steering wheel JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1744 of 2490

Speed Control - Speed

Control

D

iagn

osis and Testing

Pri

n

ciples of operation

The s

p

eed (cruise) control sy

stem is activated by an ON/OFF master switch in the J-gate surround, which has an integral

LED to indicate status.

The steering wheel switches allow the driver to set the speed, increase or decrease the selected speed, cancel and resume

the facility without his/her hand ever leaving the steering wheel

The vehicle speed can be increased an d decreased in increments of 2 kmh (1 mph) by briefly pressing the + or - buttons up

to a maximum of five times.

Alternatively, the + or - button can be held until th e desired speed is reached.

The selected speed (by whichever method) w ill be displayed in the message center.

The system will not function at speeds below 26 kmh (16 mph), and can be cancelled from the master switch, the steering

wheel switches, and by depressing th e brake pedal. The system can be overridden by accelerating as normal.

In

spection and Verification

1.

1. Veri fy the customer concern.

2. 2. Vis

ually inspect for obvious signs of mechanical or electrical damage.

3. 3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step.

4. 4. If the cause is not visually evident, verify the symptom, check for DTCs and follow the routines in this section.

Vi

sual Inspection Chart

Diagnostic Trouble Code (D

TC) index

MechanicalElectrical

Throttle body mechan

ism

Throttle body actuator

Module Switch(es) Instrument cluster

DTC

De

scr

iption

Possib

l

e Source

Acti

o

n

P0566Speed

c

ontrol

CANCEL

switch ON fault

Speed

control switches internal steering wheel

short circuit to ground

St

eering wheel cassette reel short circuit to

ground

Cassette reel to ECM circ

uit short circuit to

ground

CANCEL

switch failure (stuck ON)

Fo

r

CANCEL switch circuit

tests,GO to Pinpoint Test A.

P0567Speed c

ontrol

RESUME

switch ON fault

Speed

control switches internal steering wheel

short circuit to ground

St

eering wheel cassette reel short circuit to

ground

Cassette reel to ECM circ

uit short circuit to

ground

RESUME swit

ch failure (stuck ON)

For

RESUME switch circuit

tests,GO to Pinpoint Test B.

P0568Spee

d control switch

ground malfunction

Speed

control switches internal steering wheel

open circuit

St

eering wheel cassette reel open circuit or

high resistance

Cassette reel to ECM ci

rcuit open circuit or high

For

ACCEL/DECEL switch circuit

tests,GO to Pinpoint Test C.

Page 1745 of 2490

Pinpoint test

s

re

sistance

ACCEL/DECEL

swi

tch failure

P0569Speed

control

DECEL/SET

(SET-) switch ON fault

Speed

control switches internal steering wheel

short circuit to ground

S

teering wheel cassette

reel short circuit to

ground

Cassette reel

to ECM ci

rcuit short circuit to

ground

DEC

EL/SET

switch failure (stuck ON)

Fo

r

DECEL/SET (SET-) switch

circuit tests,GO to Pinpoint Test D.

P0570Speed

control

ACCEL/SET

(SET+) switch ON fault

Speed

control switches internal steering wheel

short circuit to ground

S

teering wheel cassette

reel short circuit to

ground

Cassette reel

to ECM ci

rcuit short circuit to

ground

ACC

EL/SET

switch failure (stuck ON)

Fo

r

ACCEL/SET circuit tests,GO

to Pinpoint Test E.

P1571Brake sw

itch malfunction

Brake sw

itch to ECM circuit open circuit, short

circuit to ground, high resistance

Brake sw

itch ignition switched ground circuit

open circuit

Brake sw

itch failure

Brake ca

ncel switch to

ECM circuit open circuit,

short circuit to ground, high resistance

Brake ca

ncel switch to speed control switch

circuit open circuit, shor t circuit to ground, high

resistance

Brake ca

ncel switch ignition switched power

supply open circuit

Brake ca

ncel switch failure

Spe

ed control switch failure

For brake swi

tch circuit tests,GO

to Pinpoint Test F.

P

INPOINT TEST A : DTC P0566; SPEED

CONTROL CANCEL SWITCH ON FAULT

WAR

NING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(501-20B Supplemental Restra

int System, Description and

Operation).

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE SPEED CONTROL SWITCHPACK IN

TERNAL CIRCUITS FOR SHORT TO GROUND

Di

sconnect the battery negative terminal.

1

Di

sconnect the speed control switch

pack electrical connector, SW02.

