power steering fluid JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 479 of 2490

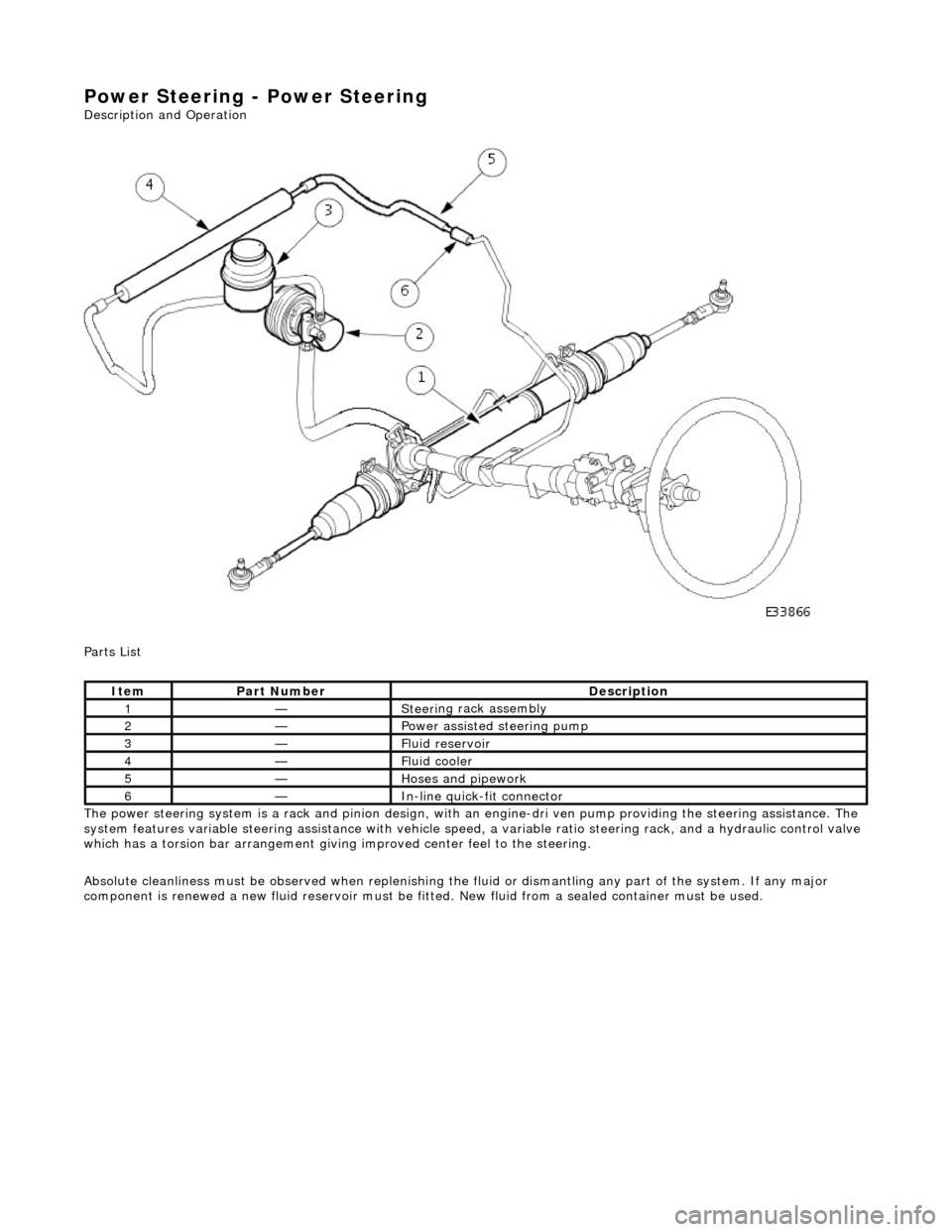

Power Steering - Power Steering

Description an

d Operation

Parts List

The power steering system is a rack and pinion design, with an engine-dri ve n pump providing the steering assistance. The

system features variable steering assistance with vehicle spee d, a variable ratio steering rack, and a hydraulic control valve

which has a torsion bar arrangement giving improved center feel to the steering.

Absolute cleanliness must be observed wh en replenishing the fluid or dismantling any part of the system. If any major

component is renewed a new fluid rese rvoir must be fitted. New fluid from a sealed container must be used.

