Ground JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1628 of 2490

Wi

th EM012 and EM024 disconnected, measure the

resistance between EM012/022 and EM024/001.

1

I s

the resistance < 0.5 OHM?

Yes GO to H10

No Inspect harness / connectors EM012 and EM024 for corrosion,

damaged / pushed back pins.

Repair as required an d reconnect plug(s).

GO to H11

H 1

0: O2 SENSOR SHORT CIRCUIT TO GROUND

Page 1629 of 2490

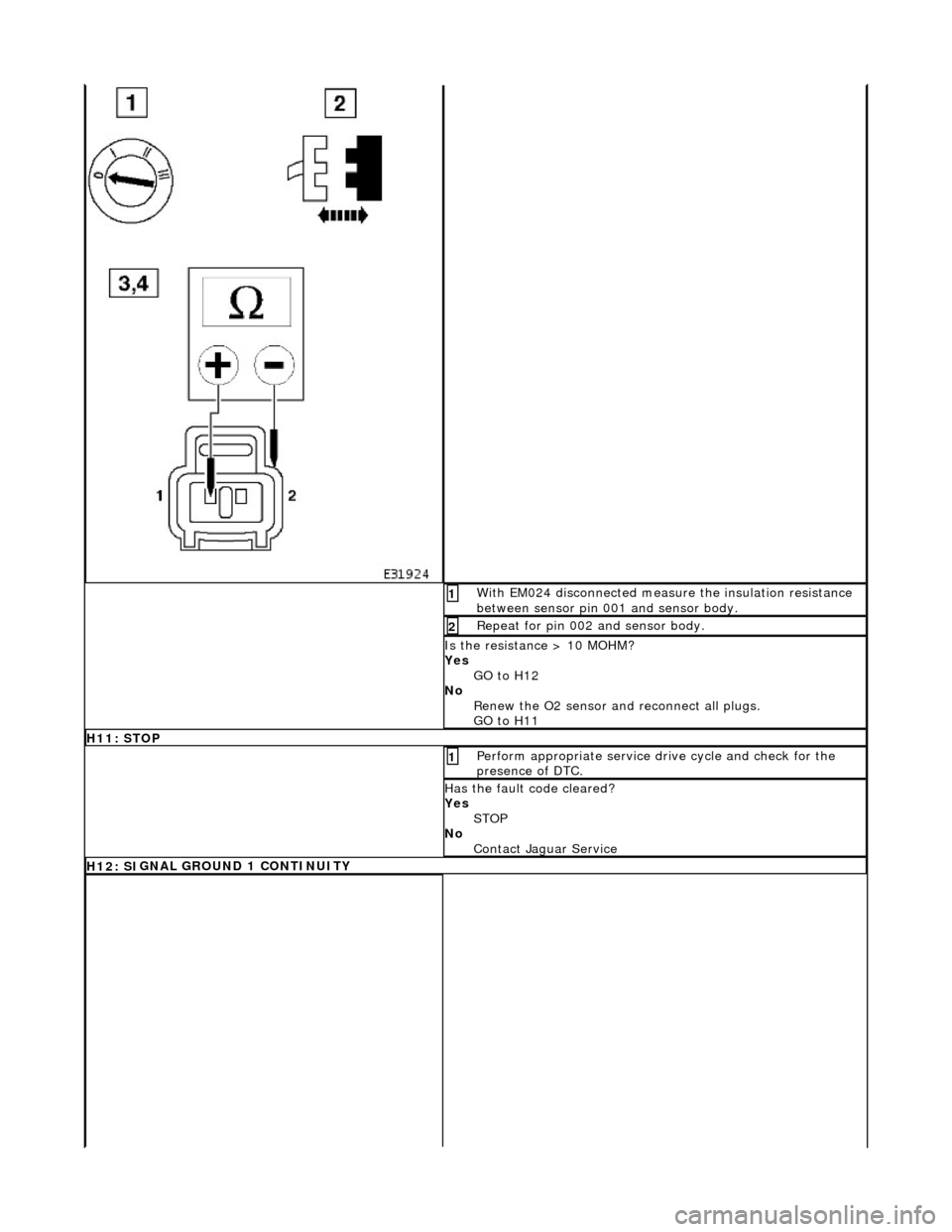

W

ith EM024 disconnected measur

e the insulation resistance

between sensor pin 001 and sensor body.

