generator JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1181 of 2490

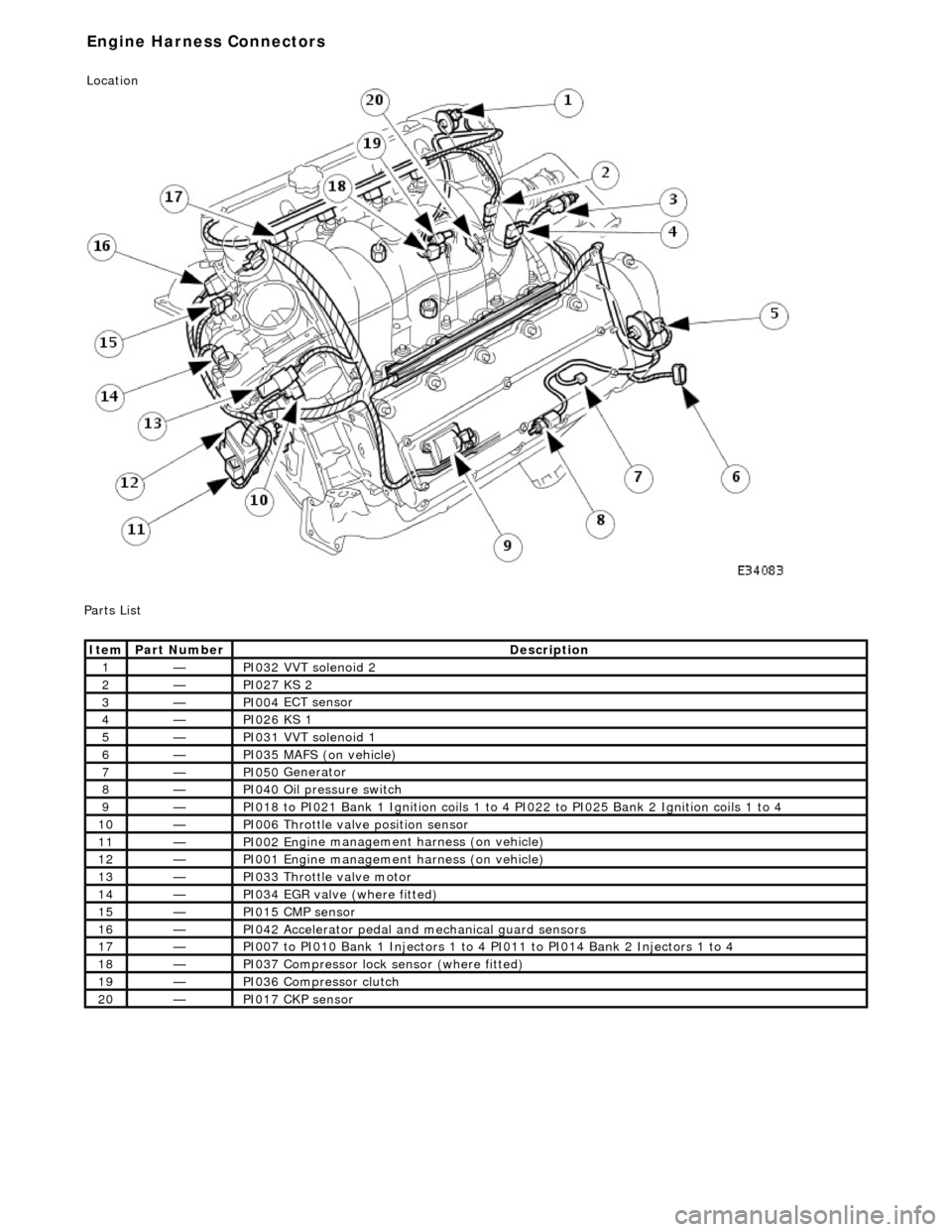

P

arts List

It

em

Par

t Number

De

scription

1—PI032

VVT solenoid 2

2—PI027

KS 2

3—PI004

ECT sensor

4—PI026

KS 1

5—PI031

VVT solenoid 1

6—PI035

MAFS (on vehicle)

7—PI050

Generator

8—PI040

Oil pressure switch

9—PI018

to PI021 Bank 1 Ignition coils 1 to 4

PI022 to PI025 Bank 2 Ignition coils 1 to 4

10—PI006

Throttle valve position sensor

11—PI002 En

gine management harness (on vehicle)

12—PI001 En

gine management harness (on vehicle)

13—PI033

Throttle valve motor

14—PI034

EGR valve (where fitted)

15—PI015 CM

P sensor

16—PI042

Accelerator pedal and

mechanical guard sensors

17—PI007

to PI010 Bank 1 Injectors 1 to 4 PI011 to PI014 Bank 2 Injectors 1 to 4

18—PI037

Compressor lock

sensor (where fitted)

