charger JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1004 of 2490

Engine Cooling - Water Pump4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the cooling system.

For additional information, refer to Cooling System Draining,

Filling and Bleedin

g

- Vehicles With

: Supercharger in this

section.

3. Remove the supercharger driv e belt. Refer to Operation

18.50.08.

4. Slacken the three screws whi

ch

secure the water pump pulley.

5. CAUTIO

N: When releasing the

belt tension, never apply

any torque in a clockwise direction to the pulley ce ntre bolt (left

hand thread) as it could subsequently loosen.

Remove the drive belt from the generator and accessory drive.

1. Use a spanner e.g. Churchill JD-230 or Snap On XDHM 1415, on the centre bo lt of the belt tensioner

idler pulley, to turn the adju ster assembly to the left

against spring tension.

2. Whilst holding the tensioner against spring tension, remove the drive belt from the generator pulley.

Release the tensioner sl owly and remove the

spanner.

Di

sconnect the belt from the ot

her pulleys, as necessary,

to move it clear of the pump pulley.

6. Remove t

he pulley from the water pump.

1. Remove the pulley securing screws.

2. Remove the pulley from the water pump.

7. Remove the water pump.

Page 1006 of 2490

4.

Fill

the cooling system.

For additional information, refer to Cooling System Draining,

Filling and Bleedin

g

- Vehicles With

: Supercharger in this

section.

Page 1007 of 2490

W

ater Pump Pulley Vehicles Without: Supercharger

26.50.05

Removal

1. Open the engine compartment and fit paintwork protection sheets.

2

. Slacken the three screws which secure the water pump pulley.

3

.

C

AUTION:

When releasing the belt tension, never apply any torque in a clockwise direction to the pulley

centre bolt (left hand thread) as it could subsequently loosen.

Remove the drive belt from the generator and accessory drive. 1. Use a spanner e.g. Churchill JD-230 or Snap On XDHM 1415, on the centre bolt of the belt tensioner idler pulley, to turn the adjuster assembly to the left against spring tension.

Page 1009 of 2490

W

ater Pump Pulley Vehicles With: Supercharger

26.50.05

Removal

1. Open the engine compartment and fit paintwork protection sheets.

2. Remove the supercharger drive belt. Refer to Operation <<18.50.08>>.

3

. Slacken the three screws which secure the water pump pulley.

4

.

C

AUTION:

When releasing the belt tension, never apply any torque in a clockwise direction to the pulley

centre bolt (left hand thread) as it could subsequently loosen.

