toe in JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2 of 2490

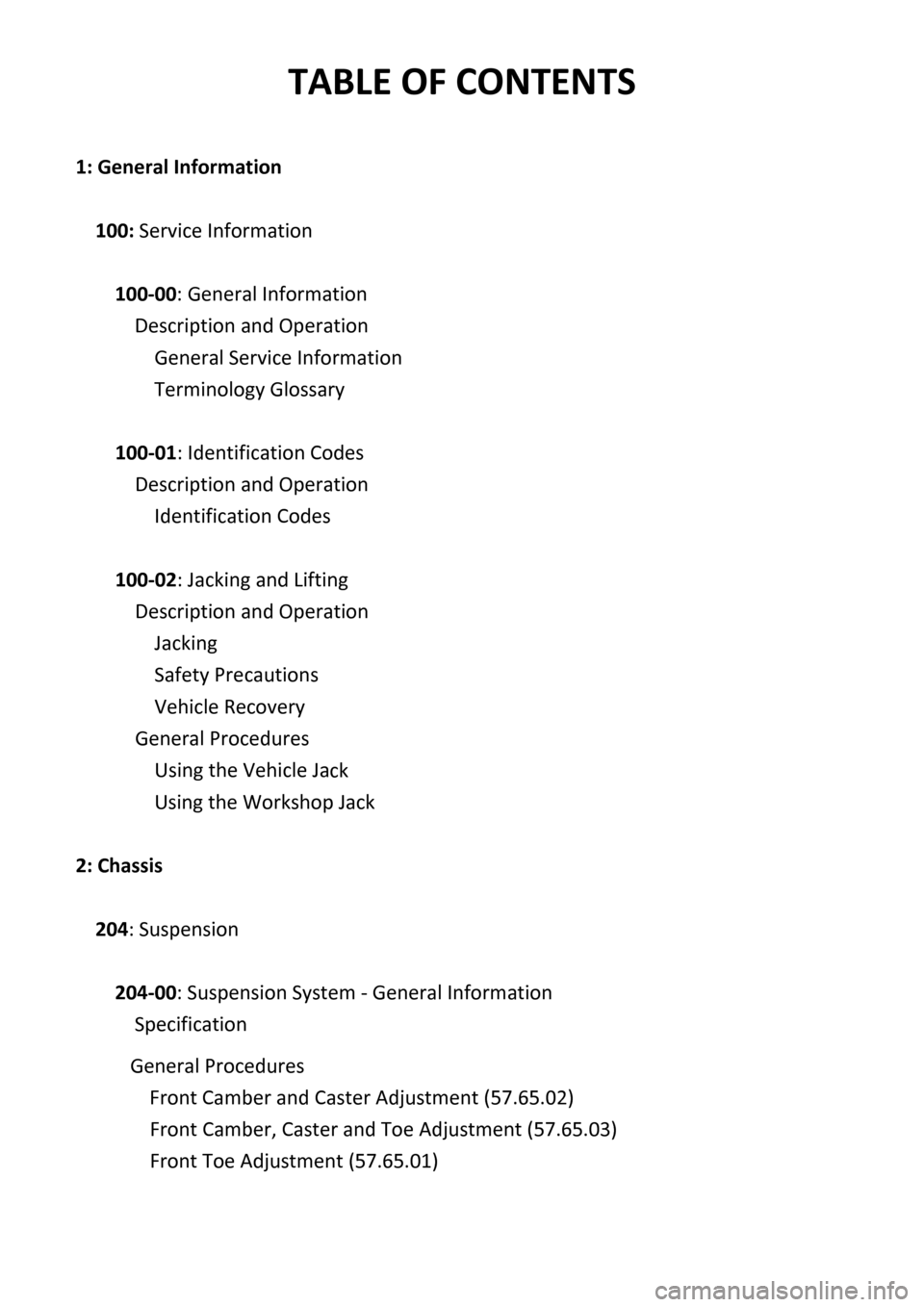

TABLE OF CONTENTS

1: General Information

100:

Service Information

100‐00: General Information

Description and Operation

General Service Information

Terminology Glossary

100‐01: Identification Codes

Description and Operation

Identification Codes

100‐02: Jacking and Lifting

Description and Operation

Jacking

Safety Precautions

Vehicle Recovery

General Procedures

Using the Vehicle Ja

ck

Using the Workshop Jack

2: Chassis

204: Suspension

204‐00: Suspension System ‐ General Information

Specification

General

Procedures

Front

Camber and Caster Adjustment (57.65.02)

