fuse JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1231 of 2490

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AB3

.

AB3

: CHECK THE RADIATOR FAN MODULE TO ECM

'PARALLEL' DRIVE CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between EM13, pin 16 (WU) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes

REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to AA4

.

AB4

: CHECK THE RADIATOR FAN MODULE IGNITION SUPPLY

Re

connect the ECM electrical connector, EM13.

1

Turn the ignition swi

tch to the ON

position.

2

Measure the

voltage between LS

31, pin 08 (WP) and GROUND.

3

Is the vol

tage greater than 10 volts?

Yes INSTALL a new radiator fan module. REFER to Section 303

-0

3A Engine Cooling

/

30

3

-03

B

Supercharger

Cooling

. CLEA

R the DTC. TEST the sy

stem for normal operation.

No REPAIR the circuit between LS31, pin 08 (WP) and battery. This circuit includes the EMS fuse box-

(fuse 14), the EMS relay, etc. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

P

INPOINT TEST AC : DTC P1516, P1517; GEAR

CHANGE PARK/NEUTRAL DRIVING MALFUNCTION

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

AC1: CH

ECK THE TRANSMISSION RANGE (TR) SE

NSOR TO ECM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the TR sensor el

ectrical connector, EM47.

2

D

isconnect the ECM electrical connector, EM10.

3

Meas

ure the resistance between EM47, pin K (RU) and EM10, pin 15 (RU).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to AC2

.

AC2: CH

ECK THE TRANSMISSION RANGE (TR)

SENSOR PARK/NEUTRAL SWITCHING ACTION

Meas

ure the resistance between pi

ns J and K of the TR sensor.

1

Mo

ve the selector lever from

PARK to NEUTRAL and back.

2

D

oes the resistance switch between open ci

rcuit and continuity as the lever moves?

Yes GO to AC3

.

No

INSTALL a new transmission range sensor. CLEAR th e DTC. TEST the system for normal operation.

AC3: CH

ECK THE D-4 SWITCH TO

TCM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the D-4 switch electrical connector, CC07.

1

Di

sconnect the TCM electrical connector, EM07.

2

Meas

ure the resistance between CC07,

pin 01 (US) and EM07, pin 13 (US).

3

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No INSTALL a new transmission range sensor. CLEAR th e DTC. TEST the system for normal operation.

P

INPOINT TEST AD : DTC P1606;

