sport mode JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 43 of 2490

Safety Standard

Canister PurgeCANPControls pu

rging of the EVAP canister

Carbon dioxideCO2Colorless gas with

a density of a

pproximately 1.5 ti mes that of air

Carbon mon

oxide

COPoi

sonous gas produced as the re

sult of incomplete combustion

Case G

round

CSE GNDControl modu

le casing ground

Catal

ytic converter

In

-line exhaust system device used to reduce the level of engine exhaust

emissions

Ce

lsius

CSI ter

m for the Centigrade scale, with

freezing point at zero and boiling point

at 100°

Central

Processor Unit

CPUTh

e section of a computer that contai

ns the arithmetic, logic and control

circuits. It performs arithm etic operations, controls instruction processing, and

provides timing signals and other housekeeping operations

Cl

osed Loop

CL

Cl

osed Loop System

CLSControl

system with one

or more feedback loops

Col

umn/Mirror Control

Module

C/MC

M

Control ModuleCMA

self-contained group of electrical/electronic components, designed as a

single replaceable un it, and controlling one or more processes

Controll

er Area Network

CANA

communication system which allows control modules to be linked together

in a network.

Crankshaft Posi

tion

Sensor

CKPSGenerates crankshaft positi on informa

tion in conjunct

ion with the CKPTR (also

generates speed information in certain applications)

Crankshaft Posi

tion

Timing Ring

CKPT

R

Toothe

d ring which

triggers the CKPS

Crankcase Ventila

tion

System

CVSys

tem which scavenges camshaft cover and crankcase emissions and feeds

them into the inlet manifold

Cubic ce nt

imeter

cm

3

Curb weightWe

ight of vehicle with fuel, lubrican

ts and coolant, but excluding driver,

passengers or payload

D

Dat

a Link Connector

DLCConne

ctor providing access and/or control of the vehicle information,

operating conditions, and diagnostic information

De

gree

deg, °Angle or tempe

rature

D

epartment of

Transportation (US)

DO

T

D

epartment of Transport

(UK)

DTp

De

utsche In

stitut für

Normung

DINGerman stand

ards regulation body

Di

agnostic Module

DMSuppl

emental Restraint System (non-c

ontrolling) module for diagnostics

overview

Di

agnostic Test Mode

DTMA le

vel of capability in an OBD system.

May include different functional states

to observe signals, a base level to re ad DTCs, a monitor level which includes

information on signal levels, bi-directional control with on /off board aids, and

