V8 supercharged JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 46 of 2490

Meter (measurement)m

Me

tric (screw thread, e.g.

M8)

M

MicrofaradMFDUni t

of electrical capacitance, one millionth of a farad

Mi

ll

imeter

mm

Mi

ll

imeter of mercury

mm

Hg

Mill

isecond

ms

Min

i

mum

mi

n.

Min u

te

minut

e

Model YearMY

ModuleMSelf

contained group of electrical/electronic components which is designed as

a single replaceable unit

Modulating signalMDA sh

ift process signal to the TCM on SC vehicles

Motorized In

-Car

AspiratorMIAD e

vice which constantly samples cabi

n temperature by passing air over a

sensor, and communicates with the A/ CCM to modify A/C system performance

to suit

Mult i Prot

ocol Adaptor

MPAAn i

n

terpreter for the various data

languages present on a vehicle

N

Nati

onal Institute of

Occupational Safety and

Health (US)

NIO S

H

Ne

wto

n

NSI unit of force. 1

N = 0.224

8 pounds force

Ne

wto

n meter

NmSI unit of torque. Must not be

co

nfused with nm (nanometer)

Ni

tr

ous Oxide

NO

xCompounds of nit rogen and oxygen fo rmed at high temperatures. Major

sourc

e of exhaust-gas air pollution

No

n

-Volatile Random

Access Memory

NVR A

M

R

A

M which retains memory even

if power supply is interrupted

Normal

ly aspirated

F

u

eling system using intake air at atmo

spheric pressure; not supercharged or

turbocharged

N ormal

ly Closed

NC

N

o

rmally Open

NO

No

r

th American

Specification

NASVehicles f or sal

e in the USA and Canadian markets

Nu

mbe

r

No

.

O

Oc

cupational Safety and

Health Administration

(US)

OS H

A

O

n

-Board Diagnostic

OB

DA system that moni

tors some or all co

mputer input and output control signals.

Signal(s) outside the pre-de termined limits imply a fault in the system or a

related system

O n

-Board Refueling

Vapor Recovery

OR V

R

O

riginal

Equipment

Manufacturer

OE M

Outp

ut

O/

PAn electrical o u

tput signal from a controlling device

Ou

ts

ide diameter

o.

d

ia

O

xides of

nitrogen

NO

x

Oxygen senso

r

O2

SA s

ensor which detects oxygen content in the exhaust gases

P

Parameter Identifi

erPIDAn in

dex number referring to a parame

ter within a module without knowledge

of its storage location

Park N e

utral Position

PN

P

Park N e

utral Position

Switch

PN PSIndic

ates the selected non-drive modes of the (automatic) transmission

Part numberpart no.