EMS CONTROL RELAY MALFUNCTION

Page 1273 of 2490

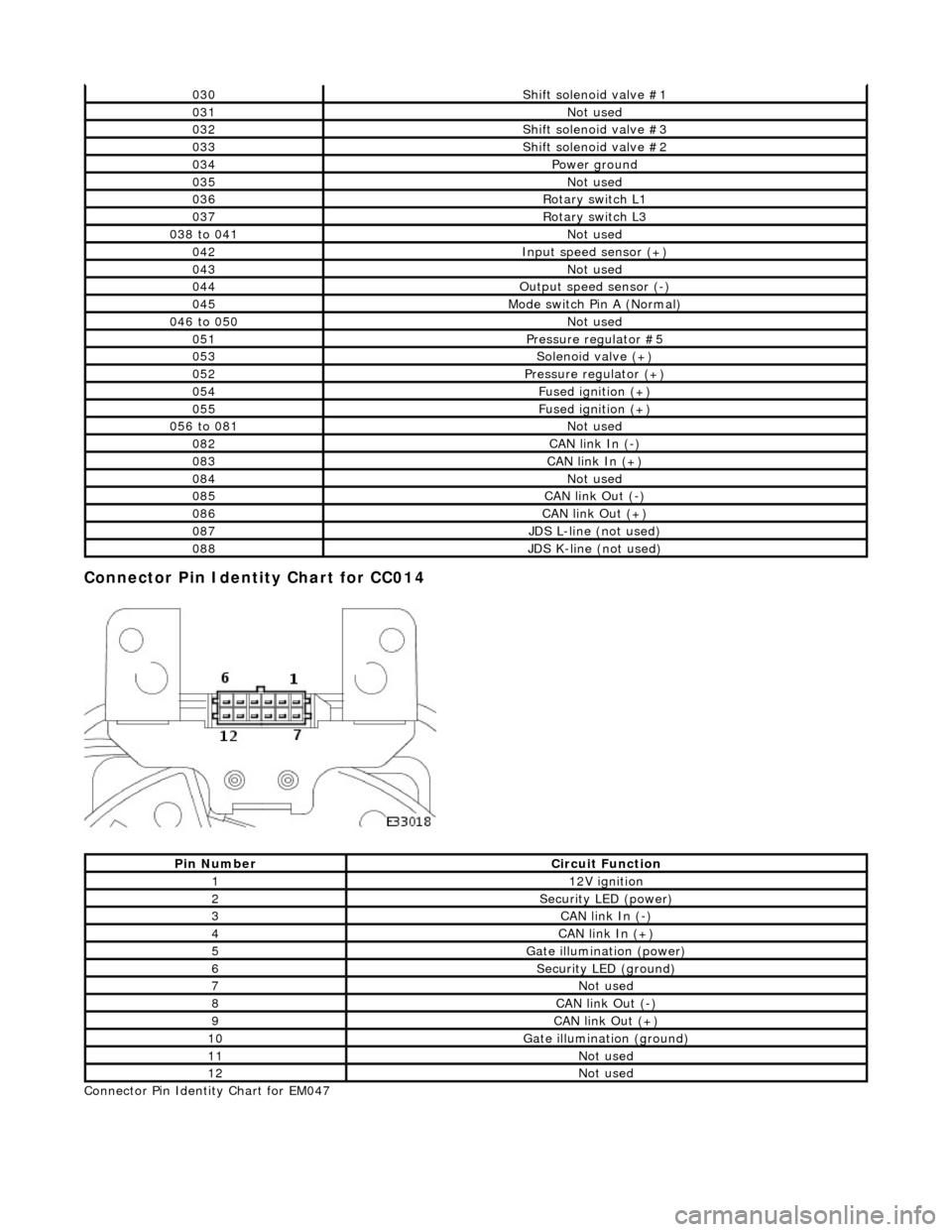

Connector Pin Identity Chart for CC014

Connector Pin Identity Chart for EM047

030Shift solenoid valve #1

031Not used

032Shift solenoid valve #3

033Shift solenoid valve #2

034Power ground

035Not used

036Rotary switch L1

037Rotary switch L3

038 to 041Not used

042Input speed sensor (+)

043Not used

044Output speed sensor (-)

045Mode switch Pin A (Normal)

046 to 050Not used

051Pressure regulator #5

053Solenoid valve (+)

052Pressure regulator (+)

054Fused ignition (+)

055Fused ignition (+)

056 to 081Not used

082CAN link In (-)

083CAN link In (+)

084Not used

085CAN link Out (-)

086CAN link Out (+)

087JDS L-line (not used)

088JDS K-line (not used)

Pin NumberCircuit Function

112V ignition

2Security LED (power)

3CAN link In (-)

4CAN link In (+)

5Gate illumination (power)

6Security LED (ground)

7Not used

8CAN link Out (-)

9CAN link Out (+)

10Gate illumination (ground)

11Not used

12Not used

Page 1278 of 2490

Pinpoint test A: P0741, P0742, P0743

Pinpoint test B: P0743

Connector pin(s) bent or tracking between

connections

*

DTC P1789 Ignition supply malfunction >7 < 9

voltsBattery charging system fault

Blown fuse

Harness fault

Connector loose or corroded

Connector pin(s) bent or tracking between

connections Ground fault

*

*

*

*

*

*GO to Pinpoint

Test K

*

DTC P0710 Transmission fluid temperature

sensor malfunctionDamaged sensor

Sensor out of range / short

Harness open circuit

Harness short

Connector loose or corroded

*

*

*

*

*GO to Pinpoint

Test L

*

PINPOINT TEST A : P0741, P0742, P0743

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

A1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to A2

A2: RENEW TORQUE CONVERTER

Renew the torque converter 1

Has the torque converter been renewed?

Yes GO to A3

A3: END

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST B : P0743

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

B1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present

Page 1331 of 2490

Pinpoint test K: P1789, P1793

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to J2

J2: RENEW TCM

Renew the TCM 1

Has the TCM been renewed?