19—PI036

Compressor clutch

20—PI017 CK

P sensor

E

ngine Harness Connectors

Location

Page 1854 of 2490

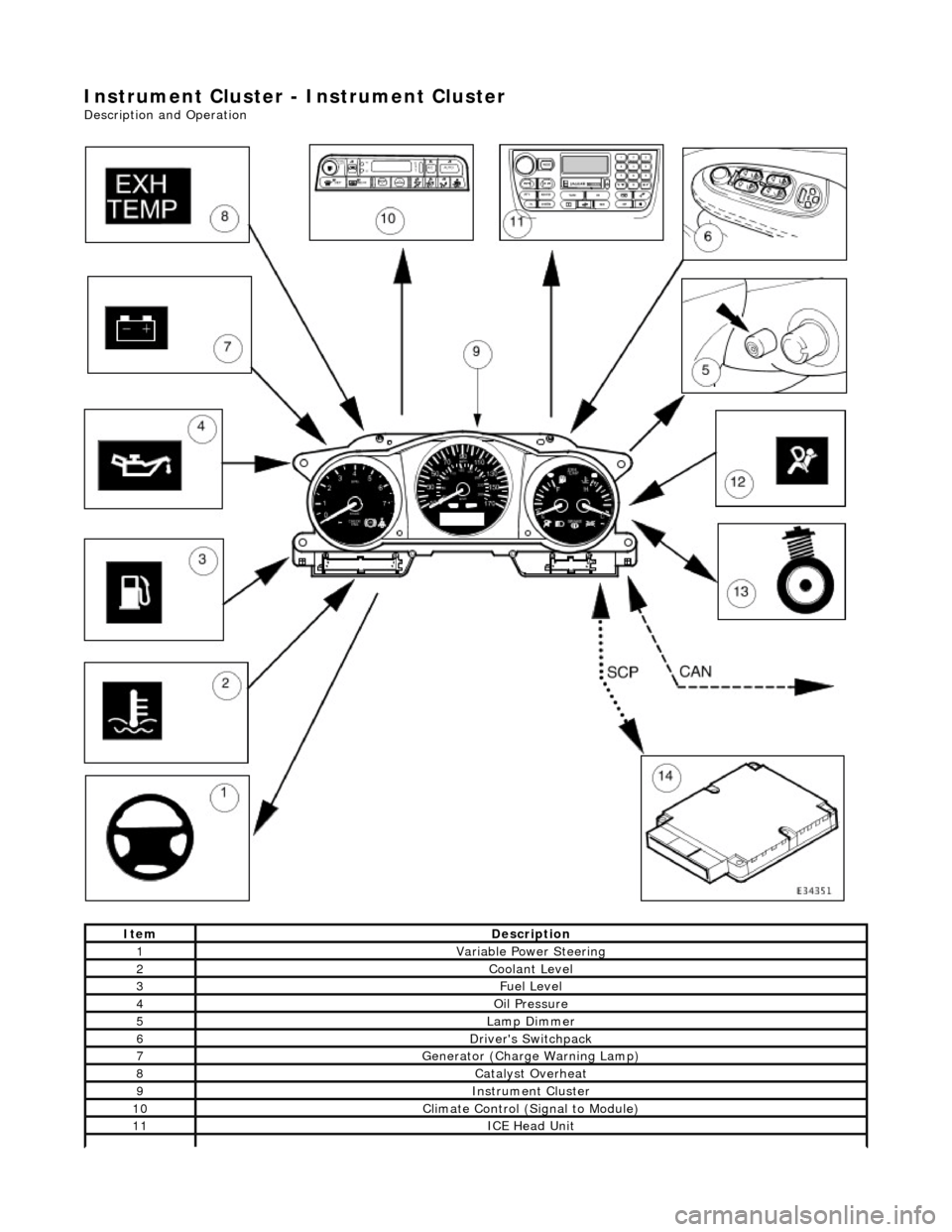

Instrument Cluster - Instrument Cluster

Description and Operation

ItemDescription

1Variable Power Steering

2Coolant Level

3Fuel Level

4Oil Pressure

5Lamp Dimmer

6Driver's Switchpack

7Generator (Charge Warning Lamp)

8Catalyst Overheat

9Instrument Cluster

10Climate Control (Signal to Module)