Front

Camber, Caster and Toe Adjustment (57.65.03)

Front

Toe Adjustment (57.65.01)

Page 3 of 2490

Rear Toe Adjustment (57.65. 08)

Whee

l

Bearing Circlip Inspection

Wheel Bearing Inspection

204‐01: Front Suspension

Specification

Description and Operation

Front Suspension

Removal and Installation

Ball Joint (60.15.02)

Rear Lower Arm (60.35.54)

Rear Lower Arm Bushing (60.35.56)

Front Shock Absorber (60.30.04)

Spring

Spring Seat (60.20.03)

Front Sta

bilizer Bar (60.10.01)

Front Stabilizer Bar Bushing (60.10.04)

Front Stabilizer Bar Link (60.10.02)

Upper Arm Bushing

Front Wheel Bearing (60.25.40)

Wheel Hub

Wheel Knuckle (60.25.23)

Wheel Knuckle and Wheel Hub Assembly (60.25.38.90)

Wheel Knuckle and Wheel Hub Assembly Conversion (60.25.43)

204‐02: Rear Suspension

Specif

ication

Description and Operation

Rear Suspension

Removal and Installation

Axle Bump Stop (64.30.15)

Rear Suspension and Axle Assembly (64.25.01)

Rear Shock Absorber (64.30.02)

Shock Absorber Lower Bushing (64.30.39)

Spring (64.20.01)