the ability to interface with remote diagnosis

Diagnostic Trouble CodeDTCAn al

pha/numeric identifier for a fault

condition identified by the On-Board

Diagnostic (OBD) system

D

ial test indicator

DTIA mechan

ical measuring

instrument, with a rotary indicating pointer

connected to a linear operating probe

D

ifferential pressure

Pressure di

fference betwee

n two regions e.g. between intake manifold and

atmospheric pressures

D

ifferential Pressure

Feedback EGR

DP

FE

An

EGR system that monito

rs differential EGR pressure across a remote orifice

to control EGR flow

D

irect current

dcCurrent which f

lows in on

e direction only, though it may have appreciable

pulsations in its magnitude

Du

al linear switch

DLSJ

-gate switch connected to the TCM on SC vehicles

E

EGR

Temperature EGRT

Sensor

EGRTSens

ing EGR function based on temperature change

EGR Vacu

um Regulator

EVRControls EGR

flow by changi

ng vacuum to the EGR valve

EGR Valve

Position

EVPAn EGR

system that direct

ly monitors EGR valve position to control EGR flow

Electrically E

rasable

Programmable Read-Only

Memory

EEP

ROM

Page 167 of 2490

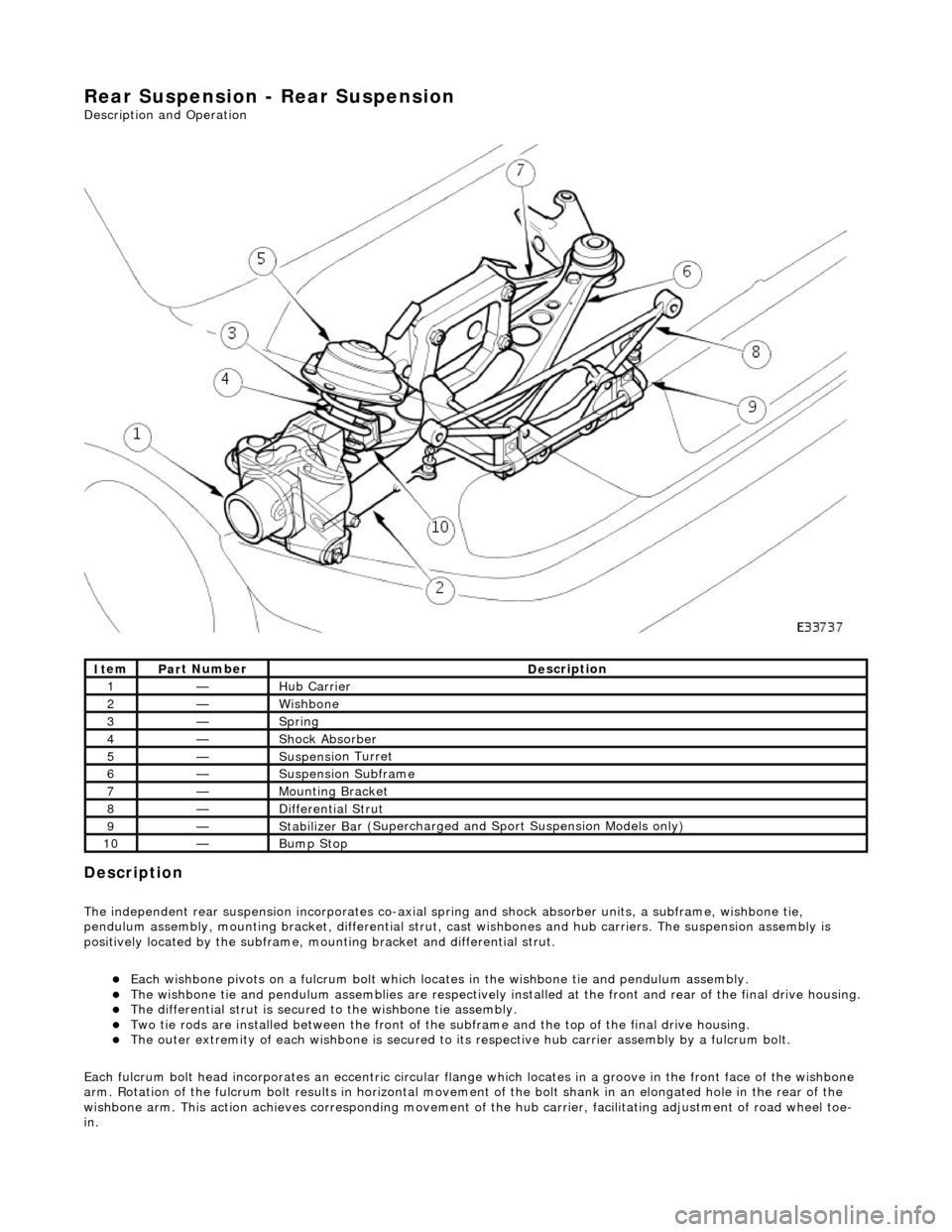

Rear

Suspension - Rear Suspension

Description an

d Operation

Description

The i

ndependent rear suspension incorporates co-axial sp

ring and shock absorber units, a subframe, wishbone tie,

pendulum assembly, mounting brac ket, differential strut, cast wishbones and hub carriers. The suspension assembly is

positively located by the subframe, mounting bracket and differential strut.

Each wi

shbone pivots on a fulcru

m bolt which locates in the wishbone tie and pendulum assembly.

The wish

bone tie and pendulum assemblies are respectively in

stalled at the front and rear of the final drive housing.

The differential

strut is secured to the wishbone tie assembly.

Two ti

e rods are installed between the front of the

subframe and the top of the final drive housing.

The ou

ter extremity of each wishbone

is secured to its respective hub carrier assembly by a fulcrum bolt.

Each fulcrum bolt head incorporates an ec centric circular flange which locates in a groove in the front face of the wishbone

arm. Rotation of the fulcrum bolt results in horizontal movement of the bolt shank in an elongated hole in the rear of the

wishbone arm. This acti on achieves corresponding movement of the hub carrier, facilita ting adjustment of road wheel toe-

in.

It

em

Par

t Number

De

scription

1—Hub Carrier

2—Wi

shbone

3—Sprin

g

4—Shock Absorber

5—Suspensi

on Turret

6—Suspensi

on Subframe

7—Moun

ting Bracket

8—D

ifferential Strut

9—Stabilizer Ba

r (Supercharged and

Sport Suspension Models only)

10—Bum

p Stop

Page 168 of 2490

Each r

oad spring and is located between the wishbone in

tegral spring seat and the body suspension turret.