Portable Diag

nostic Un

it

PD

UCompre hen

sive electrical diagnosis system specific to Jaguar vehicles

Posi

ti

on

po

s'n

Power As si

sted Steering

PASHydraul

i

c pump-assisted steering system

Power Steer

i

ng Pressure

PSP

Programmable Elect

r

onic

Control Units System

PECU SProcess whereb y

a common ECM is progra

mmed on the production line to suit

the market requirements of a particular vehicle

Programmable Read-O

nly

PROMRO

M with some provision for setting

the stored data after manufacture

Page 58 of 2490

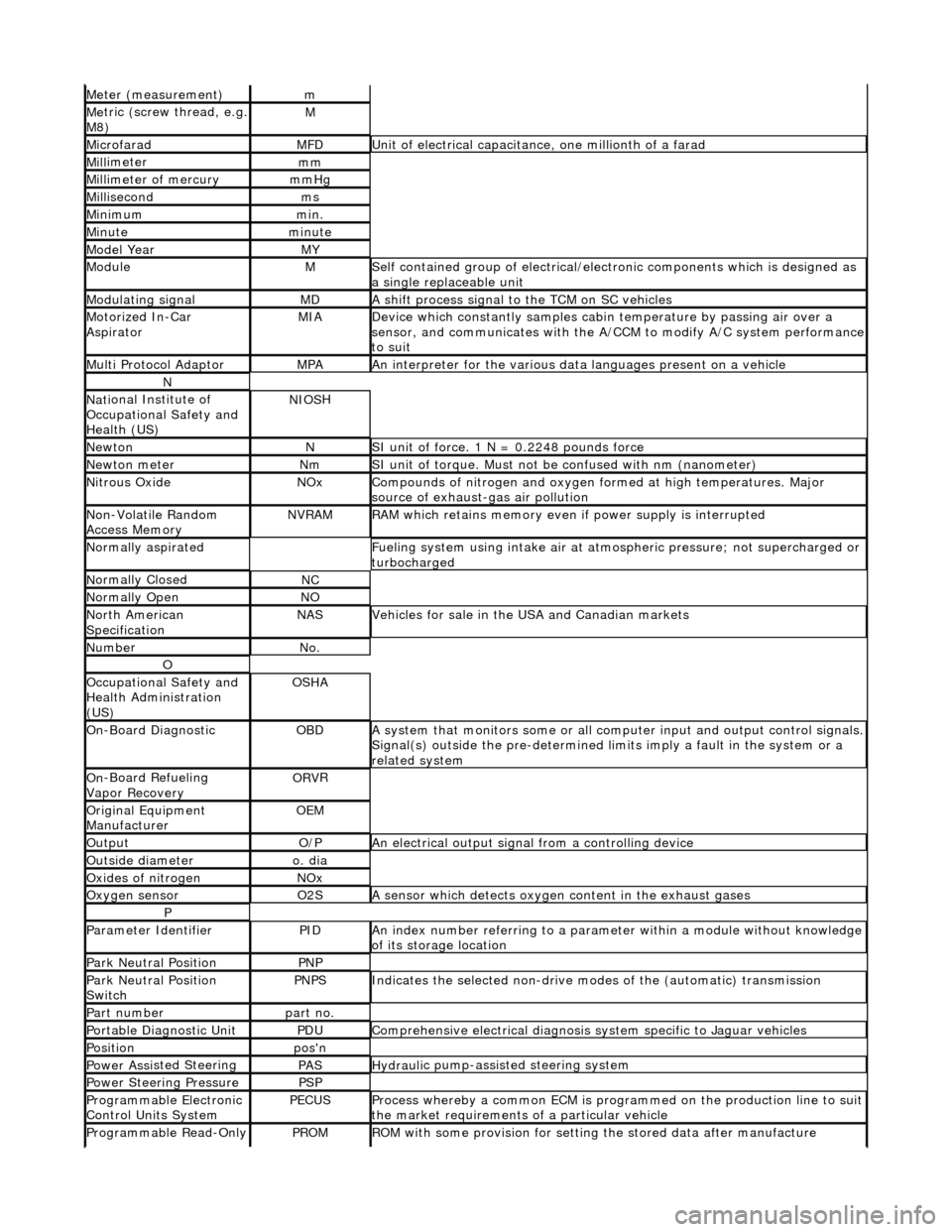

Suspension System - General Informatio

n -

Lubric

ants, Fluids, Sealants and Adhesives

Front Suspension Dimensions

• NO

TE: When a component reaches its maximum / minimum dimension limit the component must be replaced.

Rear sus

p

ension Dimensions

•

NO

TE: When a component reaches its maximum / minimum dimension limit the component must be replaced.

Vehicle ride

height

R i

de height is measured from

the center of the wheel to the apex of the wheel arch, through the wheel center line.

Showroom is with a

ll fluids at full an

d 9 liters (9.5 US quarts) of fuel.

Curb is

with all fluids at full and a full tank of fuel.

All f

i

gures quoted assume a ±

15 mm (0.59in) anticipated bu ild variance and condition.

Whee

l Alignment - Front Camber - XJR Excluding NAS, and German Super-8

Al l the above fi

gures

are at "showroom" height. (See ride height section above).

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

Whe

e

l Alignment - Front Camber - XJR NAS, and Comfort/Sport/Daimler Super-8

UnitSp

ecification

Loctite27

0

Greas eShell Retin a

x 'A'

Greas

eCastro l 'NT

R'

Com

p

onent

Di

mensi

on

Hub face

-

maximum run-out

0.

03

8 mm

Com

p

onent

Di

mensi

on

Hub face

-

maximum run-out

0.

05

7 mm

Mod

e

l

Mod

e

l Year

V

I

N RANGE

Mark

et

Sh

owroom mm(in)

Curb mm(i

n)

FromToFron

t

RearFr

on

t

Rear

Com

f

ort suspension

1

998

to 2003.5

8

123

17

F

595

25

All3

90 (

15.11)

3

84 (

15.11)

3

89 (

15.31)

3

73 (

14.68)

Sport su

spe

nsion

"""All3

89 (

15.31)

3

81 (

15.00)

3

88 (

15.27)

3

72 (

14.64)

XJR"""NAS3

89 (

15.31)

3

82 (

15.03)

3

88 (

15.27)

3

72 (

14.64)

XJR"""RO

W367 (

14.44)

3

65 (

14.37)

3

66 (

14.40)

3

58 (

14.09)

Supercharged super 8"""All3

89 (

15.31)

3

82 (

15.03)

3

88 (

15.27)

3

72 (

14.64)

XJR

Excluding NAS, and German Super-8

1998 to

2003.5

VIN - 812317 to F59525

Units

Cambe r

Left

- Hand

Rig

h

t - Hand

Bal

a

nce (RH - LH)

MinMaxMinMaxMinMax

All Right-Hand driv

e and JapanDegrees

/minutes

-

1

° 28'

-0

°

28'

-

1

° 13'

-

0

° 13'

-0

° 45'+1 °

15'

Decimal degrees-1.

4

7°

-0

.4

7°

-1

.2

2°

-0.

2

2°

-0

.7

5°

+1

.25

°

R

e

st of World

De

grees

/minutes

-

1

° 13'

-0

°

13'

-

1

° 28'

-

0

° 28'

-1

° 15'+0 °

45'

Decimal degrees-1.

2

2°

-0

.2

2°

-1

.4

7°

-0.

4

7°

-1

.2

5°

+0

.75

°

XJR

NAS, and Comfort/Sport/Daimler Super-8

1

998 to

2003.5

VIN - 812317 to F59525

Units

Cambe r

Left

- Hand

Rig

h

t - Hand

Bal

a

nce (RH -

LH)

MinMaxMinMaxMinMax

All Right-Hand drive and JapanDegrees

/minutes

-1°

02'-0

° 02'

-0°

47'

+0°

13'

-0° 45'+1°

15'

Decimal degrees-1.0

3°

-0.0

3°

-0.7

8°

+0.22

°

-0.7

5°

+1.25

°

USA, Canada an

d Mexico,

Dominican

Republic (NAS)

De grees

/minutes

-0°

32 '+0 °

28'

-1 °

02'

-0 °

02'

-1°

30 '+0 °

30'

Decimal degrees-0. 5

3°

+0

.47

°

-1

.0

3°

-0

.0

3°

-1.