Rear Stabilizer Bar (64.35.08) ‐ 4.0L SC V8 ‐ AJ26

Rear Stabilizer Bar Bushing (64.35.18) ‐ 4.0L SC V8 ‐ AJ26

Page 59 of 2490

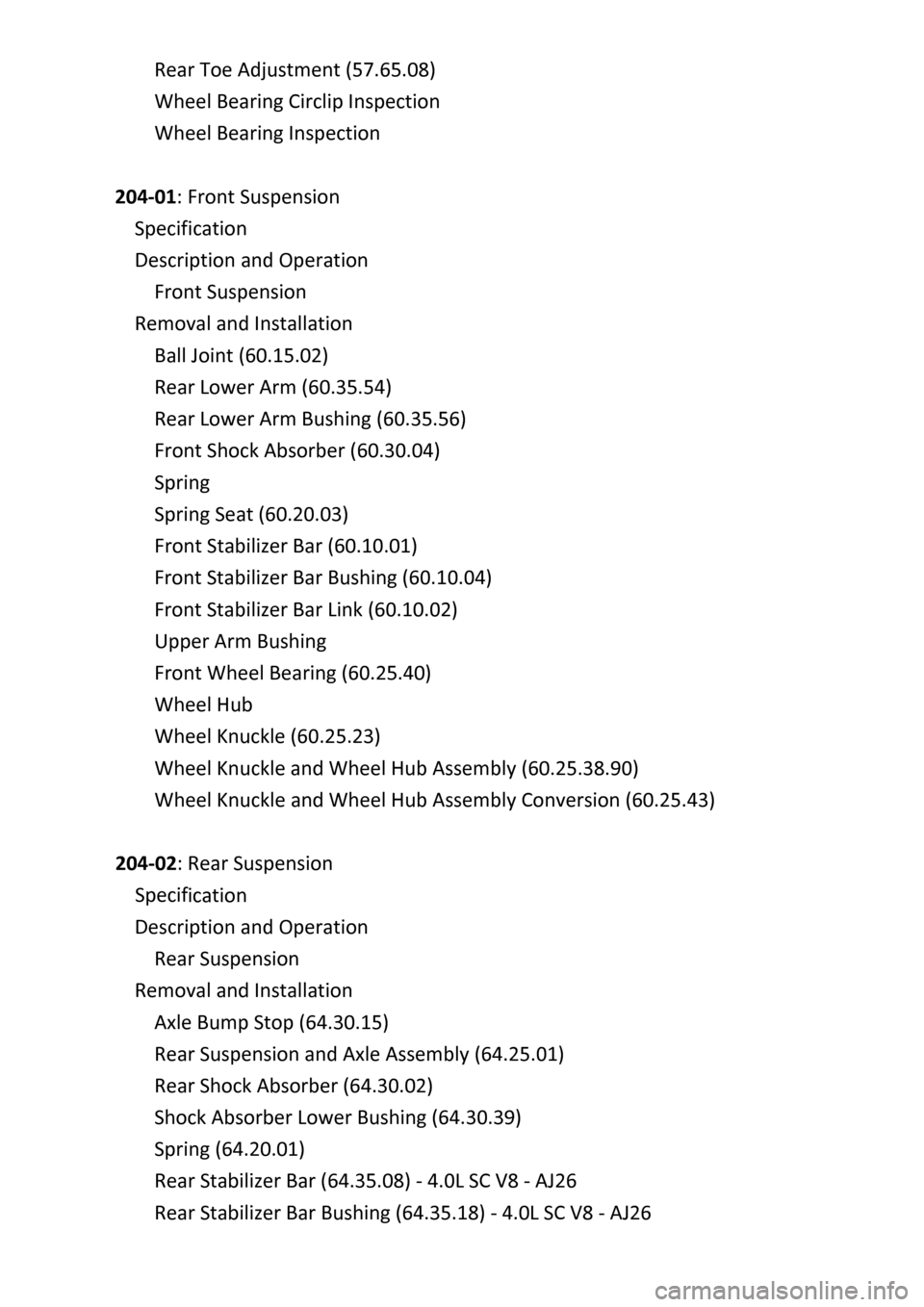

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Castor - XJR Excluding NAS, and German Super-8

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Castor - XJR NAS, and Comfort/Sport/Daimler Super-8

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Toe - XJR Excluding NAS, and German Super-8

Al

l the above figures

are at "showroom" height. (See ride height section above).

Ti

res must be inflated

to normal pressure.

For additional informat ion, refer to Section 204

-0

4 Wheels and Tires

.

Whe

el Alignment - Front Toe - XJR NAS, and Comfort/Sport/Daimler Super-8

XJR

Excluding NAS, and German Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Castor

Le

ft - Hand

Rig

ht - Hand

Bal

ance (RH - LH)

MinMaxMinMaxMinMax

All Right

-Hand drive and Japan

De

grees/minutes

+4

° 00'

+8

° 00'

+4

° 00'

+8

° 00'

-1

° 12'

+1

° 12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

R

est of World

De

grees/minutes

+4

° 00'

+8

° 00'

+4

° 00'

+8

° 00'

-1

° 12'

+1

° 12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

XJR

NAS, and Comfort/Sport/Daimler Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Castor

Le

ft - Hand

Rig

ht - Hand

Bal

ance (RH -

LH)

MinMaxMinMaxMinMax

All Right

-Hand drive and Japan

De

grees/minutes

+4

°

00'

+8

°

00'

+4

°

00'

+8

°

00'

-1

°

12'

+1

°

12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

USA, Canada an

d Mexico, Dominican

Republic (NAS)

De

grees/minutes

+4

°

00'

+8

°

00'

+4

°

00'

+8

°

00'

-1

°

12'

+1

°

12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

R

est of World

De

grees/minutes

+4

°

00'

+8

°

00'

+4

°

00'

+8

°

00'

-1

°

12'

+1

°

12'

Decimal degrees+4

.00°

+8

.00°

+4

.00°

+8

.00°

-1.

20°

+1

.20°

XJR

Excluding NAS, and German Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Fr

ont Toe

To

tal Toe

MinMax

All Right-Hand driv

e and Japan

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

R

est of World

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

XJR

NAS, and Comfort/Sport/Daimler Super-8

1

998 to 2003.5

VIN - 812317 to F59525

Units

Fr

ont Toe

To

tal Toe

MinMax

All Right-Hand driv

e and Japan

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

USA, Canada an

d Mexico

, Dominican Repulic (NAS)

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

R

est of World

De

grees/minutes

0

° 05'

+0

° 25'

Decimal degrees0.