Each shoc

k absorber unit is installed

co-axially within the road spring.

The lo

wer end of each shock absorber is secured to the

wishbone by a bolt which also functions as a pivot.

Adaptive damping is av

ailable as an option.

A

rear stabi

lizer bar is installed on

Supercharged and Sport Suspension models . Mounted at the rear of the wishbone

tie assembly, the stabilizer bar is connected to the wishbone by short links.

Op era

tion

As each road wheel r

i

ses, move

ment is transmitted through th e hub carrier assembly to the wishbone and axle shaft. The

corresponding rise of the wishbone compre sses the road spring and partially telescopes the shock absorber. During this

action, the spring absorbs result ing shocks and the shock absorber minimizes spring oscillation.

During cornering, vehicle weight is transferred to the outer road wheel with a resulting tendency for the inner wheel to lift.

On Supercharged and Sport Suspension vehicl es, a rear stabilizer bar assists in minimizing this tendency by transferring a

proportion of potential lift of the inner wheel to the outer wheel. This results in enhanced body stability with improved

cornering capabilities.

Page 1271 of 2490

Controller Area Network (CAN)

The TCM is an integral part of the CAN system which facilitates the interchange of real-time data between control modules

and sensors. Please see section 303- 14 for a full description of CAN.

OBDII Interface

Data concerning OBDII related transmission failures is stored in the ECM for access via the J1962 socket.

