Ground JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2367 of 2490

Safety Belt System - Safety Belt Shoulder Height Adjuster

Removal and Installation

Removal

Installation

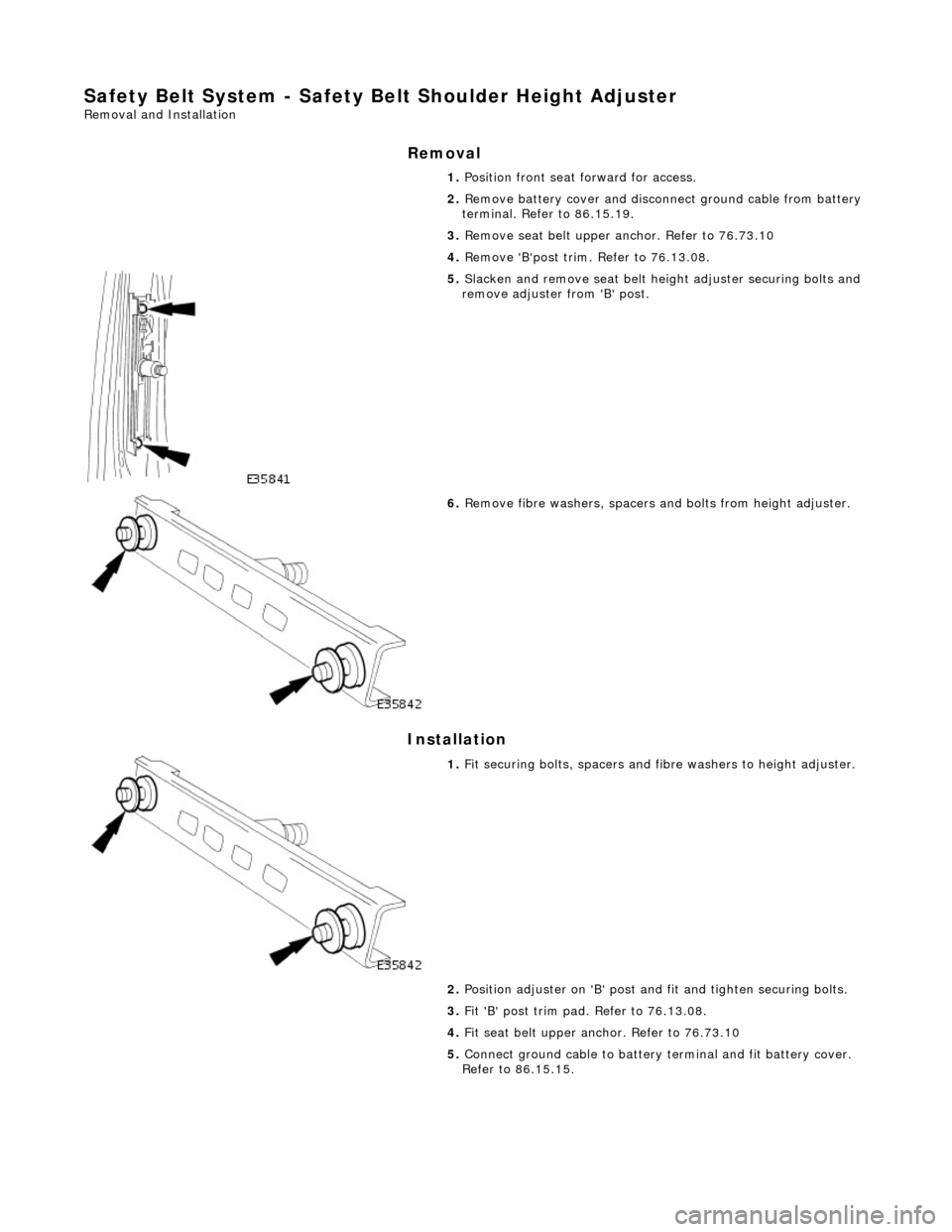

1.

Position front seat forward for access.

2. Remove battery cover and disconnect ground cable from battery

terminal. Refer to 86.15.19.

3. Remove seat belt upper anchor. Refer to 76.73.10

4. Remove 'B'post trim. Refer to 76.13.08.

5. Slacken and remove seat belt heig ht adjuster securing bolts and

remove adjuster from 'B' post.