1

Repeat

for pin 002 and sensor body.

2

I

s the resistance > 10 MOHM?

Yes GO to H12

No Renew the O2 sensor and reconnect all plugs.

GO to H11

H1

1: STOP

Perform

appropriate service drive cycle and check for the

presence of DTC.

1

Has

the fault code cleared?

Yes STOP

No Contact Jaguar Service

H12: SI

GNAL GROUND 1 CONTINUITY

Page 1630 of 2490

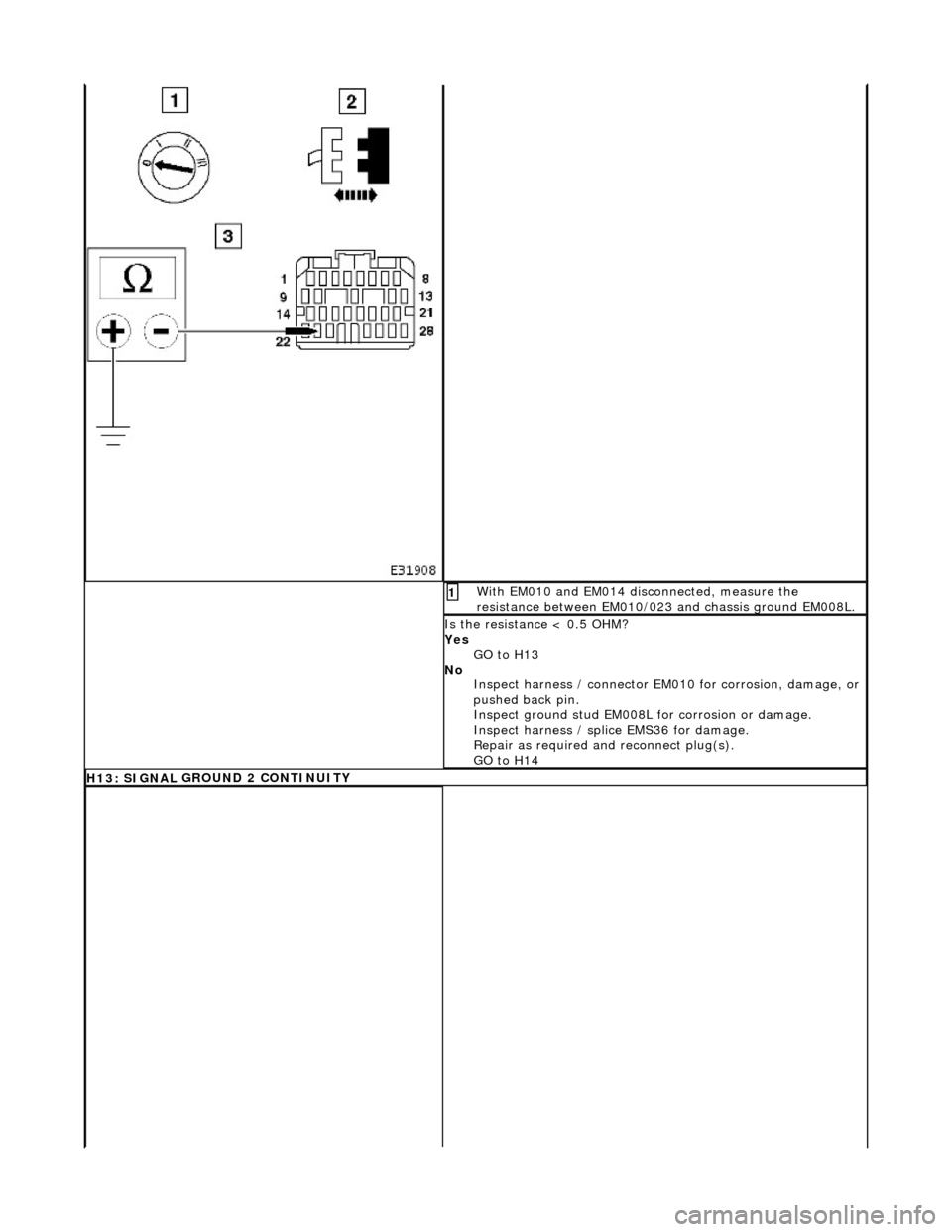

Wi

th EM010 and EM014 disconnected, measure the

resistance between EM010/023 and chassis ground EM008L.