System Functions

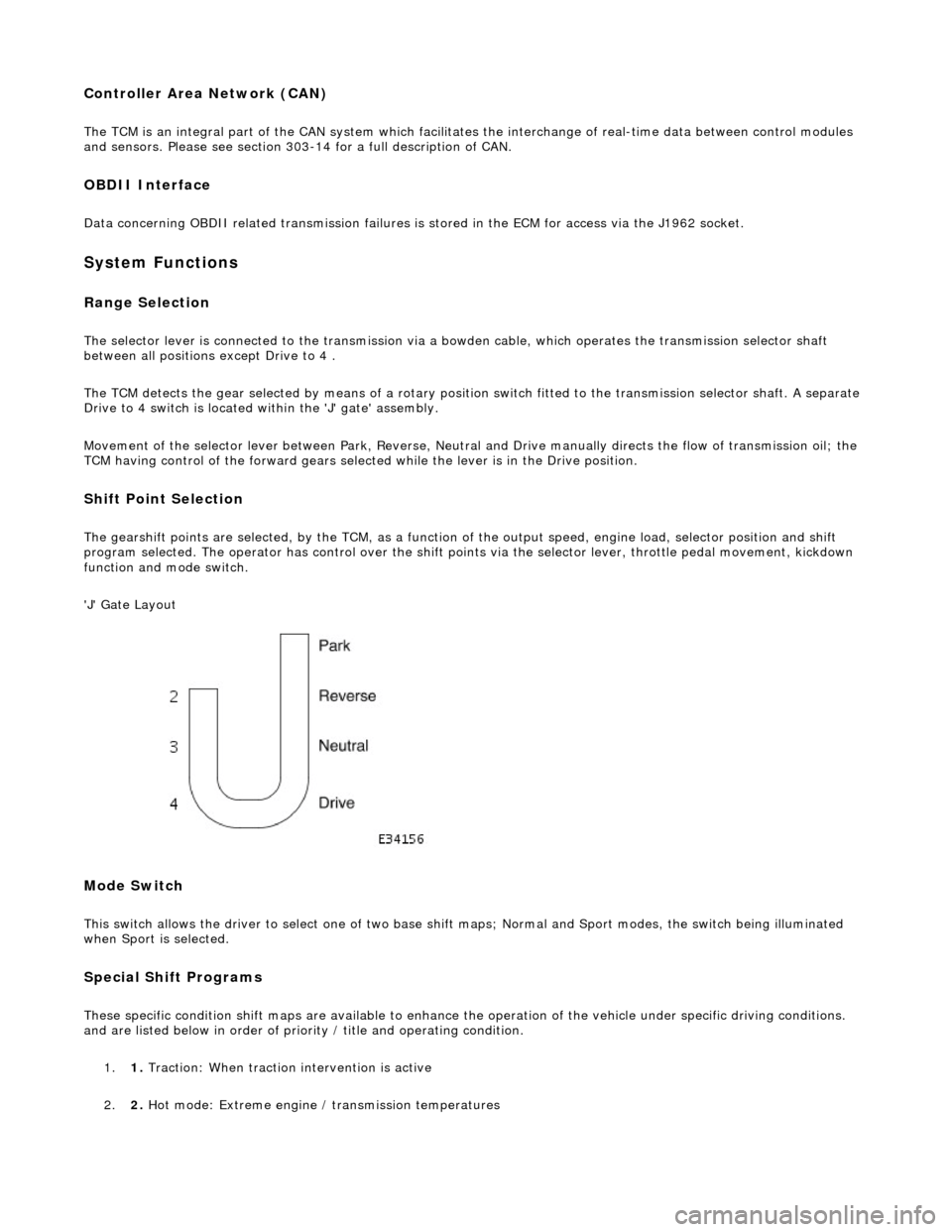

Range Selection

The selector lever is connected to the transmission via a bowden cable, which operates the transmission selector shaft

between all positions except Drive to 4 .

The TCM detects the gear selected by means of a rotary position switch fitted to the transmission selector shaft. A separate

Drive to 4 switch is located within the 'J' gate' assembly.

Movement of the selector lever between Park, Reverse, Neutral and Drive manually directs th e flow of transmission oil; the

TCM having control of the forward gears selected while the lever is in the Drive position.

Shift Point Selection

The gearshift points are selected, by the TCM, as a function of the output speed, engine load, selector position and shift

program selected. The operator has control over the shift points via the selector lever, throttle pedal movement, kickdown

function and mode switch.

'J' Gate Layout

Mode Switch

This switch allows the driver to select one of two base shift maps; Normal and Sport modes, the switch being illuminated

when Sport is selected.

Special Shift Programs

These specific condition shift maps are available to enhance the operation of the vehicle under specific driving conditions.

and are listed below in order of priority / title and operating condition.

1. 1. Traction: When traction intervention is active

2. 2. Hot mode: Extreme engine / transmission temperatures

Page 1272 of 2490

3.3. Gradient: Under specific speeds and loads

4. 4. Cruise: During cruise control

5. 5. Manual: Shift map when the LH side of the 'J gate' is used

Three specific condition shift maps have a higher priority than the two base shift maps and will intervene when appropriate

conditions prevail for traction, gradient or cruise.

When traction control (engine or brake system derived) is operational the TCM will implement the traction map to maximise

control of wheel slip.

The gradient maps are intended to enhance vehicle drivability when towing or climbing a gradient. The TCM will implement

the maps when increased driving resistan ce is detected and enhanced drivability, cooling and increa sed performance is

appropriate.

The cruise map is intended to minimize unwanted gearshifts and 'hunting' and is activated when cruising near to the set

speed, or resuming.

