injector JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1027 of 2490

Ignition coil

failure(s)

HT sho

rt to ground (tracking)

check rubber boots for cracks/damage

Spark plug

failure/fouled/incorrect

gap

Cy

linder compression low

F

uel delivery pressure (low/high)

F

uel injectors restricted/leaking

Fuel contamination

P

AS pulley bolts loose (see Service

Action S462)

W

orn camshaft/broken valve

springs

P

inpoint Test

A.

.

Check fuel

pressure,

REFER to Section 310

-00

Fuel

Sy

stem

- General

Information

.

Chec

k fuel injectors,

REFER to Fuel Injectors

- in t

his

section.

Check service actions.

P0301Misfire

detected, Cyl 1

R

EFER to possible sources for P0300

R

EFER to actions for P0300.

P0302Misfire

detected, Cyl 3

P0303Misfire

detected, Cyl 5

P0304Misfire

detected, Cyl 7

P0305Misfire

detected, Cyl 2

P0306Misfire

detected, Cyl 4

P0307Misfire

detected, Cyl 6

P0308Misfire

detected, Cyl 8

P0460F

uel level sense signal performance

Fue

l level sensor

to instrument

cluster circuits in termittent short

or open circuit

F

uel level sensor failure

Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor tests,GO to

Pinpoint Test B.

.

P1224Throttl

e control position error

Thro

ttle adaptations not performed

after battery disconnect

TP se

nsor disconnected

TP se

nsor to ECM sense circuits;

open circuit, hi gh resistance

Throttl

e motor relay failure

Th

rottle motor relay to ECM circuit

fault

Throttl

e motor relay power supply

open circuit

ECM ground circuit faul

t (relay coil

drive)

Throttl

e motor to ECM drive

circuits; open circuit, short circuit, high resistance

Throttl

e motor failure

Throttl

e body failure

Carry

out the throttle adaptation

procedure,

REFER to Section 303

-14

Electronic

Engine

Controls

.

ECM adaptations. For

throttle motor

relay tests, throttle position sensor tests, ECM ground tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1229Throttl

e motor control circuit

malfunction

Throttl

e motor disconnected

Throttl

e motor to ECM drive

circuits; short circuit or open circuit

Throttl

e motor failure

Fo

r throttle moto

r relay tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1250Engine

load malfunction

Air

intake leak

Engine

breather leak

TP se

nsor circuit fault (DTC P0121)

Throttl

e valve spring failure

F

or air intake system,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

Chec

k engine breather system for

leaks. For TP sensor tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P1313Right-hand cylinders misfire rate

cat

alyst damage (this DTC will flag

only when accompanied by an

individual cylinder misfire DTC: P0300-P0308)

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

P1314L

eft-hand cylinders misfire rate

catalyst damage (this DTC will flag only when accompanied by an

individual cylinder misfire DTC: P0300-P0308)

R

efer to possible causes for P0300-P0308

R

efer to actions for P0300-P0308.