1

I s

the resistance < 0.5 OHM?

Yes GO to H13

No Inspect harness / connector EM010 for corrosion, damage, or

pushed back pin.

Inspect ground stud EM008L for corrosion or damage.

Inspect harness / spli ce EMS36 for damage.

Repair as required an d reconnect plug(s).

GO to H14

H13: SI GNAL

GROUND 2 CONTINUITY

Page 1631 of 2490

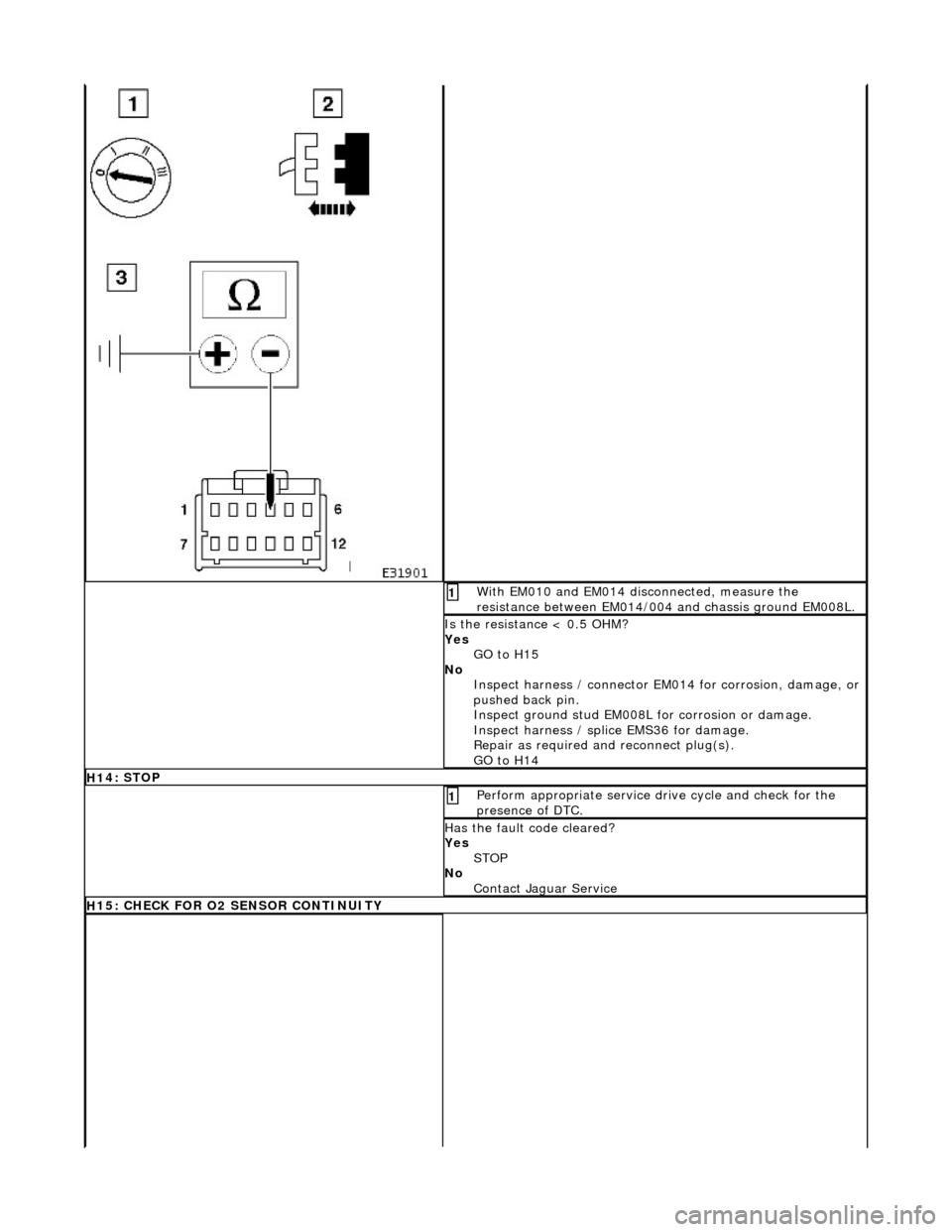

W

ith EM010 and EM014 disconnected, measure the

resistance between EM014/004 and chassis ground EM008L.