2

R

econnect the battery negative terminal.

3

Meas

ure the resistance between SW

02, pin 06 (BO) and GROUND.

4

Meas

ure the resistance between SW

02, pin 03 (SG) and GROUND.

5

Is either resi

stance

less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A2

.

A2: CHECK

THE SPEED CONTROL CASSE

TTE REEL FOR SHORT TO GROUND

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM11.

2

R

econnect the battery negative terminal.

3

M

easure the resistance between SW02, pin 06 (at the cassette reel side of the connector) and

GROUND.

4

M

easure the resistance between SW02, pin 03 (at the cassette reel side of the connector) and

GROUND.

5

Is either resi

stance

less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

Page 1746 of 2490

No

GO to A3.

A3: CHECK THE SPEED CONTRO L CANCEL SWITCH

ACTION

Meas

ure t

he resistance between SW02,

pin 06 (BO) and SW02, pin 03 (SG).

1

Operate

the speed control

CANCEL switch.

2

Do

es the resistance

vary by 680 ohms?

Yes Recheck DTCs. No short found. Po ssible intermittent fault. CLEAR the DTC. TEST the system for

normal operation.

No INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

PINPOINT TEST B : DTC

P0567; SPEED

CONTROL RESUME SWITCH ON FAULT

WARN

ING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(50

1-20B Supplemental Restra

int System, Description and

Operation).

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

B1: CHECK

THE SPEED CONTR

OL SWITCHPACK IN

TERNAL CIRCUITS FOR SHORT TO GROUND

Disc

onnect the speed control switch

pack electrical connector, SW02.

1

Measure t

he resistance between SW

02, pin 06 (BO) and GROUND.

2

Measure t

he resistance between SW

02, pin 03 (SG) and GROUND.

3

Is either resistance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to B2

.

B2: CHECK THE SPEED CONTR

OL CASSETTE REEL FOR SHORT TO GROUND

M

e

asure the resistance between SW02, pin 06 (at the cassette reel side of the connector) and

GROUND.

1

Me

asure the resistance between SW02, pin 03 (at the cassette reel side of the connector) and

GROUND.

2

Is either resistance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to B3

.

B3: CHECK THE SPEED CONTR

OL RESUME SWITCH ACTION

Meas

ure t

he resistance between SW02,

pin 06 (BO) and SW02, pin 03 (SG).

1

Operate

the speed control

RESUME switch.

2

Do

es the resistance

vary by 430 ohms?

Yes Recheck DTCs. No short found. Po ssible intermittent fault. CLEAR the DTC. TEST the system for

normal operation.

No INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

PINPOINT TES

T C : DTC P0568; SPEED CONTROL SWITCH GROUND MALFUNCTION

WAR

N

ING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(50

1-20B Supplemental Restra

int System, Description and

Operation).

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

C1: CHECK FOR CONTINUITY T

H

ROUGH STEERING WHEEL

CANCEL AND RESUME SWITCHES (SWITCHES OPEN)

Disc

onnect the speed control switch

pack electrical connector, SW02.

1

Check for c

ontinuity between SW02

, pins 06 (BO) and 03 (SG) wi th the steering wheel switches

inactive.

2

Page 1747 of 2490

Is th

e circuit continuous?

Yes INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

No GO to C2

.

C2

: CHECK FOR CONTINUITY THROUGH STEERIN

G WHEEL CANCEL SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 03 (SG) with the steering wheel CANCEL

switch operated.

1

Is th

e circuit continuous?

Yes GO to C3

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C3

: CHECK FOR CONTINUITY THROUGH STEERIN

G WHEEL RESUME SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 03 (SG) with the steering wheel RESUME

switch operated.

1

Is th

e circuit continuous?

Yes GO to C4

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C4

: CHECK FOR CONTINUITY THROUGH STEERING

WHEEL + AND - SWITCHES (SWITCHES OPEN)

Chec

k for continuity between SW02

, pins 06 (BO) and 04 (SR) with the steering wheel switches

inactive.

1

Is th

e circuit continuous?

Yes INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

No GO to C5

.

C5

: CHECK FOR CONTINUITY THROUGH STEER

ING WHEEL + SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 04 (SR) with the steering wheel CANCEL

switch operated.

1

Is th

e circuit continuous?