It

em

Par

t Number

De

scription

1—Steeri

ng rack assembly

2—Power as

sisted steering pump

3—F

luid reservoir

4—F

luid cooler

5—Hoses and pipework

6—In-

line quick-fit connector

Page 484 of 2490

P a

rts List

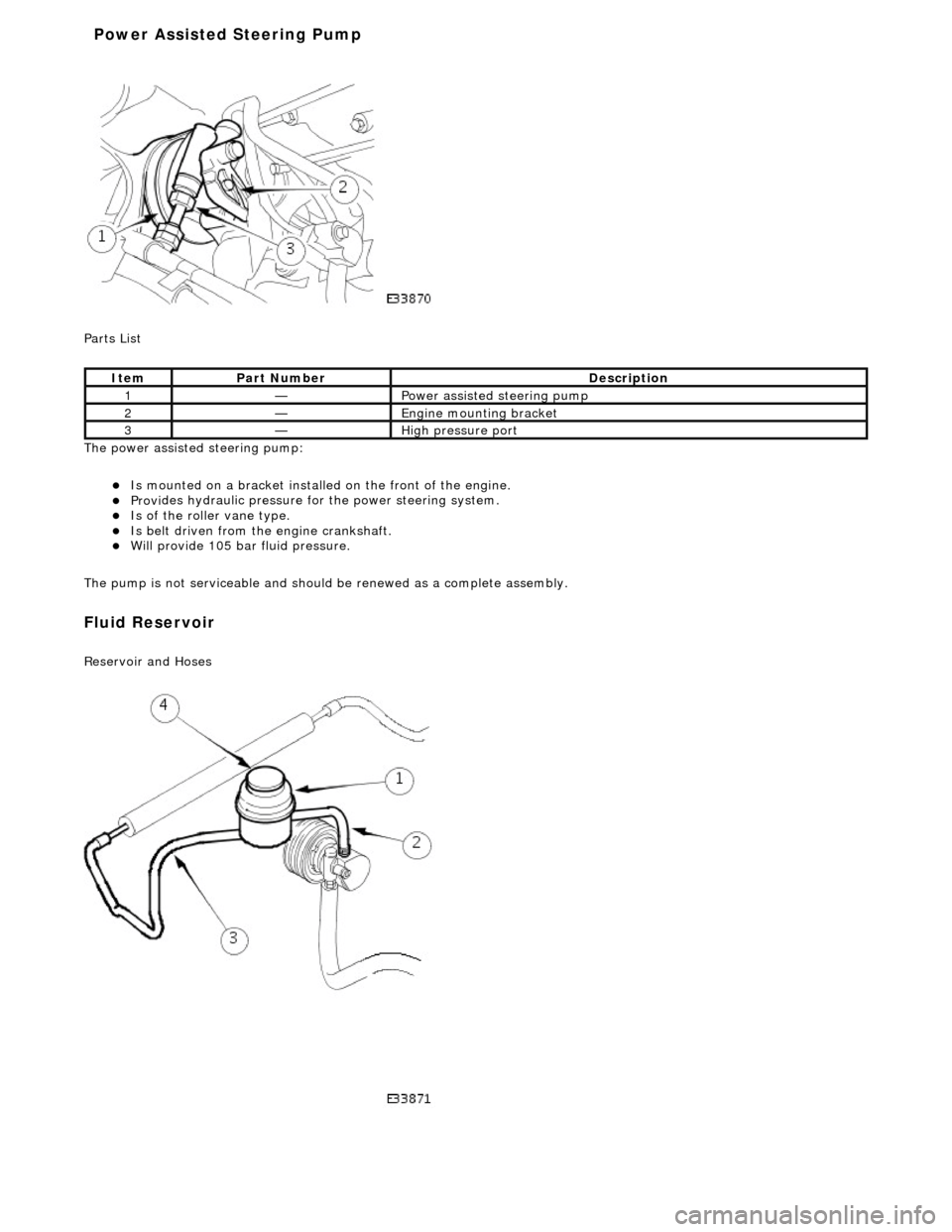

The power assisted steering pump:

Is mo u

nted on a bracket installe

d on the front of the engine.

Provides hydraul

ic pressure fo

r the power steering system.

Is of the roll

er vane type.

Is belt driven from th

e en

gine crankshaft.

Will provide 1

05 bar f

luid pressure.

The pump is not serviceable and should be renewed as a complete assembly.