Page 1011 of 2490

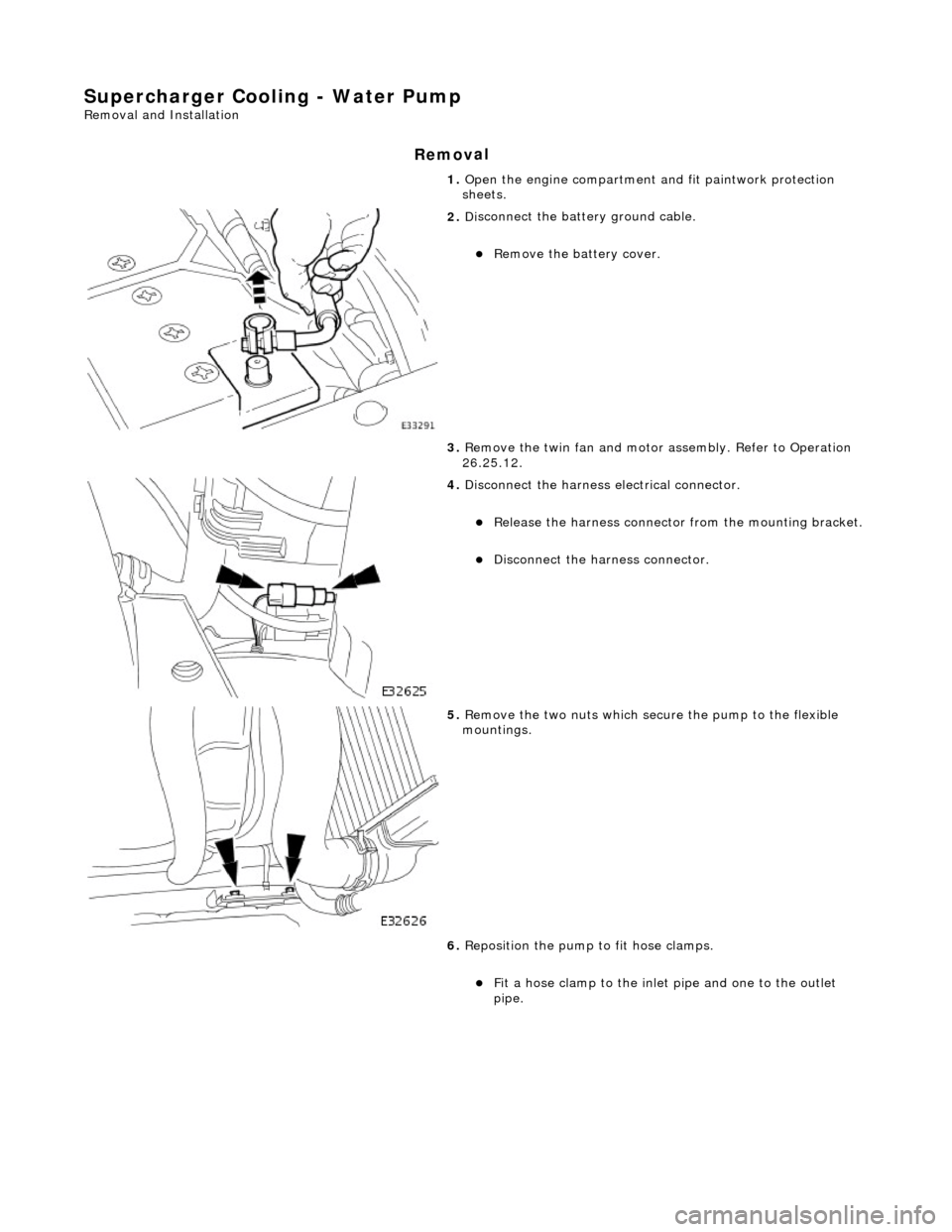

Supercharger Cooling - Water Pump

Re

moval and Installation

Remov

al

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. Di

sconnect the batt

ery ground cable.

R

emove the battery cover.

3. Remove the twin fan and motor assembly. Refer to Operation

26.25.12.

4. Disc

onnect the harness electrical connector.

R

elease the harness connector from the mounting bracket.

Disc

onnect the harness connector.

5. R

emove the two nuts which secure the pump to the flexible

mountings.

6. Reposition the pump to fit hose clamps.

Fi

t a hose clamp to the inlet pipe and one to the outlet

pipe.