6. Remove fibre washers, spacers an d bolts from height adjuster.

1. Fit securing bolts, spacers and fi bre washers to height adjuster.

2. Position adjuster on 'B' post an d fit and tighten securing bolts.

3. Fit 'B' post trim pad. Refer to 76.13.08.

4. Fit seat belt upper an chor. Refer to 76.73.10

5. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 2371 of 2490

Supplemental Restraint System - Air Bag Control Module

Removal and Installation

Removal

Installation

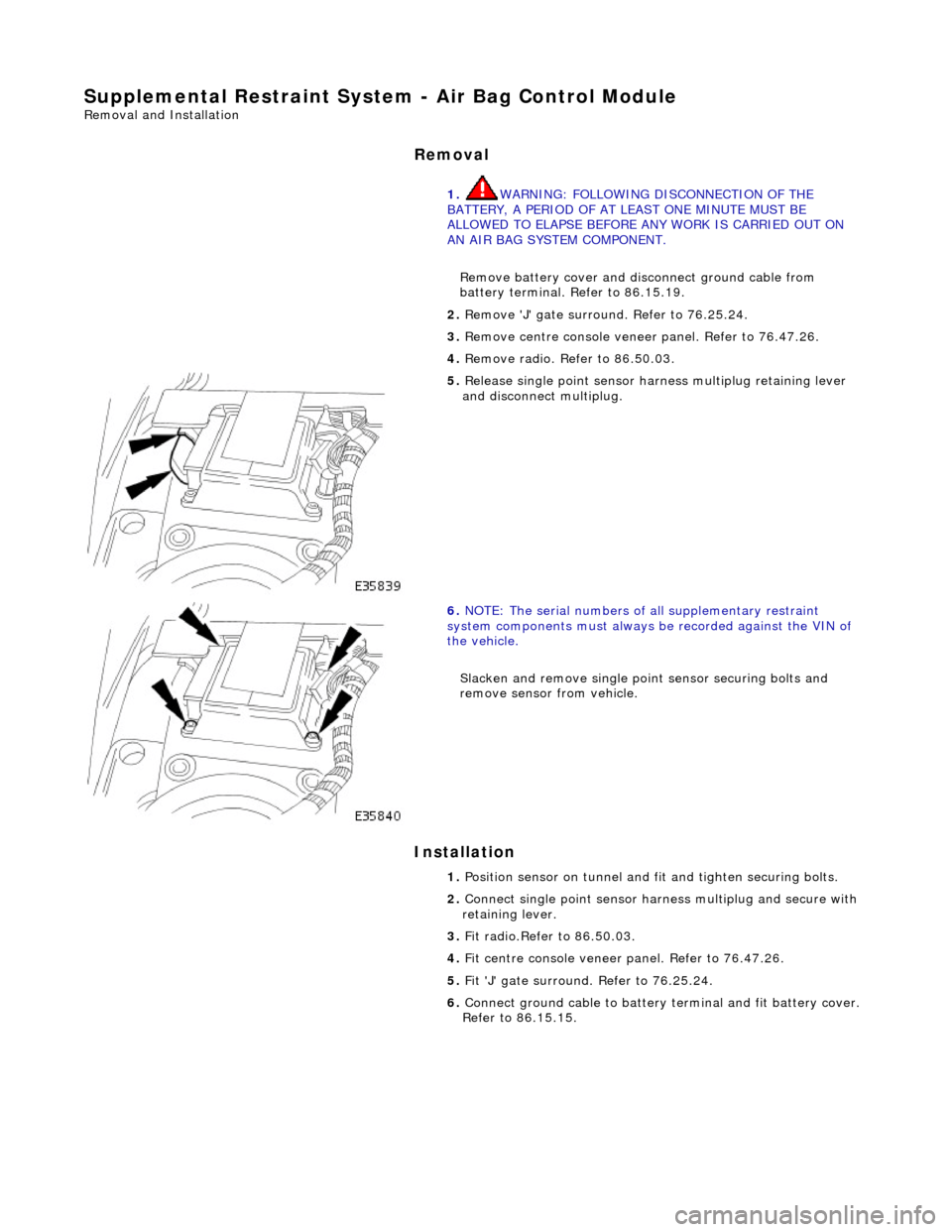

1.

WARNING: FOLLOWING DISCONNECTION OF THE

BATTERY, A PERIOD OF AT LEAST ONE MINUTE MUST BE

ALLOWED TO ELAPSE BEFORE ANY WORK IS CARRIED OUT ON

AN AIR BAG SYSTEM COMPONENT.

Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Remove 'J' gate surroun d. Refer to 76.25.24.

3. Remove centre console veneer panel. Refer to 76.47.26.

4. Remove radio. Re fer to 86.50.03.

5. Release single point sensor ha rness multiplug retaining lever

and disconnect multiplug.

6. NOTE: The serial num bers of all supplementary restraint

system components must always be recorded against the VIN of

the vehicle.

Slacken and remove single point sensor securing bolts and

remove sensor from vehicle.

1. Position sensor on tunnel and fit and tighten securing bolts.

2. Connect single point sensor harn ess multiplug and secure with

retaining lever.

3. Fit radio.Refer to 86.50.03.

4. Fit centre console veneer panel. Refer to 76.47.26.

5. Fit 'J' gate surround. Refer to 76.25.24.

6. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 2372 of 2490

Supplemental Restraint System - Driver Air Bag Module

Removal and Installation

Removal

• WARNINGS:

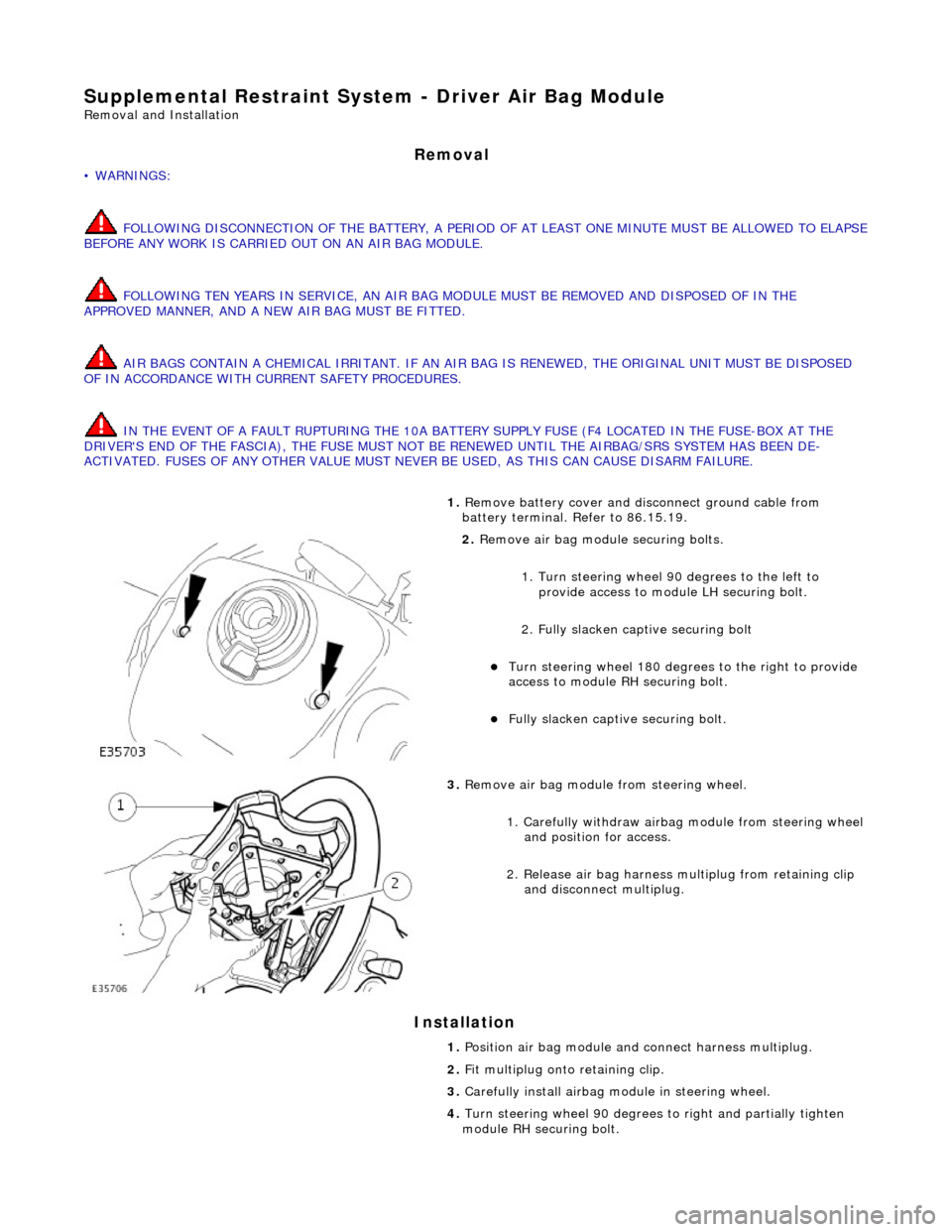

FOLLOWING DISCONNECTION OF THE BATTERY, A PERIOD OF AT LEAST ONE MINUTE MUST BE ALLOWED TO ELAPSE

BEFORE ANY WORK IS CARRIED OUT ON AN AIR BAG MODULE.

FOLLOWING TEN YEARS IN SERVICE, AN AIR BAG MO DULE MUST BE REMOVED AND DISPOSED OF IN THE

APPROVED MANNER, AND A NEW AIR BAG MUST BE FITTED.

AIR BAGS CONTAIN A CHEMICAL IRRITANT. IF AN AIR BAG IS RENEWED, THE ORIGINAL UNIT MUST BE DISPOSED

OF IN ACCORDANCE WITH CURRENT SAFETY PROCEDURES.

IN THE EVENT OF A FAULT RUPTURING THE 10A BATTERY SUPPLY FUSE (F4 LOCATED IN THE FUSE-BOX AT THE

DRIVER'S END OF THE FASCIA), THE FUSE MUST NOT BE RENEWED UNTIL THE AIRBAG/SRS SYSTEM HAS BEEN DE-

ACTIVATED. FUSES OF ANY OTHER VALUE MUST NEVER BE USED, AS THIS CAN CAUSE DISARM FAILURE.

Installation

1. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Remove air bag module securing bolts.

1. Turn steering wheel 90 degrees to the left to

provide access to module LH securing bolt.

2. Fully slacken captive securing bolt

пЃ¬Turn steering whee l 180 degrees to the right to provide

access to module RH securing bolt.

пЃ¬Fully slacken captive securing bolt.

3. Remove air bag module from steering wheel.

1. Carefully withdraw airbag module from steering wheel

and position for access.

2. Release air bag harness mu ltiplug from retaining clip

and disconnect multiplug.

1. Position air bag module and connect harness multiplug.

2. Fit multiplug onto retaining clip.

3. Carefully install airbag mo dule in steering wheel.

4. Turn steering wheel 90 degrees to right an d partially tighten

module RH securing bolt.

Page 2373 of 2490

5.

Turn steering wheel 90 degrees to left and partially tighten

module LH securing bolt.

6. Repeat steps 3 and 4 to fully ti ghten securing bolts and return

steering wheel to central position.