Fluid Reservoir

Re

servoir and Hoses

Ite

m

Par

t

Number

De

scr

iption

1—Power as

si

sted steering pump

2—Engine

m

ounting bracket

3—High

pressure port

Power Assisted Steering Pump

Page 490 of 2490

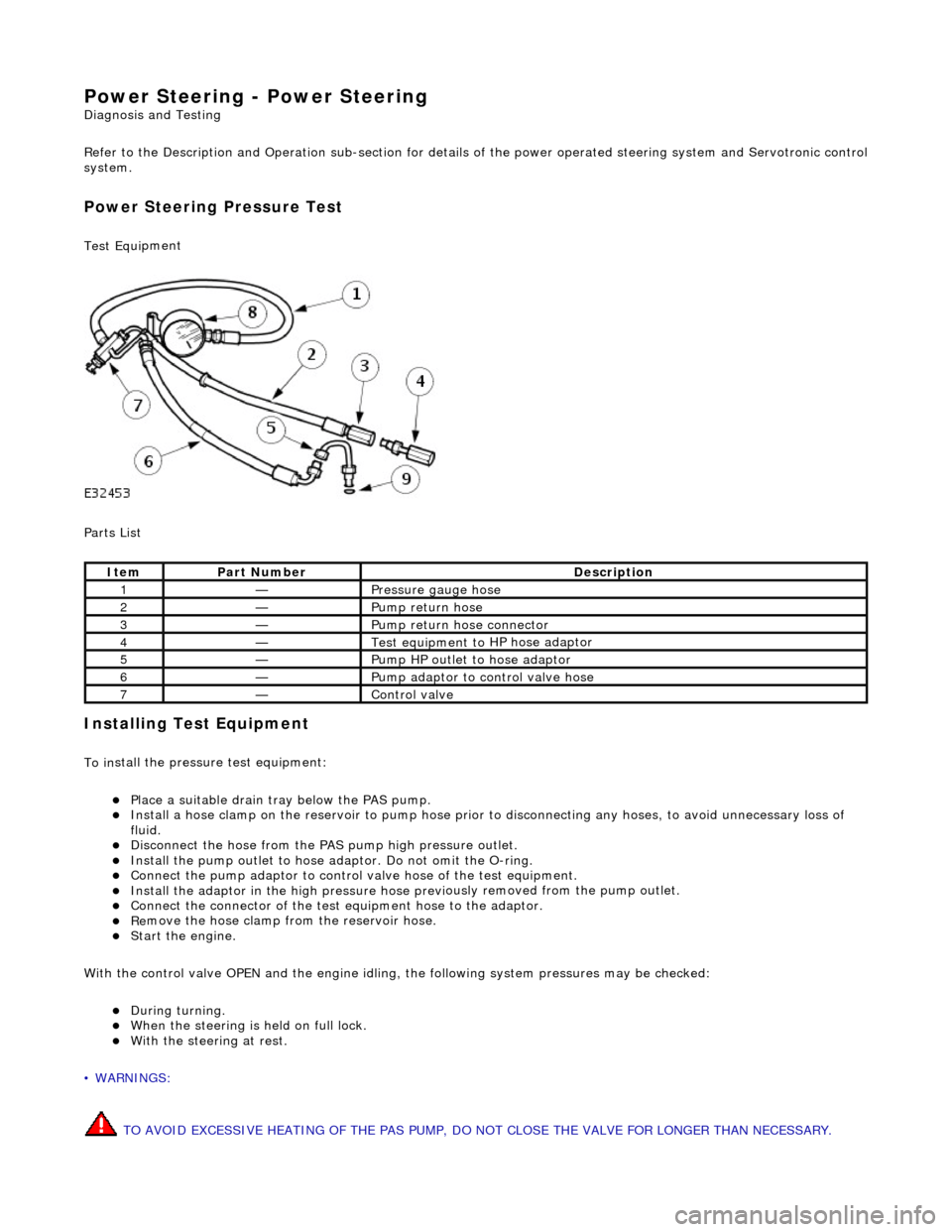

Power Steering - Power Steering

Diagn

osis and Testing

Refer to the Description and Operation sub-section for details of the power operated steering system and Servotronic control

system.

Power Steer ing Pressure Test

Test Equ

i

pment

Parts List

In

stalling Test Equipment

To

in

stall the pressure test equipment:

Pla

c

e a suitable drain tray below the PAS pump.

Install a hose clamp

on

the re

servoir to pump hose prior to disconnecting any hoses, to avoid unnecessary loss of

fluid.

Di sc

onnect the hose from the PAS pump high pres

sure outlet.

Ins

tall the pump outlet to hose ad

aptor. Do not omit the O-ring.

Conn

ect the pump adaptor to control valve hose of the test equipment.

Install th

e adaptor in the high pressure hose previ

ously re

moved from the pump outlet.

Conne

ct the connector of the test equipment hose to the adaptor.

R

e

move the hose clamp fro

m the reservoir hose.

Start th

e engine.

With the control valve OPEN and the engine idling , the following system pressures may be checked:

Du

ring turning.

W

h

en the steering is

held on full lock.

With

the steeri

ng at rest.

• WARNINGS:

TO AVOID EXCESSIVE HEATING OF THE PAS PUMP, DO NOT CLOSE THE VALVE FOR LONGER THAN NECESSARY.