1

I

s the resistance < 0.5 OHM?

Yes GO to H15

No Inspect harness / connector EM014 for corrosion, damage, or

pushed back pin.

Inspect ground stud EM008L for corrosion or damage.

Inspect harness / spli ce EMS36 for damage.

Repair as required an d reconnect plug(s).

GO to H14

H1

4: STOP

Perform

appropriate service drive cycle and check for the

presence of DTC.

1

Has

the fault code cleared?

Yes STOP

No Contact Jaguar Service

H

15: CHECK FOR O2 SENSOR CONTINUITY

Page 1632 of 2490

Wi

th EM012 and EM024 disconnected, measure the

resistance between EM012/016 and EM024/002.

1

I s

the resistance < 0.5 OHM?

Yes GO to H16

No Inspect harness / connecto rs EM012, and EM024 for

corrosion, damaged / pushed back pins.

Repair as required an d reconnect plug(s).

GO to H21

H 1

6: O2 SENSOR SCREEN GROUND CONTINUITY

Page 1635 of 2490

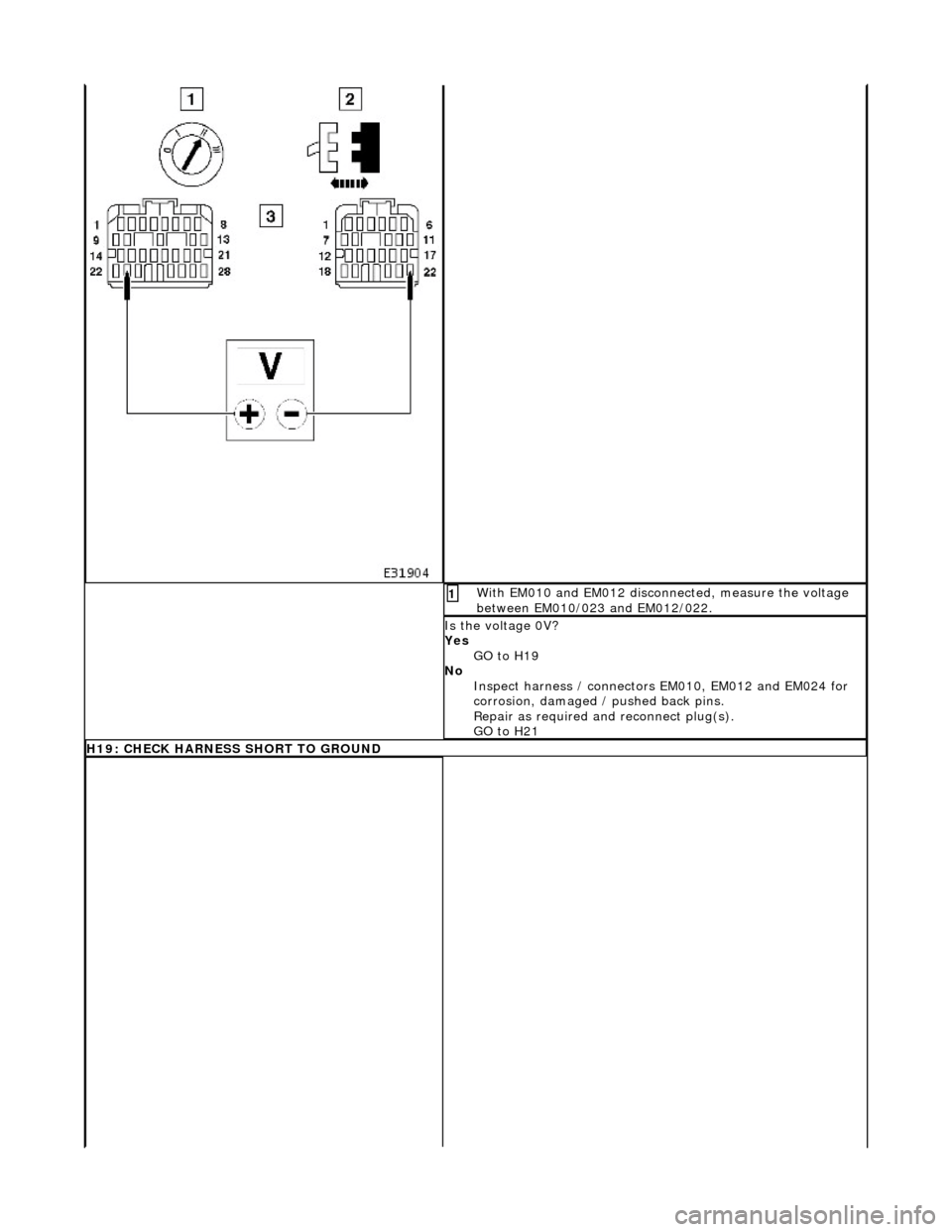

W

ith EM010 and EM012 disconnected, measure the voltage

between EM010/023 and EM012/022.