Yes GO to C6

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C6

: CHECK FOR CONTINUITY THROUGH STEER

ING WHEEL - SWITCH (SWITCH CLOSED)

Check f

or continuity between SW02, pins 06

(BO) and 04 (SR) with the steering wheel CANCEL

switch operated.

1

Is th

e circuit continuous?

Yes GO to C7

.

No

INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

C7: CHECK THE STEERING

WHEEL CASSETTE

REEL FOR CONTINUITY (CIRCUIT #1)

Di

sconnect the steering wheel cassette electrical connector, SW01.

1

Meas

ure the resistance between SW01, pin 06

and SW02, pin 06 through the cassette reel.

2

Is th

e cassette reel continuous?

Yes GO to C8

.

No

INSTALL a new steering wheel cassette. CLEAR the DTC. TEST the system for normal operation.

C8: CHECK THE STEERING

WHEEL CASSETTE

REEL FOR CONTINUITY (CIRCUIT 2)

Meas

ure the resistance between SW01, pin 03

and SW02, pin 03 through the cassette reel.

1

Is th

e cassette reel continuous?

Yes GO to C9

.

No

INSTALL a new steering wheel cassette. CLEAR the DTC. TEST the system for normal operation.

C9: CHECK THE ECM

TO CASSETTE REEL

CIRCUIT FOR CONTINUITY (CIRCUIT 1)

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM11.

2

Meas

ure the resistance between EM11, pin 01 (SR) and SW01, pin 04 (SR).

3

Page 1748 of 2490

Is the res

istance greater than 5 ohms?

Yes REPAIR the circuit. For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST

the system for normal operation.

No GO to C10

.

C10: CHECK T H

E ECM TO CASSETTE REEL

CIRCUIT FOR CONTINUITY (CIRCUIT 2)

Measure t

he resistance between EM11,

pin 05 (SG) and SW01, pin 03 (SG).

1

Is the res

istance greater than 5 ohms?

Yes REPAIR the circuit. For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST

the system for normal operation.

No Contact dealer technical support for advice on possible ECM failure.

PI

NPOINT TEST D : DTC P0

569; SPEED CONTROL DECEL/SET- SWITCH ON FAULT

WARN

ING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(50

1-20B Supplemental Restra

int System, Description and

Operation).

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

D1: CHECK

THE SPEED CONTROL SWITCHPACK IN

TERNAL CIRCUITS FOR SHORT TO GROUND

Disc

onnect the speed control switch

pack electrical connector, SW02.

1

Measure t

he resistance between SW

02, pin 06 (BO) and GROUND.

2

Measure t

he resistance between SW

02, pin 04 (SR) and GROUND.

3

Is either resistance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to D2

.

D2: CHECK

THE SPEED CONTROL CASSE

TTE REEL FOR SHORT TO GROUND

Me

asure the resistance between SW02, pin 06 (at the cassette reel side of the connector) and

GROUND.

1

M e

asure the resistance between SW02, pin 04 (at the cassette reel side of the connector) and

GROUND.

2

Is either resi stance le

ss than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to D3

.

D3: CHECK

THE SPEED CONTROL DECEL/SET- SWITCH ACTION

Meas

ure t

he resistance between SW02,

pin 06 (BO) and SW02, pin 04 (SR).

1

Operate

the speed control

DECEL/SET- switch.

2

Do

es the resistance

vary by 680 ohms?

Yes Recheck DTCs. No short found. Po ssible intermittent fault. CLEAR the DTC. TEST the system for

normal operation.

No INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

PINPOI

NT TEST E : DTC P0570; SPEED CONTROL "ACCEL/SET+" SWITCH "ON" FAULT

WAR

N

ING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(50

1-20B Supplemental Restra

int System, Description and

Operation).

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

E1

: CHECK THE SPEED CONTROL

SWITCHPACK IN

TERNAL CIRCUITS FOR SHORT TO GROUND

Page 1749 of 2490

Di

sconnect the speed control switch

pack electrical connector, SW02.

1

Meas

ure the resistance between SW

02, pin 06 (BO) and GROUND.

2

Meas

ure the resistance between SW

02, pin 04 (SR) and GROUND.

3

Is either resi

stance

less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to E2

.

E2

: CHECK THE SPEED CONTROL CASSE

TTE REEL FOR SHORT TO GROUND

M

easure the resistance between SW02, pin 06 (at the cassette reel side of the connector) and

GROUND.

1

M

easure the resistance between SW02, pin 04 (at the cassette reel side of the connector) and

GROUND.