Ite

m

Par

t

Number

De

scr

iption

1—Pressure

gauge hose

2—Pump return hose

3—Pump return hose connector

4—Test equi

pment to

HP hose adaptor

5—Pump HP outlet to hose adaptor

6—Pump adaptor

to control valve hose

7—Control valve

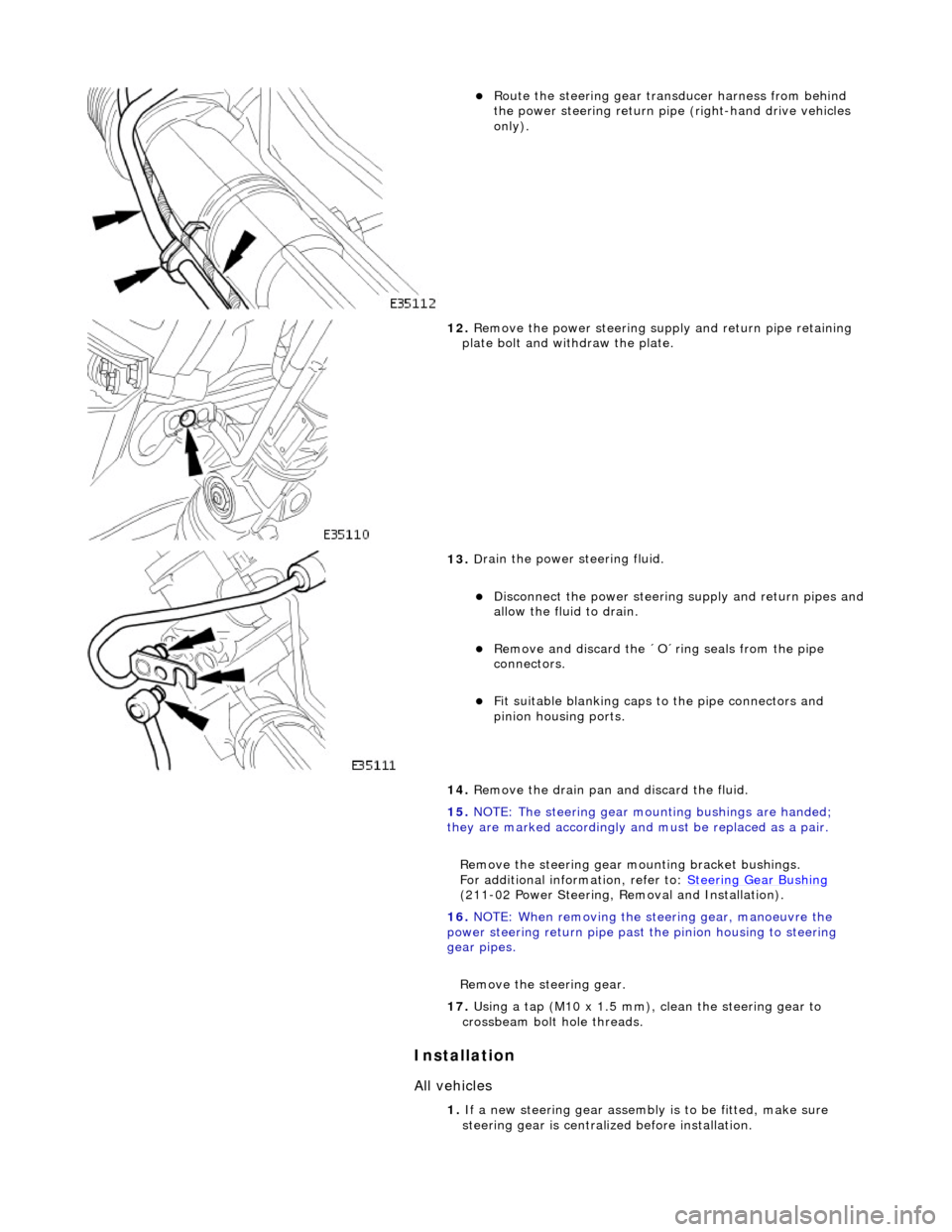

Page 494 of 2490

In

stallation

All vehicles

Route t

he steering gear transducer harness from behind

the power steering return pipe (right-hand drive vehicles

only).

12 . Remove the

power steering supply and return pipe retaining

plate bolt and with draw the plate.

13 . D

rain the power steering fluid.

Di

sc

onnect the power steering

supply and return pipes and

allow the fluid to drain.

Remove an d discard the ´O´ring seals from the

pipe

connectors.

Fi t su

itable blanking caps

to the pipe connectors and

pinion housing ports.

14. Remove the drain pan and discard the fluid.

15. NOTE: The steering gear mounting bushings are handed;

they are marked accordingly and must be replaced as a pair.

Remove the steering gear mo unting bracket bushings.

For additional information, refer to: Steering Gear Bushing

( 21

1-02 Power Steering, Removal and Installation).

16. NOTE: When removing the steering gear, manoeuvre the

power steering return pipe past the pinion housing to steering

gear pipes.

Remove the steering gear.

17. Using a tap (M10 x 1.5 mm), clean the steering gear to

crossbeam bolt hole threads.

1. If a new steering gear assembly is to be fitted, make sure

steering gear is centrali zed before installation.