Page 1028 of 2490

Pinpoint Tests

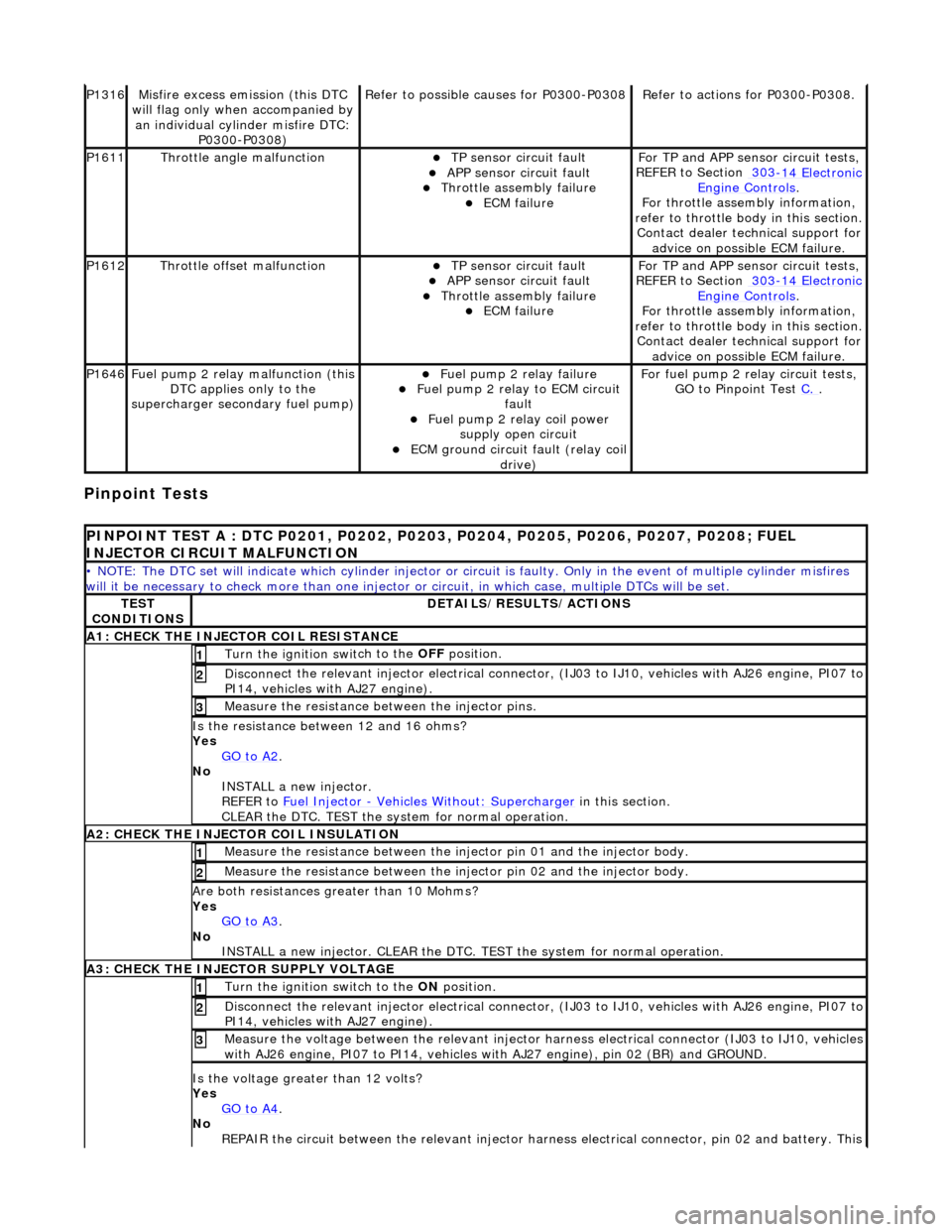

P1316Mi

sfire excess emission (this DTC

will flag only when accompanied by an individual cylinder misfire DTC: P0300-P0308)

Re

fer to possible causes for P0300-P0308

R

e

fer to actions for P0300-P0308.

P1611Thr

o

ttle angle malfunction

TP sensor

ci

rcuit fault

APP sensor circuit faul

t Throttle

assembly failure

ECM failu

r

e

F

or TP and APP

sens

or circuit tests,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

F o

r throttle assembly information,

refer to throttle body in this section.

Contact dealer technical support for advice on possible ECM failure.

P1612Throttl e

offset malfunction

TP sensor

ci

rcuit fault

APP sensor circuit faul

t Throttle

assembly failure

ECM failu

r

e

F

or TP and APP

sens

or circuit tests,

REFER to Section 303

-14 El

ectronic

Engine

C

ontrols

.

F o

r throttle assembly information,

refer to throttle body in this section.

Contact dealer technical support for advice on possible ECM failure.

P1646Fu

el pump 2 relay malfunction (this

DTC applies only to the

supercharger secondary fuel pump)

Fu

el pump 2 relay failure

Fu

el pump 2 relay to ECM circuit

fault

Fu

el pump 2 relay coil power

supply open circuit

ECM ground circuit faul t (relay coil

drive)

For fuel pump 2 r

elay circuit tests,

GO to Pinpoint Test C.

.