11ICE Head Unit

Page 1876 of 2490

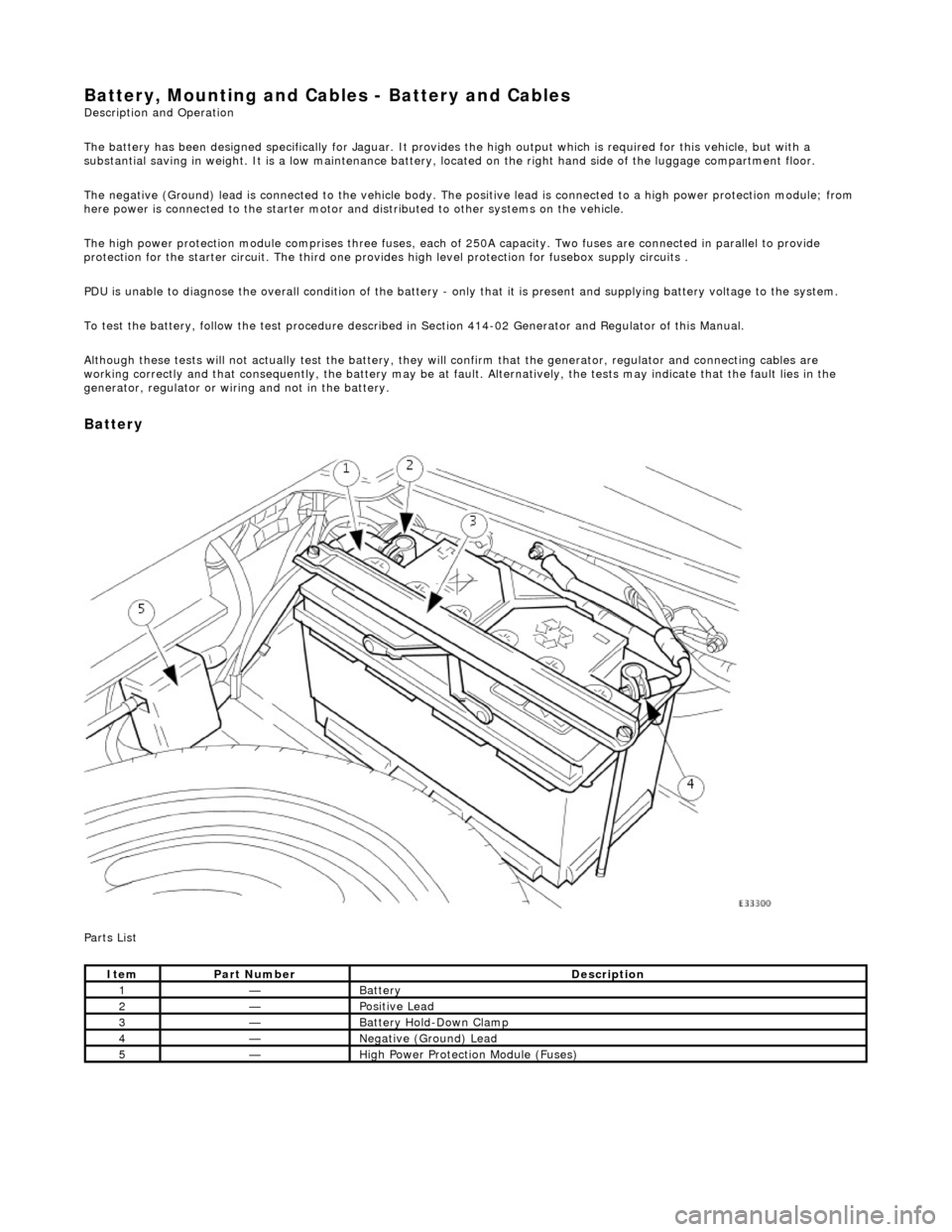

Battery, Mounting and Cables - Battery and Cables Description and Operation

The battery has been designed specifically for Jaguar. It provides the high output which is required for this vehicle, but with a

substantial saving in weight. It is a low maintenance battery, located on the right ha nd side of the luggage compartment floor.

The negative (Ground) lead is connected to the vehicle body. The positive lead is connected to a high power protection module; from

here power is connected to the starter motor an d distributed to other systems on the vehicle.

The high power protection module comprises three fuses, each of 250A capacity. Two fuses are connected in parallel to provide

protection for the starter circuit. Th e third one provides high level protection for fusebox supply circuits .

PDU is unable to diagnose the overall condition of the battery - only that it is present and supplying battery voltage to the system.

To test the battery, follow the test procedure described in Section 414-02 Generator and Regulator of this Manual.

Although these tests will not actually test the battery, they will confirm that the generator, regulator and connecting cables are

working correctly and that conseq uently, the battery may be at fault. Alternatively, the tests may indicate that the fault lies in the

generator, regulator or wiring and not in the battery.

Battery

Parts List

ItemPart NumberDescription

1—Battery

2—Positive Lead

3—Battery Hold-Down Clamp

4—Negative (Ground) Lead

5—High Power Protection Module (Fuses)