Page 495 of 2490

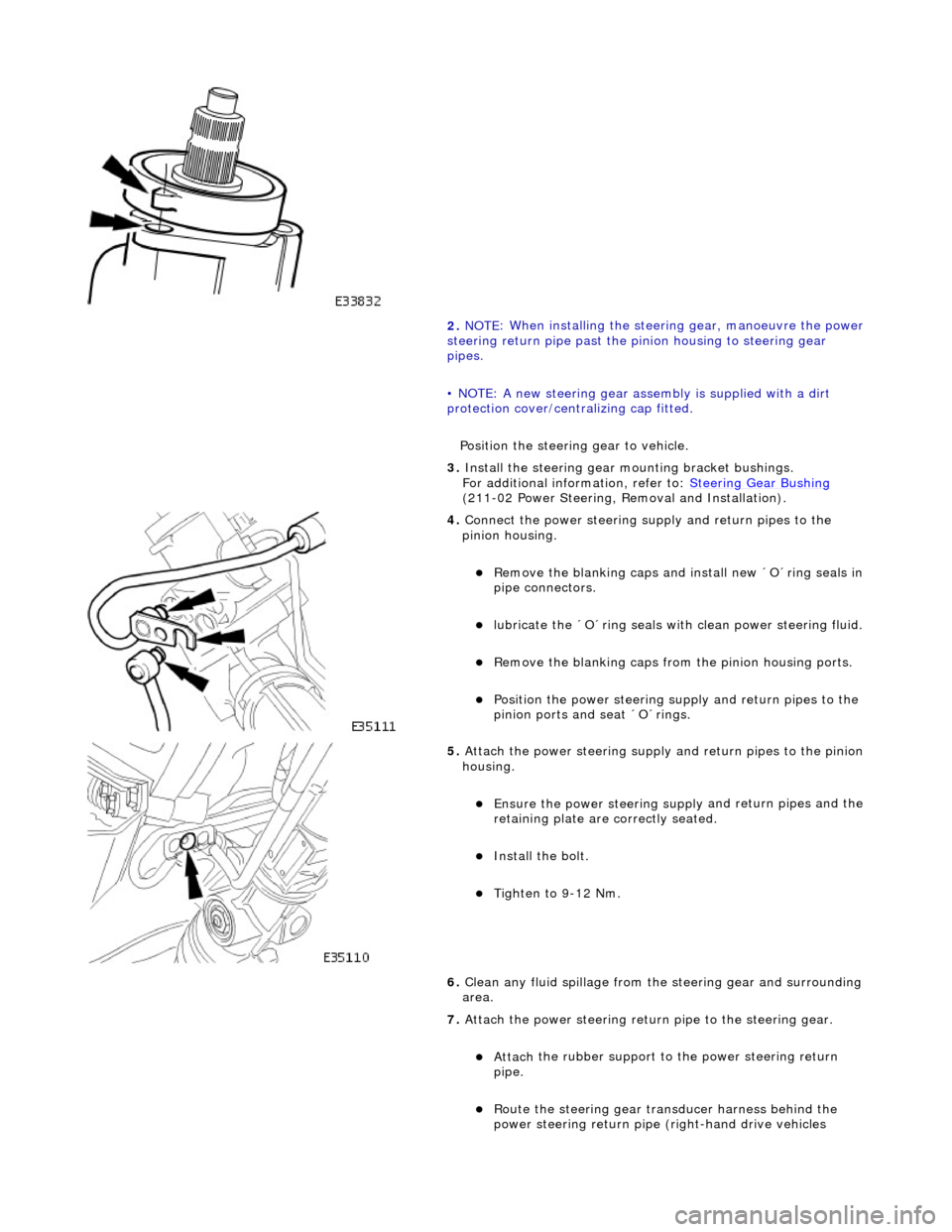

2. NOTE

: When installing the steering gear, manoeuvre the power

steering return pipe past the pinion housin g to steering gear

pipes.

• NOTE: A new steering gear assembly is supplied with a dirt

protection cover/cent ralizing cap fitted.

Position the steering gear to vehicle.

3. Install the steering gear mo unting bracket bushings.

For additional information, refer to: Steering Gear Bushing

(

211-02 Power Steering, Removal and Installation).

4. Conne

ct the power steering su

pply and return pipes to the

pinion housing.

R

emove the blanking caps an

d install new ´O´ring seals in

pipe connectors.

lubri

cate the ´O´ring seals wi

th clean power steering fluid.

R

emove the blanking caps from

the pinion housing ports.

Position the power

steering su

pply and return pipes to the

pinion ports and seat ´O´rings.

5. Attach

the power steering supply

and return pipes to the pinion

housing.

Ensure the power steering su pply

and return pipes and the

retaining plate are correctly seated.

Install th

e bolt.

Tigh

ten to 9-12 Nm.

6. Clean any fluid spillage from the steering gear and surrounding

area.

7. Attach the power steering return pipe to the steering gear.

Attach

the rubber support to

the power steering return

pipe.

Rout

e the steering gear transducer harness behind the

power steering return pipe (right-hand drive vehicles

Page 497 of 2490

Locate the ti

e rod end into the steering arm.

Inst

all a new nut.

Tigh

ten the nut to 22-28 Nm.

12

.

NOTE: Make sure the steering wheel and wheel and tire

assemblies are in the straight ah ead position before fitting the

steering column lower shaft.

Attach the steering column lower shaft.

