JAGUAR X308 1998 2.G Repair Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Repair Manual

Page 1557 of 2490

Pinpoint test C: P0137, P0138

Measure the voltage between EM010/023 and EM015/002. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to B19

No Check EMS fuse F14 and that EMS control relay (relay 1) is

energized and with all connections made.

GO to B19

B19: END

Perform appropriate service drive cycle and check for the

presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST C : P0137, P0138

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

C1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1596 of 2490

Ignition switch to position 0 1

Remove EMS fuse F14. 2

Disconnect EM010 and EM015. 3

Using a link lead, bridge EM010/016 and EM010/022. 4

Measure the voltage between EM010/023 and

EM015/001. 5

Is the voltage 0 (zero) V?

Yes Replace EMS fuse F14 but retain link lead.

GO to E17

No Inspect harness / connecto rs EM010, EM015, and EM023

for corrosion, damaged / pushed back pins.

Repair as required an d reconnect plug(s).

GO to E18

E17: CHECK B+ AT O2 SENSOR HEATER CIRCUIT

Page 1597 of 2490

Pinpoint test F: P0153

With EM010 and EM015 disconnected, measure the

voltage between EM010/023 and EM015/001. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to E18

No Check integrity of EMS fuse F1 4, EMS control relay (relay

1) is energized and all connections are made.

GO to E18

E18: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST F : P0153

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

F1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1608 of 2490

Ignition switch to position 0 1

Remove EMS fuse F14. 2

Disconnect EM010 and EM015. 3

Using a link lead, bridge EM010/016 and EM010/022. 4

Measure the voltage between EM010/023 and

EM015/001. 5

Is the voltage 0 (zero) V?

Yes Replace EMS fuse F14 but retain link lead

GO to F18

No Inspect connectors EM010, EM015, and EM023 for

corrosion, damaged / pushed back pins or repair the

harness; reconnect plug(s).

GO to F19

F18: CHECK B+ AT O2 SENSOR HEATER CIRCUIT

Page 1609 of 2490

Pinpoint test G: P0157, P0158

With EM010 and EM015 disconnected, measure the

voltage between EM010/023 and EM015/002. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to F19

No Check integrity of EMS fuse F1 4, EMS control relay (relay

1) is energized and all connections made.