Page 1014 of 2490

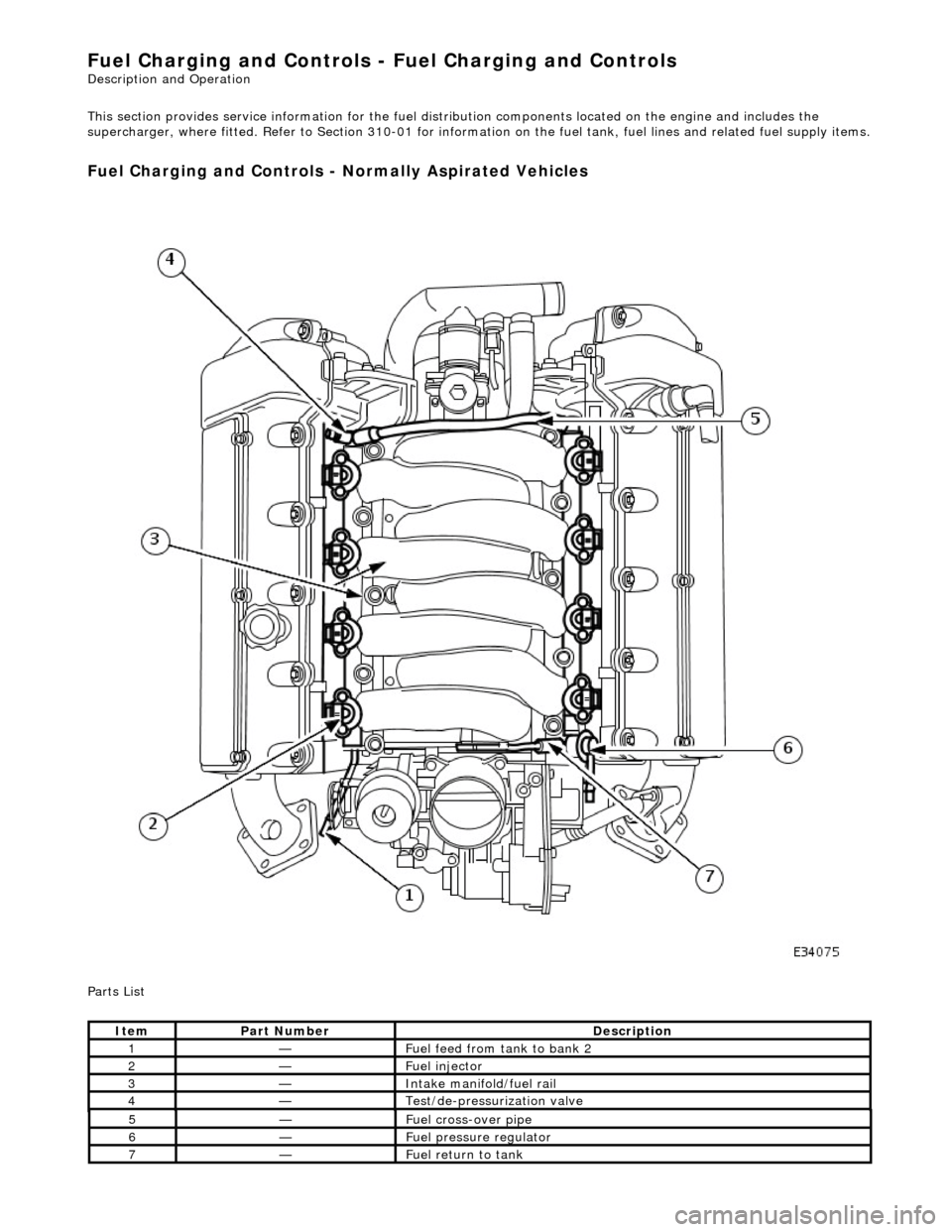

Fuel Char

ging and Controls - Fuel Charging and Controls

Description an

d Operation

This section provides service informatio n for the fuel distribution components located on the engine and includes the

supercharger, where fitted. Refer to Section 310-01 for informatio n on the fuel tank, fuel lines and related fuel supply items.