Yes GO to J3

J3: END

Drive the vehicle for a period from cold to include idle, brisk

acceleration and steady state cruising up to and including

normal engine temperature. Check for the presence of DTC 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST K : P1789, P1793

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

K1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to K2

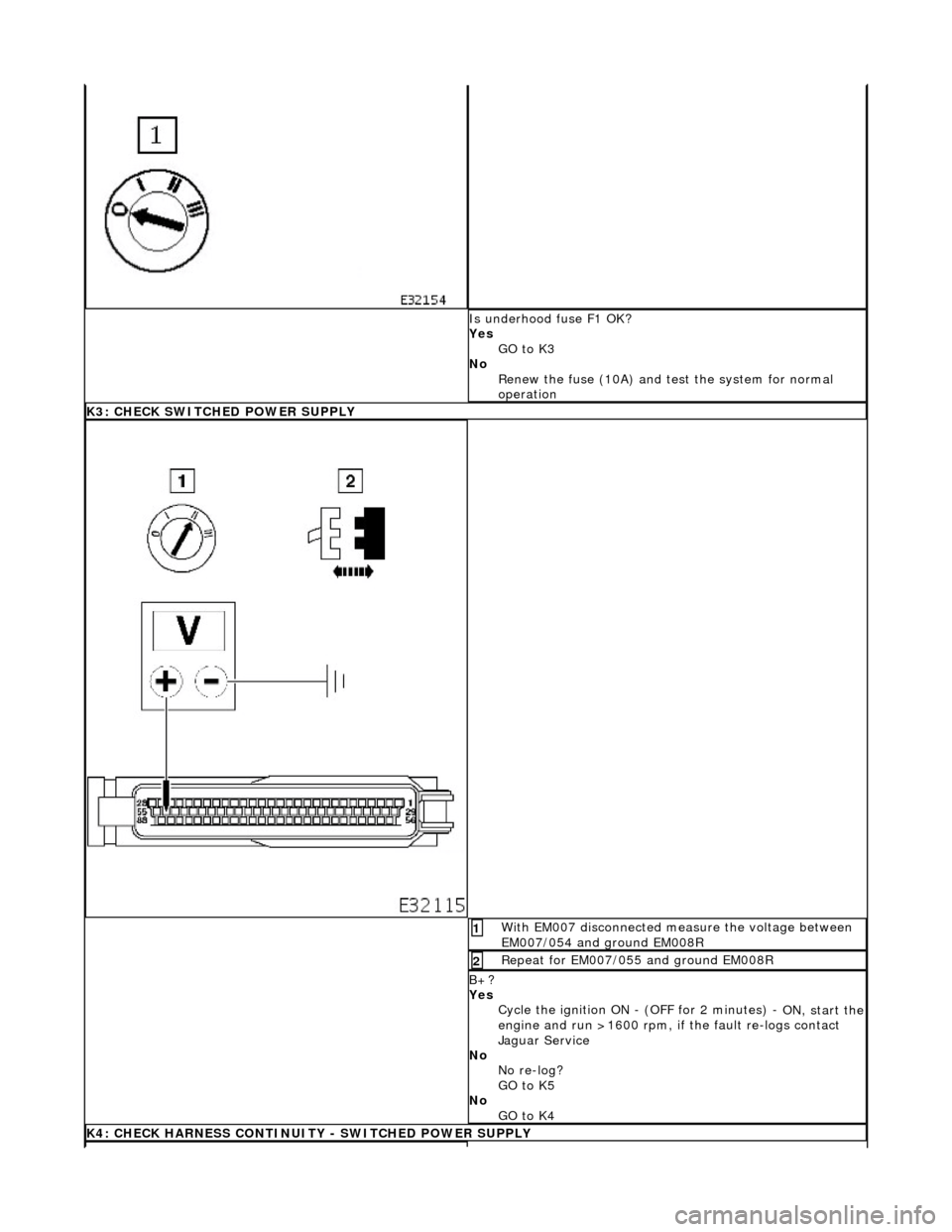

K2: CHECK FUSE

Page 1332 of 2490

Is underhood fuse F1 OK?

Yes GO to K3

No Renew the fuse (10A) and te st the system for normal

operation

K3: CHECK SWITCHED POWER SUPPLY

With EM007 disconnected measure the voltage between

EM007/054 and ground EM008R 1

Repeat for EM007/055 and ground EM008R 2

B+?

Yes Cycle the ignition ON - (OFF for 2 minutes) -

ON, start the engine and run >1600 rpm, if the fault re-logs contact

Jaguar Service

No No re-log?