08°

+0

.42°

Page 60 of 2490

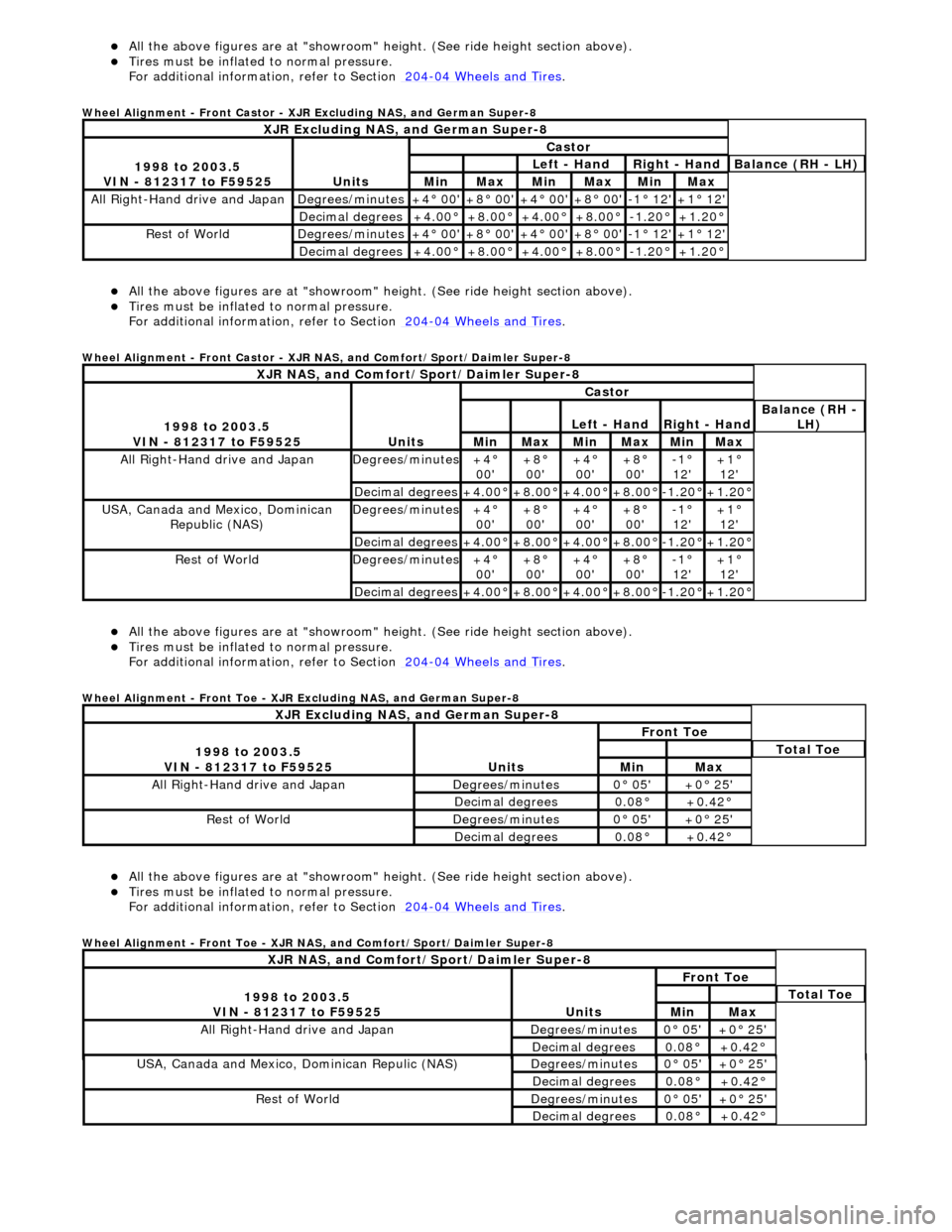

All the above fi

gures

are at "showroom" height. (See ride height section above).

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

Wh

eel Alignment - Rear Camber

All the above figu res

are at "s

howroom" height. See vehicle ride height section above.

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

W

h

eel Alignment - Rear Toe

All the above figu res

are at "s

howroom" height. See vehicle ride height section above.

Tires must be infl

ated

to normal pressure.

For additional informat ion, refer to Section 204

-04

Wheels and Tires

.

1 998 to

2003.5

VIN - 812317 to F59525

Units

Cambe r

Left

Hand

Rig

h

t Hand

Bal

a

nce (RH - LH)

Min MaxMin MaxMinMax

All MarketsDe

grees

/Minutes

-

1

° 12'

-0

° 06'-1° 12'-0

° 06'

-1

°

00

+1

°

00

De

ci

mal Degrees

-1.

2

0°

-0

.1

0°

-1.

2

0°

-0.

1

0°

-1.

0

0°

+1

.00

°

1

998 to

2003.5

VIN - 812317 to F59525

Units

To e

Left

Hand

Rig

h

t Hand

To

t

al Toe

Thr

u

st Angle

MinMaxMinMaxMin MaxMin Max

All MarketsDe

grees

/Minutes

+0

°

05'

+0

° 15'+0°

05'

+0

° 15'0°

10'

+0

° 30'-0° 05'+0 °

05'

De

ci

mal Degrees

+0

.08

°

+0

.25

°

+0

.08

°

+0

.25

°

0.