5

0°

+0

.50

°

R

e

st of World

De

grees

/minutes

-0°

47 '+0 °

13'

-1 °

02'

-0 °

02'

-1°

15 '+0 °

45'

Decimal degrees-0. 7

8°

+0

.22

°

-1

.0

3°

-0

.0

3°

-1.

2

5°

+0

.75

°

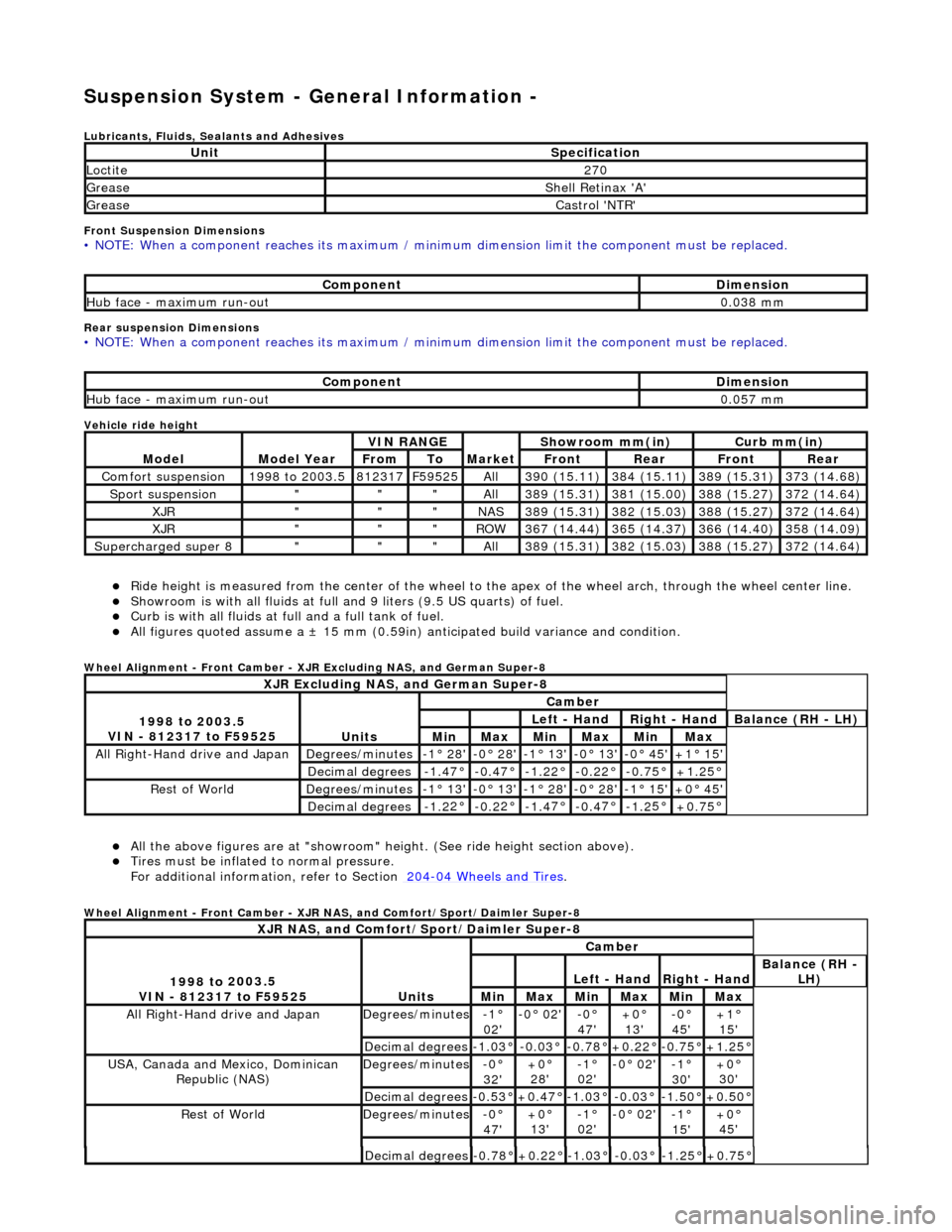

Page 167 of 2490

Rear

Suspension - Rear Suspension

Description an

d Operation

Description

The i

ndependent rear suspension incorporates co-axial sp

ring and shock absorber units, a subframe, wishbone tie,

pendulum assembly, mounting brac ket, differential strut, cast wishbones and hub carriers. The suspension assembly is

positively located by the subframe, mounting bracket and differential strut.

Each wi

shbone pivots on a fulcru

m bolt which locates in the wishbone tie and pendulum assembly.

The wish

bone tie and pendulum assemblies are respectively in

stalled at the front and rear of the final drive housing.

The differential

strut is secured to the wishbone tie assembly.

Two ti

e rods are installed between the front of the

subframe and the top of the final drive housing.

The ou

ter extremity of each wishbone

is secured to its respective hub carrier assembly by a fulcrum bolt.

Each fulcrum bolt head incorporates an ec centric circular flange which locates in a groove in the front face of the wishbone

arm. Rotation of the fulcrum bolt results in horizontal movement of the bolt shank in an elongated hole in the rear of the

wishbone arm. This acti on achieves corresponding movement of the hub carrier, facilita ting adjustment of road wheel toe-

in.