GO to K5

No GO to K4

K4: CHECK HARNESS CONTINUITY - SWITCHED POWER SUPPLY

Page 1396 of 2490

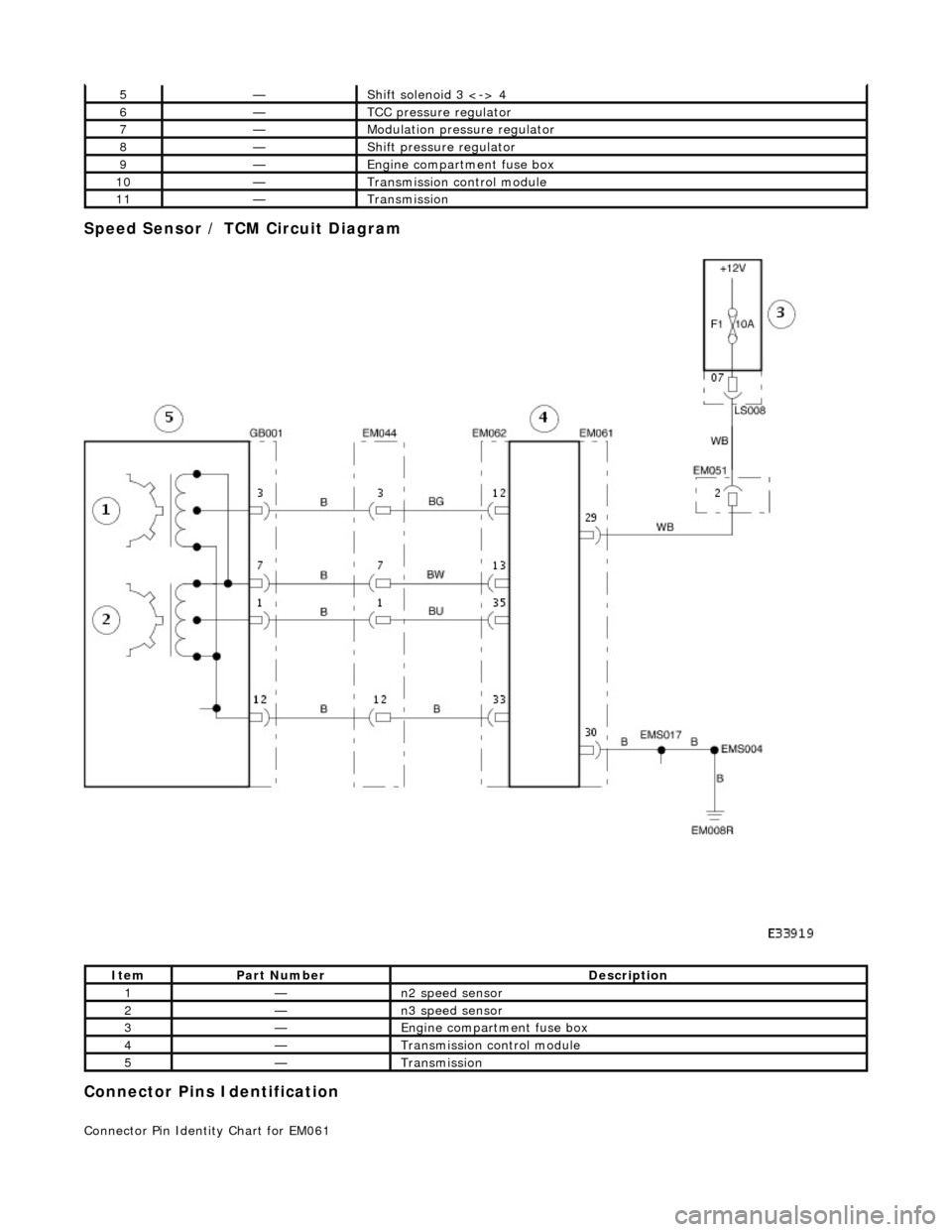

Speed Sensor / TCM Circuit Diagram

Connector Pins Identification

Connector Pin Identity Chart for EM061

5—Shift solenoid 3 <-> 4

6—TCC pressure regulator

7—Modulation pressure regulator

8—Shift pressure regulator

9—Engine compartment fuse box

10—Transmission control module

