JAGUAR X308 1998 2.G Workshop Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Workshop Manual

Page 1468 of 2490

Operation

• NOTE: The rotary position switch is NOT adjustable.

The position of the gear selector lever is detected by the range sensor; a system which consists of two sensors (switch

systems). 1. 1. The rotary position switch, which is located on the RH side of the transmission case and is coaxial with the

selector shaft.

2. 2. The D to 4 (micro) switch, which is mounted in the 'J gate' assembly.

When the selector is moved across the ga te to engage 4, or back from that side towards D the selector cable does not

move. In order that this change of state be registered by the TCM the D to 4 switch is incorporated.

The rotary switch in isolation provides a 4-bit code, which, when added to the D to 4 switch becomes a 5-bit code. The TCM

will make a failure judgement if it detects an 'illegal' code.

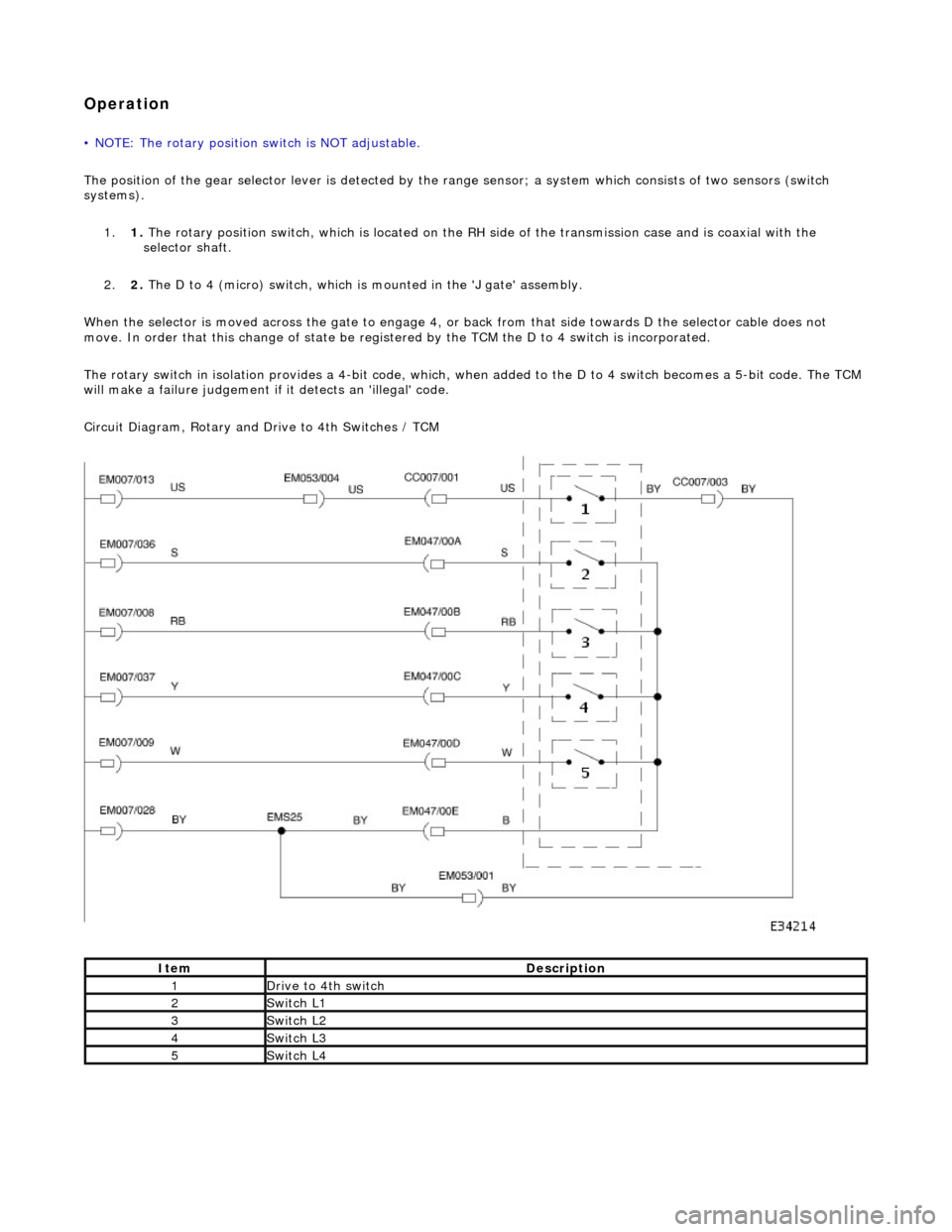

Circuit Diagram, Rotary and Drive to 4th Switches / TCM

ItemDescription

1Drive to 4th switch

2Switch L1

3Switch L2

4Switch L3

5Switch L4

Page 1469 of 2490

Automatic Transmission/Transaxle External Controls - 4.0L NA V8 -

AJ27/3.2L NA V8 - AJ26 - External Controls

Diagnosis and Testing

Symptom Chart

Symptom Chart

Pinpoint test A: P0706

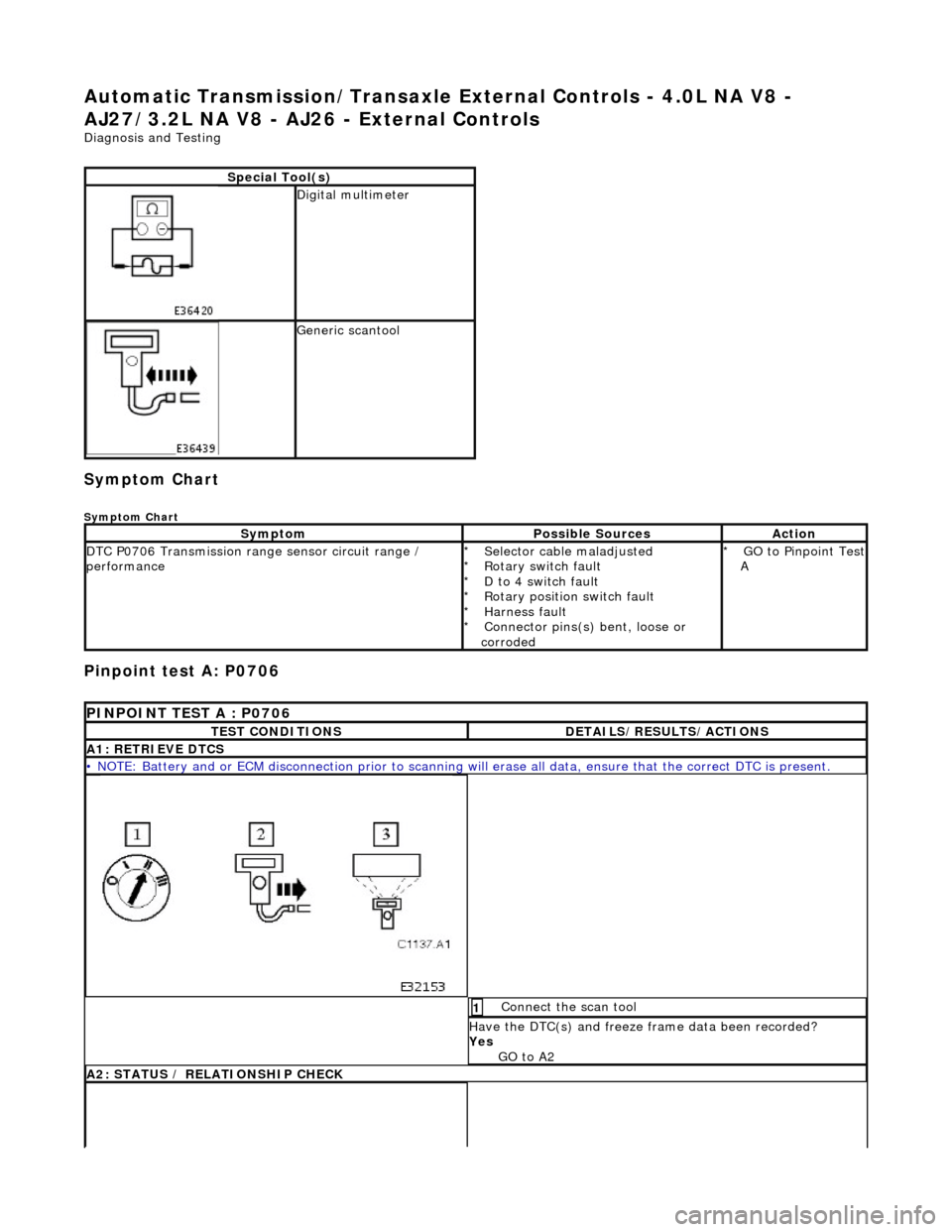

Special Tool(s)

Digital multimeter

Generic scantool

SymptomPossible SourcesAction

DTC P0706 Transmission range sensor circuit range /

performanceSelector cable maladjusted

Rotary switch fault

D to 4 switch fault

Rotary position switch fault

Harness fault

Connector pins(s) bent, loose or

corroded

*

*

*

*

*

*GO to Pinpoint Test A

*

PINPOINT TEST A : P0706

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

A1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to A2

A2: STATUS / RELATIONSHIP CHECK

Page 1505 of 2490

Shift Selection and Gear Position

Symptom Chart

Pinpoint test A: P0705

Loose selector disc seal

*

SymptomPossible SourcesAction

DTC P0705 Transmission range sensor circuit

malfunctionSelector cable maladjusted

Linear switch maladjusted

Linear position switch fault

Harness fault

Connector pins(s) bent, loose or

corroded

*

*

*

*

*GO to Pinpoint Test

A

*

PINPOINT TEST A : P0705

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

A1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to A2

A2: STATUS / RELATIONSHIP CHECK

Move the selector lever sl owly from P to 2 and back,

noting the illumination / positi on relationship as follows: 1

Does state illumination match the lever position in each

direction of travel?

Yes

GO to A4

No GO to A3

No With lever at D (when moving from 2 to P ) is 3 or 4

illuminated?