It

em

Par

t Number

De

scription

1—Hub Carrier

2—Wi

shbone

3—Sprin

g

4—Shock Absorber

5—Suspensi

on Turret

6—Suspensi

on Subframe

7—Moun

ting Bracket

8—D

ifferential Strut

9—Stabilizer Ba

r (Supercharged and

Sport Suspension Models only)

10—Bum

p Stop

Page 168 of 2490

Each r

oad spring and is located between the wishbone in

tegral spring seat and the body suspension turret.

Each shoc

k absorber unit is installed

co-axially within the road spring.

The lo

wer end of each shock absorber is secured to the

wishbone by a bolt which also functions as a pivot.

Adaptive damping is av

ailable as an option.

A

rear stabi

lizer bar is installed on

Supercharged and Sport Suspension models . Mounted at the rear of the wishbone

tie assembly, the stabilizer bar is connected to the wishbone by short links.

Op era

tion

As each road wheel r

i

ses, move

ment is transmitted through th e hub carrier assembly to the wishbone and axle shaft. The

corresponding rise of the wishbone compre sses the road spring and partially telescopes the shock absorber. During this

action, the spring absorbs result ing shocks and the shock absorber minimizes spring oscillation.

During cornering, vehicle weight is transferred to the outer road wheel with a resulting tendency for the inner wheel to lift.

On Supercharged and Sport Suspension vehicl es, a rear stabilizer bar assists in minimizing this tendency by transferring a

proportion of potential lift of the inner wheel to the outer wheel. This results in enhanced body stability with improved

cornering capabilities.

Page 520 of 2490

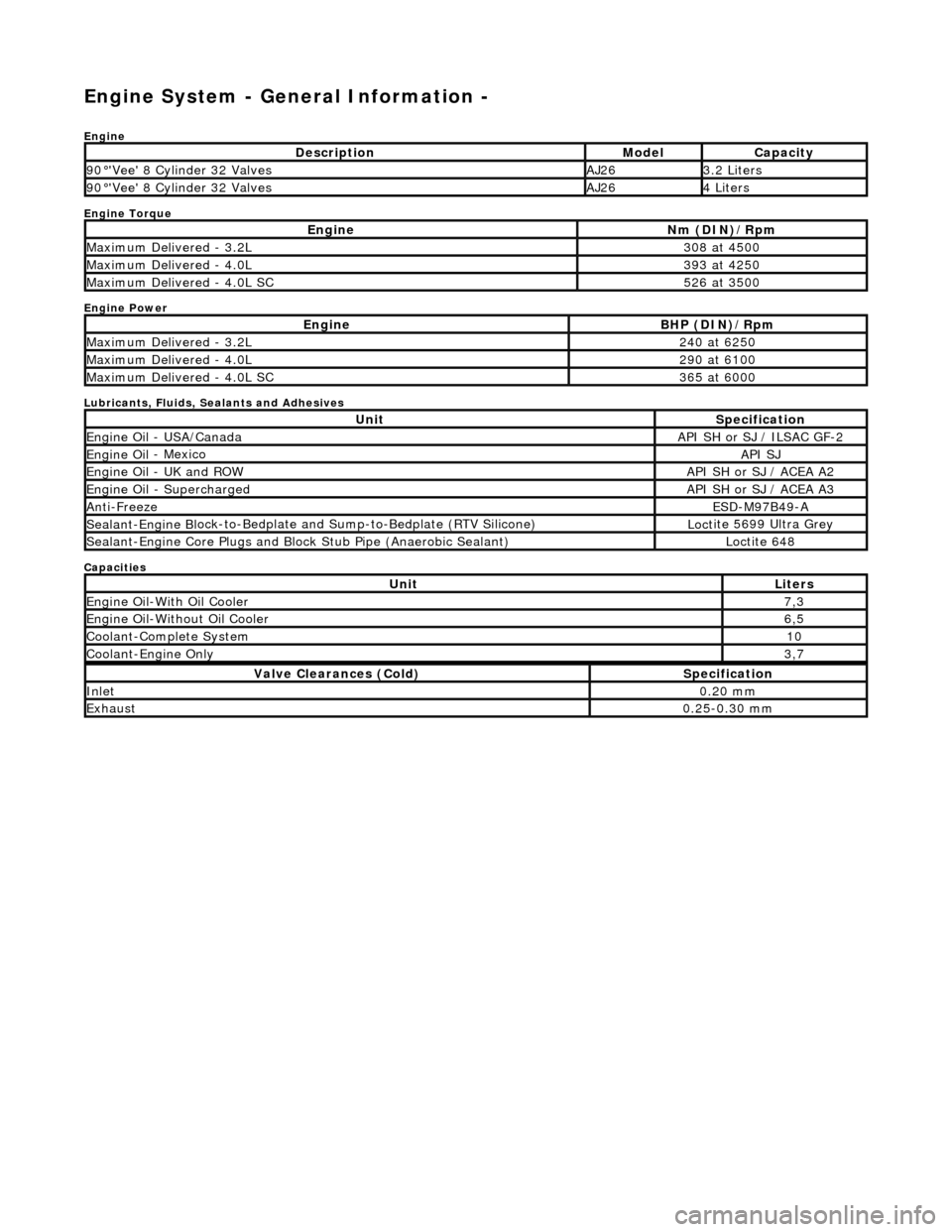

Engine System - General Inform

ation -

Eng

ine

Engine Torque

Engine Power

Lubricants, Fluids, Sealants and Adhesives

Capacities

Descr

iption

Mode

l

Capaci

ty

90

°'Ve

e' 8 Cylinder 32 Valves

AJ263.