Page 1882 of 2490

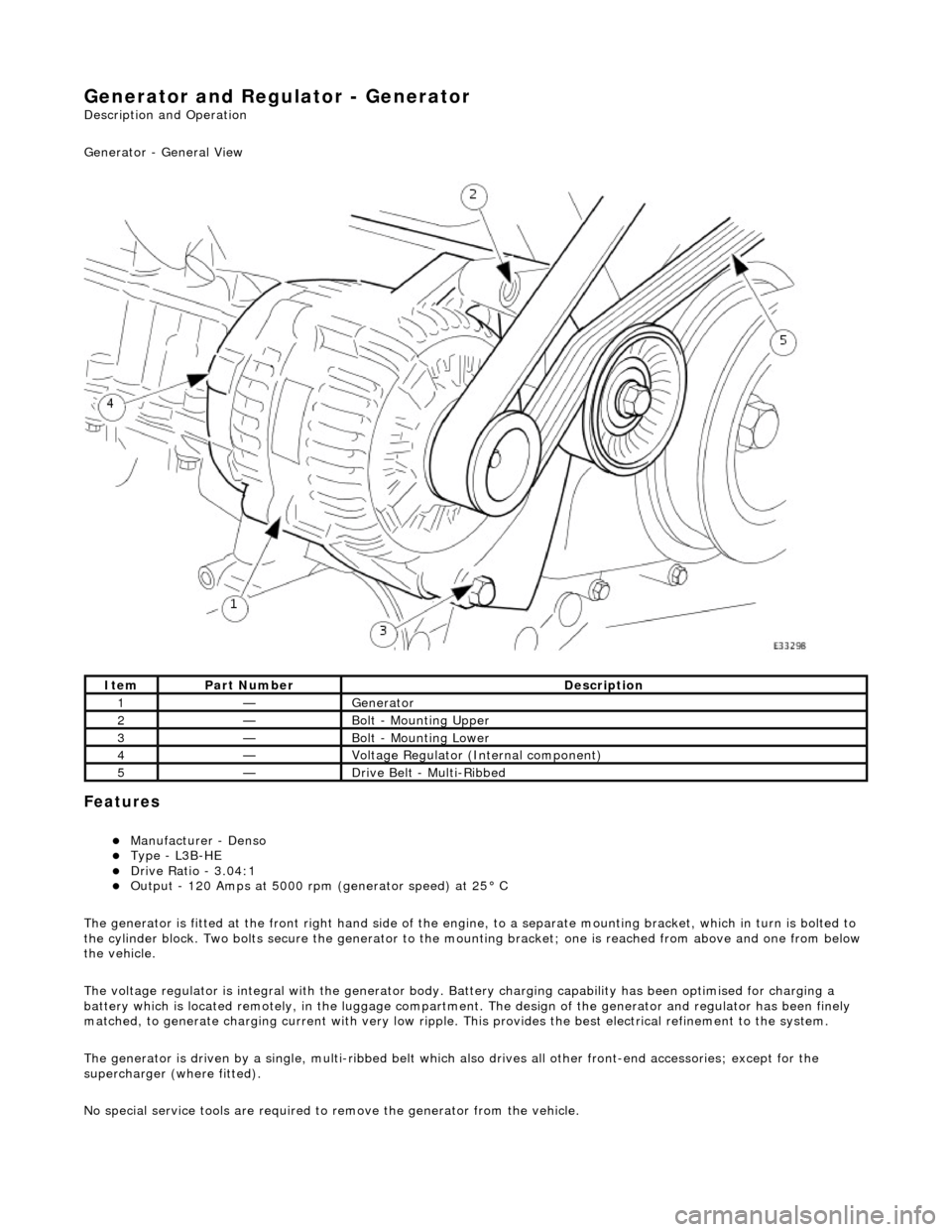

Generator and Regulator - Generator

Description and Operation

Generator - General View

Features

пЃ¬Manufacturer - Denso пЃ¬Type - L3B-HE пЃ¬Drive Ratio - 3.04:1 пЃ¬Output - 120 Amps at 5000 rpm (generator speed) at 25В° C

The generator is fitted at the front right hand side of the engine, to a sepa rate mounting bracket, which in turn is bolted to

the cylinder block. Two bolts secure th e generator to the mounting bracket; one is reached from above and one from below

the vehicle.

The voltage regulator is integral with th e generator body. Battery charging capabi lity has been optimised for charging a

battery which is located remotely, in the luggage compartment. The design of the generator and regulator has been finely

matched, to generate charging current with very low ripple. This provides the best electrical refinement to the system.

The generator is driven by a single, multi-ribbed belt which also drives all other front-e nd accessories; except for the

supercharger (where fitted).

No special service tools are required to remove the generator from the vehicle.

ItemPart NumberDescription

1—Generator

2—Bolt - Mounting Upper

3—Bolt - Mounting Lower

4—Voltage Regulator (Internal component)

5—Drive Belt - Multi-Ribbed

Page 1883 of 2490

Belt tension is achieved by an automatic tensioner; neither the belt nor the tensioner require service apart from checking

the belt wear indicators at each normal service interval.

The minimum service life of the drive belt is 100,000 miles.

Never apply oil to the belt or to the belt tensioner.