11—Transmission

ItemPart NumberDescription

1—n2 speed sensor

2—n3 speed sensor

3—Engine compartment fuse box

4—Transmission control module

5—Transmission

Page 1531 of 2490

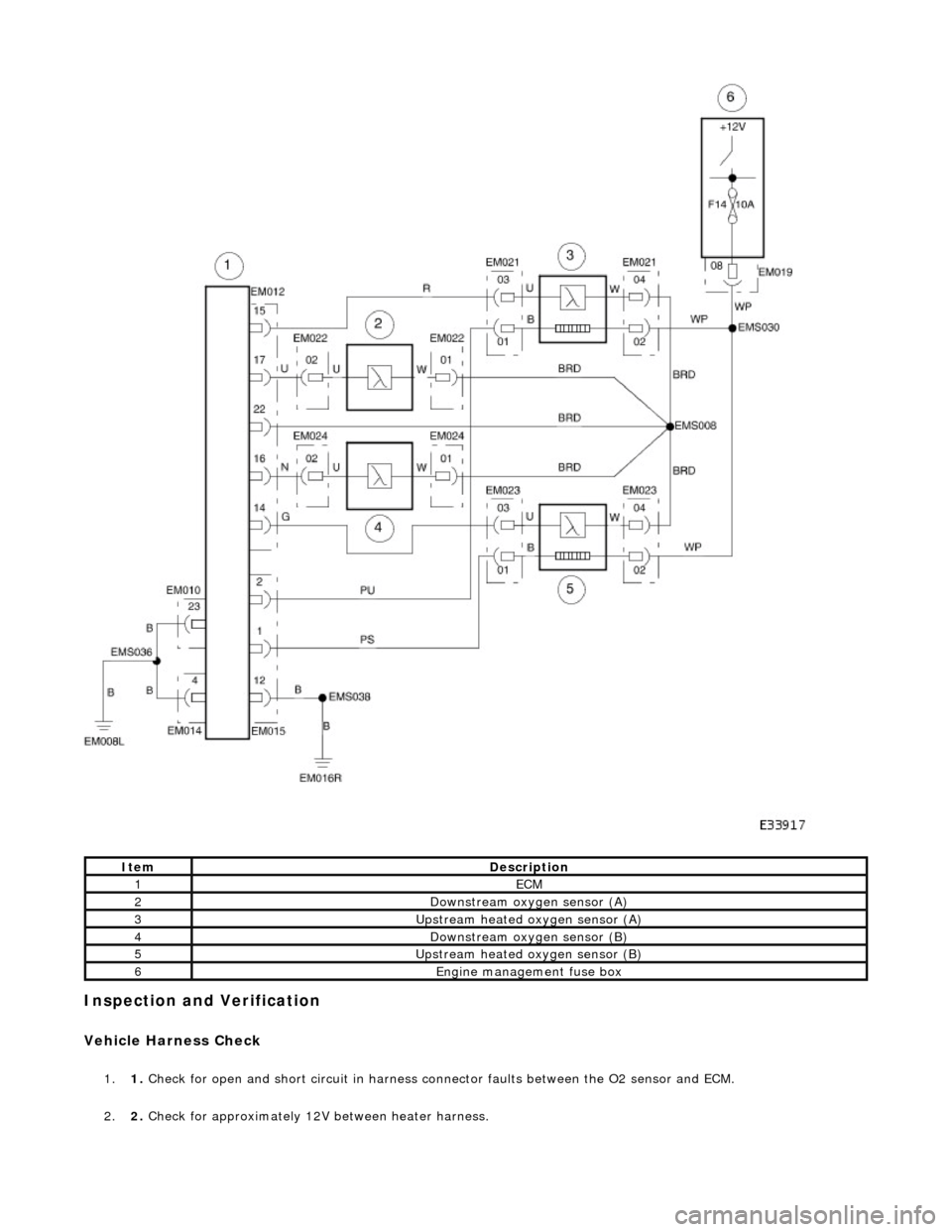

Inspection and Verification

Vehicle Harness Check

1.1. Check for open and short circuit in harness conn ector faults between the O2 sensor and ECM.

2. 2. Check for approximately 12V between heater harness.

