Cruise control JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 416 of 2490

Hydrau

lic Brake Actuation - Brake Pedal and Bracket, Brake Booster and

Brake Master Cylinder

Re mo

val and Installation

Remova

l

• C

A

UTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

1. Position vehi cl

e on a four-post lift.

2. Open engine compartment and fit paint work protection covers

to fenders.

3. Disconnect battery ground cable (IMPORTANT, refer to

operation 86.15.19 for fu rther information).

4. Remove engine compartment rear cover. Refer to operation

76.11.35.

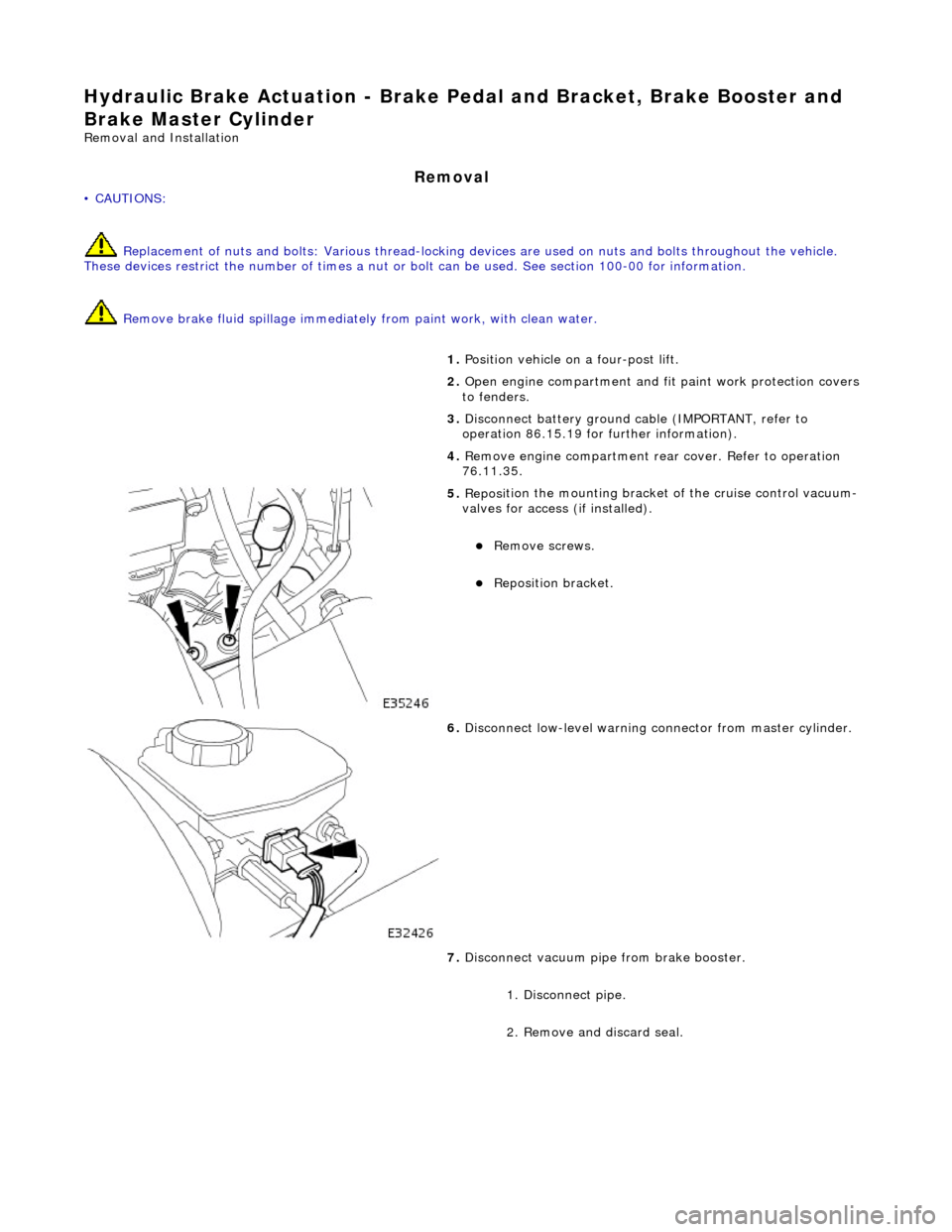

5. Reposi

tion the mounting bracket of the cruise control vacuum-

valves for access (if installed).

R e

move screws.

Reposition bracket.