17

°

+0

.50

°

-0.

0

8°

+0

.08

°

Page 62 of 2490

Suspension System - General Information - Front Camber

, Caster and Toe

Adjustment

Gen e

ral Procedures

1.

NOTE: Before checking or adju sting any alignment, examine

the vehicle for curb impact dama ge on wheels and subsequent

damage to steering and suspension components.

• NOTE: Wheel alignment must no t be carried out with a space

saver wheel installed on any of the hubs.

• NOTE: Before carrying out any ch ecking or adjustment of wheel

alignment, ensure that the vehicl e wheels, tires and tire pressures

are to Jaguar specification.

• NOTE: Position steering wheel in straight ahead position before

adjusting front wheel toe evenly on both tie rods to maintain

centralization of steering wheel.

Position alignment checking equipment on vehicle and following

equipment manufacturer's instructions, check and if necessary

adjust to Specifications in Section 204-01.

2. Check and as necessary adjust front wheel caster. Refer to

57.65.05.

3. Check and as necessary adjust front wheel camber. Refer to

57.65.06.

4. Check and as necessary adjust fr ont wheel alignment. Refer to

57.65.01.

Page 63 of 2490

Suspension System - General Infor

mation - Front Toe Adjustment

Gen

eral Procedures

1.

NOTE: Before checking or adju sting front wheel alignment,

examine the vehicle for curb impact damage on wheels and

subsequent damage to steering and suspension components.

• NOTE: Wheel alignment must no t be carried out with a space

saver wheel installed on any of the hubs.

• NOTE: Before carrying out any ch ecking or adjustment of wheel

alignment, ensure that the vehicl e wheels, tires and tire pressures

are to Jaguar specification.

• NOTE: Position steering wheel in straight ahead position before

adjusting front wheel toe evenly on both tie rods to maintain

centralization of steering wheel.

Position alignment checking equipment on road wheels and

following equipment manufacturer's instructions, check and if

necessary adjust front wheel toe to Specifications in Section

204-01.

Page 64 of 2490

Suspension System - General Inform

ation - Rear Toe Adjustment

Gen

e

ral Procedures

1.

NOTE: Wheel alignment must not be carried out with a space

saver wheel installed on any of the hubs.

• NOTE: Before carrying out any ch ecking or adjustment of wheel

alignment, ensure that the vehicl e wheels, tires and tire pressures

are to Jaguar specification.

• NOTE: Before checking or ad justing rear wheel alignment,

examine the vehicle for curb impact damage on wheels and

subsequent damage to suspension components.

Position alignment checking equipment on road wheels and

following equipment manufacturer's instructions, check and if

necessary adjust rear wheel alignment to Specifications in

Section 204-02.