ItemDescription

1ECM

2Downstream oxygen sensor (A)

3Upstream heated oxygen sensor (A)

4Downstream oxygen sensor (B)

5Upstream heated oxygen sensor (B)

6Engine management fuse box

Page 1544 of 2490

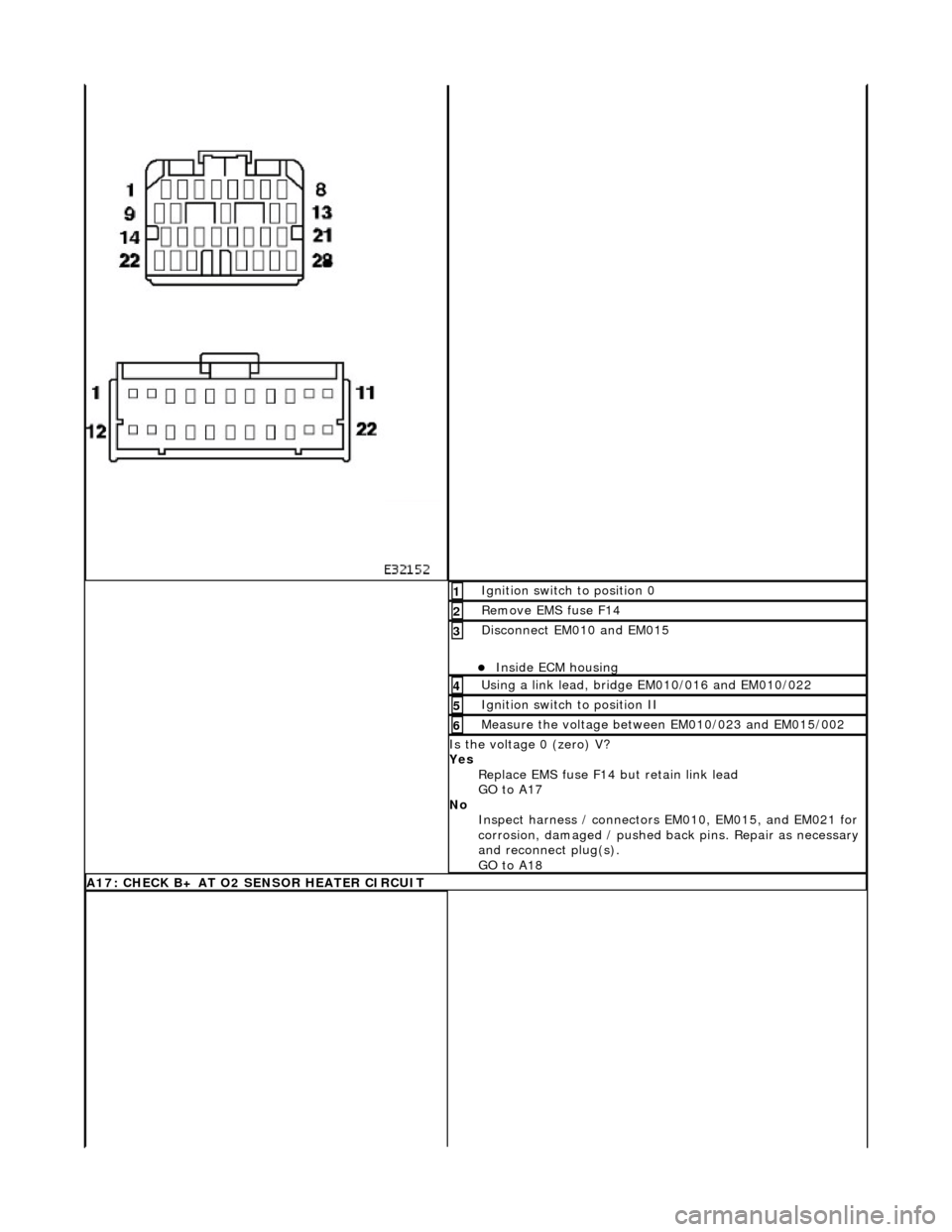

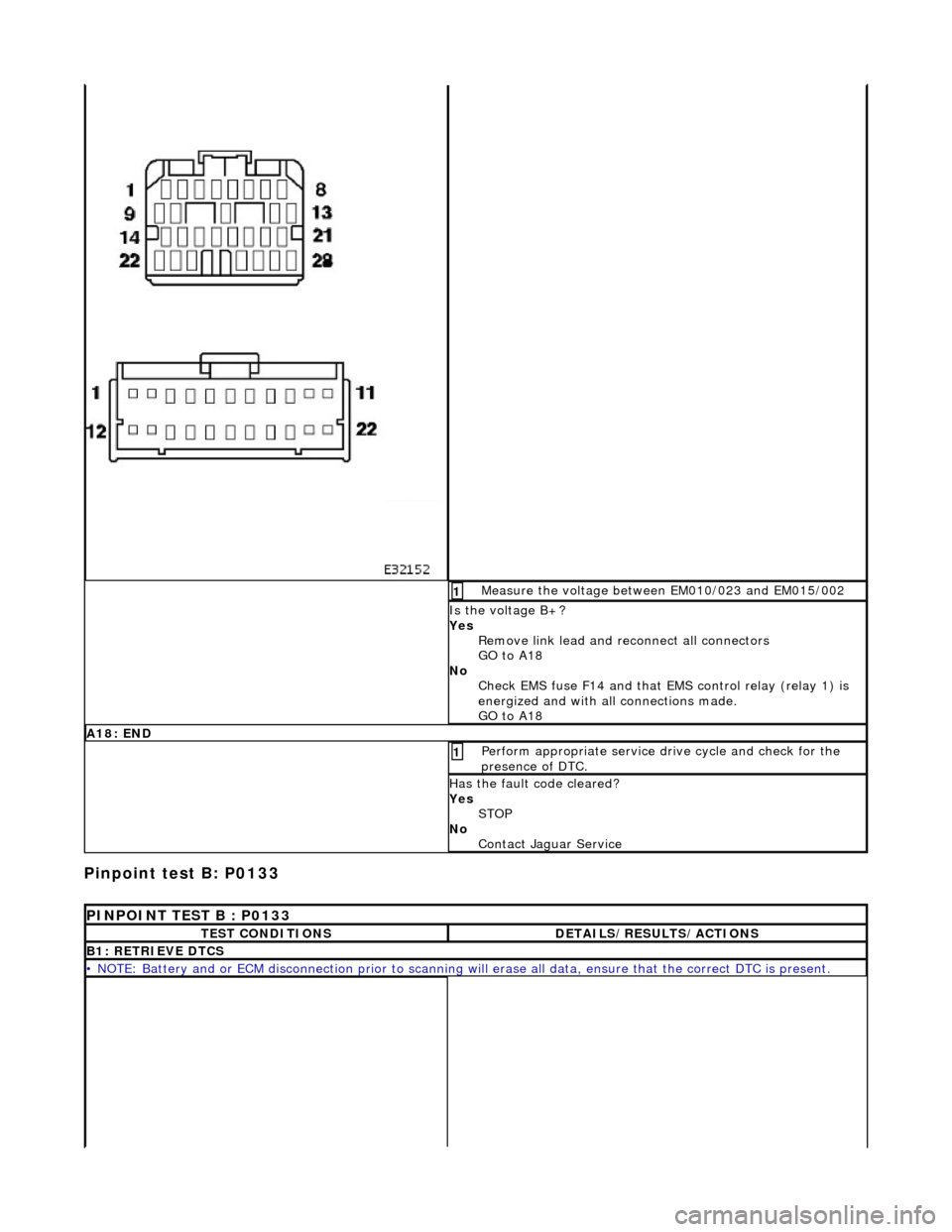

Ignition switch to position 0 1

Remove EMS fuse F14 2

Disconnect EM010 and EM015

Inside ECM housing

3

Using a link lead, bridge EM010/016 and EM010/022 4

Ignition switch to position II 5

Measure the voltage between EM010/023 and EM015/002 6

Is the voltage 0 (zero) V?

Yes Replace EMS fuse F14 but retain link lead

GO to A17

No Inspect harness / connectors EM010, EM015, and EM021 for

corrosion, damaged / pushed back pins. Repair as necessary

and reconnect plug(s).

GO to A18

A17: CHECK B+ AT O2 SENSOR HEATER CIRCUIT

Page 1545 of 2490

Pinpoint test B: P0133

Measure the voltage between EM010/023 and EM015/002 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors

GO to A18

No Check EMS fuse F14 and that EMS control relay (relay 1) is

energized and with all connections made.