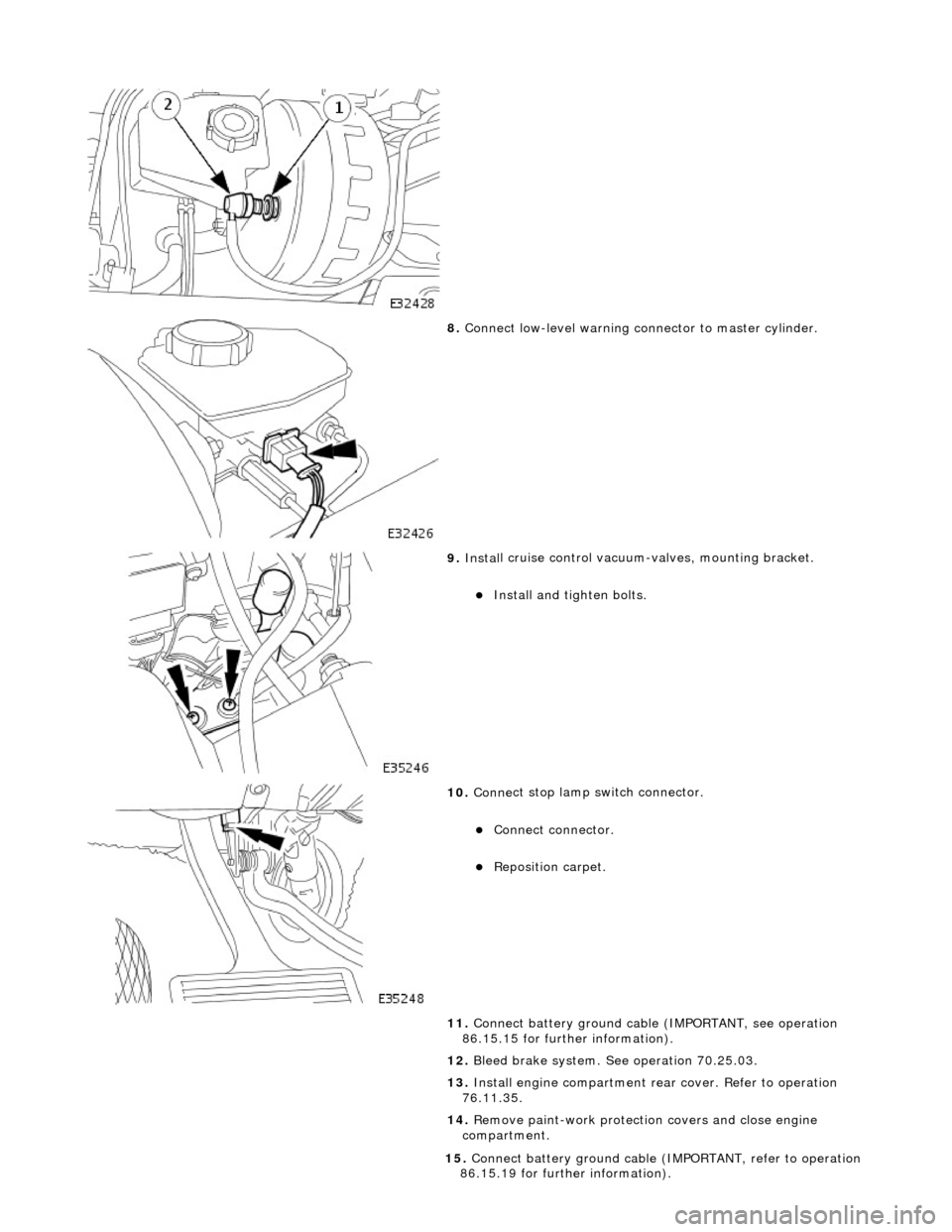

6. Disc

onnect low-level warning connector from master cylinder.

7. Disconnect vacuum pipe from brake booster.

1. Disconnect pipe.

2. Remove and discard seal.

Page 420 of 2490

8. Conne ct

low-level warning connector to master cylinder.

9. Inst al

l cruise control vacuum-valves, mounting bracket.

Install and tigh

ten bolts.

10 . Conne

ct stop lamp switch connector.

Conne

ct

connector.

Re

posi

tion carpet.

11. Connect battery ground cable (IMPORTANT, see operation

86.15.15 for further information).

12. Bleed brake system. See operation 70.25.03.

13. Install engine compartment rear cover. Refer to operation

76.11.35.

14. Remove paint-work protection covers and close engine

compartment.

15 . Conne

ct battery ground cable (I

MPORTANT, refer to operation

86.15.19 for further information).