Page 167 of 2490

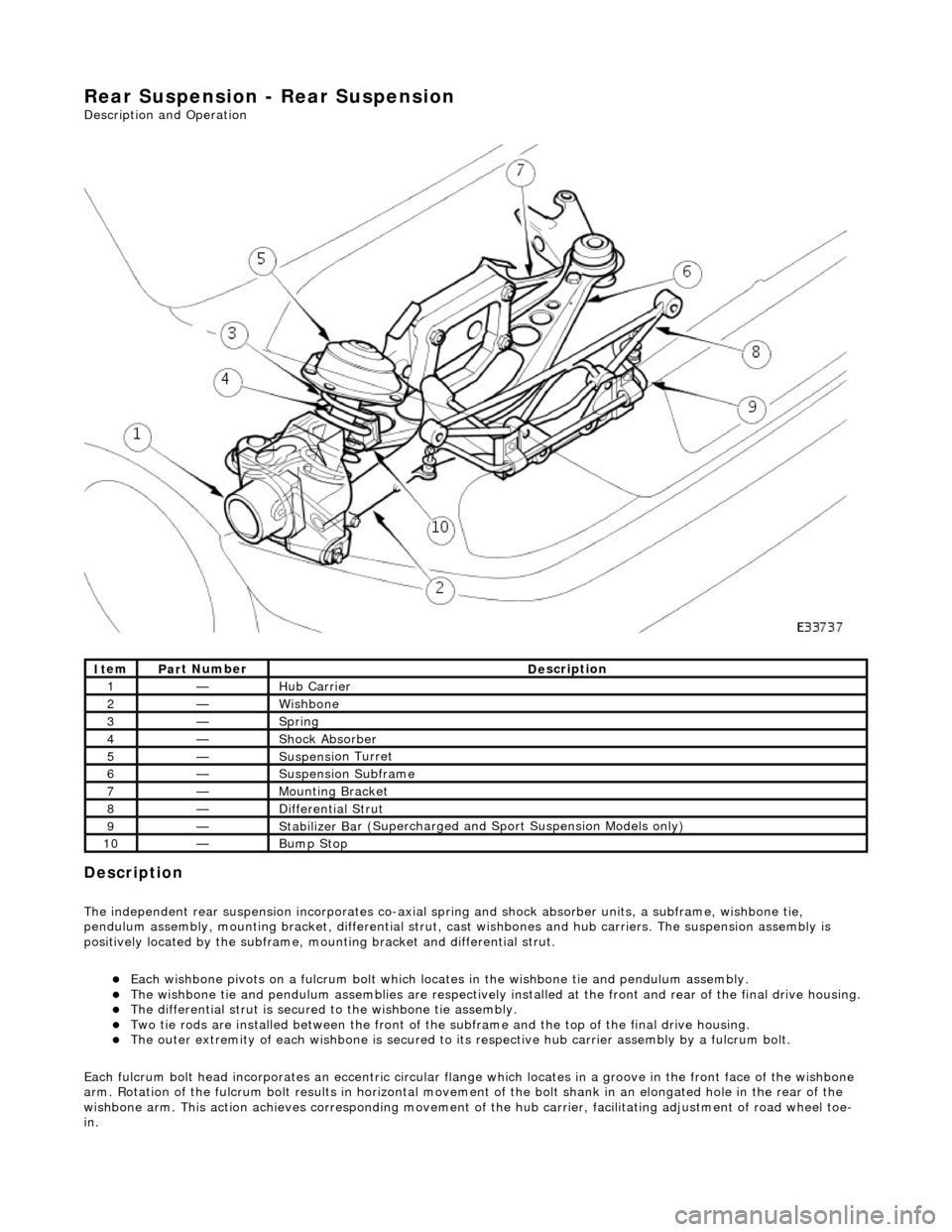

Rear

Suspension - Rear Suspension

Description an

d Operation

Description

The i

ndependent rear suspension incorporates co-axial sp

ring and shock absorber units, a subframe, wishbone tie,

pendulum assembly, mounting brac ket, differential strut, cast wishbones and hub carriers. The suspension assembly is

positively located by the subframe, mounting bracket and differential strut.

Each wi

shbone pivots on a fulcru

m bolt which locates in the wishbone tie and pendulum assembly.

The wish

bone tie and pendulum assemblies are respectively in

stalled at the front and rear of the final drive housing.

The differential

strut is secured to the wishbone tie assembly.

Two ti

e rods are installed between the front of the

subframe and the top of the final drive housing.

The ou

ter extremity of each wishbone

is secured to its respective hub carrier assembly by a fulcrum bolt.

Each fulcrum bolt head incorporates an ec centric circular flange which locates in a groove in the front face of the wishbone

arm. Rotation of the fulcrum bolt results in horizontal movement of the bolt shank in an elongated hole in the rear of the

wishbone arm. This acti on achieves corresponding movement of the hub carrier, facilita ting adjustment of road wheel toe-

in.

It

em

Par

t Number

De

scription

1—Hub Carrier

2—Wi

shbone

3—Sprin

g

4—Shock Absorber

5—Suspensi

on Turret

6—Suspensi

on Subframe

7—Moun

ting Bracket

8—D

ifferential Strut

9—Stabilizer Ba

r (Supercharged and

Sport Suspension Models only)

10—Bum

p Stop

Page 266 of 2490

WHE

N CHANGING A WHEEL, ENSURE THAT THE VEHICLE CANNOT MOVE. ALWAYS APPLY THE PARK BRAKE AND

SELECT TRANSMISSION 'P' POSITION.

NEVER RUN THE ENGINE WITH ONE WHEEL OFF THE GROUND, FOR EXAMPLE, WHEN CHANGING THE WHEEL. THE

VEHICLE COULD MOVE.

TIGHTEN THE WHEEL NUTS TO SPECIFICATION. WHEELS MAY COME LOOSE IF OVER OR UNDER TIGHTENED.