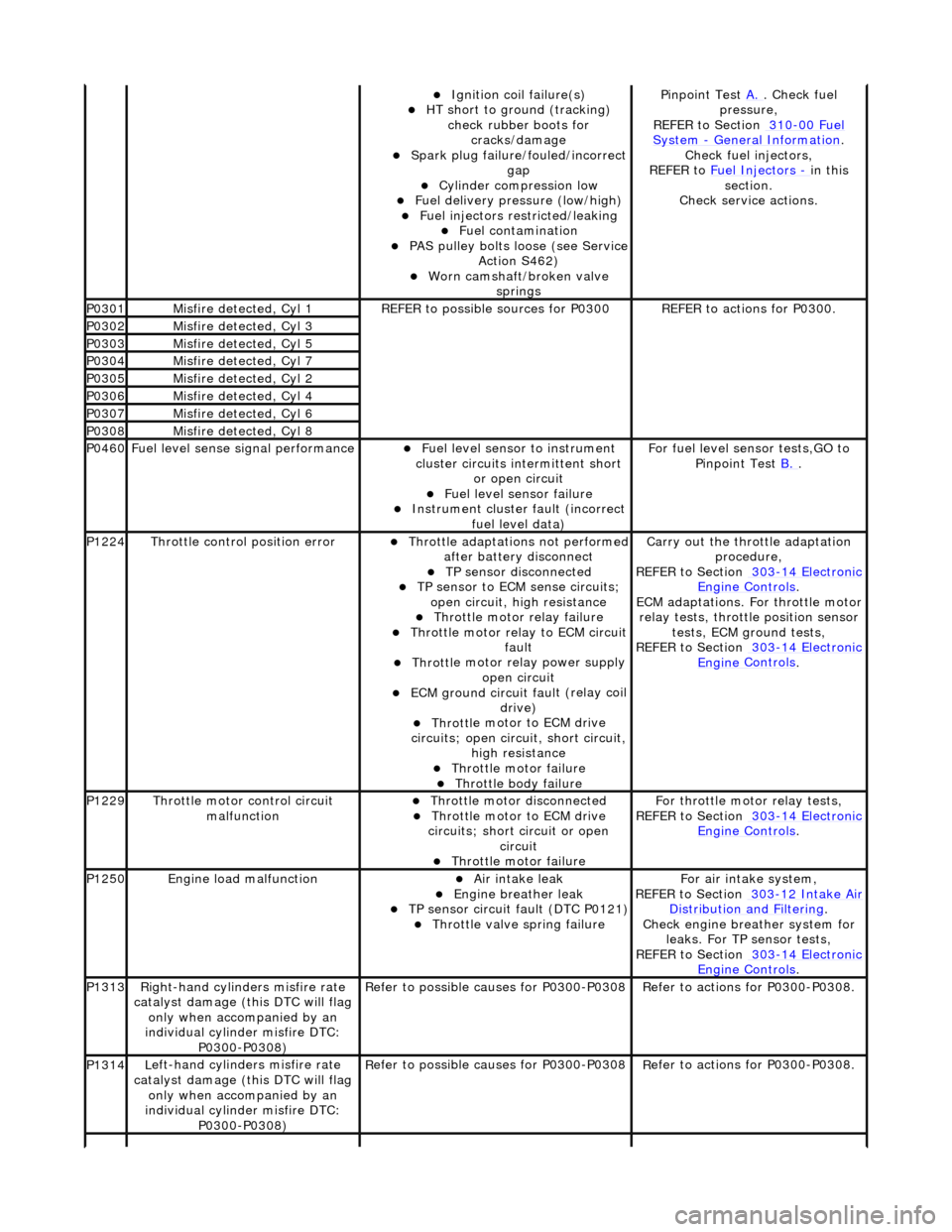

PI

NPOINT TEST A : DTC P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208; FUEL

INJECTOR CIRCUIT MALFUNCTION

• NOTE

: The DTC set will indicate which cylinder injector or circ

uit is faulty. Only in the event of multiple cylinder misfires

will it be necessary to chec k more than one injector or circuit, in which case, multiple DTCs will be set.

TES

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

A1

: CH

ECK THE INJECTOR COIL RESISTANCE

Turn the ignition swi

t

ch to the OFF

position.

1

Disconne

ct the relevant injector electrical connector

, (IJ03 to IJ10, vehicles with AJ26 engine, PI07 to

PI14, vehicles with AJ27 engine).

2

Meas ure t

he resistance between the injector pins.

3

Is

t

he resistance between 12 and 16 ohms?

Yes GO to A2

.

No

INST

ALL a new injector.

REFER to Fuel Injector

- Ve hicles With

out: Supercharger

in this

section.

CLEAR the DTC. TEST the system for normal operation.

A2: CHECK

THE INJECTOR COIL INSULATION

Meas

ure t

he resistance between the inje

ctor pin 01 and the injector body.

1

Measure t

he resistance between the inje

ctor pin 02 and the injector body.

2

Are both re

sistances greater than 10 Mohms?

Yes GO to A3

.

No

INST

ALL a new injector. CLEAR the DTC. TE

ST the system for normal operation.

A3: CHECK THE INJECTOR

SUPPLY VOLTAGE

Turn the ignition swi

t

ch to the ON

position.

1

Disconne

ct the relevant injector electrical connector

, (IJ03 to IJ10, vehicles with AJ26 engine, PI07 to

PI14, vehicles with AJ27 engine).

2

Meas ure t

he voltage between the relevant injector harness electrical connector (IJ03 to IJ10, vehicles

with AJ26 engine, PI07 to PI 14, vehicles with AJ27 engine), pin 02 (BR) and GROUND.

3

Is the volt

age greater than 12 volts?

Yes GO to A4

.