Page 431 of 2490

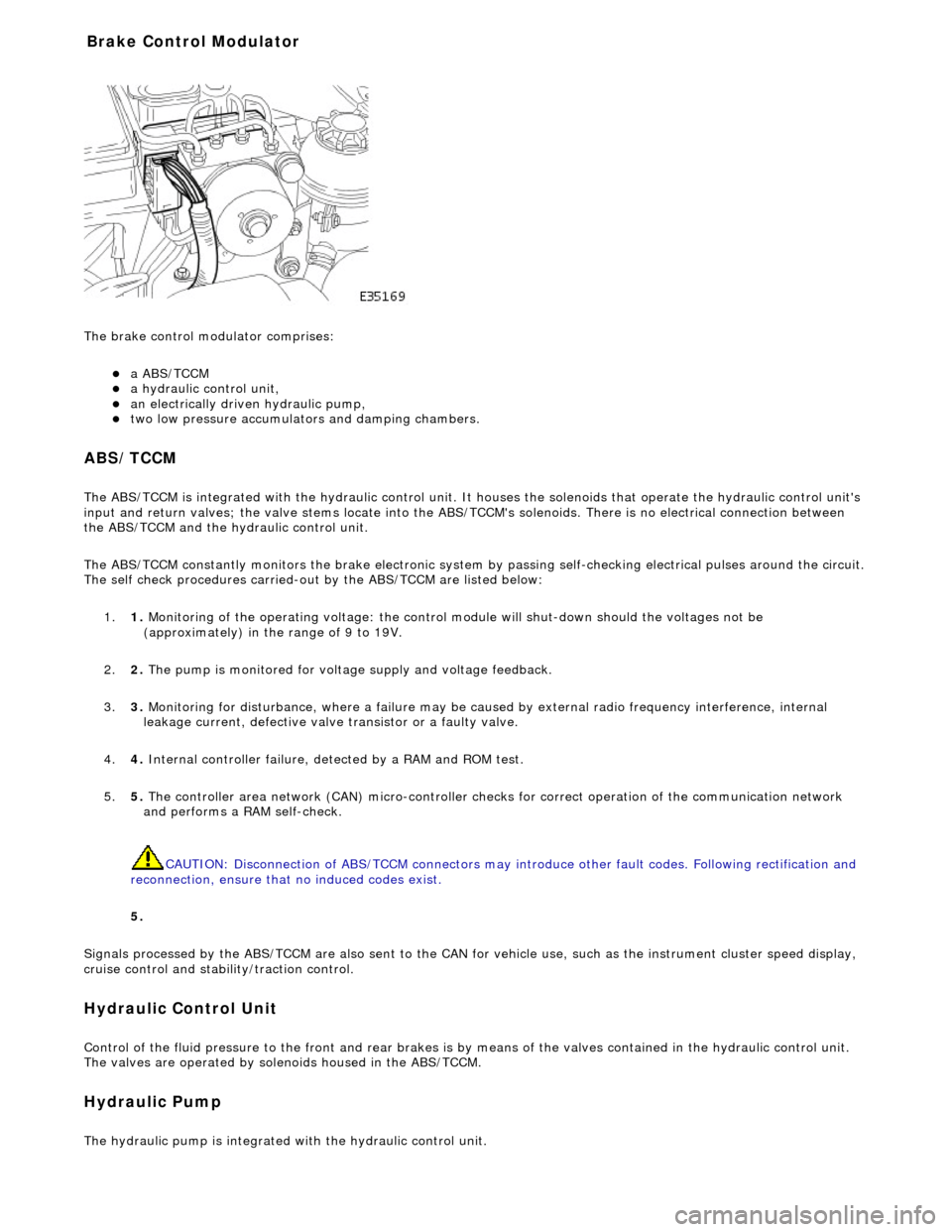

The brake

control modulator comprises:

a A

BS/TCCM

a h

ydraulic control unit,

an electrically driven hydrau

lic pump,

two low pressure accumulato

rs and damping chambers.

ABS/TCCM

The AB

S/TCCM is integrated with the hydrau

lic control unit. It houses the solenoids that operate the hydraulic control unit's

input and return valves; the valve stems locate into the ABS/TCCM's solenoids. There is no electrical connection between

the ABS/TCCM and the hydraulic control unit.

The ABS/TCCM constantly monitors the brake electronic system by passing self-checking electrical pulses around the circuit.

The self check procedures carried-out by the ABS/TCCM are listed below:

1. 1. Monitoring of the operating voltage: the control mo dule will shut-down should the voltages not be

(approximately) in the range of 9 to 19V.

2. 2. The pump is monitored for volt age supply and voltage feedback.

3. 3. Monitoring for disturbance, where a failure may be caus ed by external radio frequency interference, internal

leakage current, defective valve transistor or a faulty valve.

4. 4. Internal controller failure, de tected by a RAM and ROM test.

5. 5. The controller area network (CAN) micr o-controller checks for correct operation of the communication network

and performs a RAM self-check.

CAUTION: Disconnection of ABS/TCCM connectors may introduce other fault codes. Following rectification and

reconnection, ensure that no induced codes exist.

5.

Signals processed by the ABS/TCCM are also sent to the CAN for vehicle use, such as the instrument cluster speed display,

cruise control and stability/traction control.

Hydraulic Control Unit

Control of

the fluid pressure to

the front and rear brakes is by means of the valves contained in the hydraulic control unit.

The valves are operated by solenoids housed in the ABS/TCCM.

Hydraulic Pump

The

hydraulic pump is integrated

with the hydraulic control unit.