USE WHEELS AND WHEEL NUTS DESI GNED FOR XJ SERIES VEHICLES ONLY. AFTERMARKET WHEELS OR WHEEL

NUTS MAY NOT FIT OR FUNCTION PROPERLY AND COULD CAUSE INJURY OR DAMAGE.

In

spection and Verification

To maximize ti

re performance, inspec

t the tires frequently for signs of:

Unev

en wear.

Incorrect

ti

re pressure.

Wh

ee

l imbalance.

Cuts. Abrasi

ons.

B

u

lges (blister).

Ply s

e

paration.

Embedded objects. Impact damage.

Inspe c

tion should be

more frequent when:

Continuo

us high speed op

eration is required.

Ra

pid or extreme temperatures changes occur.

R

o

ad surfaces are rough.

Roads ar

e littered

with debris.

Tread W

e

ar Indicator

•

NO

TE: Tire condition must comply with prevailing local legislation.

New tires must be installed if the wear in dicators are exposed or if there is severe shoulder wear. Shoulder wear is usually

caused by either excessive camber or toe on tires.

T i

re Vibration Diagnosis

A

tir

e vibration diagnostic procedure always

begins with a road test. The road test and the custom er interview (if available)

will provide much of the information need ed to find the source of vibration.

During the road test, drive the vehicle on a road that is smooth and free of undulations. If vibration is apparent, note and

record the following:

The s p

eed at which the vibration occurs.

W

h

at type of vibration occurs in each

speed range - mechanical or audible.

How the vibrati

on is affected

by changes in the following:

- -engine torque

- -vehicle speed

- -engine speed.

Type of v i

bration - sensitivity:

- - torque sensitive,

- - vehicle speed sensitive,

- - or engine speed sensitive.