7. Fit ground cable to battery terminal. Refer to 86.15.15.

Page 2374 of 2490

Supplemental Restraint System - Passenger Air Bag Module

Removal and Installation

Removal

• WARNINGS:

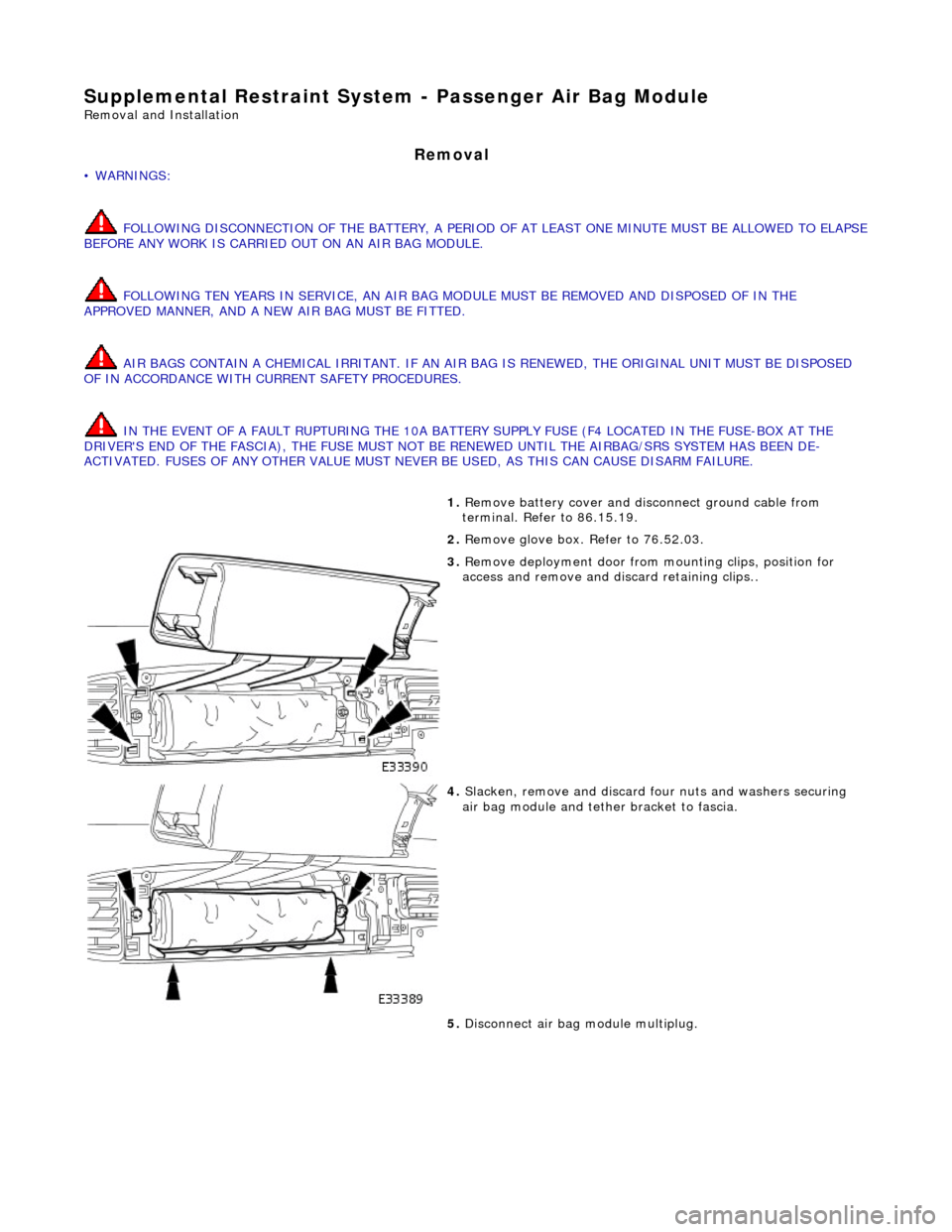

FOLLOWING DISCONNECTION OF THE BATTERY, A PERIOD OF AT LEAST ONE MINUTE MUST BE ALLOWED TO ELAPSE

BEFORE ANY WORK IS CARRIED OUT ON AN AIR BAG MODULE.

FOLLOWING TEN YEARS IN SERVICE, AN AIR BAG MO DULE MUST BE REMOVED AND DISPOSED OF IN THE

APPROVED MANNER, AND A NEW AIR BAG MUST BE FITTED.

AIR BAGS CONTAIN A CHEMICAL IRRITANT. IF AN AIR BAG IS RENEWED, THE ORIGINAL UNIT MUST BE DISPOSED

OF IN ACCORDANCE WITH CURRENT SAFETY PROCEDURES.

IN THE EVENT OF A FAULT RUPTURING THE 10A BATTERY SUPPLY FUSE (F4 LOCATED IN THE FUSE-BOX AT THE

DRIVER'S END OF THE FASCIA), THE FUSE MUST NOT BE RENEWED UNTIL THE AIRBAG/SRS SYSTEM HAS BEEN DE-

ACTIVATED. FUSES OF ANY OTHER VALUE MUST NEVER BE USED, AS THIS CAN CAUSE DISARM FAILURE.

1. Remove battery cover and disc onnect ground cable from

terminal. Refer to 86.15.19.

2. Remove glove box. Refer to 76.52.03.

3. Remove deployment door from mounting clips, position for

access and remove and di scard retaining clips..