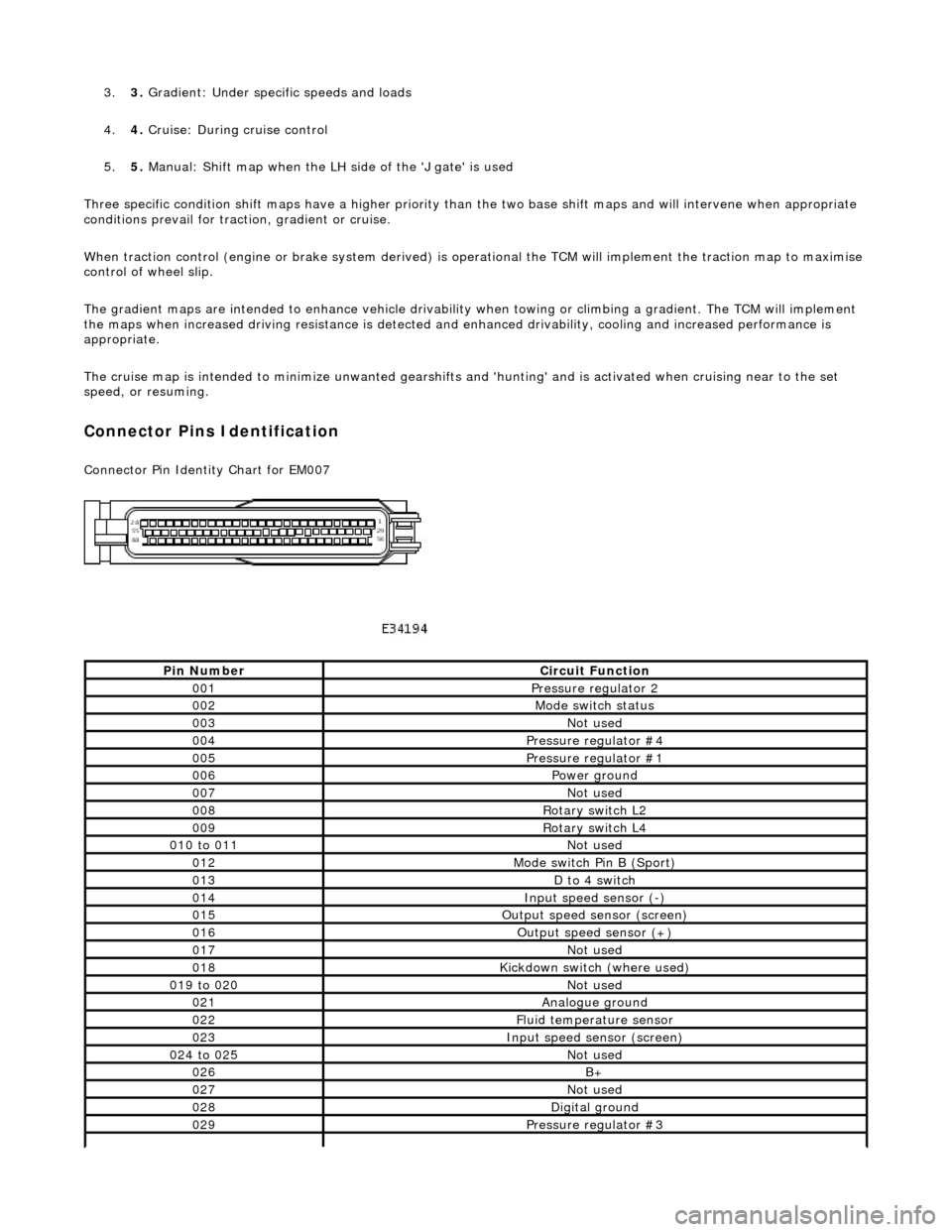

Connector Pins Identification

Connector Pin Identity Chart for EM007

Pin NumberCircuit Function

001Pressure regulator 2

002Mode switch status

003Not used

004Pressure regulator #4

005Pressure regulator #1

006Power ground

007Not used

008Rotary switch L2

009Rotary switch L4

010 to 011Not used

012Mode switch Pin B (Sport)

013D to 4 switch

014Input speed sensor (-)

015Output speed sensor (screen)

016Output speed sensor (+)

017Not used

018Kickdown switch (where used)

019 to 020Not used

021Analogue ground

022Fluid temperature sensor

023Input speed sensor (screen)

024 to 025Not used

026B+

027Not used

028Digital ground

029Pressure regulator #3

Page 1275 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Diagnostic Strategy

Diagnosis and Testing

Quick Reference Fault Chart

Quick Reference Fault Chart

Special Tool(s)

Digital multimeter

Generic scantool

SymptomPossible SourcesAction

Normal transmission

operation but fault codes

stored• NOTE: If P0706 is logged ignore P0742

Output speed sensor circuit fault

TCM faulty

ABS system fault (this code may log er roneously following an ABS problem)

Position switch and D to 4 switch circuit fault

P R 4 circuit fault

*

*

*

*

*

GO to

P0721 GO to

P1603 GO to

P0742

*

*

*

Sport mode will not selectMode switch circuit fault

*GO to

P0790

*

Mode switch state lamp not

workingMode switch supply

Mode switch circuit fault

*

*GO to

P0790

*

Poor, or reduced shift

qualityPresence of EMS faults

(may affect the accuracy of the torque signal)

*GO to EMS *

Transmission temperature sensor circuit

*GO to

P0710

*

Out of sequence shiftOutput / input speed sensor circuit fault

Mechanical fault (check all other operations)

*

*GO to

P1731

*

No torque converter lock-

upP R 4 circuit fault

*GO to

P0743

*

Mechanical fault, should P R 4 be OK

*GO to

P0741

*

Harsh shifts, engine stalling (torque converter stuck on)P R 4 circuit fault

Mechanical fault, should P R 4 be OK

*

*GO to

P0742

*

Default to 4th gearSolenoid / pressure regulator supply from TCM

*GO to

P0702

*

• NOTE: If the code logs wh

en 3rd is selected, then the D to 4 switch is the most probable cause If the code logs when D is selected fro m the LH side of the gate,