Fuel Charging and Controls -

Normally Aspirated Vehicles

P

a

rts List

It

e

m

Par

t

Number

De

scr

iption

1—F

u

el feed from tank to bank 2

2—Fue

l

injector

3—Inta

k

e manifold/fuel rail

4—Te

st

/de-pressurization valve

5—F

u

el cross-over pipe

6—F

u

el pressure regulator

7—F

u

el return to tank

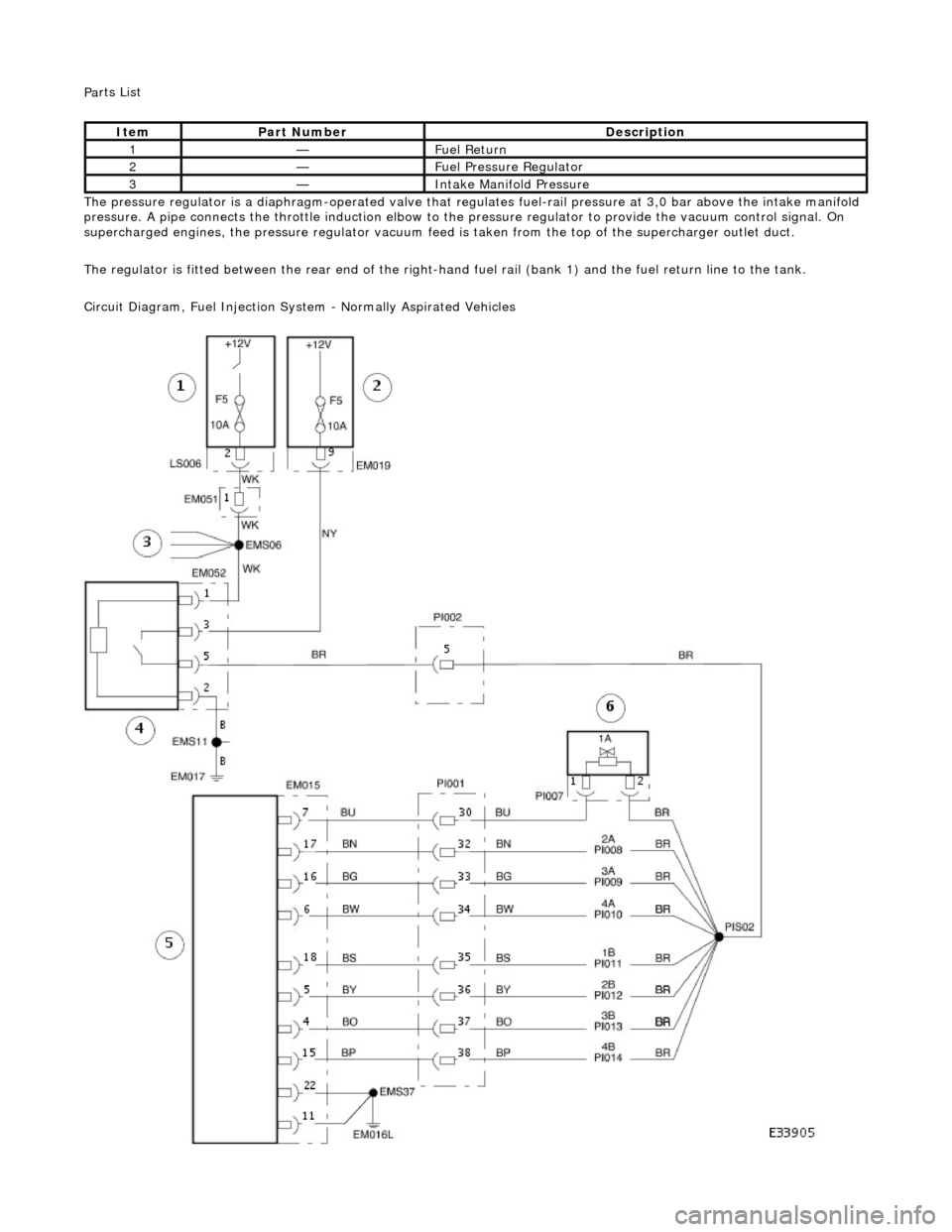

Page 1016 of 2490

Pa

rts List

The pressure regulator is a diap hragm-operated valve that regula tes fuel-rail pressure at 3,0 bar above the intake manifold

pressure. A pipe connects the throttle induction elbow to the pressure regulator to provide the vacuum control signal. On

supercharged engines, the pressure regulator vacuum feed is taken from the top of the supercharger outlet duct.

The regulator is fitted between the rear end of the right-hand fuel rail (bank 1) and the fuel return line to the tank.

Circuit Diagram, Fuel Injection Syst em - Normally Aspirated Vehicles

Ite

m

Par

t

Number

De

scr

iption

1—F

u

el Return

2—F

u

el Pressure Regulator

3—Inta

k

e Manifold Pressure

Page 1026 of 2490

REFE

R to Section 310

-00

Fu

el

Sy

ste

m

- General

Information

.