1

Is th

e voltage 0V?

Yes GO to H19

No Inspect harness / connectors EM010, EM012 and EM024 for

corrosion, damaged / pushed back pins.

Repair as required an d reconnect plug(s).

GO to H21

H

19: CHECK HARNESS SHORT TO GROUND

Page 1636 of 2490

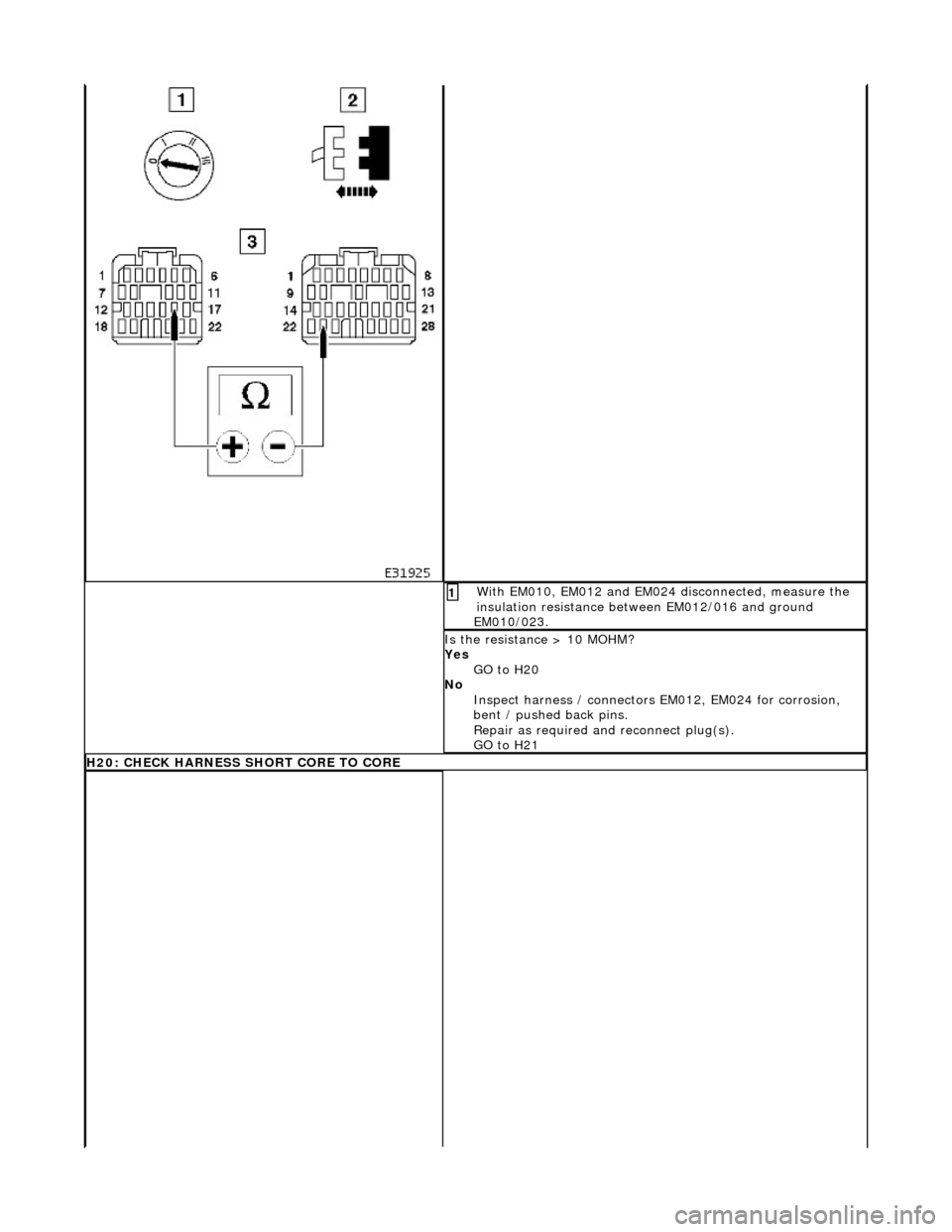

Wi

th EM010, EM012 and EM024 disconnected, measure the

insulation resistance between EM012/016 and ground

EM010/023.