2 L

iters

90

°'Ve

e' 8 Cylinder 32 Valves

AJ264 Li

te

rs

EngineNm (D

I

N)/Rpm

M

a

ximum Delivered - 3.2L

3

08 at

4500

M

a

ximum Delivered - 4.0L

3

93 at

4250

M

a

ximum Delivered - 4.0L SC

5

26 at

3500

EngineBH

P (D

IN)/Rpm

M

a

ximum Delivered - 3.2L

2

40 at

6250

M

a

ximum Delivered - 4.0L

2

90 at

6100

M

a

ximum Delivered - 4.0L SC

3

65 at

6000

UnitS

p

ecification

Engine Oil

-

USA/Canada

API SH or SJ

/ ILSAC G

F-2

Engine

Oil

- Mexico

API SJ

Engine

Oil

- UK and ROW

API SH or SJ

/ ACEA A2

Engine Oil -

Supercharged

API SH or SJ

/ ACEA A3

Anti-Freez

e

ESD-M97B

49

-A

Sealant-Engine B

l

ock-to-Bedplate an

d Sump-to-Bedplate (RTV Silicone)

Loct

ite 5699 Ultra Grey

Sealant-Engine

C

ore Plugs and Bloc

k Stub Pipe (Anaerobic Sealant)

Loctite 648

UnitLit

ers

Engine

Oil-W

ith Oil Cooler

7,

3

Engine Oil-W i

thout Oil Cooler

6,

5

Cool ant

-Complete System

10

Coo

lan

t-Engine Only

3,

7

Val v

e Clearances (Cold)

S

p

ecification

Inlet0.

20

mm

Exhaus

t0.25

-0.30 mm

Page 899 of 2490

16. Disconnect the air cleaner cover.

Remove the five clips which se cure the air cleaner cover.

17. Remove the intake tube / air flow meter / air cleaner cover

assembly.

1. Remove the intake tube / air flow meter / air cleaner

cover assembly.

2. Remove and discard the ru bber seal; air intake tube

to throttle body.

18. Remove the centre trim panel from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

19. Release the hoses (Quick Fit connections) from the expansion

tank, using 303 - 623.

1. Release the hose, expansion tank to thermostat housing (coolant outlet pipe on supercharged

engines).

Page 921 of 2490

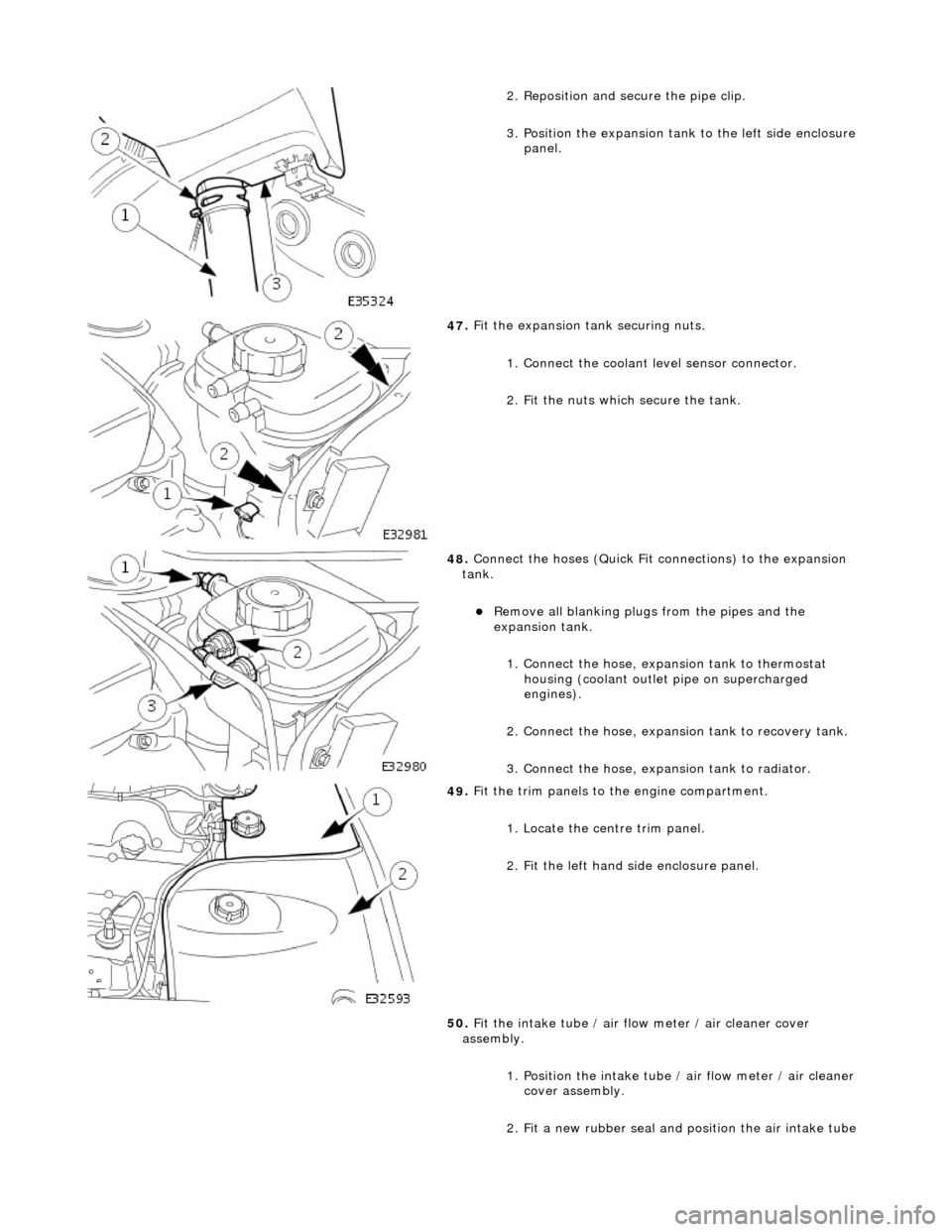

2

. Reposition and secure the pipe clip.