1. Attach the steering column lower shaft.

2. Install the steering column lower shaft retaining bolt.

1. Tighten to 28 - 34 Nm

.

3

. Tighten to 28 - 34 Nm.

13. Fit a new power steering fluid re servoir, refill with new power

steering fluid and blee d air from the system.

For additional information, refer to: Power Steering System

Fillin

g and Bleeding

(211-00 Steering System - General

Information, Gene ral Procedures).

14. Check and adjust the front toe.

For additional information, refer to: Front Toe Adjustment

(204-00 Suspen

sion System -

General Information, General

Procedures).

Page 903 of 2490

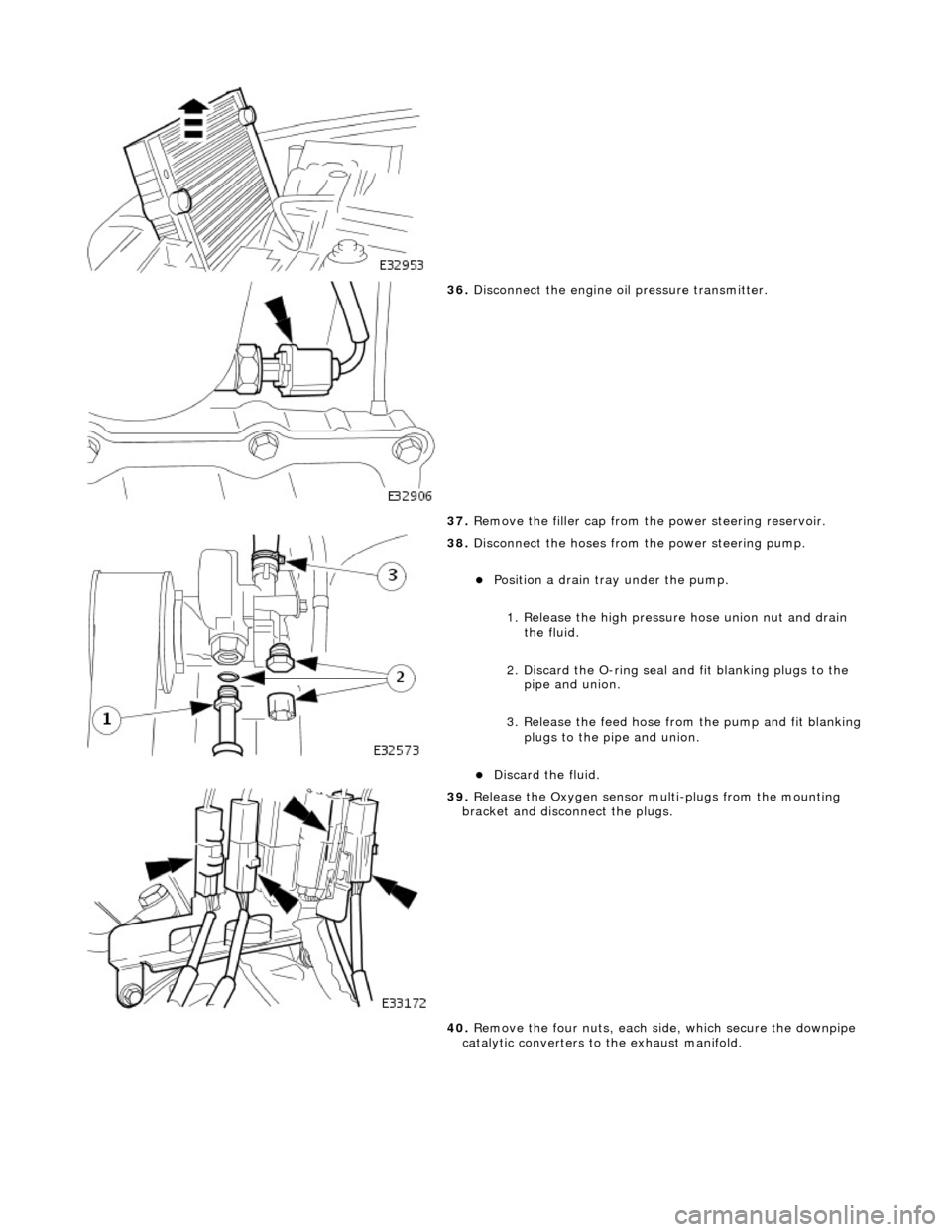

36. Disconnect the engine oi l pressure transmitter.

37. Remove the filler cap from the power steering reservoir.

38. Disconnect the hoses from the power steering pump.

Position a drain tray under the pump.

1. Release the high pressure hose union nut and drain the fluid.

2. Discard the O-ring seal an d fit blanking plugs to the

pipe and union.

3. Release the feed hose from the pump and fit blanking

plugs to the pipe and union.

Discard the fluid.

39. Release the Oxygen sensor multi-plugs from the mounting

bracket and disconnect the plugs.

40. Remove the four nuts, each side, which secure the downpipe

catalytic converters to the exhaust manifold.