1

Is

the resistance > 10 MOHM?

Yes GO to H20

No Inspect harness / connectors EM012, EM024 for corrosion,

bent / pushed back pins.

Repair as required an d reconnect plug(s).

GO to H21

H20: CHECK HA RNESS SHO

RT CORE TO CORE

Page 1691 of 2490

Fuel System - Gener

al Information - Fuel Tank Draining

Gen

eral Procedures

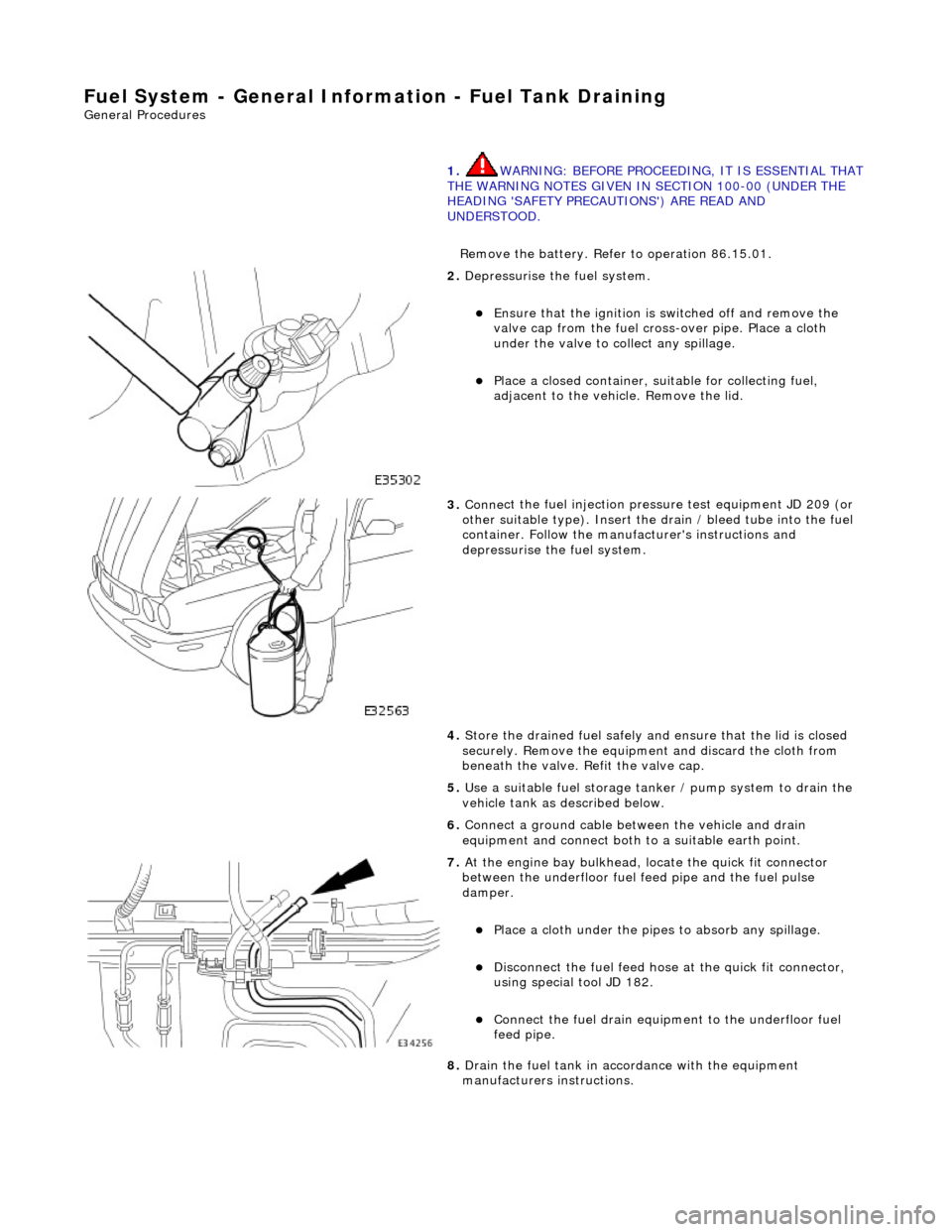

1.

WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Remove the battery. Refer to operation 86.15.01.

2. De

pressurise the fuel system.

пЃ¬E

nsure that the ignition is

switched off and remove the

valve cap from the fuel cross-over pipe. Place a cloth

under the valve to collect any spillage.

пЃ¬Pla

ce a closed container, su

itable for collecting fuel,

adjacent to the vehicle. Remove the lid.

3. Conne

ct the fuel injection pressu

re test equipment JD 209 (or

other suitable type). Insert the drain / bleed tube into the fuel

container. Follow the manufa cturer's instructions and

depressurise the fuel system.

4. Store the drained fuel safely and ensure that the lid is closed

securely. Remove the equipmen t and discard the cloth from

beneath the valve. Refit the valve cap.

5. Use a suitable fuel storage tank er / pump system to drain the

vehicle tank as described below.

6. Connect a ground cable betw een the vehicle and drain

equipment and connect both to a suitable earth point.

7. At the engine bay bulkhead, lo cate the quick fit connecto

r

between the underfloor fuel feed pipe and the fuel pulse

damper.

пЃ¬Pla

ce a cloth under the pipes

to absorb any spillage.

пЃ¬D

isconnect the fuel feed hose

at the quick fit connector,

using special tool JD 182.

пЃ¬Conne

ct the fuel drain equipment to the underfloor fuel

feed pipe.

8. Drain the fuel tank in accordance with the equipment

manufacturers instructions.

Page 1692 of 2490

Fuel Tank and Lines - Fuel Tank and Li

nes

Description an

d Operation

Fuel Tank

Parts List

The steel fuel tank is located inside the trunk and mounted across the vehicle behind the passenger compartment bulkhead.

The fuel tank is held in posi tion by two retaining straps fi tted to body-mounted brackets.

The fuel tank has an integral non-adjustable fill er pipe and integral breather and vapor pipework.

A single fuel pump is mounted inside the tank on vehicles with normally aspirated engines. For vehicles with supercharged

engines, two pumps are fitted in the tank. Fuel is drawn by the pump(s) from the fuel tank and supplied via the fuel lines

and 70 micron filter to the fuel rails.

The fuel lines run from front-to-rear down the vehicle's left-hand-side.

Ite

m

Part

Number

Descr

iption

1—Fu

el filler latch box

2—Pressure reli

ef pipe, ORVR

(shown) / tank breather pipe on non-ORVR systems

3—Tank grounding

cable

4—Evaporative flan

ge assembly

(ORVR type shown)

5—Trunk elec

trical harne

ss (part of)