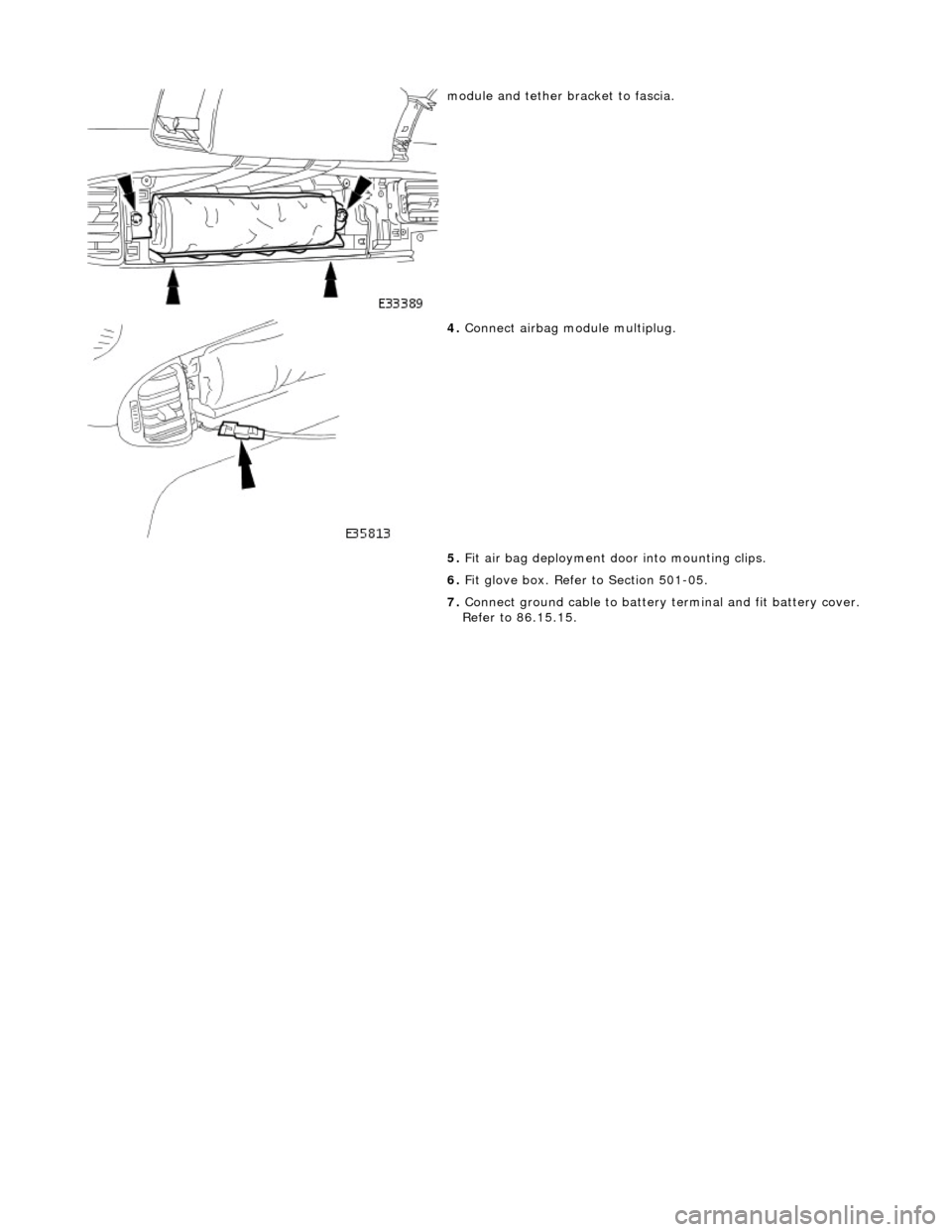

4. Slacken, remove and discard fo ur nuts and washers securing

air bag module and tether bracket to fascia.

