air in

take leak

Engine breath

er leak

TP sens

or circuit fault (DTC P0121)

Throttle

valve spring failure

Check air i

ntake system for leaks,

REFER to Section 303

-12

Intake Air

Distribution and Filterin

g

.

Check engi

ne breather system for

leaks,

REFER to Section 303

-08 En

gine

Emissi

on Control.

Se e

pinpoint test for P0121. For

throttle body information,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

.

P1251Thr

o

ttle position malfunction

(engine off)

TP sensor to ECM wiri

ng open

circuit or high resistance

F o

r TP sensor circ

uit tests,GO to

Pinpoint Test D.

, andGO to Pinpoint