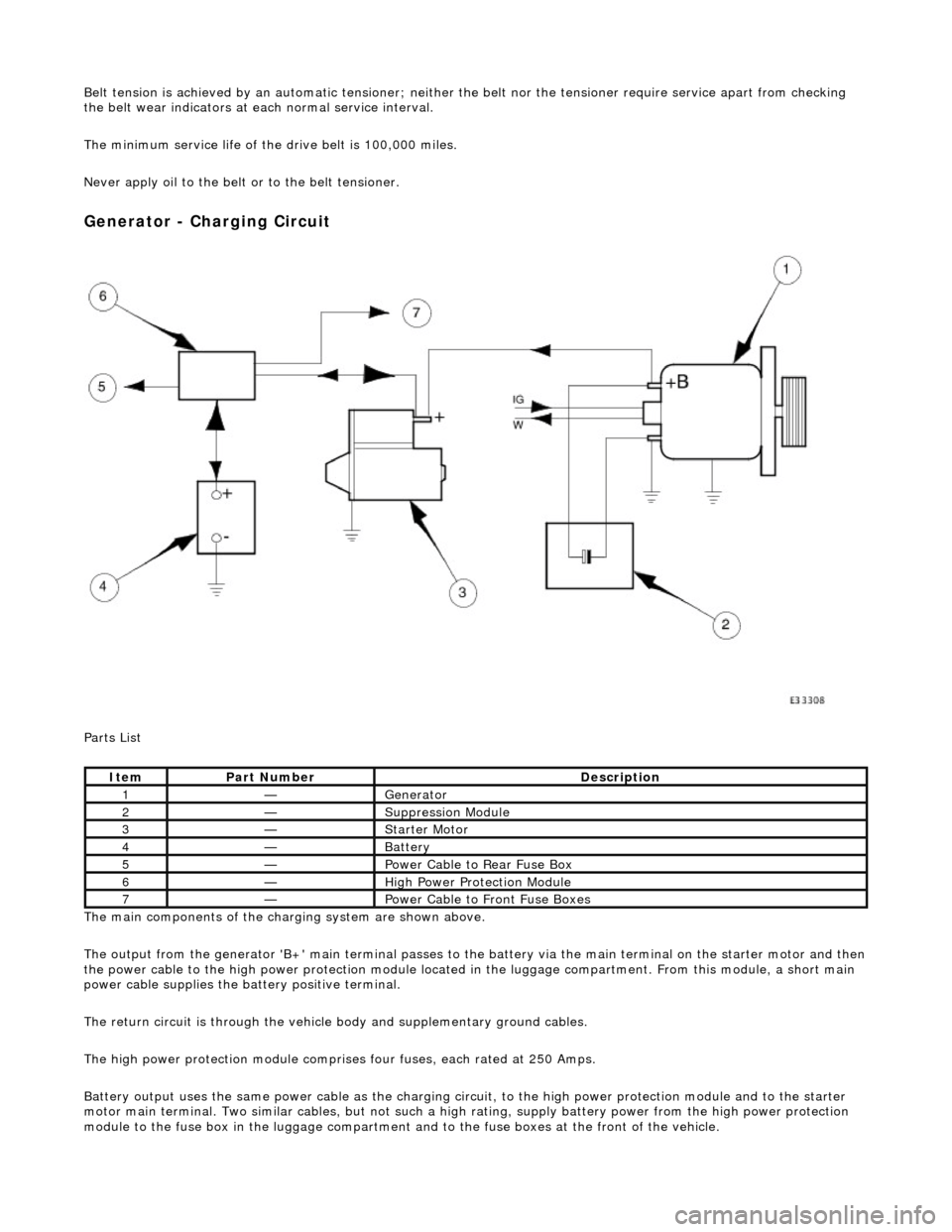

Generator - Charging Circuit

Parts List

The main components of the charging system are shown above.

The output from the generator 'B+' main te rminal passes to the battery via the main terminal on the starter motor and then

the power cable to the high power protection module located in the luggage compartment. From this module, a short main

power cable supplies the ba ttery positive terminal.

The return circuit is through the vehicle body and supplementary ground cables.

The high power protection mo dule comprises four fuses, each rated at 250 Amps.

Battery output uses the same power cable as the charging circ uit, to the high power protection module and to the starter

motor main terminal. Two similar cables, but not such a high rating, supply battery power from the high power protection

module to the fuse box in the luggage compartment an d to the fuse boxes at the front of the vehicle.

ItemPart NumberDescription

1—Generator

2—Suppression Module

3—Starter Motor

4—Battery

5—Power Cable to Rear Fuse Box

6—High Power Protection Module

7—Power Cable to Front Fuse Boxes

Page 1884 of 2490

The interference suppression module (where fitted) connects to the generator main terminal 'B +' and a ground stud on the

rear face of the generator.

A multi-plug (3 pin) is connecte d to the rear of the generator:

пЃ¬Pin 1 not connected. пЃ¬Pin 2 ignition supply to the regulator. пЃ¬Pin 3 output to the charge warning lamp.