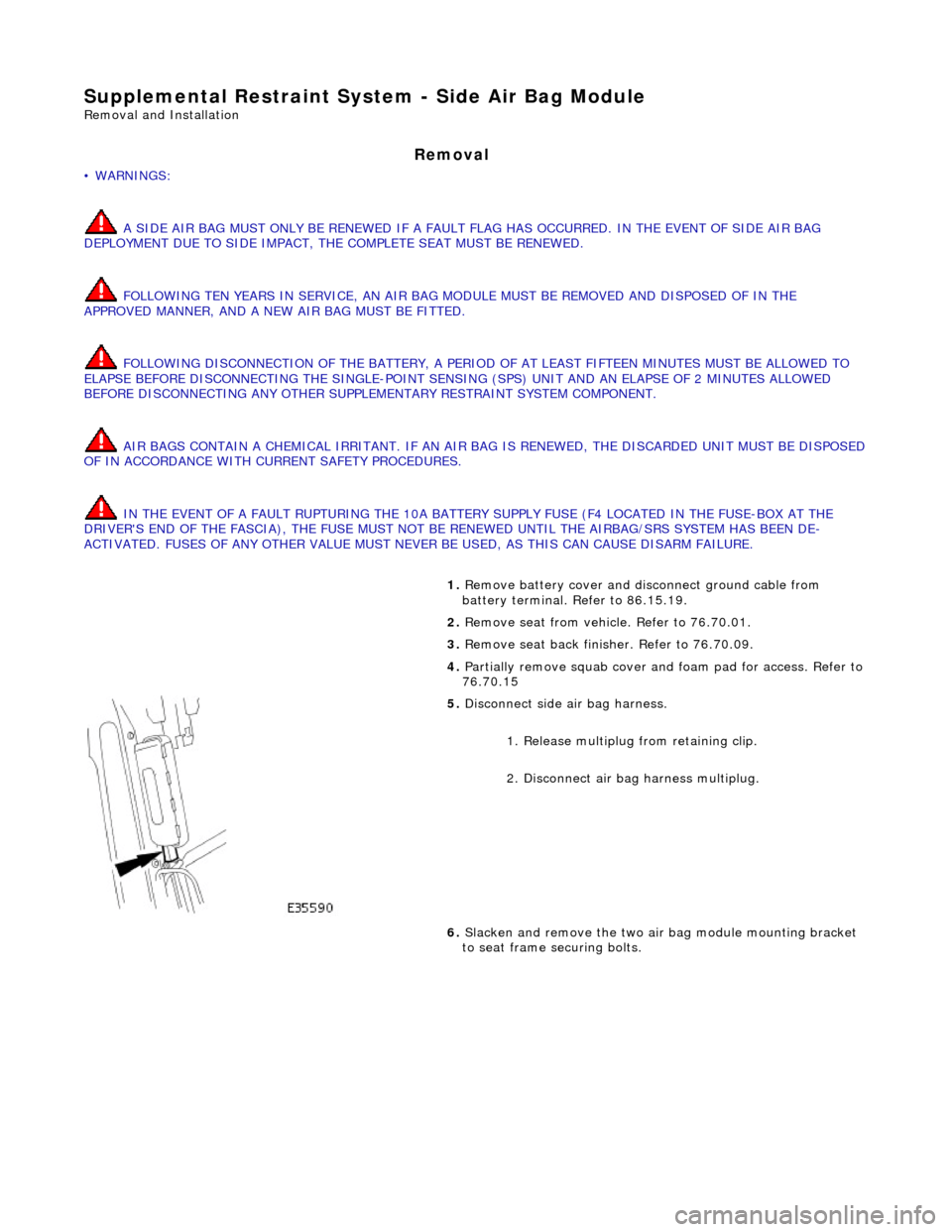

5. Disconnect air bag module multiplug.

Page 2376 of 2490

module and tether bracket to fascia.

4. Connect airbag module multiplug.

5. Fit air bag deployment d oor into mounting clips.

6. Fit glove box. Refer to Section 501-05.

7. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 2377 of 2490

Supplemental Restraint System - Side Air Bag Module

Removal and Installation

Removal

• WARNINGS:

A SIDE AIR BAG MUST ONLY BE RENEWED IF A FAULT FLAG HAS OCCURRED. IN THE EVENT OF SIDE AIR BAG

DEPLOYMENT DUE TO SIDE IMPACT, THE COMPLETE SEAT MUST BE RENEWED.

FOLLOWING TEN YEARS IN SERVICE, AN AIR BAG MO DULE MUST BE REMOVED AND DISPOSED OF IN THE

APPROVED MANNER, AND A NEW AIR BAG MUST BE FITTED.

FOLLOWING DISCONNECTION OF THE BATTERY, A PERIOD OF AT LEAST FIFTEEN MINUTES MUST BE ALLOWED TO

ELAPSE BEFORE DISCONNECTING THE SINGLE-POINT SENSIN G (SPS) UNIT AND AN ELAPSE OF 2 MINUTES ALLOWED

BEFORE DISCONNECTING ANY OTHER SUPPLEMENTARY RESTRAINT SYSTEM COMPONENT.

AIR BAGS CONTAIN A CHEMICAL IRRITANT. IF AN AIR BAG IS RENEWED, THE DISCARDED UNIT MUST BE DISPOSED

OF IN ACCORDANCE WITH CURRENT SAFETY PROCEDURES.

IN THE EVENT OF A FAULT RUPTURING THE 10A BATTERY SUPPLY FUSE (F4 LOCATED IN THE FUSE-BOX AT THE

DRIVER'S END OF THE FASCIA), THE FUSE MUST NOT BE RENEWED UNTIL THE AIRBAG/SRS SYSTEM HAS BEEN DE-

ACTIVATED. FUSES OF ANY OTHER VALUE MUST NEVER BE USED, AS THIS CAN CAUSE DISARM FAILURE.

1. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

2. Remove seat from vehi cle. Refer to 76.70.01.

3. Remove seat back fini sher. Refer to 76.70.09.

4. Partially remove squab cover and foam pad for access. Refer to

76.70.15

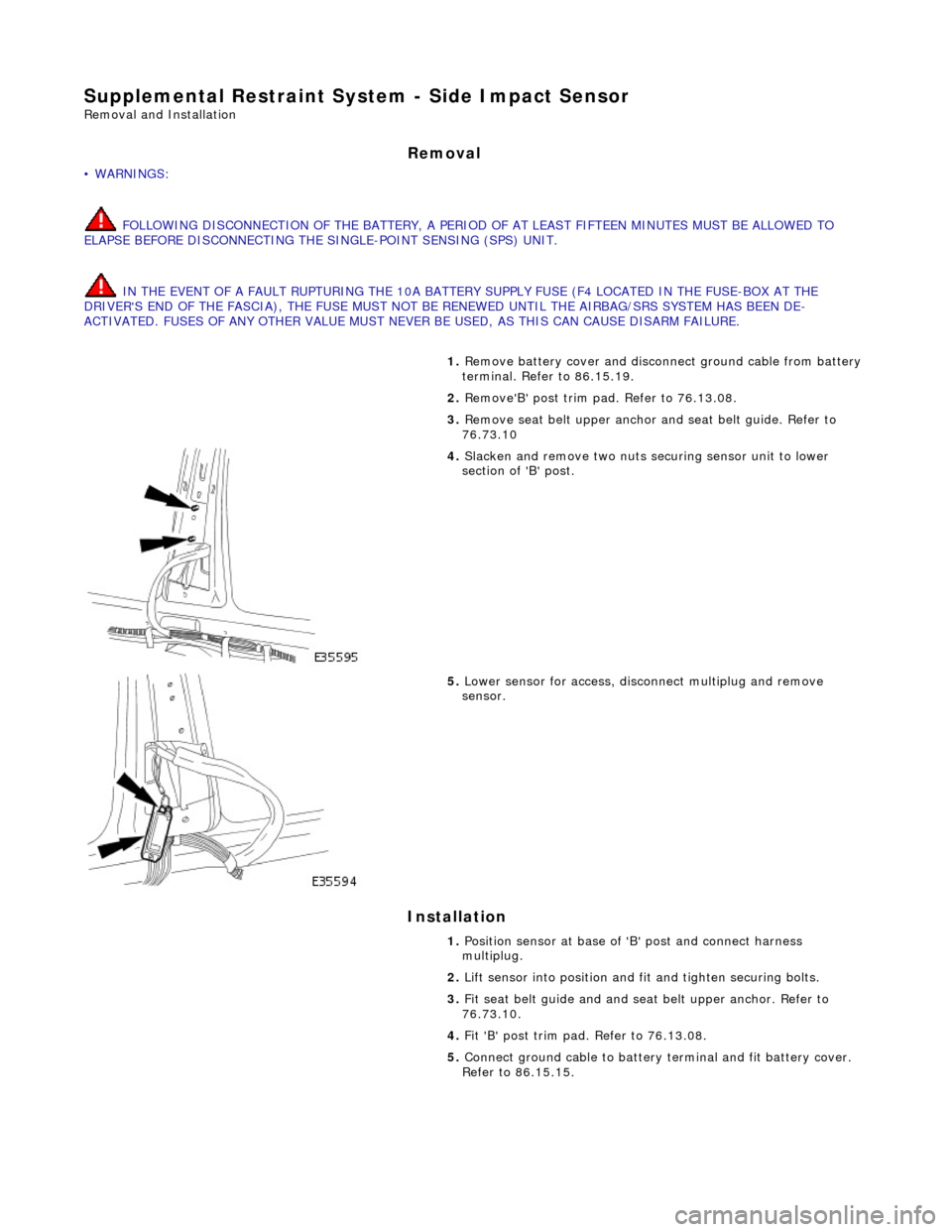

5. Disconnect side air bag harness.

1. Release multiplug from retaining clip.

2. Disconnect air ba g harness multiplug.

6. Slacken and remove the two air bag module mounting bracket

to seat frame securing bolts.

Page 2378 of 2490

Installation

7. Remove air bag module from seat and arrange for disposal in

approved manner.

1. CAUTION: Side air bags are de dicated to either LH or RH

seat installation. When the air bag module is installed, the

multiplug connector must face the seat base.

Position air bag module on the seat frame ensuring that harness

connector faces the seat base.

2. Fit and tighten the securing bolts.

3. Connect the air bag harness mult iplug and fit multiplug onto

retaining clip.

4. CAUTIONS:

Hog rings removed during the following procedure must not

be re-used. Do not commence the following procedure unless new hog rings are availabl e. Use of used or non-Jaguar parts can

impair air bag deployment and cause serious personal injury.

Hog ring pliers must be used to install new hog rings. Use

of ordinary pliers will result in ring deformation, leading to

possible failure and personal in jury during airbag deployment.

Fit the seat squab cover. Refer to 76.70.15.

5. Fit the seat back finisher. Refer to 76.70.09.

6. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 2379 of 2490

Supplemental Restraint System - Side Impact Sensor

Removal and Installation

Removal

• WARNINGS:

FOLLOWING DISCONNECTION OF THE BA TTERY, A PERIOD OF AT LEAST FIFTEEN MINUTES MUST BE ALLOWED TO

ELAPSE BEFORE DISCONNECTING THE SINGLE-POINT SENSING (SPS) UNIT.

IN THE EVENT OF A FAULT RUPTURING THE 10A BATTER Y SUPPLY FUSE (F4 LOCATED IN THE FUSE-BOX AT THE

DRIVER'S END OF THE FASCIA), THE FUSE MUST NOT BE RENEWED UNTIL THE AIRBAG/SRS SYSTEM HAS BEEN DE-

ACTIVATED. FUSES OF ANY OTHER VALUE MUST NEVER BE USED, AS THIS CAN CAUSE DISARM FAILURE.