3. Position the expansion tank to the left side enclosure

panel.

47

.

Fit the expansion tank securing nuts.

1. Connect the coolant level sensor connector.

2. Fit the nuts which secure the tank.

48

.

Connect the hoses (Quick Fit connections) to the expansion

tank.

Remove all blanking plug s

from the pipes and the

expansion tank.

1. Connect the hose, expansion tank to thermostat housing (coolant outlet pipe on supercharged

engines).

2. Connect the hose, expansion tank to recovery tank.

3. Connect the hose, expansion tank to radiator.

49

.

Fit the trim panels to the engine compartment.

1. Locate the centre trim panel.

2. Fit the left hand side enclosure panel.

50. Fit the intake tube / air flow meter / air cleaner cover

assembly.

1. Position the intake tube / air flow meter / air cleaner

cover assembly.

2. Fit a new rubber seal and po sition the air intake tube

Page 924 of 2490

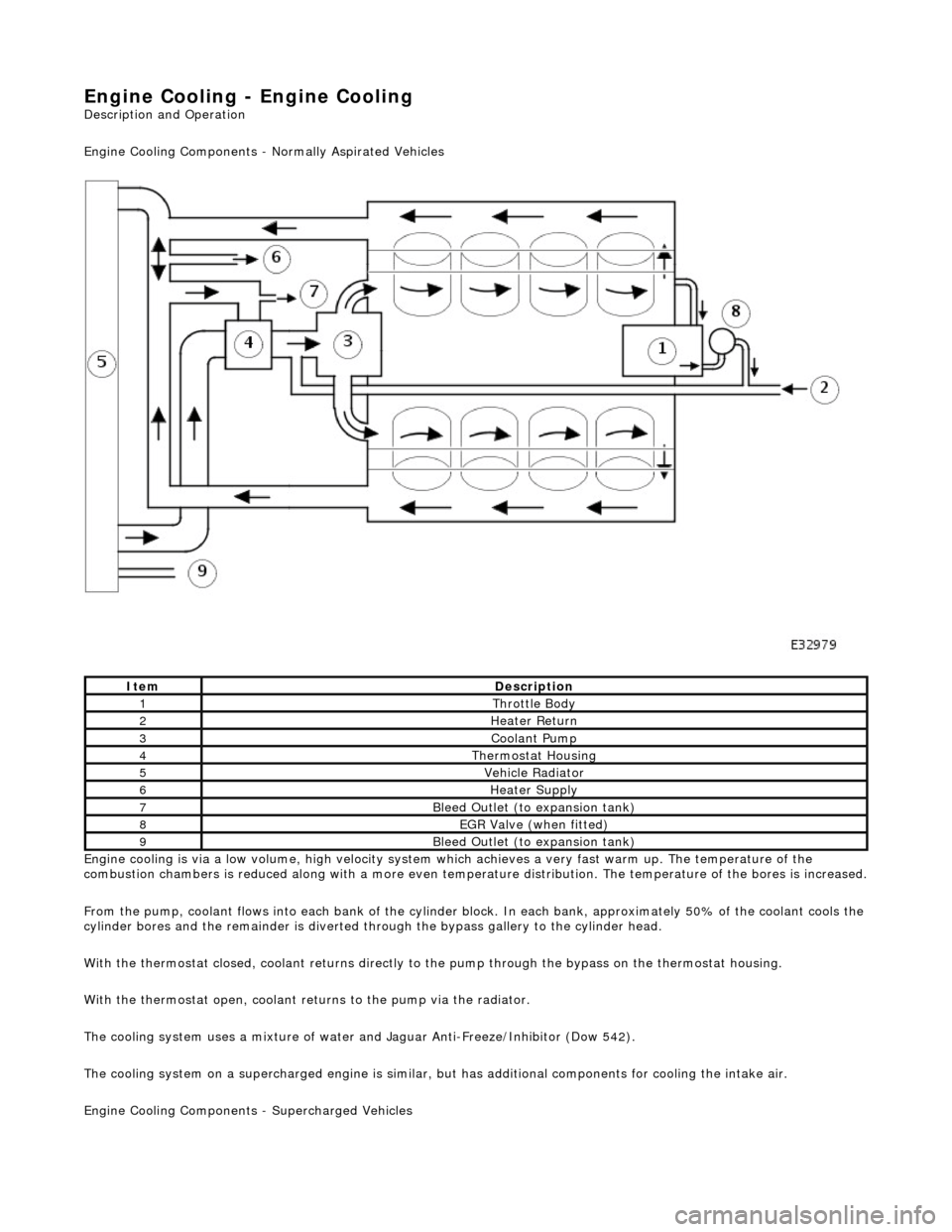

Engine Cooling

- Engine Cooling

Descr

i

ption and Operation

Engine Cooling Comp onents - Normally Aspirated Vehicles

Engine cooling is via a low volume, high velocity system which achieves a very fast warm up. The temperature of the

combustion chambers is reduced along with a more even temperature distribution. The temperature of the bores is increased.