then check selector cable adjustment

'J gate' or selector ca ble out of adjustment

D to 4th switch

Rotary position switch circuit

*

*

*GO to

P0706

*

Input speed sensor circuit fault

Input speed sensor faulty

*

*GO to

P0715

*

Solenoid #1 circuit fault

*GO to

P0753

*

Solenoid #2 circuit fault

*GO to

*

Page 1388 of 2490

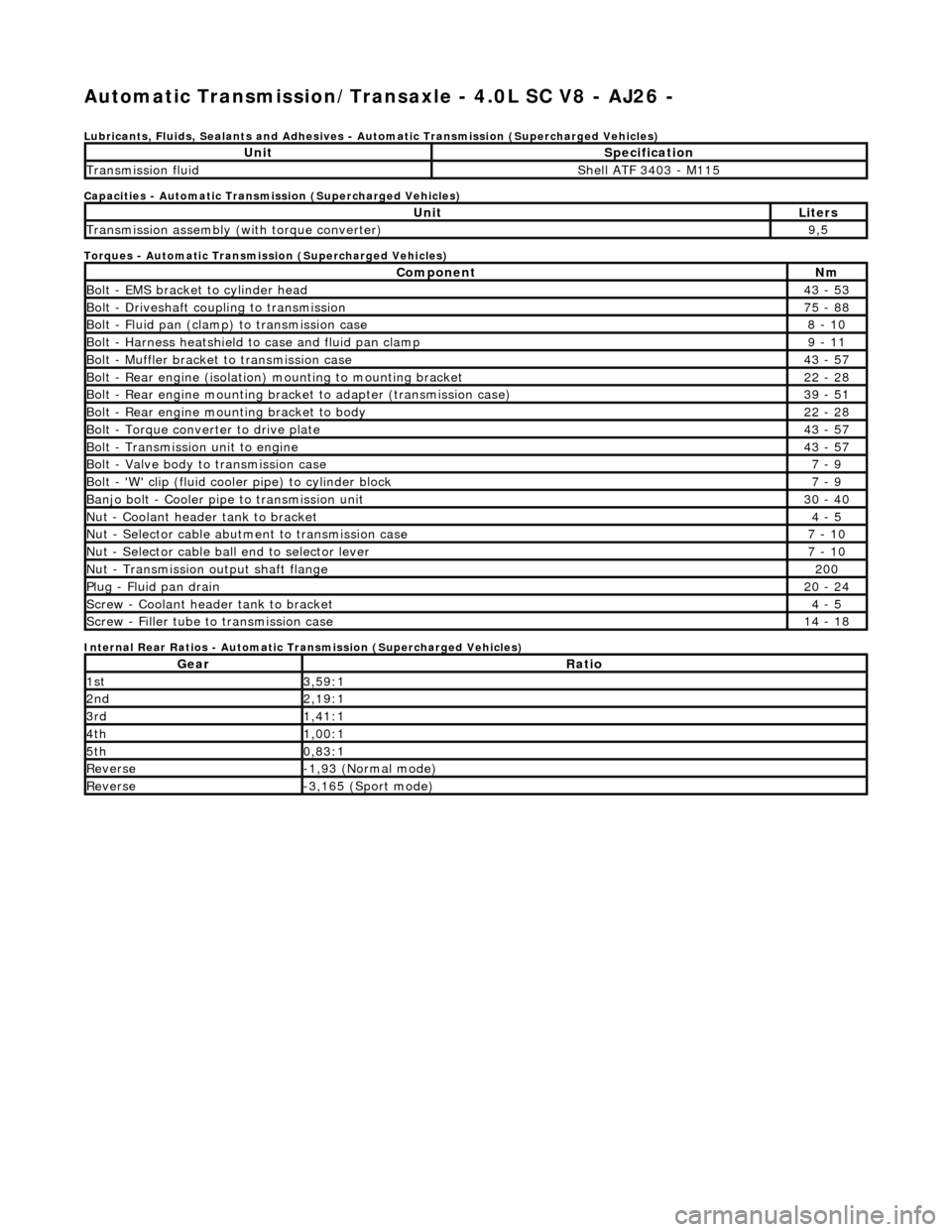

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 -

Lubricants, Fluids, Sealants and Adhesives - Automatic Transmission (Supercharged Vehicles)

Capacities - Automatic Transmission (Supercharged Vehicles)

Torques - Automatic Transmission (Supercharged Vehicles)

Internal Rear Ratios - Automatic Transmission (Supercharged Vehicles)