No

R

EPAIR the circuit between the relevant injector harn

ess electrical connector, pin 02 and battery. This

Page 1029 of 2490

ci

rcuit includes the EMS fuse box,

fuse 05, and the fuel injection relay. For additional information,

refer to the wiring diagrams. CLEAR DTC. TEST the system for normal operation.

A4: CHECK

THE INJECTOR GROUND

CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

Di

sconnect the battery negative terminal.

2

D

isconnect the ECM electrical connector, (EM15, vehi

cles with AJ26 engine, EM84, vehicles with AJ27

engine).

3

Meas

ure the resistance between the relevant injector harness electrical connector (IJ03 to IJ10,

vehicles with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and the ECM electrical

connector, pins as follows -

Vehicles with AJ26 engine:

Cy

l 1 IJ03, pin 01 (BU) and EM15, pin 07

Cy

l 2 IJ07, pin 01 (BU) and EM15, pin 18

Cy

l 3 IJ04, pin 01 (BN) and EM15, pin 17

Cy

l 4 IJ08, pin 01 (BN) and EM15, pin 05

Cy

l 5 IJ05, pin 01 (BG) and EM15, pin 16

Cy

l 6 IJ09, pin 01 (BG) and EM15, pin 04

Cy

l 7 IJ06, pin 01 (BW) and EM15, pin 06

Cy

l 8 IJ10, pin 01 (BW) and EM15, pin 15

Vehicles with AJ27 engine:

Cy

l 1 PI07, pin 01 (B

G) and EM84, pin 02

Cy

l 2 PI11, pin 01 (BW) and EM84, pin 06

Cy

l 3 PI08, pin 01 (BO) and EM84, pin 21

Cy

l 4 PI12, pin 01 (BW) and EM84, pin 04

Cy

l 5 PI09, pin 01 (B

G) and EM84, pin 14

Cy

l 6 PI13, pin 01 (BO) and EM84, pin 03

Cy

l 7 PI10, pin 01 (BW) and EM84, pin 05

Cy

l 8 PI14, pin 01 (BR) and EM84, pin 13

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the circuit between the relevant injector harness electrical connector pin 01 and the engine

control module electrical connecto r. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to A5

.

A5: CHECK

THE INJECTOR GROUND CI

RCUIT FOR SHORT CIRCUIT TO BATTERY

R

econnect the battery negative terminal.

1

Meas

ure the voltage between the relevant injector harness electrical connector (IJ03 to IJ10, vehicles

with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and GROUND.

2

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A6

.

A6: CHECK

THE INJECTOR GROUND CI

RCUIT FOR SHORT CIRCUIT TO GROUND

Meas

ure the resistance between the relevant injector harness electrical connector (IJ03 to IJ10,

vehicles with AJ26 engine, PI07 to PI14, vehicles with AJ27 engine), pin 01 and GROUND.

1

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No Contact dealer technical support for advice on possible ECM failure.

P

INPOINT TEST B : DTC P0460; FUEL

LEVEL SENSE SIGNAL PERFORMANCE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE FUEL LEVEL SENSOR REFERENCE GROUND

Di

sconnect the fuel level sensor electrical connector, BT15.