Bra

ke Control Modulator

Page 527 of 2490

E

ngine Management System Components

Electronic Throt

tle

The

electronic throttle assembly, in resp

onse to signals from both the driver and the ECM, adjusts idle speed, sets the

throttle valve to the position requested by the driver's accelerator / throttle pedal, cruise and traction control, power

limitation and catalyst warm-up.

Mass

Air Flow Meter

The sensor i

s located in the air flow mete

r assembly and outputs an analogue voltag e to the ECM. This sensor measures air

flow into the engine inlet system and is calibrated to measure kg / hour.

In

take Air Temperature

Th

e intake air temperature sensor is loca

ted in the air flow meter assembly and outputs an analogue voltage to the ECM.

The ECM will substitute a default value eq ual to 50°C should this sensor fail.

Fuel Injectors

The eigh

t bottom fed fuel injectors are located in the fuel rails. Th

e fuel injectors are electromagnetic solenoid valves

controlled by the ECM. The pulse time for the injector combined with the fuel pr essure determines the volume of fuel

injected to the manifold.

Fue

l Delivery

The fu

el pump provides fuel to the fuel rail where the circulat

ing pressure is controlled by a pressure regulator valve; excess

fuel is returned to the fuel tank.

The pressure regulator valve is controlled by manifold depression so that fuel delivery pressure is maintained at

approximately 3 bar above manifold pressure.

Fuel Pump

Relay

The ECM controls thi

s component for normal

engine running. The security system may disable this relay via communication

with the ECM.

Fuel Lev

el Sensing

The tank fuel

is measured by the fuel le

vel sensor . This signal is used by the ECM as an in put to certain diagnostics.

Eva

porative Valve

Excess vapour

formed in the fuel tank is

absorbed into the evaporative emission pu rge control canister. While the engine is

running, the fuel absorbed in the canister is gradually purged back into the engine. The rate of purging is governed by

engine operating conditions and vapour concentration level. Operating conditions which affect the purge rate are:

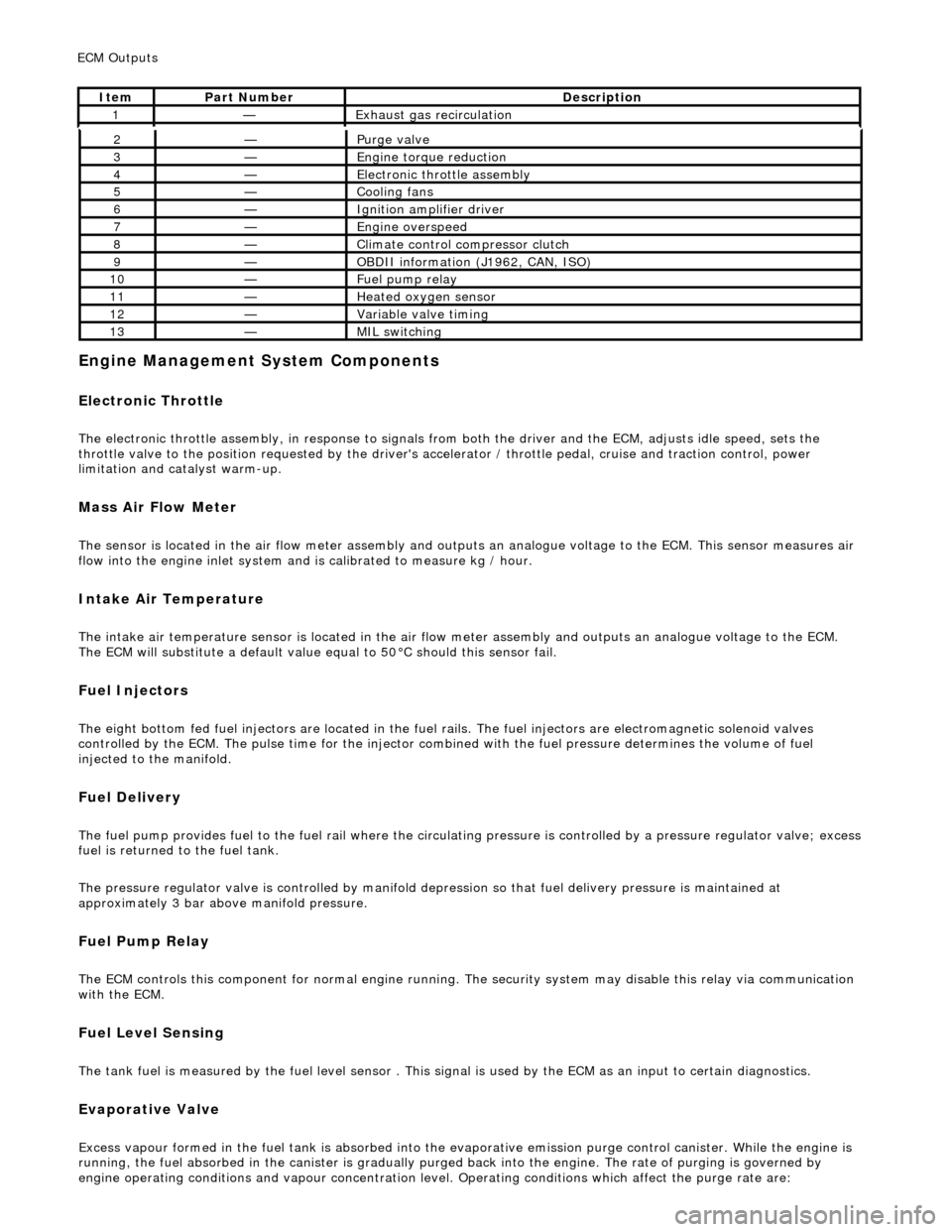

2—Purge

valve

3—Engine

torque reduction

4—E

lectronic throttle assembly

5—Coo

ling fans

6—Ignition amplifier driver

7—Engine overspeed

8—Cli

mate control compressor clutch

9—O

BDII information (J1962, CAN, ISO)

10—F

uel pump relay

11—Heat

ed oxygen sensor

12—Vari

able valve timing

13—MIL sw

itching

ECM Out

puts

It

em

Par

t Number

De

scription

1—Exhaus

t gas recirculation

Page 1025 of 2490

Default mode Definitions

MECH

ANICAL LIMP-HOME MODE:

No el

ectronic throttle operation (mechanical

operation for last quarter of pedal travel)

M

aximum 25° throttle opening,

depending on adjustment of th rottle mechanical linkage

Engine

speed restricted to 3000

rpm maximum, by fuel cut-off

Hi

gh idle speed (1200 rpm approx.)

Misfire

at idle, due to cylinder cut as a means of control

ling idle speed (the misfire will switch cylinders, as the

strategy varies th e cylinder cut)

Cruise (speed) contr

ol inhibited

REVERSE THROTTLE PROGRESSION ENABLED:

El

ectronic throttle operation, limited to maximum 25°

Cruise (speed) contr

ol inhibited

• NOTE: The throttle oper ation uses the same map as for reverse gear.

ENGINE SPEED LIMIT:

Engine

runs normally, up to 3000 rpm

Engine

speed restricted to 3000

rpm maximum, by fuel cut-off

Cruise (speed) contr

ol inhibited

LIMP-HOME UNAVAILABLE:

Cruise (speed) contr

ol inhibited

R

everse throttle pr

ogression engaged at second occurrence of DTC flagging

Diagnostic Trouble Code (D

TC) index

DT

C

Cond

ition

P

ossible Causes

Acti

on

P0171Right-hand cylinders combustion too

leanAir

intake leak between MAF

sensor and throttle

F

uel filter system blockage

F

uel injector blockage

F

uel pressure regulator failure (low

fuel pressure)

Low f

uel pump output

H0

2S harness wiring fault

E

xhaust leak (before catalyst)

ECM receivi

ng incorrect signal from

one or more of the following

sensors - ECT, MAF, IAT, TP.

Fo

r intake system,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

F

or fuel filter,

REFER to Section 310

-01

Fuel Tank

and Lines.

Chec

k the fuel injectors. Check the

fuel pressure regu lator. Check fuel

pressure. For HO2S circuit tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

F

or exhaust information,

REFER to Section 309

-00

Exhaust

Sy

stem

.

For se

nsor circuit tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

P0172Right-hand cylinders combustion too

ri

ch

Engine

misfire

Bl

ocked air filter

F

uel system return blockage

Leak

ing fuel injector(s)

F

uel pressure regulator failure

(high fuel pressure)

ECM receivi

ng incorrect signal from

one or more of the following sensors - ECT, MAF, IAT, TP

Chec

k for 'engine misfire detected'

DTCs. Check the air filter element,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

Chec

k the fuel lines,

REFER to Section 310

-01

Fuel Tank

and Lines.

Chec

k the fuel injectors,

REFER to Fuel Injectors

- in t

his

section.

For fuel pressure regulator check,GO

to Pinpoint Test D.

.

Check the fuel

pressure,

Page 1082 of 2490

Default mode Definitions

MECHANIC

AL LIMP-HOME MODE:

No elec

tronic throttle operation (mechanical

operation for last quarter of pedal travel)

Ma

ximum 25° throttle opening,

depending on adjustment of th rottle mechanical linkage

Engine speed restri

cted to 3000

rpm maximum, by fuel cut-off

High i

dle speed (1200 rpm approx.)

Misfire

at idle, due

to cylinder cut as a means of control

ling idle speed (the misfire will switch cylinders, as the

strategy varies th e cylinder cut)

Cruise (speed) contr o

l inhibited

REVERSE THROTTLE PROGRESSION ENABLED:

Elec

tronic throttle operation, limited to maximum 25°

Cruise (speed) contr

o

l inhibited

• NOTE: The throttle oper ation uses the same map as for reverse gear.

ENGINE SPEED LIMIT:

Engine runs

normally, up to 3000 rpm.