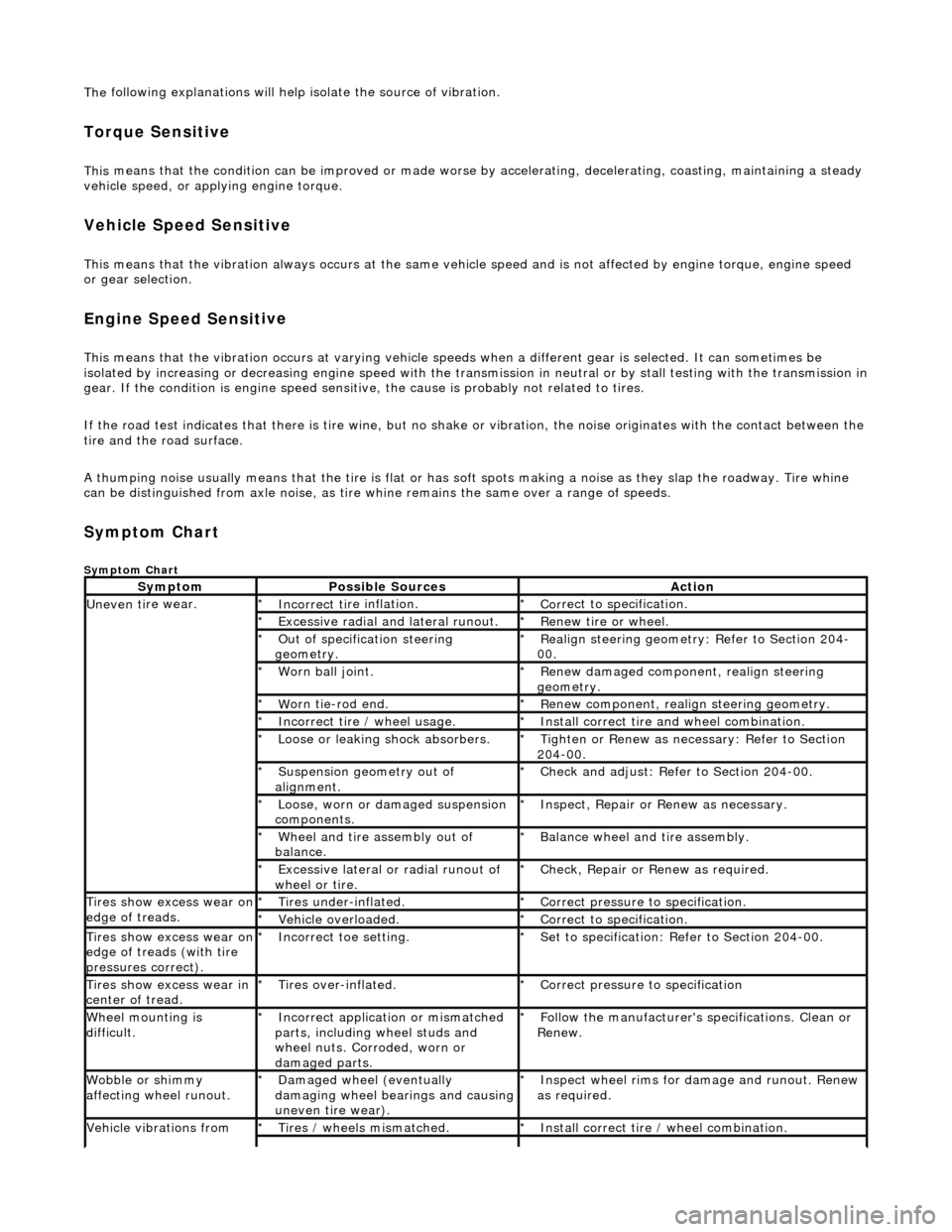

Page 267 of 2490

The

following explanations will help isolate the source of vibration.

Torque Sensitive

This

means that the condition can be impr

oved or made worse by accelerating, dece lerating, coasting, maintaining a steady

vehicle speed, or applying engine torque.

Ve

hicle Speed Sensitive

This means th

at the vibration al

ways occurs at the same vehicle speed and is not affected by engine torque, engine speed

or gear selection.

Engine Speed Sensit

ive

This means th

at the vibration

occurs at varying vehicle spee ds when a different gear is selected. It can sometimes be

isolated by increasing or decreasing engine speed with the tran smission in neutral or by stall testing with the transmission in

gear. If the condition is engine speed sensitive, the cause is probably not related to tires.

If the road test indicates that there is tire wine, but no shake or vibration, the noise originates with the contact between th e

tire and the road surface.

A thumping noise usually means that the tire is flat or has soft spots making a noise as they slap the roadway. Tire whine

can be distinguished from axle no ise, as tire whine remains the same over a range of speeds.

Sym

ptom Chart

Sy

mptom Chart

Sy

mptom

Possib

le Sources

Acti

on

Uneven ti

re wear.

Incorrect ti

re inflation.

*

Cor

rect to specification.

*

Exce

ssive radial an

d lateral runout.

*

Renew tire

or wheel.

*

O

ut of specification steering

geometry.

*

R

ealign steering geometry: Refer to Section 204-

00.

*

W

orn ball joint.

*

Renew

damaged component, realign steering

geometry.

*

W

orn tie-rod end.

*

R

enew component, realign steering geometry.

*

Incorrect

tire / wheel usage.

*

Inst

all correct tire and wheel combination.

*

Loose or leaki

ng shock absorbers.

*

Tigh

ten or Renew as nece

ssary: Refer to Section

204-00.

*

Suspensi

on geometry out of

alignment.

*

Che

ck and adjust: Refer to Section 204-00.

*

Loose, worn or da mage

d suspension

components.

*

In

spect, Repair or Renew as necessary.

*

Wh

eel and tire assembly out of

balance.

*

Balance wheel an

d tire assembly.

*

Excessive later

al or radial runout of

wheel or tire.

*

Check, Repair o

r

Renew as required.

*

Tire

s show excess wear on

edge of treads.

Ti

res under-inflated.

*

Cor

rect pressure to specification.

*

Vehi

cle overloaded.

*

Cor

rect to specification.

*

Tire

s show excess wear on

edge of treads (with tire

pressures correct).

Incorre

ct toe setting.

*

Se

t to specification: Refer to Section 204-00.

*

Tire

s show excess wear in

center of tread.

Tire

s over-inflated.

*

Cor

rect pressure to specification

*

W

heel mounting is

difficult.

Incorrect app

lication or mismatched

parts, including wheel studs and

wheel nuts. Corroded, worn or

damaged parts.

*

Fol

low the manufacturer's specifications. Clean or

Renew.

*

Wobble or sh

immy

affecting wheel runout.

Damaged wh

eel (eventually

damaging wheel bearings and causing

uneven tire wear).

*

Inspect wheel rims for

damage and runout. Renew

as required.

*

Vehicle vibrations from

Tire

s / wheels mismatched.

*

Inst

all correct tire / wheel combination.

*