GO to A18

A18: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST B : P0133

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

B1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1556 of 2490

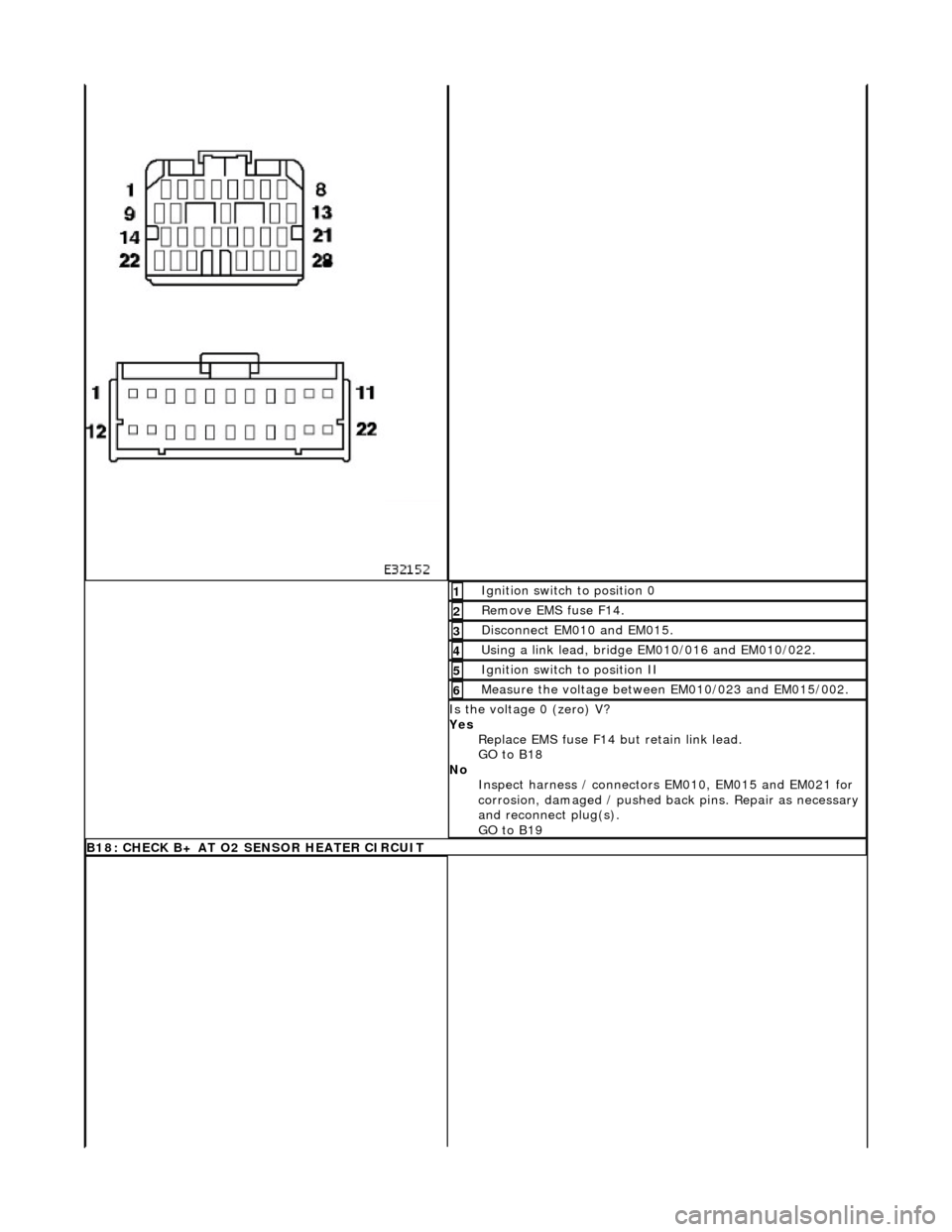

Ignition switch to position 0 1

Remove EMS fuse F14. 2

Disconnect EM010 and EM015. 3

Using a link lead, bridge EM010/016 and EM010/022. 4

Ignition switch to position II 5

Measure the voltage between EM010/023 and EM015/002. 6

Is the voltage 0 (zero) V?

Yes Replace EMS fuse F14 but retain link lead.

GO to B18

No Inspect harness / connectors EM010, EM015 and EM021 for

corrosion, damaged / pushed back pins. Repair as necessary

and reconnect plug(s).

GO to B19

B18: CHECK B+ AT O2 SENSOR HEATER CIRCUIT