2

Is either resi

stance

less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to E3

.

E3

: CHECK THE SPEED CONTROL

ACCEL/SET+ SWITCH ACTION

Meas

ure the resistance between SW02,

pin 06 (BO) and SW02, pin 04 (SR).

1

Op

erate the cruise control

ACCEL/SET+ switch.

2

D

oes the resistance

vary by 430 ohms?

Yes Recheck DTCs. No short found. Po ssible intermittent fault. CLEAR the DTC. TEST the system for

normal operation.

No INSTALL a new speed control switchpack. CLEAR the DTC. TEST the system for normal operation.

P

INPOINT TEST F : DTC P1571;

BRAKE SWITCH MALFUNCTION

WAR

NING: Where tests involve the removal of the steering

wheel, and/or disconnection of air bag connectors, the

procedure for disarming air bags must be followed,

REFER to: Air Bag Supplemental Re straint System (SRS)

(501-20B Supplemental Restra

int System, Description and

Operation).

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

F1: CHECK THE BRAKE

SWITCH TO

ECM CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

Di

sconnect the brake switch electrical connector, AC24.

2

D

isconnect the ECM electrical connector, EM10.

3

Meas

ure the resistance between AC24,

pin 01 (US) and EM10, pin 10 (US).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to F2

.

F2: CHECK THE BRAKE

SWITCH TO ECM

CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between AC24, pin 01 (US) and GROUND.

3

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to F3

.

F3: CHECK THE BRAKE

SWITCH TO

ECM CIRCUIT FOR SHORT TO GROUND

Turn the ignition swi

tch to the OFF

position.

1

Meas

ure the resistance between AC24, pin 01 (US) and GROUND.