Engine

speed restri

cted to 3000 rp

m maximum, by fuel cut-off.

Cruise (speed) contr o

l inhibited

LIMP-HOME UNAVAILABLE:

Cruise (speed) contro

l inhibited

Re

verse throttle pr

ogression engaged at second occurrence of DTC flagging

AmberRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P01 16,

P0117, P0118, P0125

Ambe

rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P01 01,

P0102, P0103, P0104

Ambe

rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P03 00,

P0301, P0302, P0303, P0304, P0305,

P0306, P0307, P0308, P1313, P1314

Ambe rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P03 27,

P0328, P0332, P0333, P1648

Ambe

rRestri

cted

Performance

R e

verse throttle pr

ogression enabled

P1474

AmberRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P1230

Ambe rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P1671

Ambe rRestri

cted

Performance

Engine

Speed Limit (runs normally, limited to

3000 rpm)

P11 12,

P1113

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1601 (SC on

ly)

AmberRestri

cted

Performance

Gearbox defau l

t to 4th gear

P16

05 (

NA only)

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P0702

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1795

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1796

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1797

Ambe

rRestri

cted

Performance

Gearbox defau l

t to 4th gear

P1605

Ambe

rNoneGearbox defau l

t to 4th gear

P0705 (SC on

ly)

AmberNoneGearbox defau l

t to 4th gear

P0706

Ambe

rNoneGearbox defau l

t to 4th gear

P1720

Page 1110 of 2490

2.2. Cruise

3. 3. Mechanica l

guard

4. 4. Fixed idle

5. 5. Redundancy

6. 6. Full authority

7. 7. Engine shut-down

Normal mode occurs when the EC M uses the mechanical and monitoring arrangem ent of the throttle valve to control throttle

opening. The ECM does not permit driver demand to be exceeded but it can be restricted to allow for such features as

stability / traction control, or engine power limitation.

The ECM determines engine idle speed by controlling the throttle valve motor to vary the blade angle between the non-

adjustable preset limits of the mechanic al guard and the throttle valve motor.

Cruise mode is engaged as a result of the ECM calculating and controlling the required throttle valve opening via the

vacuum system. When the driver releases the throttle pedal, the input shaft disengages from the mechanical guard or the

vacuum actuator pulls the guard away from th e throttle valve. The throttle pedal will feel light should it be pushed again to

accelerate (pressing the pedal further will re-engage the input shaft with the mechanical guard and restore normal feel).

The ECM utilizes sensors to monitor the relative positions of the mechanical guard and throttle valve and adjusts them to

maintain the set cruise speed.

Mechanical guard mode permits full mechanical operation of the throttle if the ECM detects that a problem has been

encountered with the throttle valve position sensor, dc motor, associated harnesses / connecto rs or the ECM.

Fixed idle mode occurs when any two of the three sensors (two input shaft sensors and the mechanical guard sensor) fail.

The ECM will assume values which represent a blade angl e of approximately 2,5° and 1200 rpm (unloaded) maximum

engine speed.

Redundancy mode occurs when any one of the three sensors (two input shaft sensors and the mechanical guard sensor)

fails. The operational pair will be deemed to be safe to co ntinue without intervention, but cruise will be inhibited.

Full authority mode is invoked when a mech anical guard failure occurs which indicates that the guard is stuck fully open.

The red warning lamp will be lit and road speed will be li mited to 120 kph.

Engine shut-down mode will occur followin g multiple failures, such as mechanical guard mode following full authority mode

(or vice versa) or the throttle blade sticks.

Intake Elbow

The intake elbow directs the metered airflow from the electronic throttle to the intake manifold. Stub pipes on both sides of

Page 1111 of 2490

the

intake elbow provide connections for vacuum actuators and are also used to redirect emissions into the engine.

On the right-hand side of the elbow a la rge diameter pipe connects to the brake servo. The smaller pipe provides a vacuum

feed to the fuel rail pressure regulator and throttle cruise control system. On the le ft-hand side of the elbow the front pipe

supplies vacuum control for the evaporative emissions system valves.

Emissions from the engine part load breather (bank 2) and pu rged fuel vapor from the EVAP valve are drawn via a common

T piece into the left-hand side of the intake elbow. Re-cir culated exhaust gas enters the intake elbow via the EGR valve

which is mounted directly on the rear of the elbow : where the EGR system is not used, a blanking plate is fitted.

The fuel system, throttle and emission control system s are described more fully in the relevant sections.

Intake Manifold

Filtered air from the vehicle's intake ducting is metered by th e electronic throttle and distributed to the two cylinder banks

via an integral intake manifold.

The intake manifold is manufactured in plastic with integral plastic fuel rails and metal-thread inserts; the very smooth

internal surfaces give excellent air flow.

Individual ducts lead off a central chamber to the inlet valves of each cylinder.