Check f o

r DTCs indicating a sensor

fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

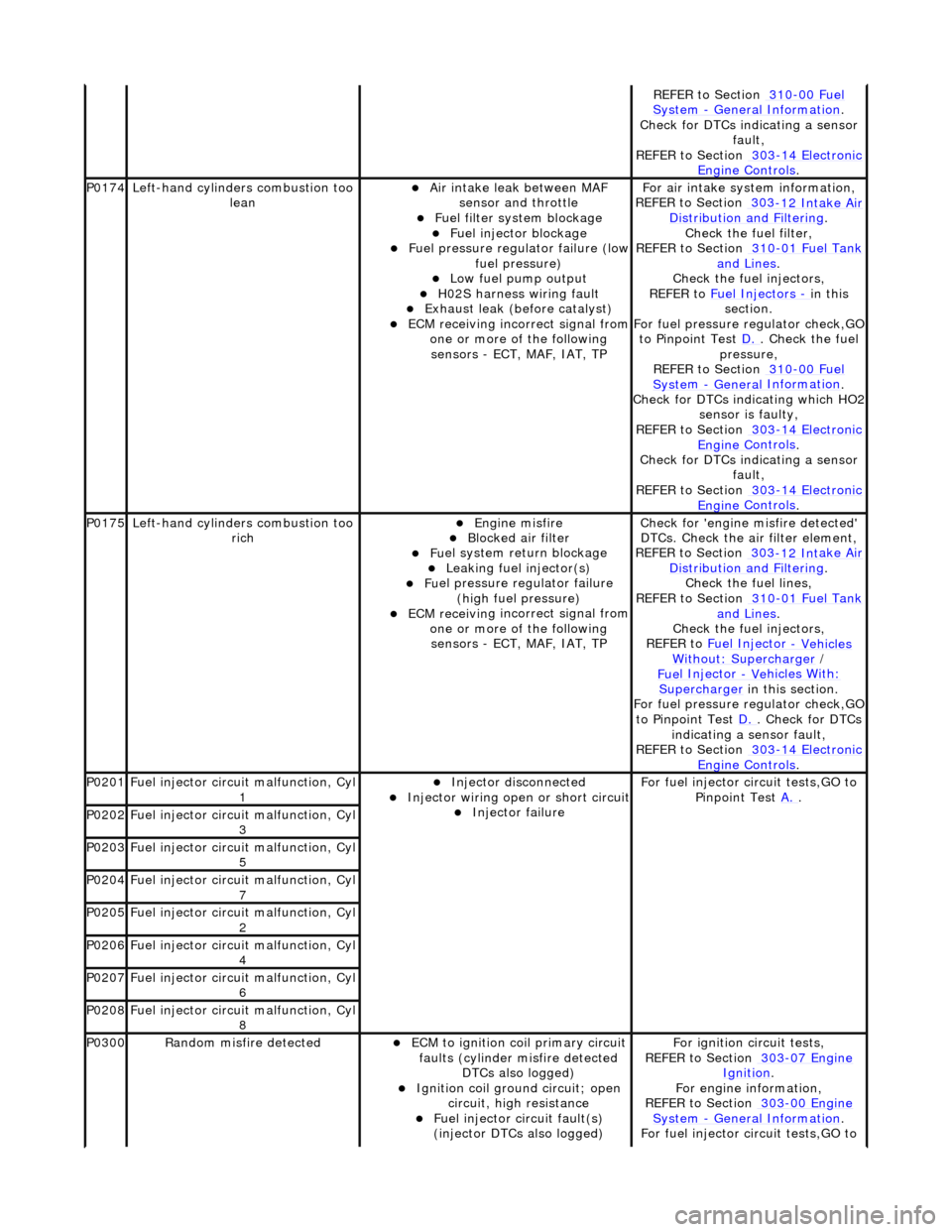

P0174

Left-hand cyl i

nders combustion too

lean

Air in

take leak between MAF

sensor and throttle

F u

el filter system blockage

F

u

el injector blockage

F

u

el pressure regulator failure (low

fuel pressure)

Low f u

el pump output

H0

2S harness wiri

ng fault

E

x

haust leak (before catalyst)

ECM receivi

n

g incorrect signal from

one or more of the following sensors - ECT, MAF, IAT, TP

F o

r air intake sy

stem information,

REFER to Section 303

-12 Int

ake Air

Distribu tion and Filterin

g

.