2

Page 1859 of 2490

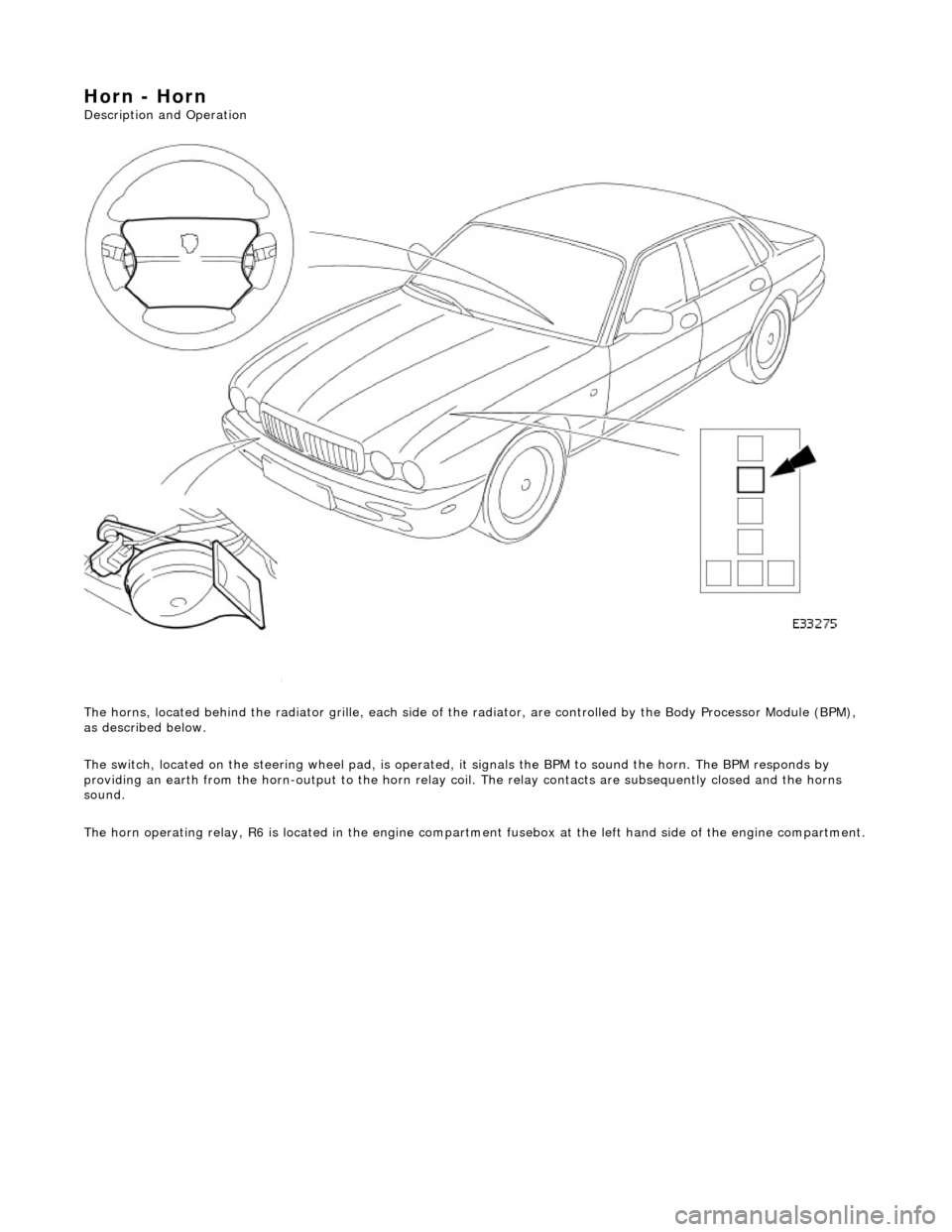

Horn - Horn

Description and Operation

The horns, located behind the radiator gril le, each side of the radiator, are controlled by the Body Processor Module (BPM),

as described below.

The switch, located on the steering wheel pad, is operated, it signals the BPM to sound the horn. The BPM responds by

providing an earth from the horn-output to the horn relay coil. The relay contacts are subsequently closed and the horns

sound.

The horn operating relay, R6 is located in the engine compartm ent fusebox at the left hand side of the engine compartment.