1

Page 1032 of 2490

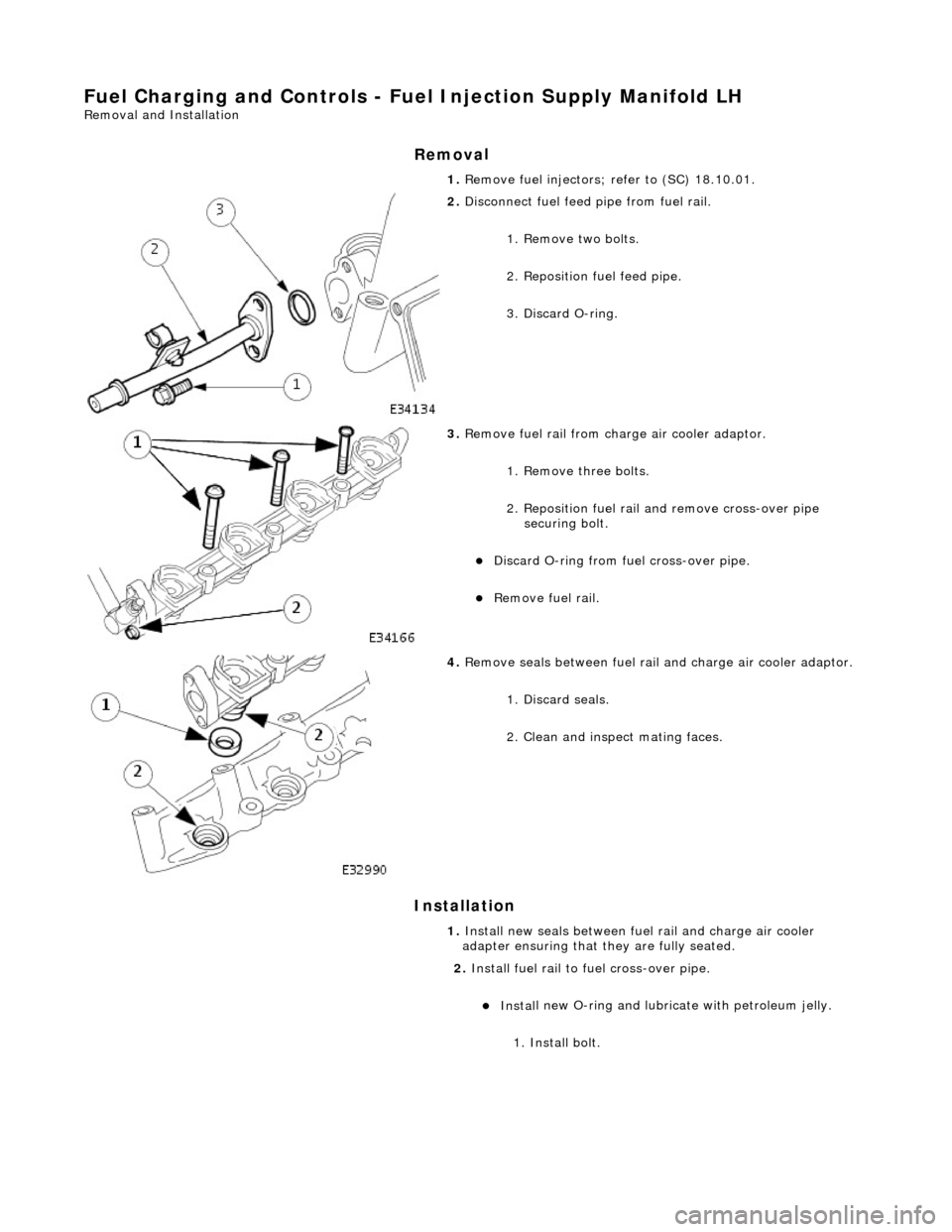

Fuel Char

ging and Controls - Fu

el Injection Supply Manifold LH

Remo

val and Installation

Remov

a

l

Installation

1. Re

move fuel injectors; refer to (SC) 18.10.01.

2. Disc

onnect fuel feed

pipe from fuel rail.

1. Remove two bolts.

2. Reposition fuel feed pipe.

3. Discard O-ring.

3. Re

move fuel rail from charge air cooler adaptor.

1. Remove three bolts.

2. Reposition fuel rail and remove cross-over pipe securing bolt.

Di

scard O-ring from fuel cross-over pipe.

R

e

move fuel rail.

4. Re

move seals between fuel rail

and charge air cooler adaptor.

1. Discard seals.

2. Clean and inspect mating faces.

1. Install new seals between fuel rail and charge air cooler

adapter ensuring that they are fully seated.

2. Install fuel rail to fuel cross-over pipe.

Inst al

l new O-ring and lubricate with petroleum jelly.

1. Install bolt.

Page 1033 of 2490

3.

Install

fuel rail to charge air cooler adaptor.

Locate fuel

rail into adaptor.

1. Install bolts.

4. Conne

ct fuel feed pi

pe to fuel rail.