Check the fuel fi lter,

REF

ER to Section 310

-01

Fu

el Tank

and Lines.

Chec k the

fuel injectors,

REFER to Fuel Injectors

- in t h

is

section.

For fuel pressure regulator check,GO

to Pinpoint Test D.

. Ch

eck the fuel

pressure,

REFER to Section 310

-00 Fu

el

Sy

ste

m

- General

Information

.

Check f o

r DTCs indicating which HO2

sensor is faulty,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

Check f o

r DTCs indicating a sensor

fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

P0175Left-hand cyli

nders combustion too

rich

Engine m

isfire

Bl

ocked air

filter

F

u

el system return blockage

Leak

i

ng fuel injector(s)

F

u

el pressure regulator failure

(high fuel pressure)

ECM receivi n

g incorrect signal from

one or more of the following sensors - ECT, MAF, IAT, TP

Check for 'en

gine misfire detected'

DTCs. Check the air filter element,

REFER to Section 303

-12 Int

ake Air

Distribu tion and Filterin

g

.

Chec k the

fuel lines,

REFER to Section 310

-01 Fu

el Tank

and Lines.

Chec k the

fuel injectors,

REFER to Fuel Injector

- Vehicles Wi

thout: Supercharger

/

Fue

l Injector

- Ve

hicles With

:

Supercharger

in this

section.

For fuel pressure regulator check,GO

to Pinpoint Test D.

. Check for DT

Cs

indicating a sensor fault,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

P0201F

u

el injector circuit malfunction, Cyl

1

Injector discon n

ected

Inject

or wir

ing open or short circuit

Injector fail

ure

F

o

r fuel injector circuit tests,GO to

Pinpoint Test A.

.

P0202Fu

el injector circuit malfunction, Cyl

3

P0203F u

el injector circuit malfunction, Cyl

5

P0204F u

el injector circuit malfunction, Cyl

7

P0205Fu

el injector circuit malfunction, Cyl

2

P0206Fu

el injector circuit malfunction, Cyl

4

P0207F u

el injector circuit malfunction, Cyl

6

P0208F u

el injector circuit malfunction, Cyl

8

P0300Ran d

om misfire detected

ECM t

o

ignition coil primary circuit

faults (cylinder misfire detected DTCs also logged)

Ignition coil ground circuit; open

ci

rcuit, high resistance

F

u

el injector circuit fault(s)

(injector DTCs also logged)

F o

r ignition circuit tests,

REFER to Section 303

-07 En

gine

Ignition.

F or engi

ne information,

REFER to Section 303

-00 En

gine

Sy

ste

m

- General

Information

.

F o

r fuel injector circuit tests,GO to

Page 1028 of 2490

Pinpoint Tests

P1316Mi

sfire excess emission (this DTC

will flag only when accompanied by an individual cylinder misfire DTC: P0300-P0308)

Re

fer to possible causes for P0300-P0308

R

e

fer to actions for P0300-P0308.

P1611Thr

o

ttle angle malfunction

TP sensor

ci

rcuit fault

APP sensor circuit faul

t Throttle

assembly failure

ECM failu

r

e

F

or TP and APP

sens

or circuit tests,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

F o

r throttle assembly information,

refer to throttle body in this section.

Contact dealer technical support for advice on possible ECM failure.

P1612Throttl e

offset malfunction

TP sensor

ci

rcuit fault

APP sensor circuit faul

t Throttle

assembly failure

ECM failu

r

e

F

or TP and APP

sens

or circuit tests,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

F o

r throttle assembly information,

refer to throttle body in this section.