6—Fue

l

level sensor

flange/connector

7—Fu

el tank retaining straps

8—F

u

el tank retaining stra

ps adjustable clamps

9—Fu

el tank retaining straps lower brackets

10—Tank vapor outlet pipe to un

derflo

or pipe quick-fit connector

11—F

u

el filler latch bo

x water drain pipe

Page 1698 of 2490

Fuel Tank and Lines - Fuel Tank and Li

nes

D

iagn

osis and Testing

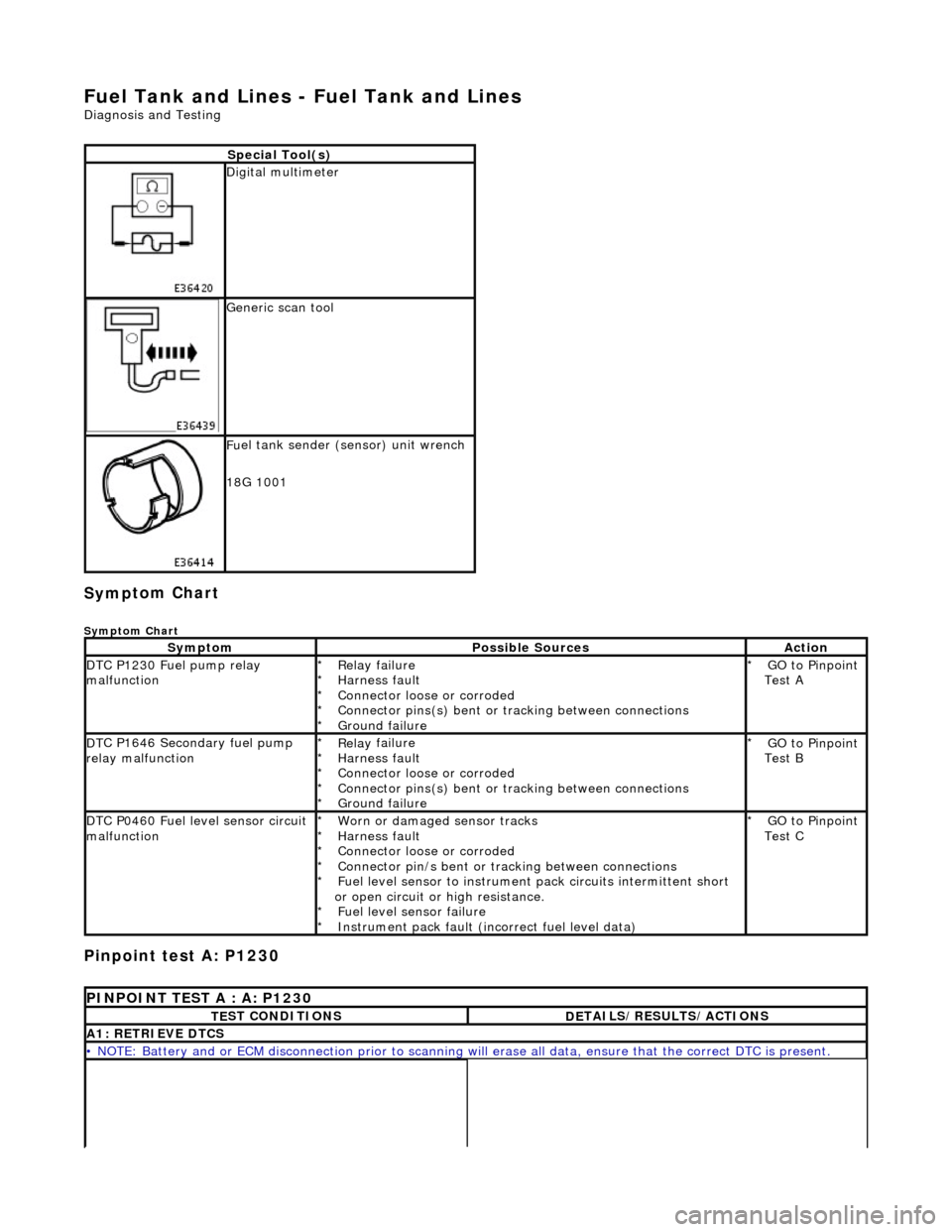

Sym

p

tom Chart

Sy

m

ptom Chart

Pinpoint test A: P1230

S

p

ecial Tool(s)

D

i

gital multimeter

Generi

c scan tool

F

u

el tank sender (sensor) unit wrench

18G 1001

Sy m

ptom

Possib

l

e Sources

Acti

o

n

D

T

C P1230 Fuel pump relay

malfunction

Re lay

failure

Harness fault

Connector loose or corroded

Connector pins(s) bent or tracking between connections

Ground failure

*

*

*

*

*

GO to Pinpoint

Test A

*

D

T

C P1646 Secondary fuel pump

relay malfunction

Re lay

failure

Harness fault

Connector loose or corroded

Connector pins(s) bent or tracking between connections

Ground failure

*

*

*

*

*

GO to Pinpoint

Test B

*

D

T

C P0460 Fuel level sensor circuit

malfunction

Worn

or damaged sensor tracks

Harness fault

Connector loose or corroded

Connector pin/s bent or tracking between connections

Fuel level sensor to instrument pack circui ts intermittent short

or open circuit or high resistance. Fuel level sensor failure

Instrument pack fault (inc orrect fuel level data)

*

*

*

*

*

*

*

GO to Pinpoint

Test C

*

P

INPOINT TES

T A : A: P1230

T

E

ST CONDITIONS

D

E

TAILS/RESULTS/ACTIONS

A1

: RETRIEV

E DTCS

•

NOTE

: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.