UnitSpecification

Transmission fluidShell ATF 3403 - M115

UnitLiters

Transmission assembly (with torque converter)9,5

ComponentNm

Bolt - EMS bracket to cylinder head43 - 53

Bolt - Driveshaft coupling to transmission75 - 88

Bolt - Fluid pan (clamp) to transmission case8 - 10

Bolt - Harness heatshield to case and fluid pan clamp9 - 11

Bolt - Muffler bracket to transmission case43 - 57

Bolt - Rear engine (isolation) mounting to mounting bracket22 - 28

Bolt - Rear engine mounting brac ket to adapter (transmission case)39 - 51

Bolt - Rear engine mounting bracket to body22 - 28

Bolt - Torque converter to drive plate43 - 57

Bolt - Transmission unit to engine43 - 57

Bolt - Valve body to transmission case7 - 9

Bolt - 'W' clip (fluid cooler pipe) to cylinder block7 - 9

Banjo bolt - Cooler pipe to transmission unit30 - 40

Nut - Coolant header tank to bracket4 - 5

Nut - Selector cable abutment to transmission case7 - 10

Nut - Selector cable ball end to selector lever7 - 10

Nut - Transmission output shaft flange200

Plug - Fluid pan drain20 - 24

Screw - Coolant header tank to bracket4 - 5

Screw - Filler tube to transmission case14 - 18

GearRatio

1st3,59:1

2nd2,19:1

3rd1,41:1

4th1,00:1

5th0,83:1

Reverse-1,93 (Normal mode)

Reverse-3,165 (Sport mode)

Page 1394 of 2490

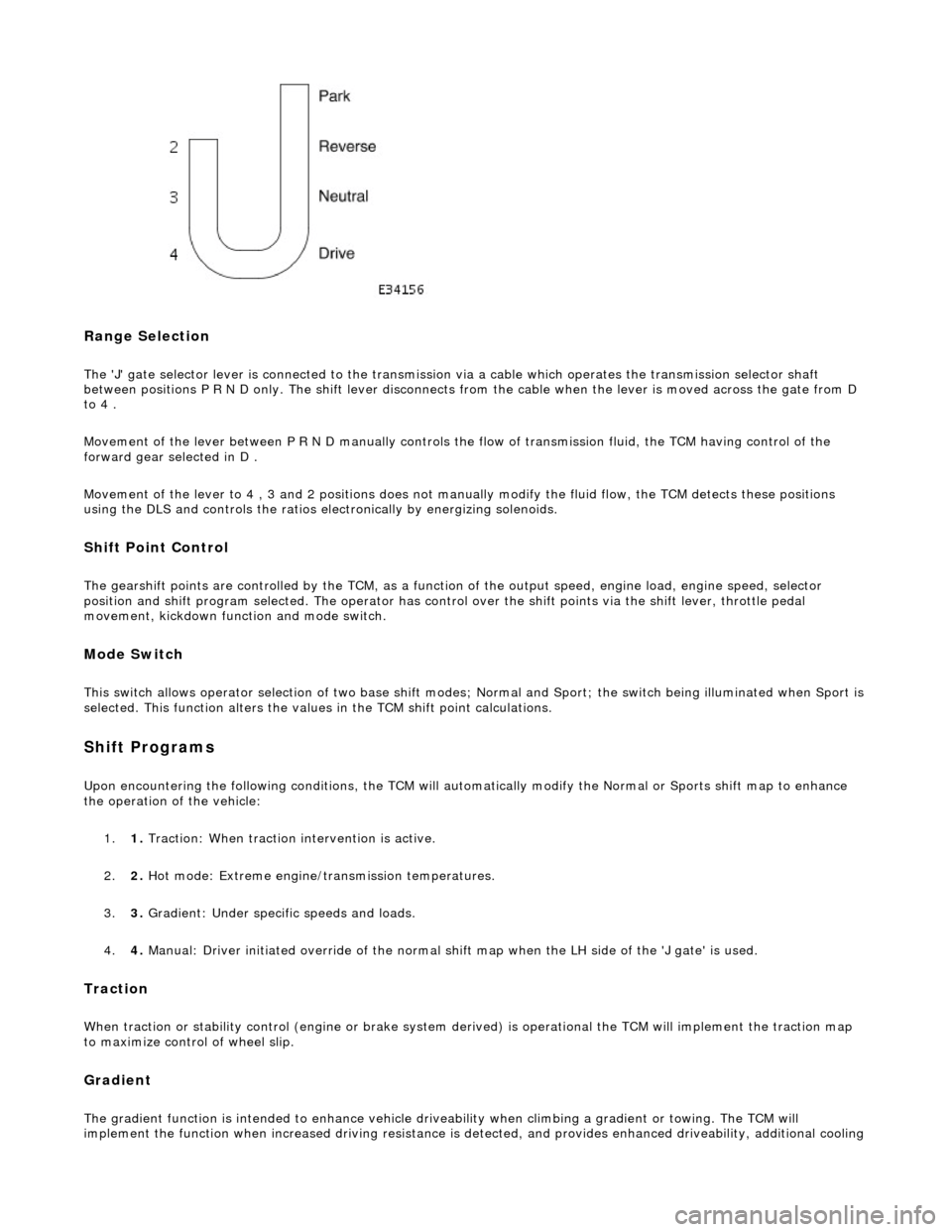

Range Selection

The 'J' gate selector lever is connected to the transmission via a cable which operates the transmission selector shaft

between positions P R N D only. The shift lever disconnects from the cable when the lever is moved across the gate from D

to 4 .