Contact dealer technical support for advice on possible ECM failure.

P1646Fu

el pump 2 relay malfunction (this

DTC applies only to the

supercharger secondary fuel pump)

Fu

el pump 2 relay failure

Fu

el pump 2 relay to ECM circuit

fault

Fu

el pump 2 relay coil power

supply open circuit

ECM ground circuit faul t (relay coil

drive)

For fuel pump 2 r

elay circuit tests,

GO to Pinpoint Test C.

.

PI

NPOINT TEST A : DTC P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208; FUEL

INJECTOR CIRCUIT MALFUNCTION

• NOTE

: The DTC set will indicate which cylinder injector or circ

uit is faulty. Only in the event of multiple cylinder misfires

will it be necessary to chec k more than one injector or circuit, in which case, multiple DTCs will be set.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

A1

: CH

ECK THE INJECTOR COIL RESISTANCE

Turn the ignition swi

t

ch to the OFF

position.

1

Disconne

ct the relevant injector electrical connector

, (IJ03 to IJ10, vehicles with AJ26 engine, PI07 to

PI14, vehicles with AJ27 engine).

2

Meas ure t

he resistance between the injector pins.

3

Is

t

he resistance between 12 and 16 ohms?

Yes GO to A2

.

No

INST

ALL a new injector.

REFER to Fuel Injector

- Ve hicles With

out: Supercharger

in this

section.

CLEAR the DTC. TEST the system for normal operation.

A2: CHECK

THE INJECTOR COIL INSULATION

Meas

ure t

he resistance between the inje

ctor pin 01 and the injector body.

1

Measure t

he resistance between the inje

ctor pin 02 and the injector body.

2

Are both re

sistances greater than 10 Mohms?

Yes GO to A3

.

No

INST

ALL a new injector. CLEAR the DTC. TE

ST the system for normal operation.

A3: CHECK THE INJECTOR

SUPPLY VOLTAGE

Turn the ignition swi

t

ch to the ON

position.

1

Disconne

ct the relevant injector electrical connector

, (IJ03 to IJ10, vehicles with AJ26 engine, PI07 to

PI14, vehicles with AJ27 engine).

2

Meas ure t

he voltage between the relevant injector harness electrical connector (IJ03 to IJ10, vehicles

with AJ26 engine, PI07 to PI 14, vehicles with AJ27 engine), pin 02 (BR) and GROUND.

3

Is the volt

age greater than 12 volts?

Yes GO to A4

.

No

R

EPAIR the circuit between the relevant injector harn

ess electrical connector, pin 02 and battery. This

Page 1040 of 2490

Fuel Char

ging and Controls - Fu

el Injectors4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

Installation

1. Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Depressurize fuel syst em; refer to 19.50.02.

3. Drain radiator coolant; refer to 2

6.10.01.

4. Remove air cleaner cover / inta ke assembly; refer 19.10.30.

5. Remove throttle body; refer to 19.70.04.

6. Remove throttle induction elbo w; refer to (SC) 19.70.28.

7. Remove exhaust gas re-circulation valve (EGR) if fitted; refer

to 17.45.01.

8. Remove supercharger outlet duct and gasket; refer to

18.50.16.

9. Remove coolant outlet pipe; refer to (SC) 26.31.08 .

10. Remove supercharger drive belt; refer to 18.50.08.

11. Remove supercharger assembly; refer to 18.50.15.

12. Remove bank 1 or 2 charge air cooler as required; refer to

18.50.18 and / or 18.50.19.