1. Install new O-ring and lubricate with petroleum jelly.

2. Install two bolts.

5. Install fuel injectors; refer to (SC) 18.10.01.

Page 1034 of 2490

Fuel Char

ging and Controls - Fu

el Injection Supply Manifold RH

Remo

val and Installation

Remov

a

l

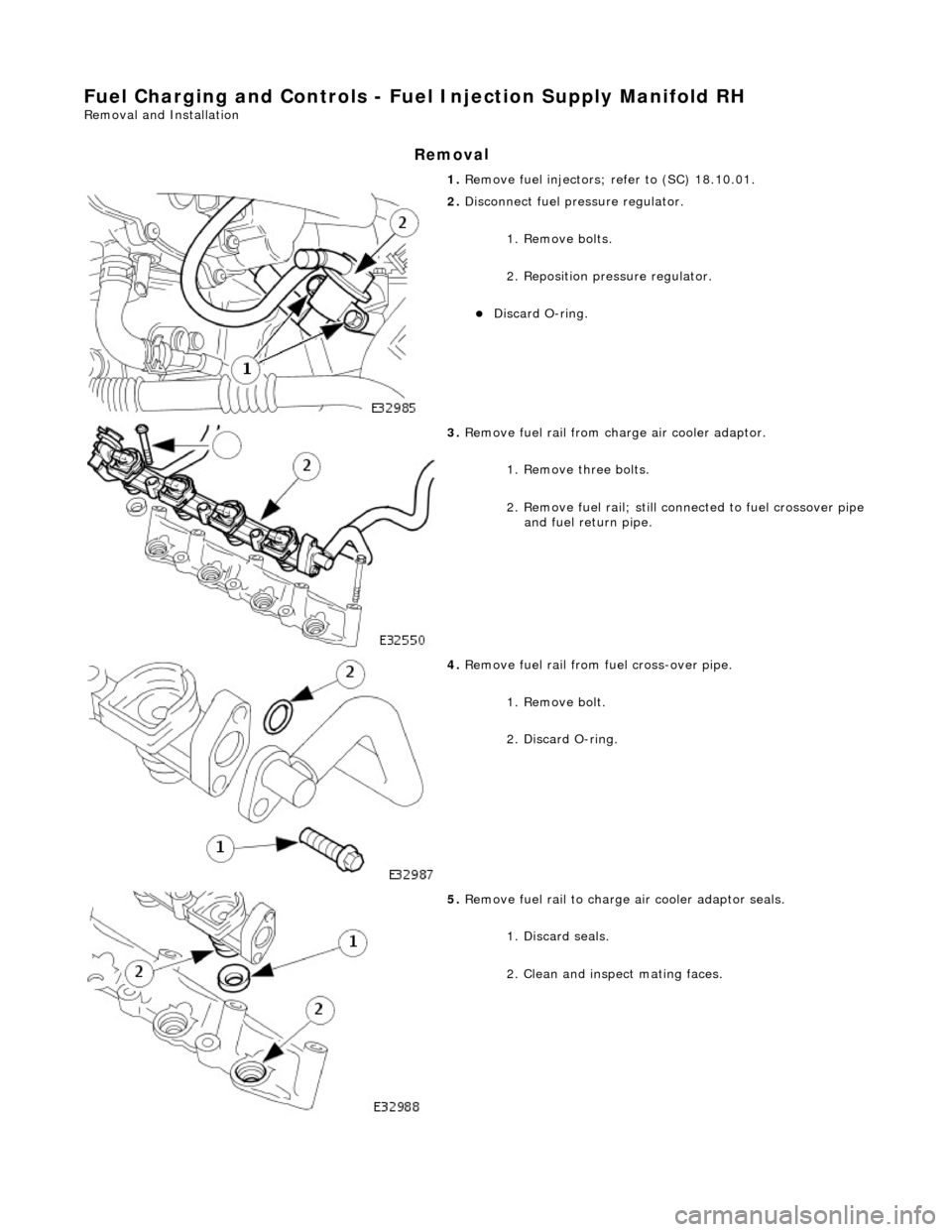

1.

Re

move fuel injectors; refer to (SC) 18.10.01.

2. Disc

onnect fuel pressure regulator.

1. Remove bolts.

2. Reposition pres sure regulator.

Disc

ard O-ring.

3. Re

move fuel rail from charge air cooler adaptor.

1. Remove three bolts.

2. Remove fuel rail; still co nnected to fuel crossover pipe

and fuel return pipe.

4. Re

move fuel rail from fuel cross-over pipe.

1. Remove bolt.

2. Discard O-ring.

5. Re

move fuel rail to charge air cooler adaptor seals.

1. Discard seals.

2. Clean and inspect mating faces.

Page 1035 of 2490

I

nstallation

1.

Inst

all new seals between fuel rail and charge air cooler

adapter, ensuring they are fully seated.

2. Install

fuel rail to fuel cross-over pipe.

1. Install new O-ring and lubricate with petroleum jelly.

2. Install bolt.

3. Install

fuel rail to charge air cooler adaptor.

1. Align fuel rail to adaptor; still connected to fuel crossover pipe and fuel return pipe. Locate fuel rail

into adaptor.

2. Install three bolts which se cure fuel rail to adaptor.

Tighten to 18-24 Nm.

4. Install

fuel pressure regulator.