F r

om the pump, coolant flows into each bank of the cylinder bl

ock. In each bank, approximately 50% of the coolant cools the

cylinder bores and the remainder is diverted th rough the bypass gallery to the cylinder head.

With the thermostat closed, coolant returns directly to the pump through the bypass on the thermostat housing.

With the thermostat open, coolant returns to the pump via the radiator.

The cooling system uses a mixture of water and Jaguar Anti-Freeze/Inhibitor (Dow 542).

The cooling system on a supercharged engine is similar, but has additional components for cooling the intake air.

Engine Cooling Co mponents - Supercharged Vehicles

ItemDescrip

tion

1Thr

ottle B

ody

2Hea

ter Return

3Coolant Pum p

4Ther

mostat Housing

5Vehicle Radia

t

or

6Hea

ter Su

pply

7Bleed

Outl

et (to expansion tank)

8EGR V

a

lve (when fitted)

9Bleed

Outl

et (to expansion tank)

Page 925 of 2490

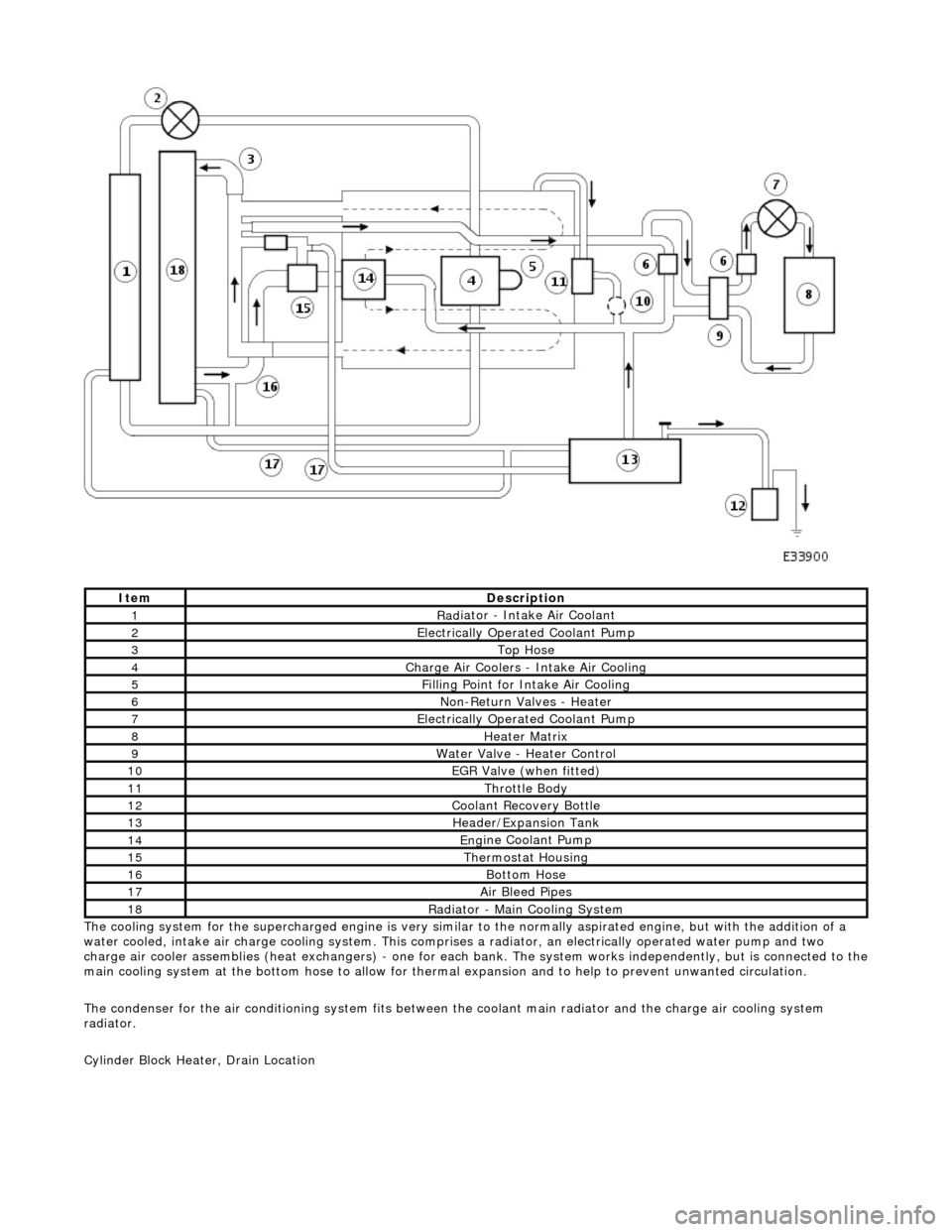

T

he cooling system for the supercharged engine is very similar

to the normally aspirated engine, but with the addition of a

water cooled, intake air charge cooling system. This comprises a radiator, an electrically operated water pump and two

charge air cooler assemblies (heat exchangers) - one for each bank. The system works independently, but is connected to the

main cooling system at the bottom hose to allow for therma l expansion and to help to prevent unwanted circulation.

The condenser for the air conditioning system fits between th e coolant main radiator and the charge air cooling system

radiator.