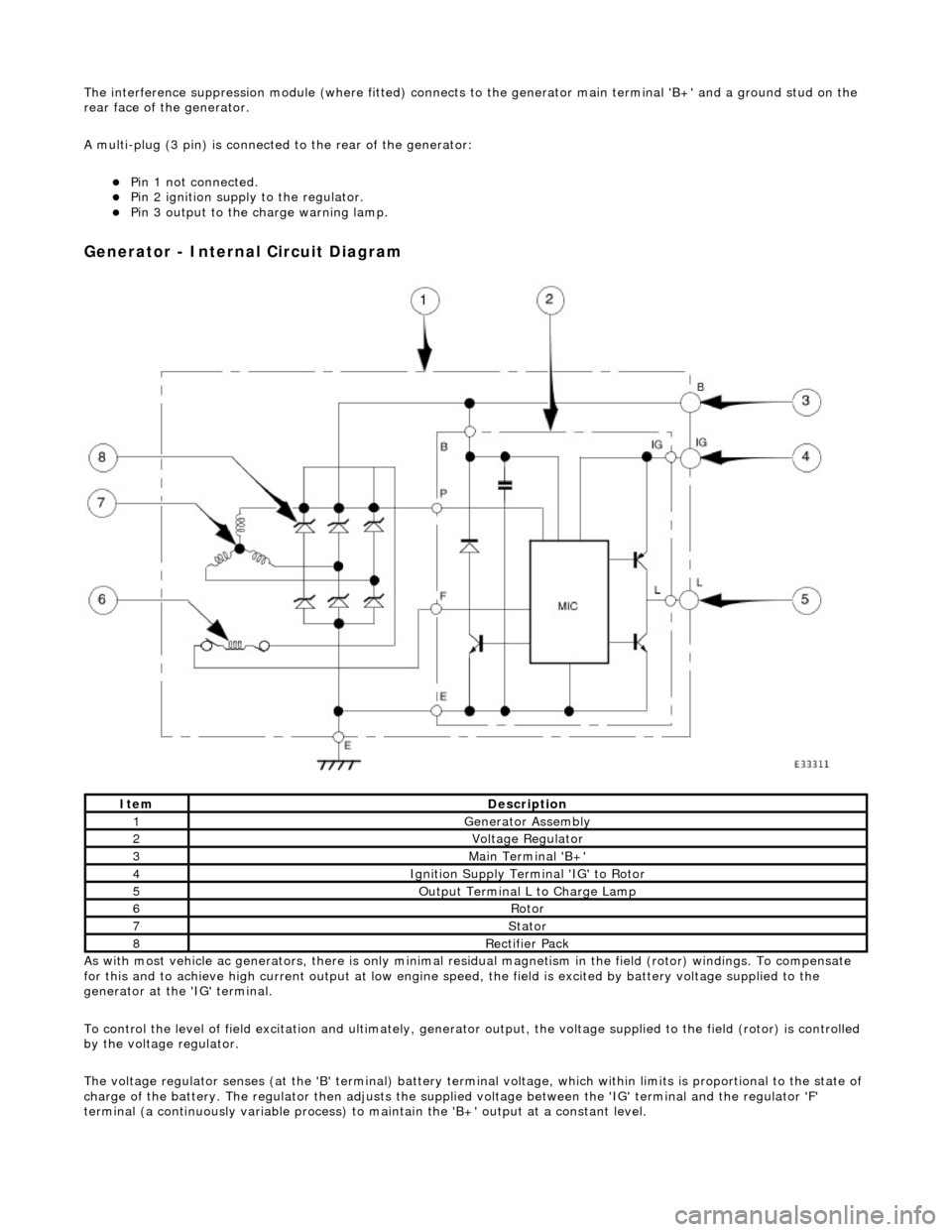

Generator - Internal Circuit Diagram

As with most vehicle ac generators, there is only minimal residual magnet ism in the field (rotor) windings. To compensate

for this and to achieve high current outp ut at low engine speed, the field is excited by battery voltage supplied to the

generator at the 'IG' terminal.

To control the level of field excitation and ultimately, generator output, the voltag e supplied to the field (rotor) is controlled

by the voltage regulator.

The voltage regulator senses (at the 'B' terminal) battery terminal voltage, which within limits is proportional to the state o f

charge of the battery. The regulator then adjusts the supplied voltage between the 'IG' terminal and the regulator 'F'

terminal (a continuously variable process) to maintain the 'B+' output at a constant level.

ItemDescription

1Generator Assembly

2Voltage Regulator

3Main Terminal 'B+'

4Ignition Supply Terminal 'IG' to Rotor

5Output Terminal L to Charge Lamp

6Rotor

7Stator

8Rectifier Pack

Page 1885 of 2490

If the field were not controlled, the 'B+' output would rise to a level which could damage bulbs and ECMs. The regulator

compares the output voltage to an intern al voltage reference circuit to achieve the controlled output of the generator.