Yes GO to A3

Page 1522 of 2490

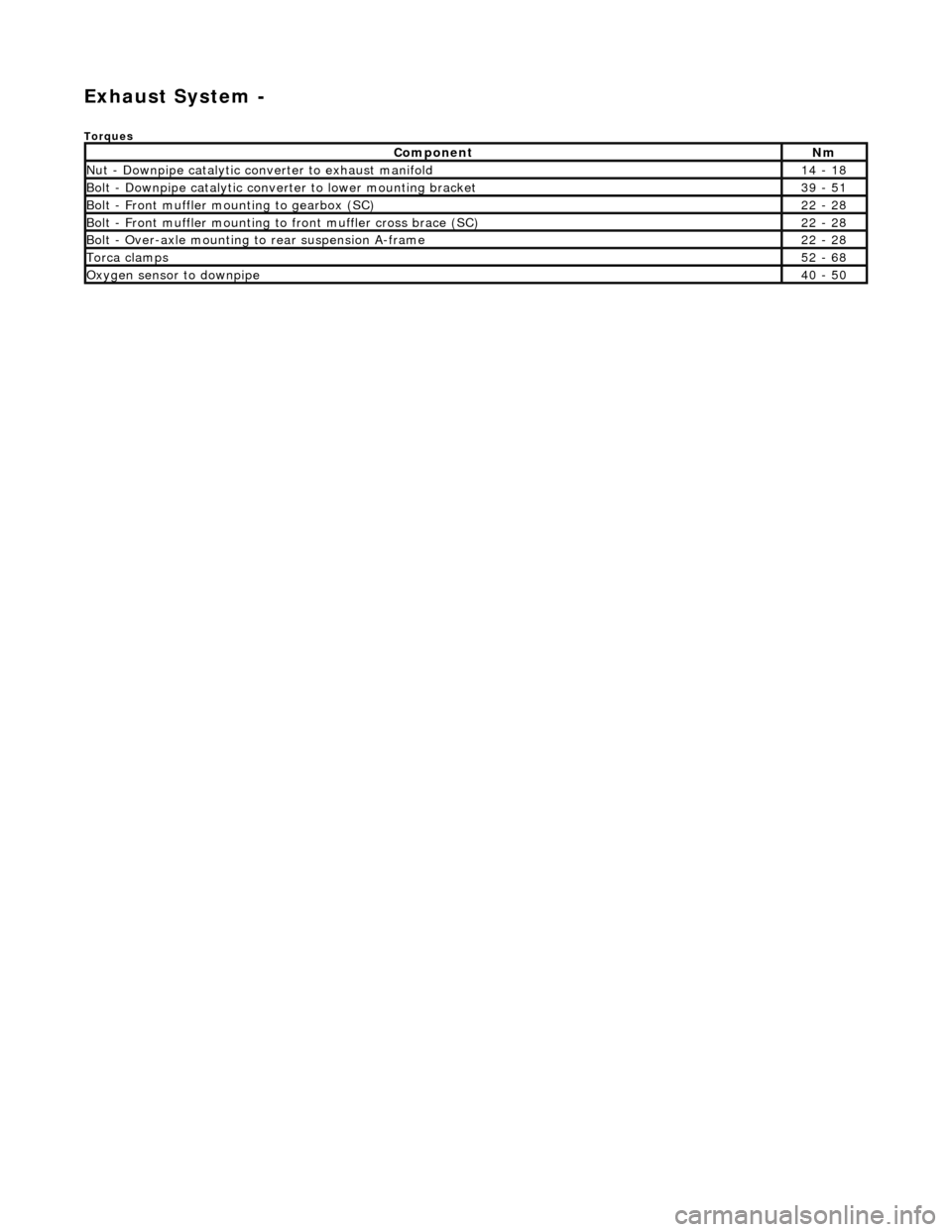

Exhaust System -

Torques

ComponentNm

Nut - Downpipe catalytic converter to exhaust manifold14 - 18

Bolt - Downpipe catalytic converter to lower mounting bracket39 - 51

Bolt - Front muffler mounting to gearbox (SC)22 - 28

Bolt - Front muffler mounting to front muffler cross brace (SC)22 - 28

Bolt - Over-axle mounting to rear suspension A-frame22 - 28

Torca clamps52 - 68

Oxygen sensor to downpipe40 - 50

Page 1525 of 2490

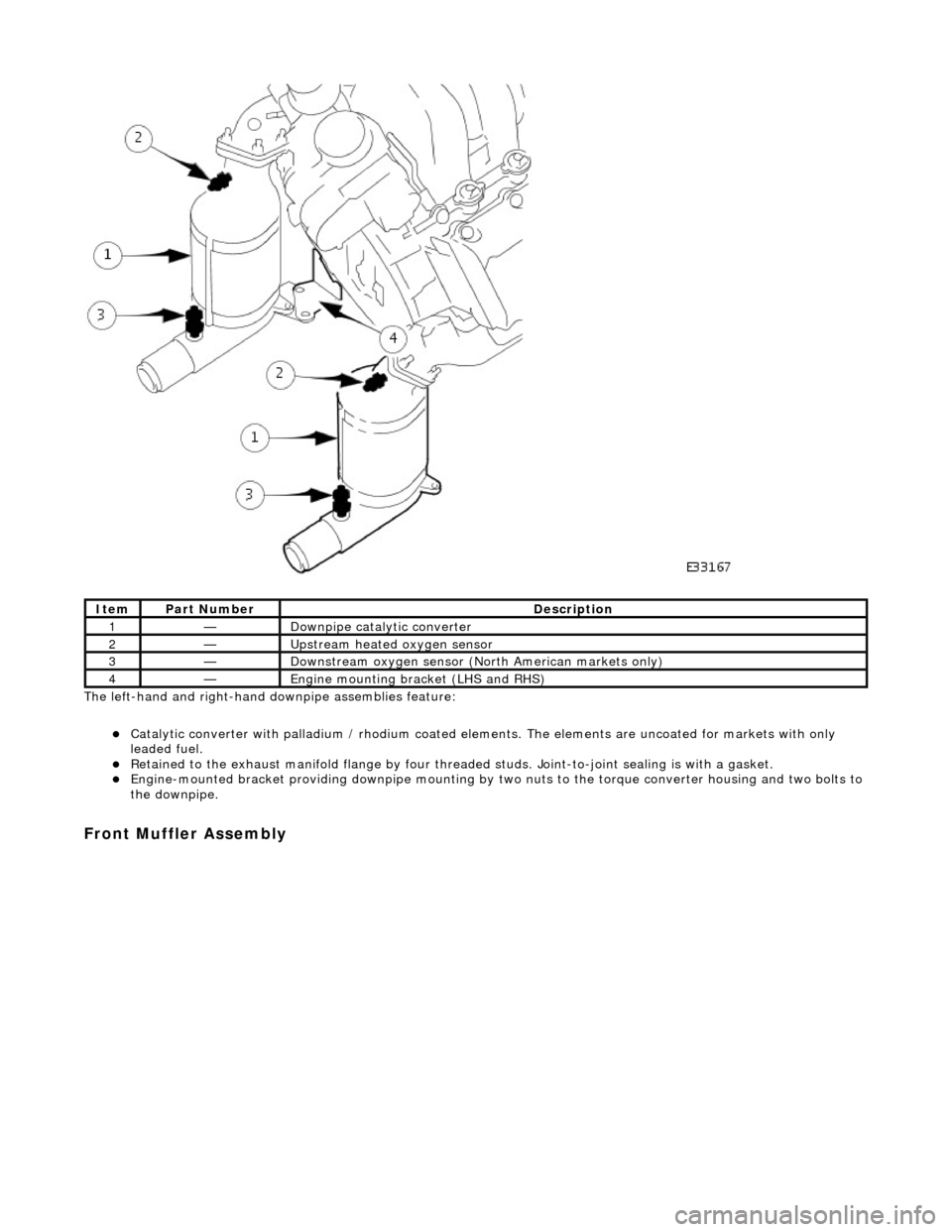

The left-hand and right-hand do wnpipe assemblies feature:

Catalytic converter with palladium / rhodium coated elem ents. The elements are uncoated for markets with only

leaded fuel.

Retained to the exhaust manifold flange by four thread ed studs. Joint-to-joint sealing is with a gasket. Engine-mounted bracket providing downpipe mounting by two nuts to the torque converter housing and two bolts to

the downpipe.

Front Muffler Assembly

ItemPart NumberDescription

1—Downpipe catalytic converter

2—Upstream heated oxygen sensor

3—Downstream oxygen sensor (North American markets only)

4—Engine mounting bracket (LHS and RHS)

Page 1528 of 2490

Joints and Clamps

Pipe-to-pipe joints which are slip joints, feature:

Clamping by Torca strap clamp. Indicator rings providing Maximum, Mini mum and Nominal engagement marks.

Oxygen Sensor (O2)

Location

Page 1529 of 2490

Parts List

Operation

ItemPart NumberDescription

1—Heated oxygen sensor (upstream)

2—Oxygen sensor (downstream)