Cylinder Block Heater, Drain Location

ItemDe

scription

1Rad

iator - Intake Air Coolant

2Ele

ctrically Operated Coolant Pump

3Top Hose

4Charge Air Coo

lers -

Intake Air Cooling

5Fi

lling Point for Intake Air Cooling

6N

on-Return Valves - Heater

7Ele

ctrically Operated Coolant Pump

8Hea

ter Matrix

9Wate

r Valve - Heater Control

10EGR V

alve (when fitted)

11Thr

ottle Body

12Coolan

t Recovery Bottle

13H

eader/Expansion Tank

14Eng

ine Coolant Pump

15The

rmostat Housing

16Bottom

Hose

17Air Bleed

Pipes

18Rad

iator - Main Cooling System

Page 927 of 2490

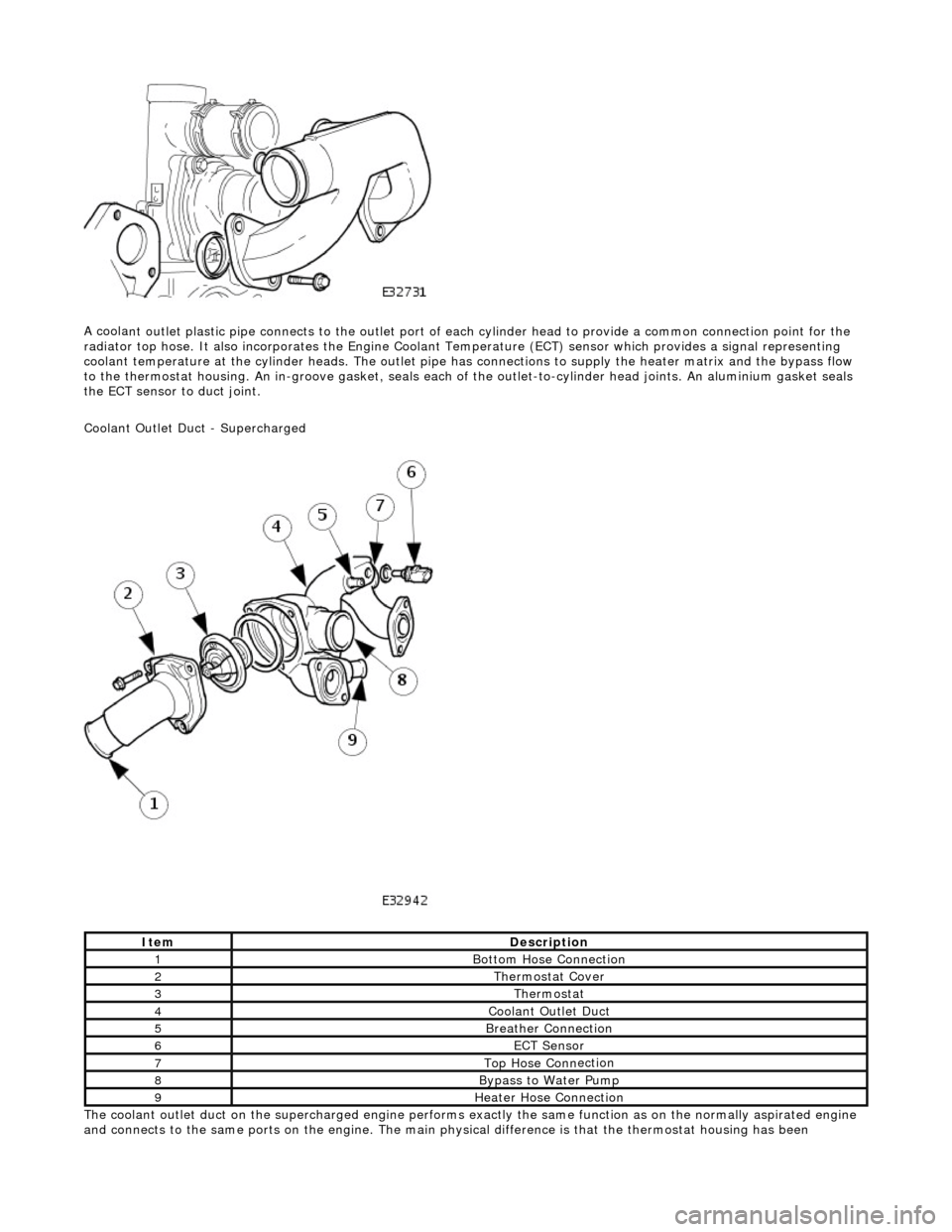

A coola

nt outlet plastic pipe connects to the outlet port of ea

ch cylinder head to provide a common connection point for the

radiator top hose. It also incorporates the Engine Coolant Te mperature (ECT) sensor which provides a signal representing

coolant temperature at the cylinder heads. The outlet pipe has connections to supply the heater matrix and the bypass flow

to the thermostat housing. An in-groove ga sket, seals each of the outlet-to-cylinder head joints. An aluminium gasket seals

the ECT sensor to duct joint.

Coolant Outlet Duct - Supercharged

The coolant outlet duct on the supercharged engine performs exactly the same function as on the normally aspirated engine

and connects to the same ports on the engine. The main physical difference is that the thermostat housing has been

ItemDe

scription

1Bottom

Hose Connection

2The

rmostat Cover

3The

rmostat

4Coolan

t Outlet Duct

5B

reather Connection

6ECT Se

nsor

7Top Hose Conn

ection

8Bypa

ss to Water Pump

9Hea

ter Hose Connection