Install a new O-r

ing to fu

el pressure regulator and

lubricate with petroleum jelly

1. Install bolts.

5. Install fuel injectors; refer to (SC) 18.10.01.

Page 1037 of 2490

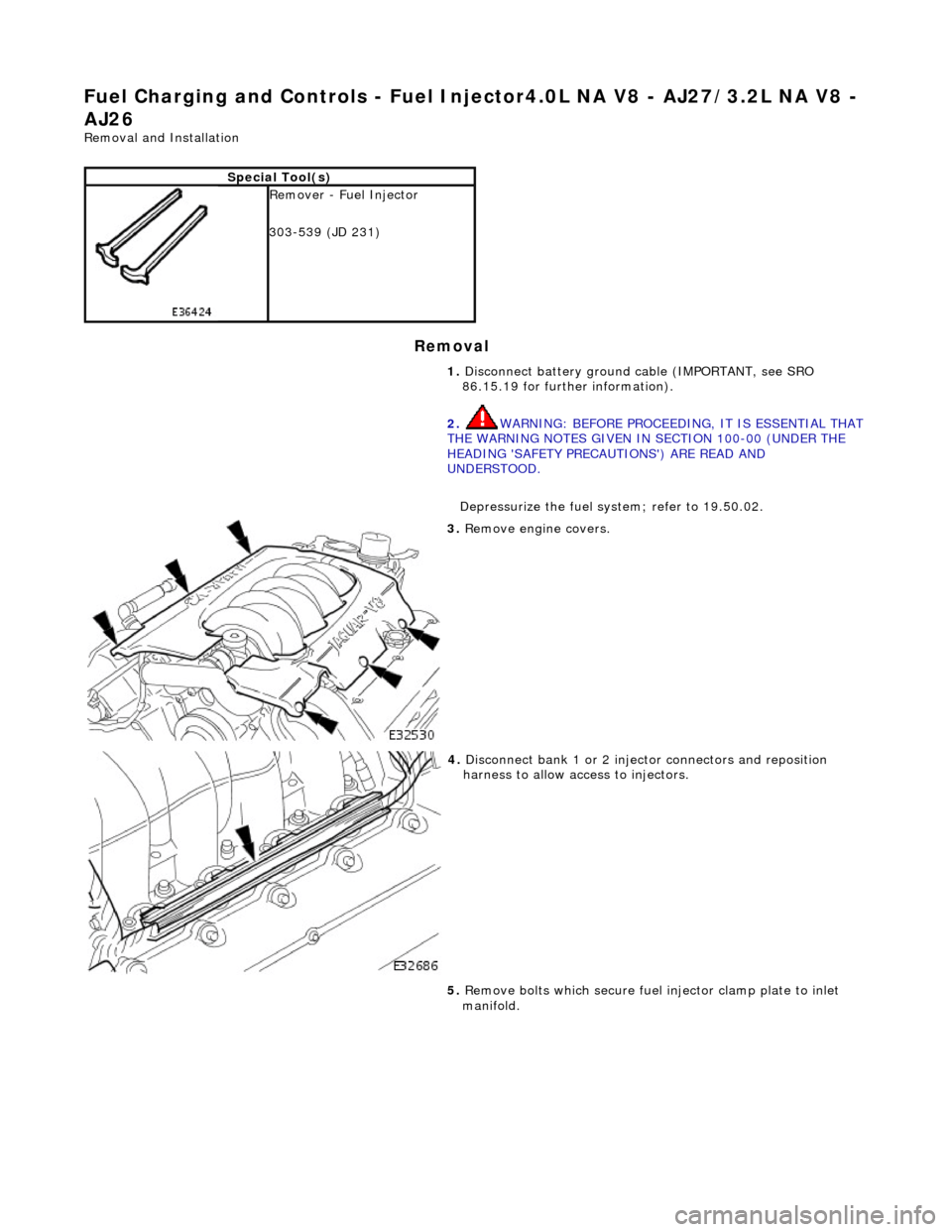

Fuel Ch

arging and Controls

- Fuel Injector4.0L NA V8 - AJ27/3.2L NA V8 -

AJ26

Re

moval and Installation

Remov

al

S

pecial Tool(s)

R

emover - Fuel Injector

303-539 (JD 231)

1. Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Depressurize the fuel sy stem; refer to 19.50.02.

3. R

emove engine covers.

4. Di

sconnect bank 1 or 2 inject

or connectors and reposition

harness to allow access to injectors.

5. Remove bolts which secure fuel injector clamp plate to inlet

manifold.

Page 1038 of 2490

In

stallation

6.

Us

ing special tool JD-231, remove injector(s).

Discard

seals an

d clean all mating faces.

1. Installation

is a reversal

of the removal procedure.

Instal

l new seals and lubricate with petroleum jelly.