Page 1804 of 2490

Air Conditioning - Air Conditioning (A/C) Compressor

Removal and Installation

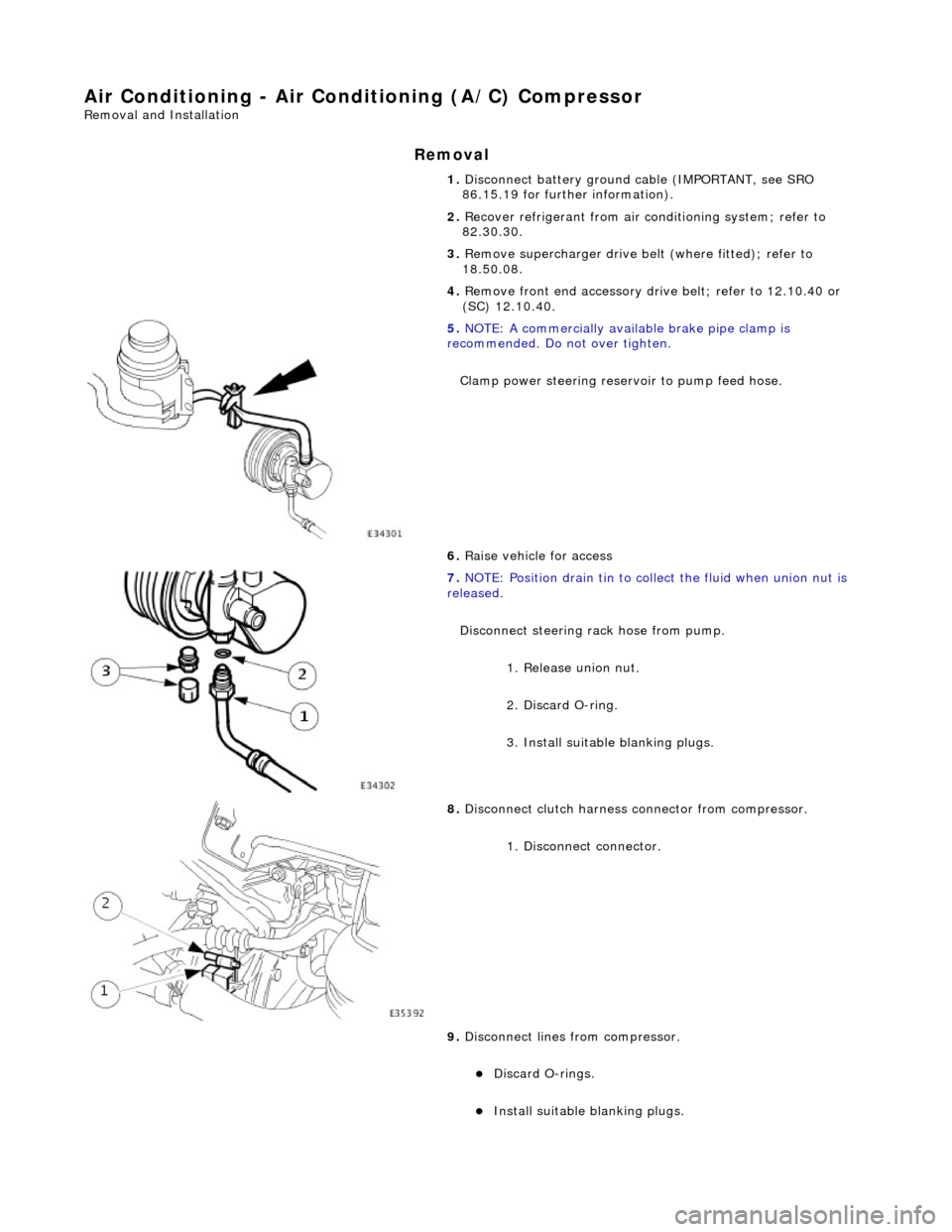

Removal

1. Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Recover refrigerant from air co nditioning system; refer to

82.30.30.

3. Remove supercharger drive belt (where fitted); refer to

18.50.08.

4. Remove front end accessory dr ive belt; refer to 12.10.40 or

(SC) 12.10.40.

5. NOTE: A commercially availa ble brake pipe clamp is

recommended. Do not over tighten.

Clamp power steering reservoir to pump feed hose.

6. Raise vehicle for access

7. NOTE: Position drain tin to collect the fluid when union nut is

released.

Disconnect steering rack hose from pump. 1. Release union nut.

2. Discard O-ring.

3. Install suitable blanking plugs.

8. Disconnect clutch harness connector from compressor.

1. Disconnect connector.

9. Disconnect lines from compressor.

Discard O-rings.

Install suitable blanking plugs.