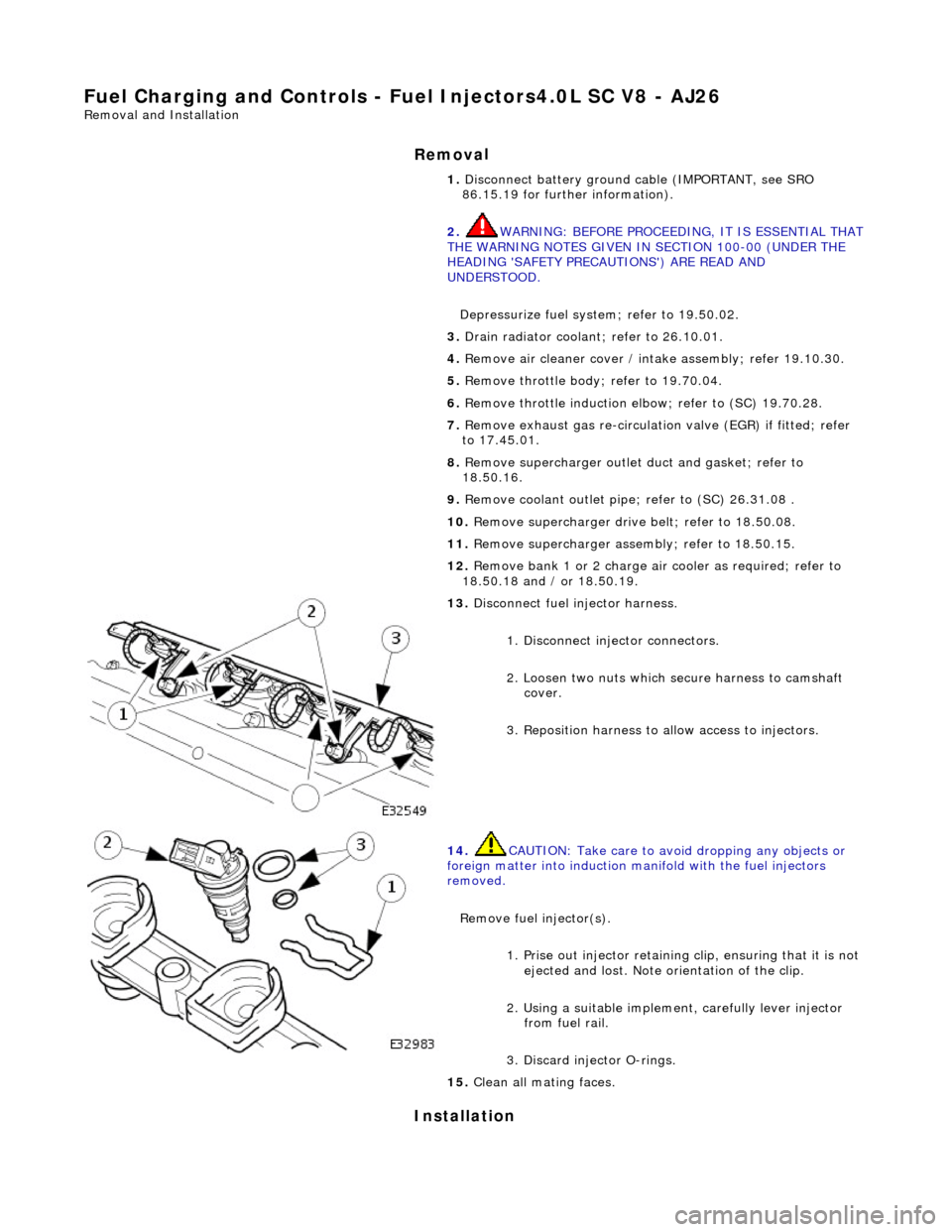

13 . Di

sconnect fuel injector harness.

1. Disconnect injector connectors.

2. Loosen two nuts which se cure harness to camshaft

cover.

3. Reposition harness to al low access to injectors.

14. CAUTI

ON: Take care to avoi

d dropping any objects or

foreign matter into induction ma nifold with the fuel injectors

removed.

Remove fuel injector(s). 1. Prise out injector retaining clip, ensuring that it is not

ejected and lost. Note orientation of the clip.

2. Using a suitable implemen t, carefully lever injector

from fuel rail.

3. Discard injector O-rings.

15 . Cle

an all mating faces.