GO to F19

F19: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST G : P0157, P0158

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

G1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1696 of 2490

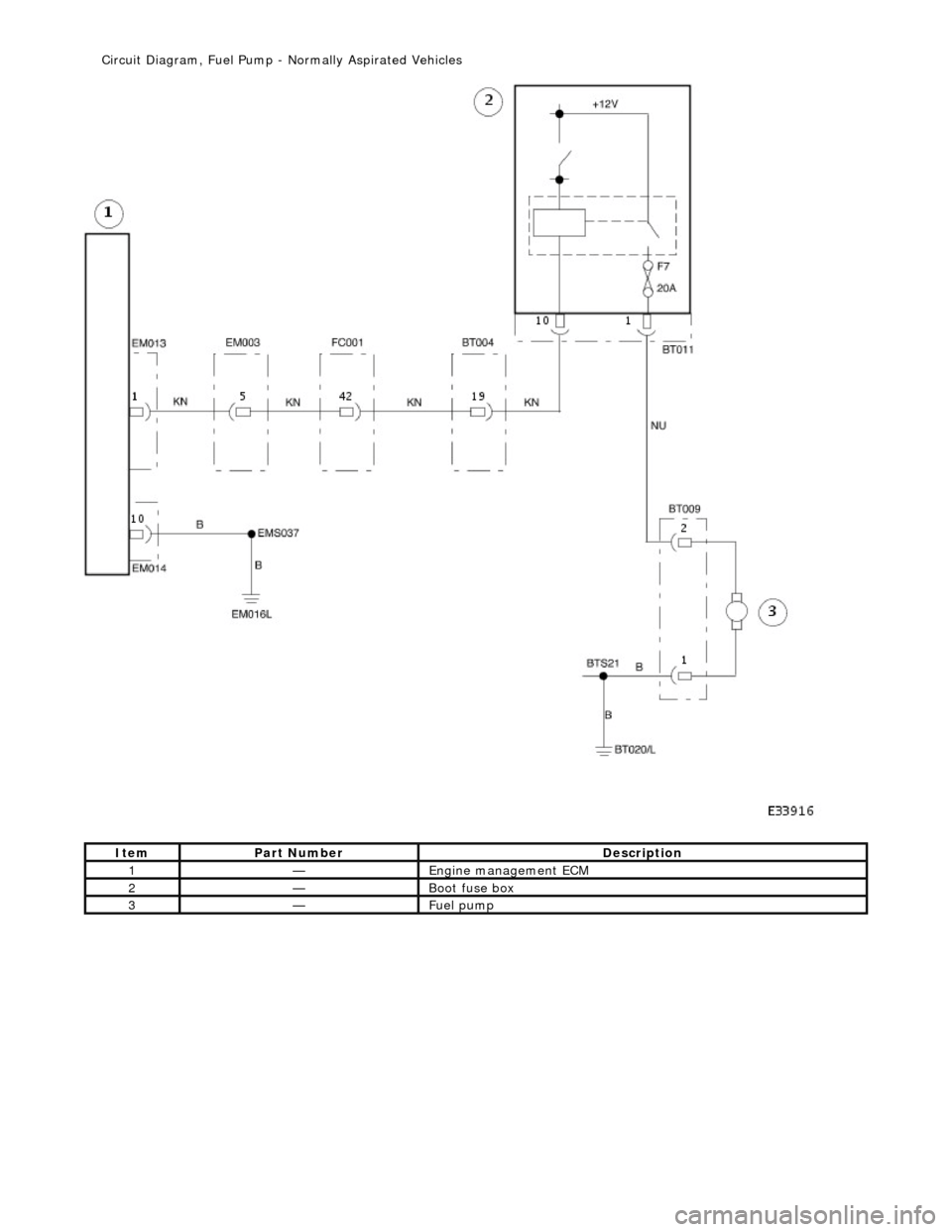

Ite

m

Par

t

Number

De

scr

iption

1—Engine

m

anagement ECM

2—Boot fuse box

3—Fue

l

pump

Ci

rcui

t Diagram, Fuel Pump -

Normally Aspirated Vehicles

Page 1697 of 2490

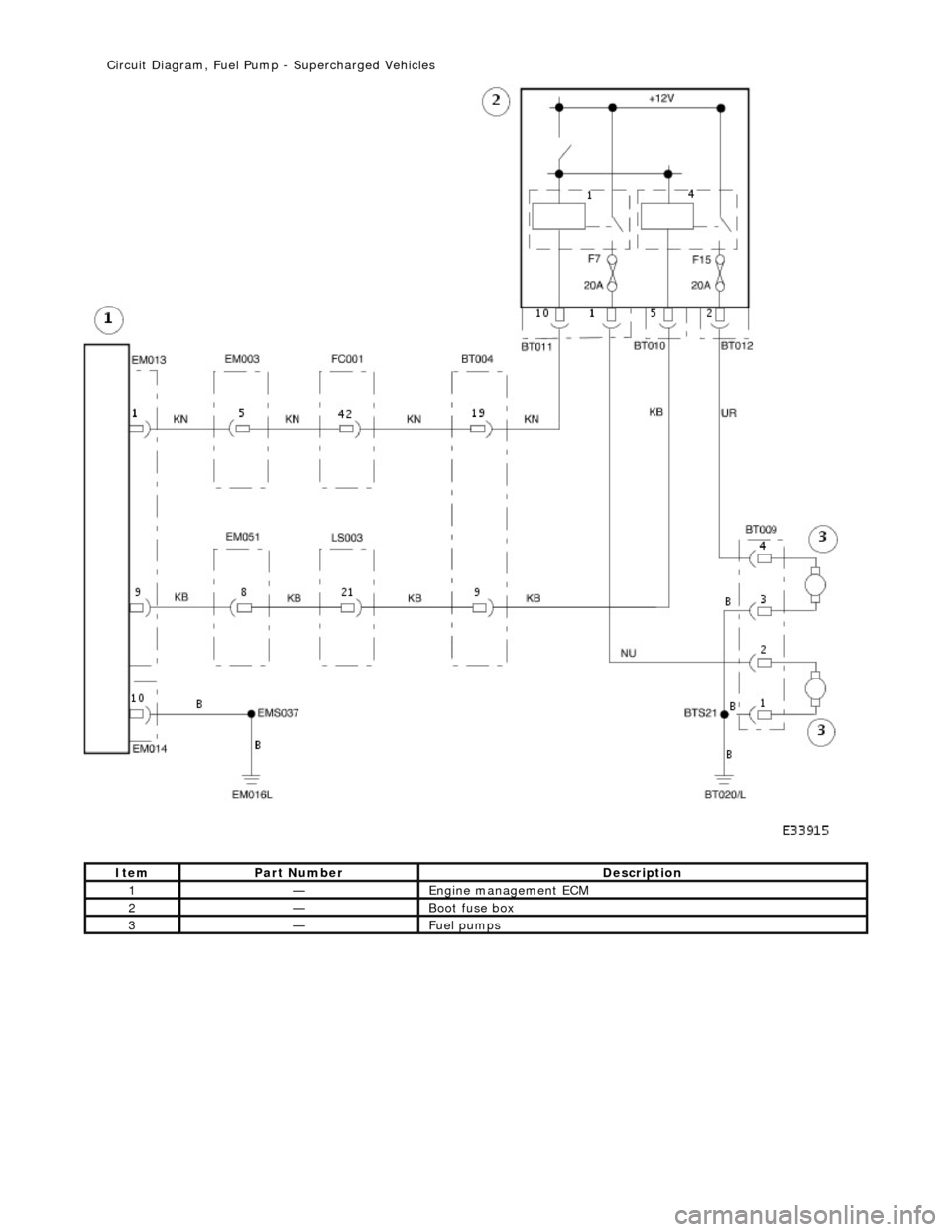

It

em

Par

t Number

De

scription

1—Engine

management ECM

2—Boot fuse box

3—Fue

l pumps

Ci

rcuit Diagram, Fuel Pump

- Supercharged Vehicles

Page 1699 of 2490

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to A2

A2

: CHECK FUSE

•

NOTE: See further steps for poss

ible cause of fuse failure.

Chec

k fuse F7 integrity (located in the trunk).

1

OK

?

Yes GO to A3

No Renew fuse and test the syst em for normal operation.

A3:

CHECK SHORT TO SUPPLY

Page 1709 of 2490

Wi

th BT009 disconnected an

d relay 4 removed, measure

the resistance between BT009/002 and relay socket pin

5.

1

I

s the resistance < 0.5 OHM?

Yes GO to A13

No Inspect harness / connector BT 009, fuse holder F7 and

BT011/001 for corrosion, damage, bent or pushed back

pins. Repair as required and test the system for normal

operation.

A13: CHECK HARNESS SHO

RT TO GROUND

Page 1713 of 2490

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to B2

B2

: CHECK FUSE

•

NOTE: See further steps for poss

ible cause of fuse failure.

Chec

k fuse 15 integrity (located in the trunk)

1

OK

?

Yes GO to B3

No Renew fuse and test the syst em for normal operation.

B3:

CHECK SHORT TO SUPPLY