Page 2423 of 2490

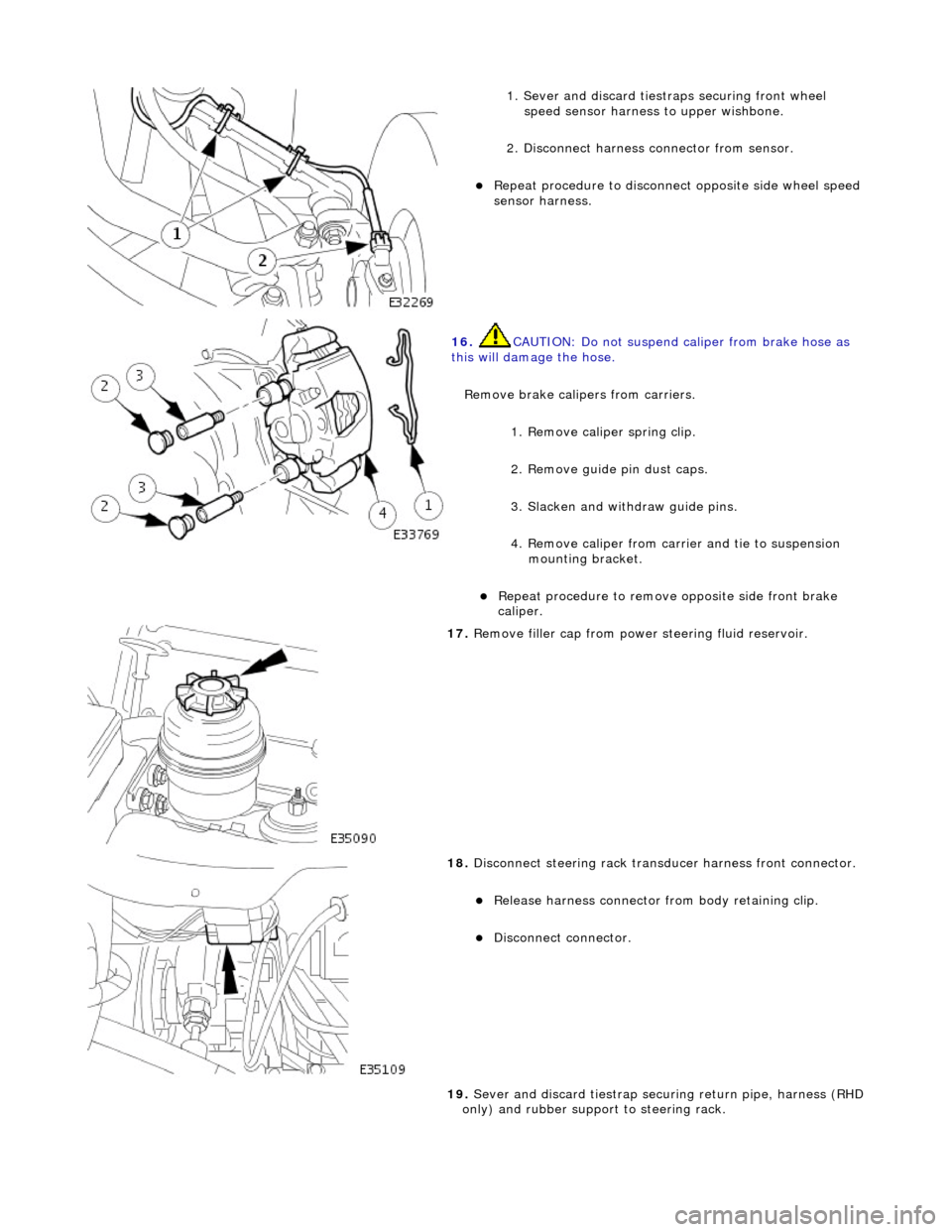

1. Sever and discard tiestraps securing front wheel

speed sensor harness to upper wishbone.

2. Disconnect harness connector from sensor.

Repeat procedure to disconnect opposite side wheel speed

sensor harness.

16. CAUTION: Do not suspend caliper from brake hose as

this will damage the hose.

Remove brake calipers from carriers.

1. Remove caliper spring clip.

2. Remove guide pin dust caps.

3. Slacken and withdraw guide pins.

4. Remove caliper from carrier and tie to suspension mounting bracket.

Repeat procedure to remove opposite side front brake

caliper.

17. Remove filler cap from power steering fluid reservoir.

18. Disconnect steering rack transducer harness front connector.

Release harness connector from body retaining clip.

Disconnect connector.

19. Sever and discard tiestrap secu ring return pipe, harness (RHD

only) and rubber support to steering rack.

Page 2424 of 2490

20. RHD vehicles. Sever and discard tiestrap securing harness to

steering rack.

21. Route harness from behind steering return pipe.

22. Position a drain receptacle below pinion housing.

23. Remove pipe retaining plate secu ring bolt and withdraw plate.

24. Drain power steering fluid.

Disconnect pipes and al low fluid to drain.

Remove and discard 'O'-ring seals from pipe connectors.

Fit blanking plugs to pipe connectors and pinion housing

ports.

25. Remove drain receptacle.

26. Remove pipe support from steering rack.

Release return pipe from support.