Page 1904 of 2490

Audio Unit - Audio System

Description and Operation

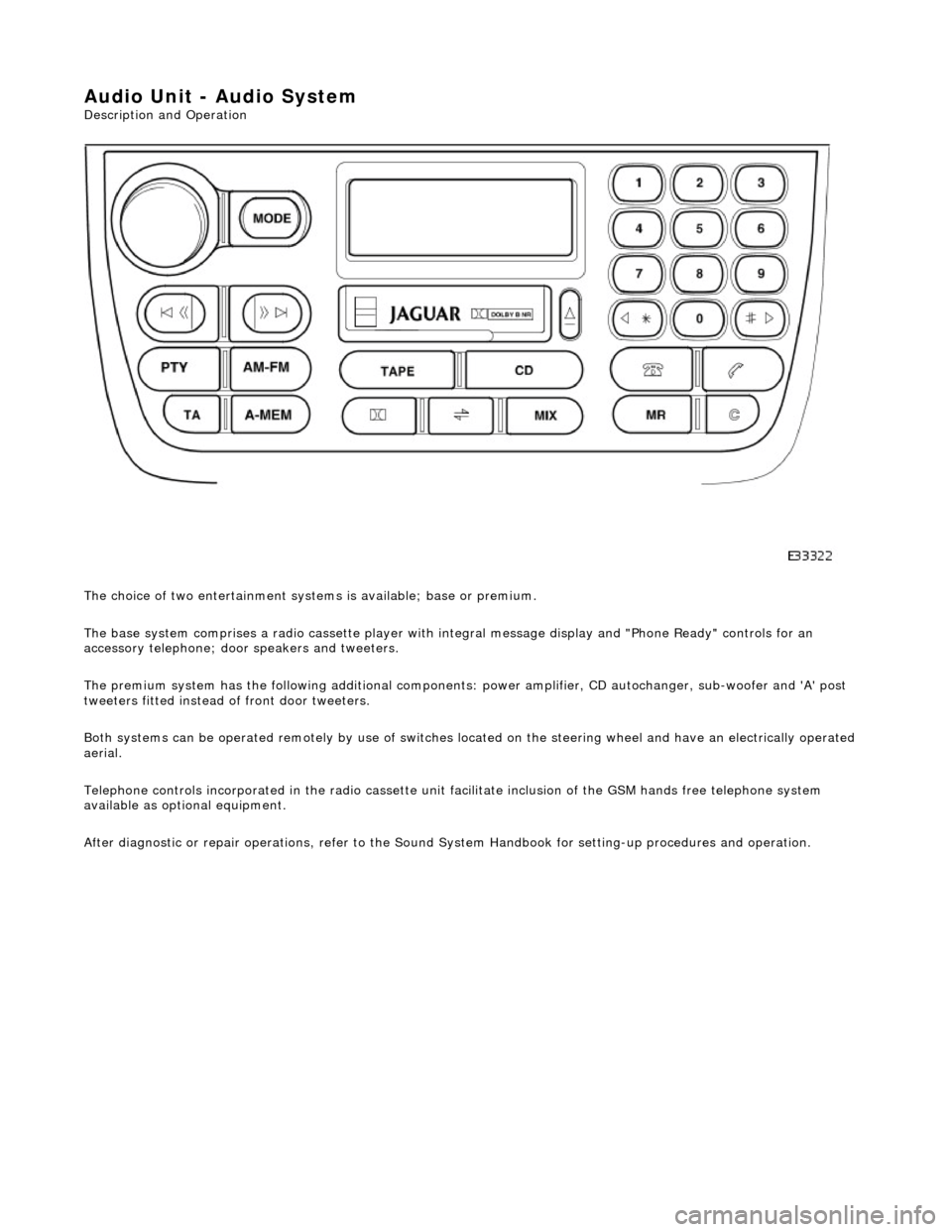

The choice of two entertainment system s is available; base or premium.

The base system comprises a radio cassette player with in tegral message display and "Phone Ready" controls for an

accessory telephone; door speakers and tweeters.

The premium system has the following additional components: power amplifier, CD autochanger, sub-woofer and 'A' post

tweeters fitted instead of front door tweeters.

Both systems can be operated remotely by use of switches loca ted on the steering wheel and have an electrically operated

aerial.

Telephone controls incorporated in the ra dio cassette unit facilitate inclusion of the GSM hands free telephone system

available as optional equipment.

After diagnostic or repair operations, refer to the Sound System Handbook for setting-up procedures and operation.

Page 2122 of 2490

Seating - Front Seat

Removal and Installation

Removal

1. Move the seat fully rearward and slacken and remove the

front securing bolts.

2. Move steering wheel to fully forward position.

3. Ensure that squab is fully upright, then move the seat fully

forward.

4. WARNING: FOLLOWING DISCONNECTION OF THE

BATTERY A PERIOD OF AT LEAST ONE MINUTE MUST BE

ALLOWED TO ELAPSE BEFORE WORKING ON A FRONT SEAT WITH

A SIDE AIRBAG FITTED.

Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

5. Remove the slider covers an d slacken and remove the two

rear securing bolts.

6. Supporting and positioning the seat for access, disconnect

multiplugs.

Disconnect side air bag harness multiplug.

Release from retaining brackets and disconnect seat

harness multiplugs.

Disconnect seat control module harness multiplug.

Cut through and remove any ti es securing harnesses to

seat frame.

7. NOTE: Securing bolt remains captive with belt anchor.

Slacken and remove seat be lt anchor securing bolt.

Page 2242 of 2490

Instrument Panel and Console - Instrument Panel

Removal and Installation

Removal

1. Turn ignition switch to position II.

2. Motor driver and front passenger seats rearward.

3. Position steering wheel in stra ight ahead position and fully

lower and extend steering column.

4. Turn ignition switch to position O.

5. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

6. Remove 'J' gate finish er. Refer to 76.25.24.

7. Remove 'J' gate finisher retain ing panel. Refer to 76.25.26.

8. Remove centre console veneer panel. Refer to 76.47.26.

9. Disconnect and remove radio.

10. Remove centre console switch module. Refer to 86.80.32.

11. Remove centre console. Refer to 76.25.01.

12. Slacken and remove centre cons ole vent duct rear securing

screw and withdraw duct assemb ly from air conditioning unit

manifold.

13. WARNING: BEFORE ANY AIRBAG/SRS SERVICE IS

PERFORMED, AT LEAST ONE MINUTE MUST ELAPSE AFTER

DISCONNECTION OF THE BATTERY CABLE, TO ALLOW

DISSIPATION OF BACK-UP POWER SUPPLY ENERGY.

Remove driver airbag. Refer to 76.73.39.

14. Remove steering wheel. Refer to Section 211-04.

15. Remove steering column lo wer cowl. Refer to 76.46.03.

16. Remove steering column u pper cowl. Refer to 76.46.02.

17. Remove driver side unders cuttle. Refer to 76.46.11.

18. Remove combined windshield wiper/washer switch and

audible warning speaker assembly. Refer to 86.65.42.

19. Remove glovebox. Refer to 76.52.03.

20. Remove 'A' post lower trim pads. refer to 76.13.30.

21. Carefully withdraw driver stowage bin trim, remove bin

securing screw and remove bin from facia.