Movement of the lever between P R N D manu ally controls the flow of transmission fluid, the TCM having control of the

forward gear selected in D .

Movement of the lever to 4 , 3 and 2 positions does not manu ally modify the fluid flow, the TCM detects these positions

using the DLS and controls the ratios electronically by energizing solenoids.

Shift Point Control

The gearshift points are controlled by the TCM, as a function of the output speed, engine load, engine speed, selector

position and shift program selected. The operator has control over the shift points via the shift lever, throttle pedal

movement, kickdown function and mode switch.

Mode Switch

This switch allows operator selection of two base shift modes; Normal and Sport; th e switch being illuminated when Sport is

selected. This function alters the values in the TCM shift point calculations.

Shift Programs

Upon encountering the following conditions, the TCM will auto matically modify the Normal or Sports shift map to enhance

the operation of the vehicle:

1. 1. Traction: When traction intervention is active.

2. 2. Hot mode: Extreme engine/transmission temperatures.

3. 3. Gradient: Under specific speeds and loads.

4. 4. Manual: Driver initiated override of the normal shif t map when the LH side of the 'J gate' is used.

Traction

When traction or stability control (engine or brake system de rived) is operational the TCM will implement the traction map

to maximize control of wheel slip.

Gradient

The gradient function is intended to enhance vehicle drivea bility when climbing a gradient or towing. The TCM will

implement the function when increased driving resistance is de tected, and provides enhanced driveability, additional cooling

Page 1465 of 2490

The Drive-to-fourth switch:

Detects when the gear selector lever is moved from Drive to Fourth. Is hard-wired to the transmission control module.

The Neutral position switch:

Is hard-wired to the body processor module. Detects when the gear selector lever is moved to the Neutral position.

The Park position switch:

Is hard-wired to the body processor module. Detects when the gear selector leve r is moved to the Park position.

The gear selector module:

Provides illumination of the gear sele ctor surround, which is dimmable via a CA N signal from the instrument cluster. Provides red illumination, on the gear selector surround, of the gear selected, by CAN signals from the instrument

cluster.

Illuminates the security system Active LED on the gear se lector surround, in response to an input from the body

processor module.

Is connected to the fascia harness via a 12-way connector. Refer to Connec tor Pins Identification, 307-01A.

The gear selector interlock solenoid:

Prevents the gear selector lever from be ing moved from the Park position, unless th e ignition switch is in position II,

and the brake pedal is depressed.

Is controlled by an input from the body processor module.

The seven gear selector positions are:

P : The transmission is mechanically locked (starting available). R : Reverse gear. N : No power to the rear wh eels (starting available). D : All 5 forward gears available. 4 : Upshift to 4th gear only. 3 : Upshift to 3rd gear only. 2 : Upshift to 2nd gear only.

Performance Mode Pushbutton

The performance mode pushbutton:

Is mounted on the gear selector surround. Selects Normal or Sport mode when pressed by the driver. Is illuminated when Sport mode is selected.

Page 1502 of 2490

The performance mode pushbutton:

Is mounted on the 'J' gate surround. This 'push-on push-off' swit ch selects Normal or Sport mode ( push-on for Sport) Is illuminated when Sport mode is selected. Is hard-wired to the transmission control module.

With 'Normal' selected the transmissi on will start off in 2 nd gear with kickdown to 1 st being available.

'Sport' mode allows 1 st gear en gagement from rest and modifies values in the TCM shift point calculations to provide higher

upshift speeds and enhanced availability of downshifts.

Kickdown Switch

The kickdown switch:

Is floor mounted under th e accelerator pedal. Is operated by pressing the pedal beyond the full throttle position. Provides maximum acceleration on driver demand, by signalling the TCM to select the lowest gear to give maximum

wheel torque.

Gear selector interlock solenoid:

Prevents the gear selector lever from being moved from P , unless the ignition switch is in position II, and the brake

pedal is depressed.

Is controlled by an output from the BPM

Park position switch:

Is hard-wired to the BPM Detects when the gear selector lever is moved to the Park position