3—Catalytic converter

Page 1530 of 2490

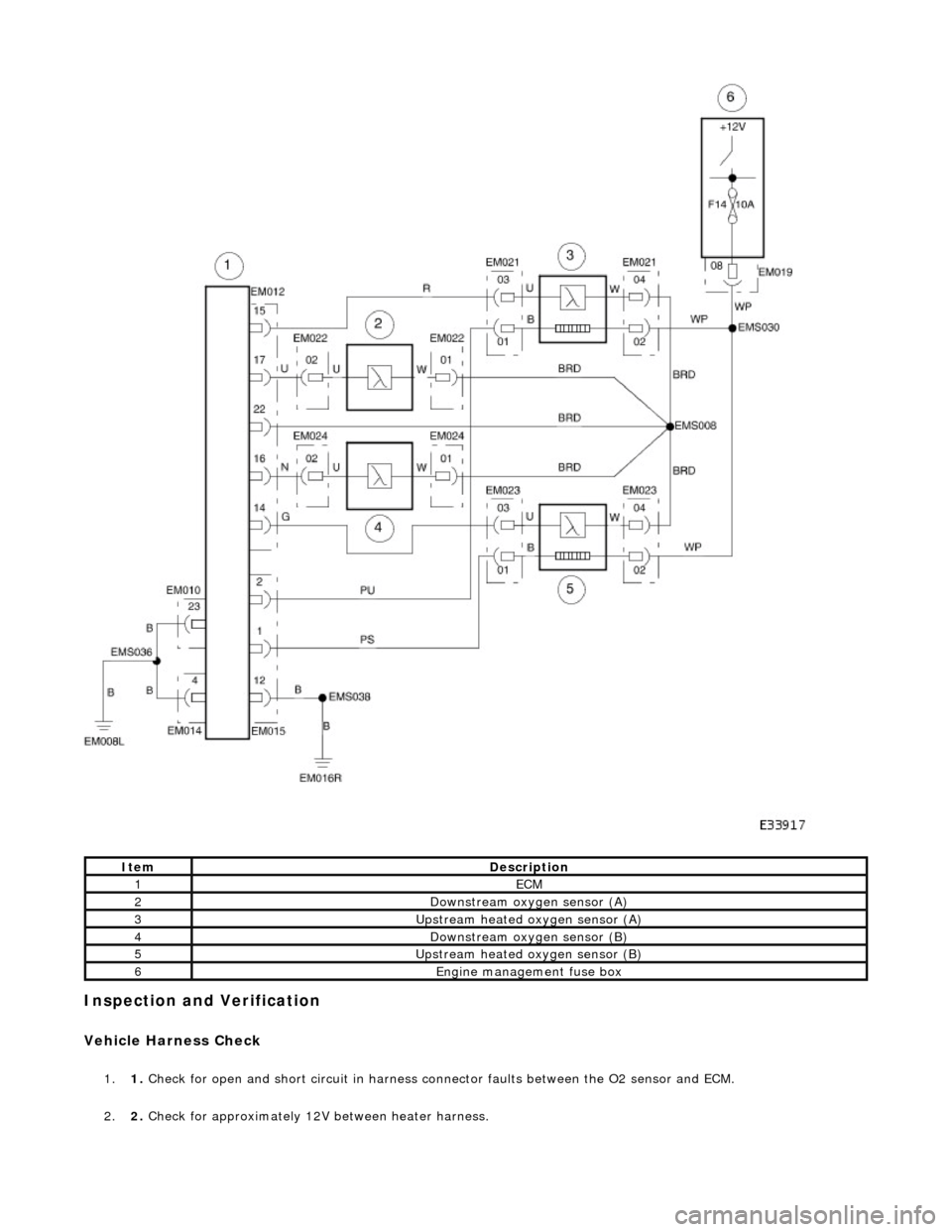

The upstream heated oxygen sensor is located at the catalytic converter inlet and detects the concentration of oxygen in the

raw exhaust gases; an internal heater reduces the warm up time of the sensor output.

An oxygen sensor (without heater) is located at the converter outlet.

The ECM receives input signals from the se nsors and varies the fuel injector duration (mixture) to provide optimum gas

emissions.

Circuit Diagram, O2 Sensors / ECM

Page 1531 of 2490

Inspection and Verification

Vehicle Harness Check

1.1. Check for open and short circuit in harness conn ector faults between the O2 sensor and ECM.

2. 2. Check for approximately 12V between heater harness.

ItemDescription

1ECM

2Downstream oxygen sensor (A)

3Upstream heated oxygen sensor (A)

4Downstream oxygen sensor (B)

5Upstream heated oxygen sensor (B)

6Engine management fuse box

Page 1532 of 2490

Heater Resistance Check

1.1. Verify that the resistance between the heater term inals is between 4OHM and 10OHM at -20°C to 100°C.

Performance Check

1.1. Run the engine at 2500 RPM for two minutes, to heat up the O2 sensor.

2. 2. Check the voltage of the sensor output: Alternates between less than 0.4V at feed back engine conditions and in

excess of 0.5V, see graph.

These voltages are for reference only.

3. 3. Check that cycle of the upstream se nsor output is in accordance with the appropriate pinpoint test.

4. 4. Check that cycle of the downstream sensor output is in accordance with the appropriate pinpoint test.