Silicon-rubber gaskets, loca ted in channels in the intake manifold, seal th e joints between the ducts and the cylinder heads.

Engine Ventilation

The e

ngine is ventilated through two brea

thers; a part-load breather and a full-load breather, one on each camshaft cover.

The outlet hose for the part-load breather is connected between the bank 2 camshaft cover and the intake elbow. The full-

load outlet hose is connected from the bank 1 camshaft cover to the intake duct between the MAF sensor assembly and the

throttle body.

Constructed in plastic, the hoses incorporate O-ring seal s and quick-release connectors; refer to Section 303-01.

I

ntake Air Distribution and Filtering - Supercharged Vehicles

Ai

r is supplied to the supercharger via an

intake cleaner/duct, throttle assembly and intake elbow which are similar to those

used for normally aspirated engines. The su percharger delivers pressurized air to two separate charge air cooler units, each

unit being mounted on the cy linder bank which it supplies. Pr essurized cooled air is fed from the charge air coolers directly

into each inlet port.

Page 1113 of 2490

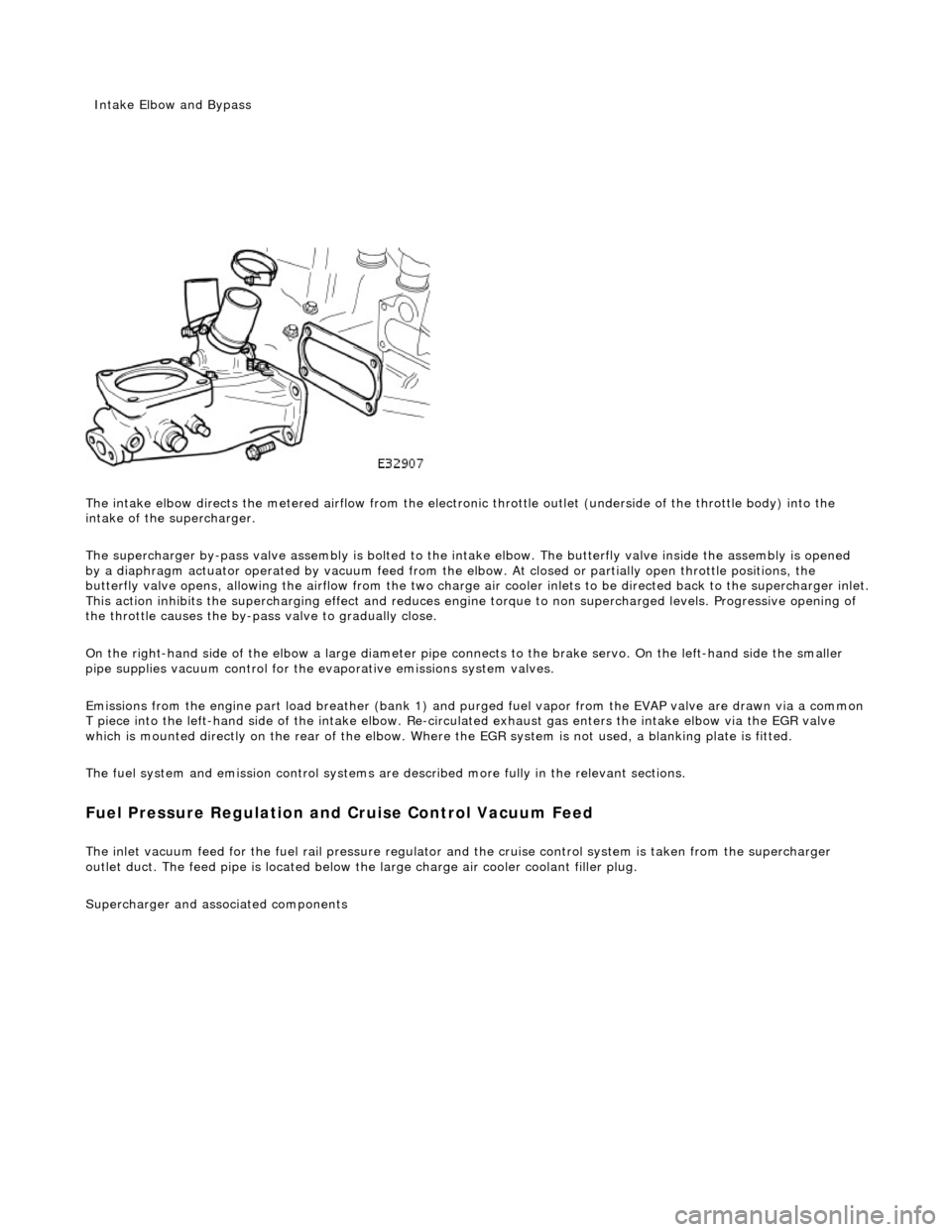

The intake elbow di

rects the metered airflow from the electronic throttle outlet (und

erside of the throttle body) into the

intake of the supercharger.