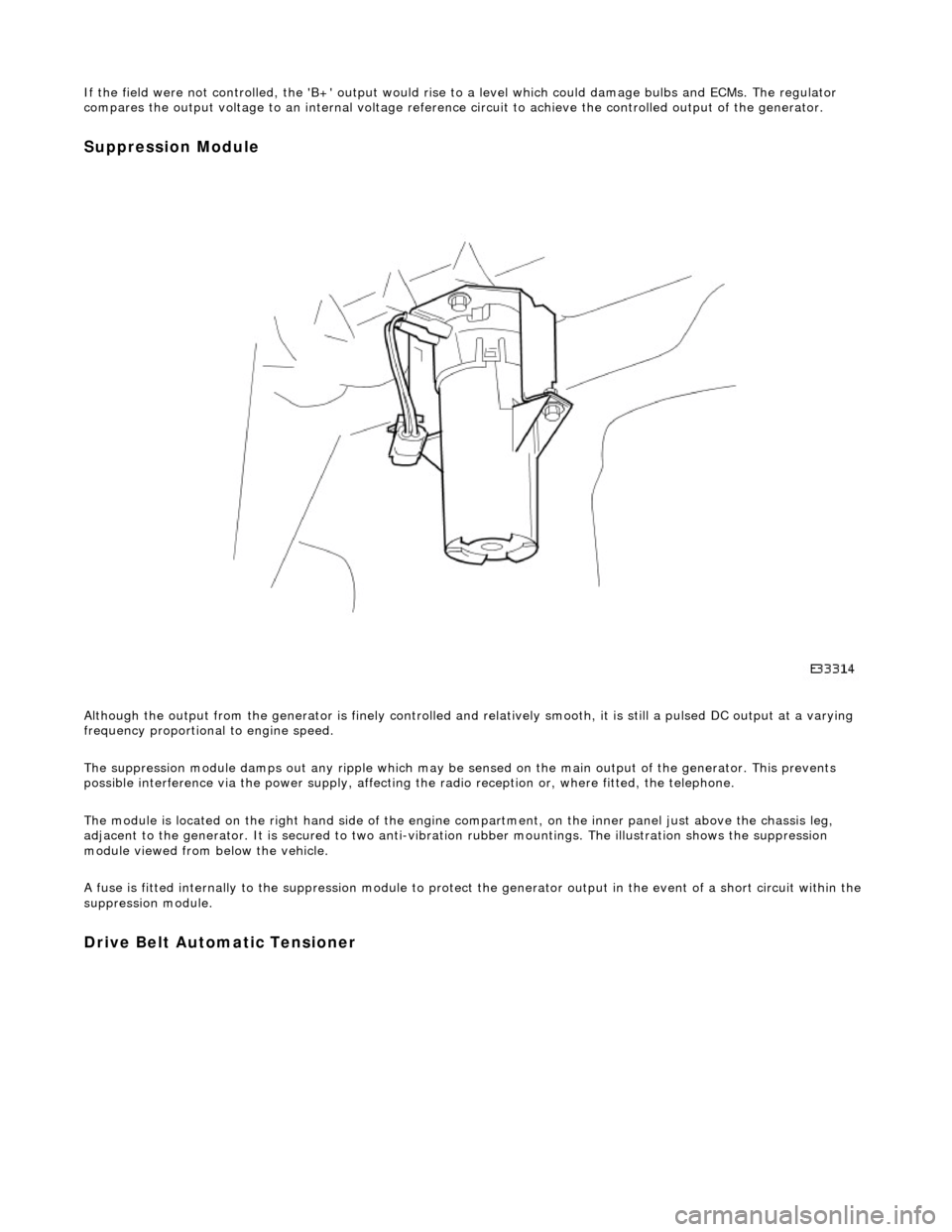

Suppression Module

Although the output from the generator is fi nely controlled and relatively smooth, it is still a pulsed DC output at a varying

frequency proportional to engine speed.

The suppression module damps ou t any ripple which may be sensed on the main output of the generator. This prevents

possible interference via the power supply, affecting the radio reception or, where fitted, the telephone.

The module is located on the right hand side of the engine compartment, on the inner panel just above the chassis leg,

adjacent to the generator. It is secured to two anti-vibration rubber moun tings. The illustration shows the suppression

module viewed from below the vehicle.

A fuse is fitted internally to the suppression module to protect the generator output in the event of a short circuit within th e

suppression module.

Drive Belt Automatic Tensioner

Page 1887 of 2490

Generator and Regulator - Generator

Diagnosis and Testing

Refer to PDU User Guide

Refer to the PDU User Manual for detailed instructions on testing the charging circuit.

When diagnosing the charging ci rcuit, the PDU indicates only whether the generator is charging or not charging. The reason

for this is that the PDU cannot handle the potential full charging current and that the voltage control circuits are located

within the generator assembly, making th em inaccessible by the PDU directly.

It is possible that the battery has failed. In this case, the voltage output at the generator could be correct, but the voltage

at the battery terminals, and therefore the rest of the vehicl e system, will be adversely affected by the faulty battery.

The same result is given by the PDU if the battery is faulty (generator not faulty), wiring fault (damaged or severe corrosion

at the terminals) or if th e generator is at fault.

Inspection and Verification

The following manual tests help to pinpoint which component is at fault.

Testing the Battery Circuit

Using the Vehicle Battery

Remove the battery cover.

Ensure that all electrical loads are swit ched OFF and that the engine is cool.

Start the engine and allow to IDLE.

Whilst the engine is idling, disconnect the battery negative terminal and, using a digital multimeter (DMM), measure the

voltage between the terminal on the batter y negative cable and the battery positive terminal. If the generator is working,

the measured voltage should be within the range 13V to 15V.

This indicates the system voltage without the battery in circuit. If the generator is inoperative, the engine will stall when t he

ground lead is disconnected.

Repeat the test, using the ground bolt, as indicated (shown dotted on the illustration). There should be hardly any

MechanicalElectrical

Visually check the condition of the drive beltConnections on the rear face of the generator

are fully located?

Check that the belt we ar indicator, located on the automatic belt

tensioner, is within the limit marks

Page 1888 of 2490

detectable difference in the voltage reading (due to minimal current flow); if there is a detectable difference, clean the cable terminal and the adjacent area of the body.

When the voltage has been measured, STOP THE ENGINE.

Reconnect the battery or fit a new battery if it was established that the battery was at fault (Refer to 414-01).

If the cooling fans operate during the above test, the large demand of current will overload the generator and cause the

engine to stall.

If the battery is in a low state of charge the voltage will rise momentarily when the battery is disconnected. However, the

maximum that the voltage can increase to with this new gene rator is 25V and then only for a maximum time of 200 mS.

Using a Substitute Battery

A substitute battery may be fitted for the tests. This batter y must be a known good example and must have been off-charge for at least twelve hours, with a term inal voltage of approximately 12.8V.

Ensure that all electrical loads are swit ched OFF and that the engine is cool.

Start the engine and allow to IDLE.

Measure the voltage across the battery term inals. It should have dropped a little due to the large start current and then

risen to a value of between 13V and 15V.

If the above test (whichever one used) indicates that the generator is not working then the connections on the rear face of

the generator should be checked. If there is a faulty connection, then the ge nerator will not perform correctly no matter

how fast it is driven.