Page 1039 of 2490

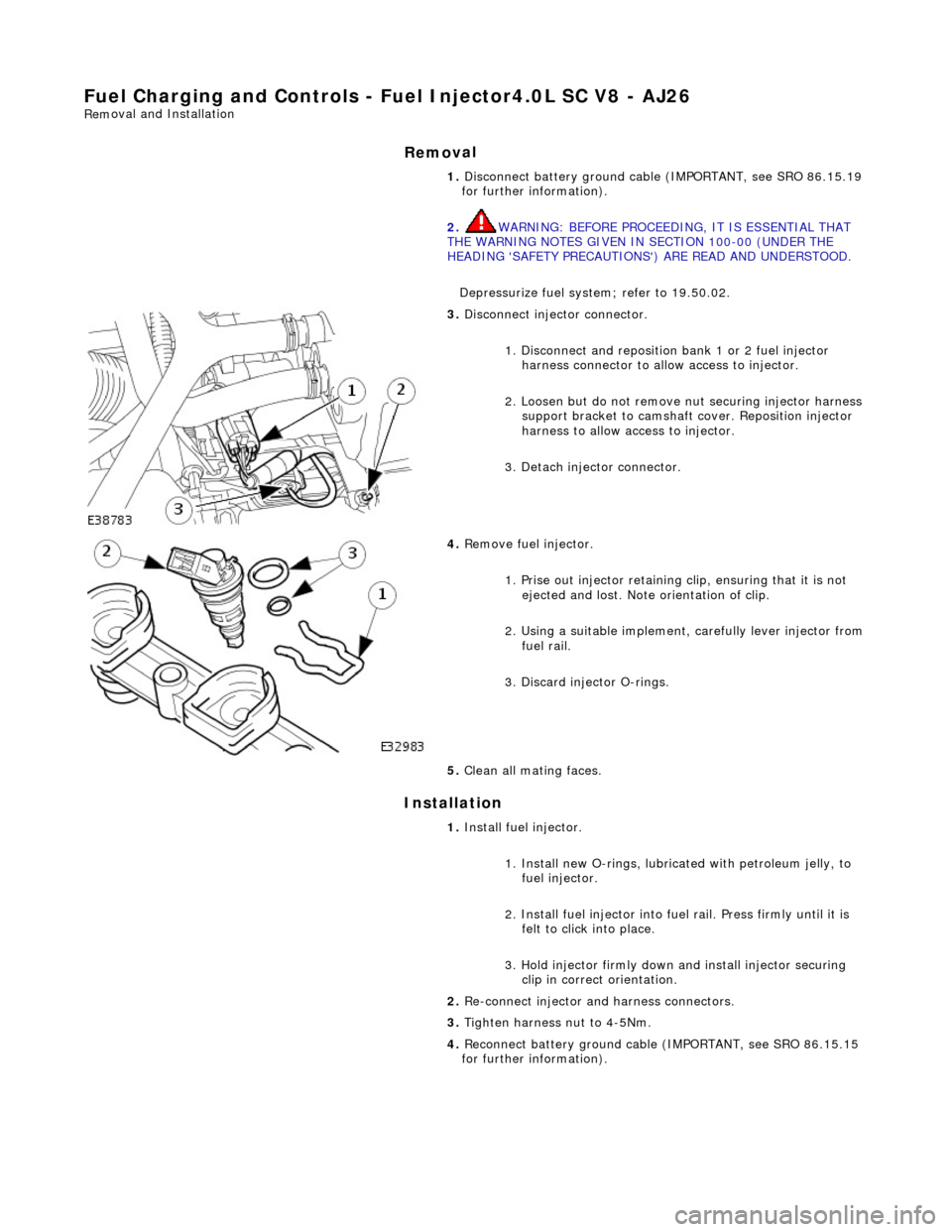

Fuel Charging and Controls

- Fuel Injector4.0L SC V8 - AJ26

Rem

oval and Installation

Remov

al

Installation

1.

Disconnect battery ground cabl e (IMPORTANT, see SRO 86.15.19

for further information).

2. WARNING: BEFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND UNDERSTOOD.

Depressurize fuel system; refer to 19.50.02.

3.

Disconnect injector connector.

1. Disconnect and reposition bank 1 or 2 fuel injector harness connector to allow access to injector.

2. Loosen but do not remove nut securing injector harness support bracket to camshaft cover. Reposition injector

harness to allow access to injector.

3. Detach injector connector.

4.

Remove fuel injector.

1. Prise out injector retaining clip, ensuring that it is not ejected and lost. Note orientation of clip.

2. Using a suitable implement, carefully lever injector from

fuel rail.

3. Discard injector O-rings.

5. Clean all mating faces.

1. Install fuel injector.

1. Install new O-rings, lubricat ed with petroleum jelly, to

fuel injector.

2. Install fuel injector into fuel rail. Press firmly until it is felt to click into place.

3. Hold injector firmly down and install injector securing clip in correct orientation.

2. Re-connect injector and harness connectors.

3. Tighten harness nut to 4-5Nm.

4. Reconnect battery ground cable (IMPORTANT, see SRO 86.15.15

for further information).