Installation

1. Remove battery cover and disconnect ground cable from battery

terminal. Refer to 86.15.19.

2. Remove'B' post trim pa d. Refer to 76.13.08.

3. Remove seat belt upper anchor and seat belt guide. Refer to

76.73.10

4. Slacken and remove two nuts securing sensor unit to lower

section of 'B' post.

5. Lower sensor for access, disco nnect multiplug and remove

sensor.

1. Position sensor at base of 'B' post and connect harness

multiplug.

2. Lift sensor into position and fit and tighten securing bolts.

3. Fit seat belt guide and and seat belt upper anchor. Refer to

76.73.10.

4. Fit 'B' post trim pad. Refer to 76.13.08.

5. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 2421 of 2490

Uni-Body, Subframe and Mounting System - Front Axle Crossmember

Removal and Installation

Removal

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

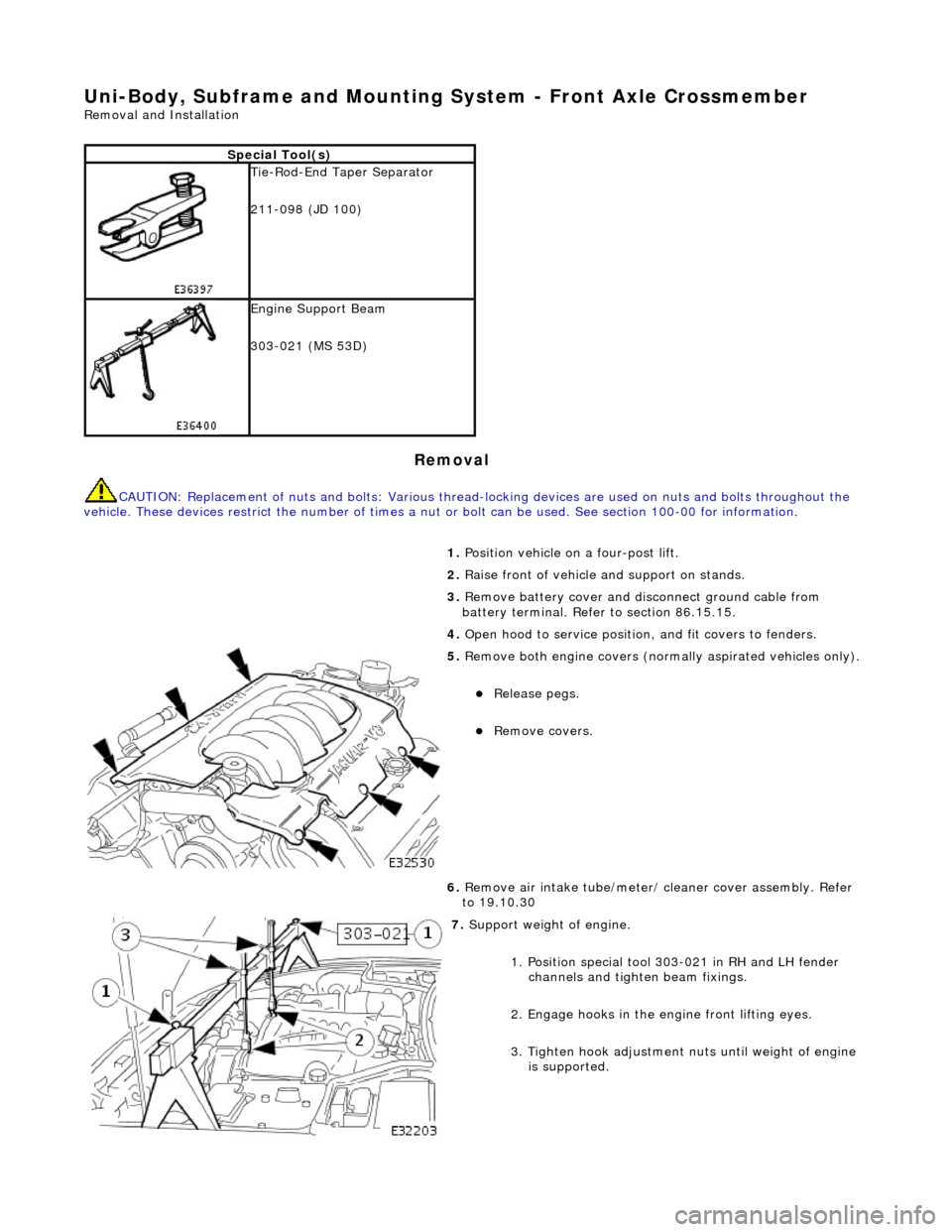

Special Tool(s)

Tie-Rod-End Taper Separator

211-098 (JD 100)

Engine Support Beam

303-021 (MS 53D)

1. Position vehicle on a four-post lift.

2. Raise front of vehicle and support on stands.

3. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to section 86.15.15.

4. Open hood to service position, and fit covers to fenders.

5. Remove both engine covers (nor mally aspirated vehicles only).

пЃ¬Release pegs.

пЃ¬Remove covers.

6. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

7. Support weight of engine.

1. Position special tool 303-021 in RH and LH fender channels and tighte n beam fixings.

2. Engage hooks in the en gine front lifting eyes.

3. Tighten hook adjustment nuts until weight of engine is supported.