The supercharger by-pass valve assembly is bolted to the intake elbow. The butterfly valve inside the assembly is opened

by a diaphragm actuator operated by vacu um feed from the elbow. At closed or partially open throttle positions, the

butterfly valve opens, allowing th e airflow from the two charge air cooler inlets to be directed back to the supercharger inlet .

This action inhibits the supercharging e ffect and reduces engine torque to non supercharged levels. Progressive opening of

the throttle causes the by-pass valve to gradually close.

On the right-hand side of the elbow a la rge diameter pipe connects to the brake servo. On the left-hand side the smaller

pipe supplies vacuum control for the evaporative emissions system valves.

Emissions from the engine part load breather (bank 1) and pu rged fuel vapor from the EVAP valve are drawn via a common

T piece into the left-hand side of the intake elbow. Re-cir culated exhaust gas enters the intake elbow via the EGR valve

which is mounted directly on the rear of the elbow. Where the EGR system is not used, a blanking plate is fitted.

The fuel system and emission control systems are described more fully in the relevant sections.

Fuel Pressure Regula

tion and

Cruise Control Vacuum Feed

The inlet v

acuum feed fo

r the fuel rail pressure regula tor and the cruise control system is taken from the supercharger

outlet duct. The feed pipe is located below the large charge air cooler coolant filler plug.

Superchar

ger

and associated components

Inta

ke Elbow and Bypass

Page 1191 of 2490

Fue

l pump

Engine coolan

t temperature

(ECT) sensor

Blocked part-load breather (

service action S474)

Injec

tor leak

Emiss

ions

.

Check bull

etins for throttle cleaning procedure.

Check fuel pressure. For ECT sensor circuit tests,

GO to Pinpoint Test C.

. Refer to Servi

ce action

S474 for part-load breather procedure. For

injector leak test, Refer to technical service bulletin 303-39.

D

ifficult to start after hot

soak (vehicle standing

after engine has reached operating temperature)

Roc

hester valve

Thr

ottle contaminated

Purge

valve

Fue

l pump

Engine coolan

t temperature

(ECT) sensor

Blocked part-load breather (

service action S474)

Injec

tor leak

Engine cranks too

fa

st/slow

Batt

ery

Starter relay Harness Cyl

inder compression loss

(NA short term only. Refer to technical service bulletin; 303-39)

R

efer to service action

S491

F

or battery information,

REFER to Section 414

-0

1 Battery, Mounting and

Cables.

F

or starting system.

REFER to Section 303

-06 Sta

rting System

.

R

efer to technical servic

e bulletins and service

actions.

Engine

stalls

Engine st

alls soon after

start

F

uel pump relay

ECM relay Thr

ottle contaminated

CMP/CKP sen

sor

synchronization malfunction

Harness Fue

l pump

MAF

sensor malfunction

Engine coolan

t temperature

(ECT) sensor

Fue

l lines

Air leakage

F

uel pressure regulator

Check r

elay dates. Chec

k for DTCs. For fuel

pump relay tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or ECM relay tests, GO to Pinpoint Test

AD.

.

Check bull

etins for throttle cleaning procedure.

For CMP sensor circuit test s, GO to Pinpoint Test

C.

, for

CKP sensor circuit tests, GO to Pinpoint

Test N.

. Check fuel

pressure. For MAF sensor

circuit tests, GO to Pinpoint Test A.

. For EC

T

sensor tests, GO to Pinpoint Test C.

. F

or fuel

system,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

and

REF

ER to Section 310

-0

1 Fuel Tank and Lines

. F

or intake system information,

REFER to Section 303

-1

2 Intake Air Distribution

and F

iltering

.

Engine

stalls on overrun

Thr

ottle contaminated

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Check bull

etins for throttle cleaning procedure.

Check relay dates. For ECM relay tests, GO to Pinpoint Test AD.

. F

or fuel pump relay tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s, GO to Pinpoint Test

O.

, for

CKP sensor circuit tests, GO to Pinpoint

Test N.

.

E

ngine stalls at steady

speed, with or without cruise enabled

Thr

ottle contaminated

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Harness Blocked part-load breather

(

service action S474)

Check bull

etins for throttle cleaning procedure.

Check relay dates. For EC M relay circuit tests,GO

to Pinpoint Test AD.

. F

or fuel pump relay circuit

tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s,GO to Pinpoint Test

O.

, for

CKP sensor circuit tests,GO to Pinpoint

Test N.

. Che

ck service actions.

Engine st

alls when

maneuvering

ECM relay F

uel pump relay

CMP/CKP sen

sor

synchronization malfunction

Check r

elay dates. For EC

M relay circuit tests,GO

to Pinpoint Test AD.

. F

or fuel pump relay circuit

tests,

REFER to Section 303

-0

4 Fuel Charging and

Controls.

F

or CMP sensor circuit test

s,GO to Pinpoint Test

O.

, for

CKP sensor circuit tests,GO to Pinpoint

Test N.

.