Checking Generator Connections

ItemDescription

1Multi-Plug Connector

2B+ Main Output Terminal

Page 1889 of 2490

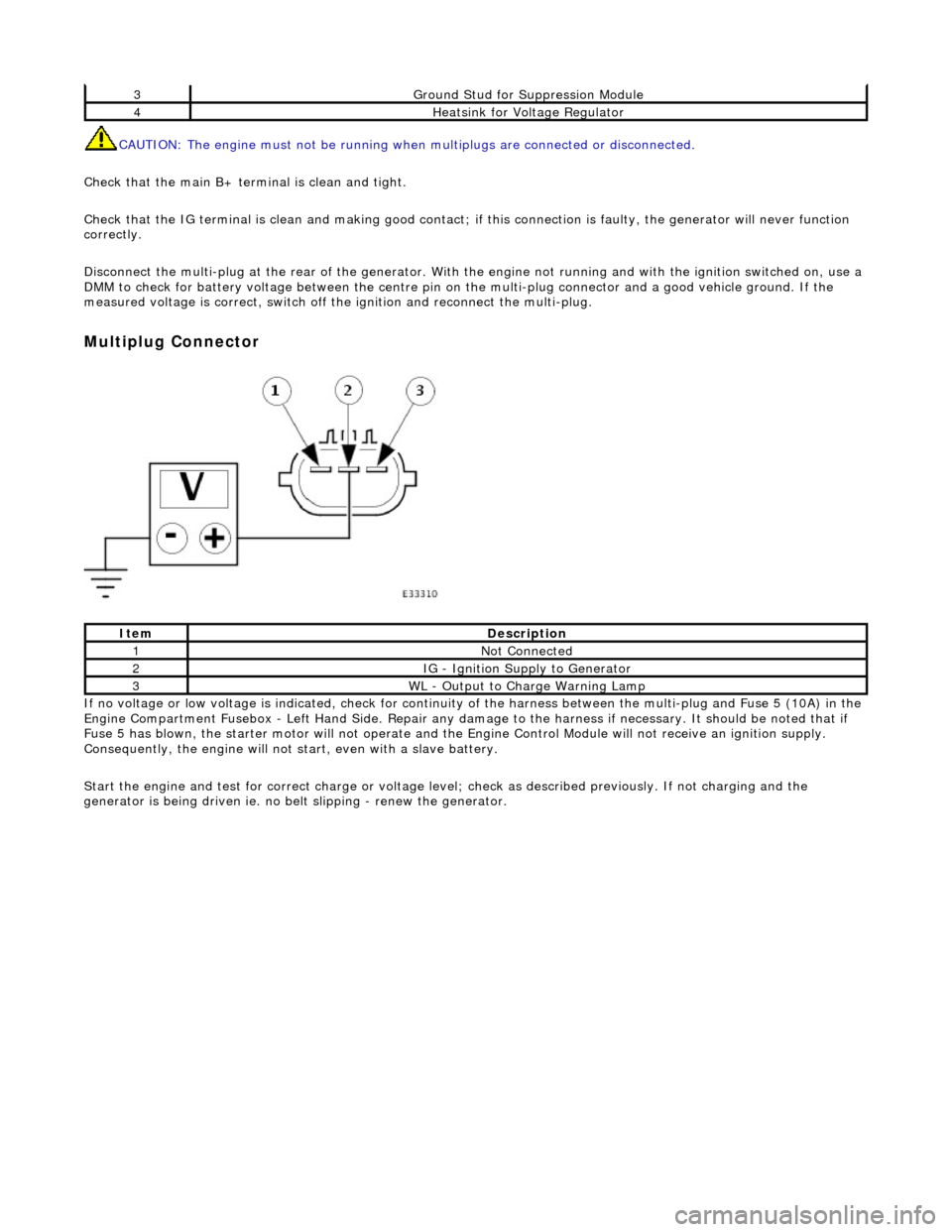

CAUTION: The engine must not be running when multiplugs are connected or disconnected.

Check that the main B+ terminal is clean and tight.

Check that the IG terminal is clean and ma king good contact; if this connection is faulty, the generator will never function

correctly.

Disconnect the multi-plug at th e rear of the generator. With the engine not running and with the ignition switched on, use a

DMM to check for battery voltage between the centre pin on the multi-plug connector and a good vehicle ground. If the

measured voltage is correct, switch off the ignition and reconnect the multi-plug.

Multiplug Connector

If no voltage or low voltage is indicated, check for continuity of the harness between the multi-plug and Fuse 5 (10A) in the

Engine Compartment Fusebox - Left Hand Si de. Repair any damage to the harness if necessary. It should be noted that if

Fuse 5 has blown, the starter motor will not operate and the Engine Control Module will not receive an ignition supply.

Consequently, the engine will not st art, even with a slave battery.

Start the engine and test for correct ch arge or voltage level; check as described previously. If not charging and the

generator is being driven ie. no be lt slipping - renew the generator.

3Ground Stud for Suppression Module

4Heatsink for Voltage Regulator

ItemDescription

1Not Connected

2IG - Ignition Supply to Generator

3WL - Output to Charge Warning Lamp