engine JAGUAR XF 2009 1.G AJ133 5.0L Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 36, PDF Size: 0.38 MB

Page 12 of 36

3-10

04/14/2009 NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine

Technical Training

Relays

Engine Management System

RELAYS

Main Relay

The main Engine Management System (EMS) relay is

not a main power input; it is used to initiate the power-up

and power-down routines within the ECM.

This input comes from the engine junction box (EJB).

When the ignition is turned on 12V is applied to the igni-

tion sense input. The ECM then starts its power-up rou-

tines and turns on the ECM main relay, the main power

to the ECM and its associated system components.

When the ignition is turned OFF, the ECM will maintain

its powered-up state for several seconds (or up to 20

minutes in extreme cases when cooling fans are

required) while it initiates its power-down routine and,

on completion, will turn off the ECM main relay.

The main relay is located in the EJB. The operation of

the main relay is controlled by the ECM, which provides

a ground path for the main relay coil, energizing the

relay and closing the relay contacts.

The main relay supplies battery voltage to the following

engine sensors and actuators:

• Throttle position (TP) sensor (through ECM)

• Fuel injectors

• Ignition coils

• Coil capacitor

• CPS solenoids

• All heated oxygen sensors

• Evaporative emission (EVAP) canister purge valve

• Diagnostic Monitoring of Tank Leakage (DMTL)

Failure Modes

• Relay drive open circuit

• Short circuit to battery voltage or ground

• Component failure

Failure Symptoms

• Engine will not start

Starter Relay

The starter motor relay is located in the EJB. Operation

of the starter motor relay is controlled by the ECM,

which provides a ground path for the relay coil, energiz-

ing the relay and closing the relay contacts. When the

relay contacts are closed, battery voltage is supplied,

through the starter motor relay, to the starter module

solenoid coil.

The starter solenoid is energized and connects the starter

motor with a direct battery feed to operate the starter

motor.

Once the engine has started, the ECM removes the

starter motor relay ground, opening the relay contacts

and terminating the battery feed to the starter solenoid,

which in turn stops the operation of the starter motor.

NOTE:

Diagnose using Jaguar Land Rover approved

diagnostic equipment.

Page 13 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-11

Engine Management System

Crankshaft Position Sensor

CRANKSHAFT POSITION SENSOR

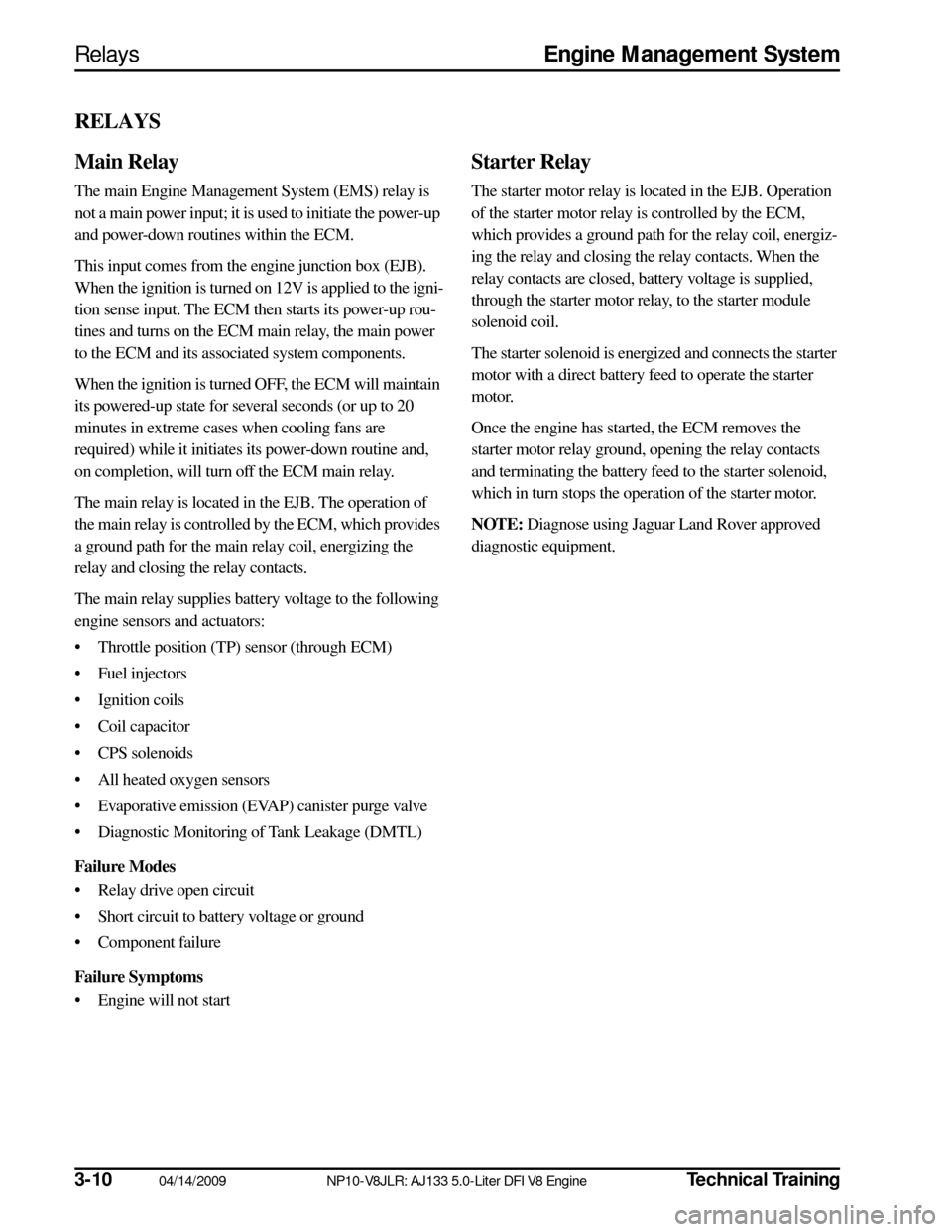

The crankshaft position (CKP) sensor is located on the

forward side of the transmission torque converter hous-

ing, in line with the engine flexplate.

The sensor is secured with a single bolt into the flywheel

housing. A reluctor ring is fitted to the outer diameter of

the crankshaft flexplate; the sensor reacts to the gaps in

the reluctor ring to determine engine speed and position

information.

The CKP sensor is an inductive-type sensor which pro-

duces a sinusoidal output voltage signal. This voltage is

induced by the proximity of the moving reluctor ring

gaps, which excite the magnetic flux around the tip of

the sensor when each gap passes.

The output voltage increases in magnitude and fre-

quency with the engine speed and, consequently, with

the speed at which the reluctor ring gaps pass the sensor.

NOTE:

The output is also dependent on the air gap

between the sensor and the teeth (the larger the gap, the

weaker the signal, the lower the output voltage).

DIRECTION OF ROTATION

FLEXPLATE

RELUCTOR

VOLTAGE OUTPUT S IGNAL

NP10V8094

Page 14 of 36

3-12

04/14/2009 NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine

Technical Training

Crankshaft Position Sensor

Engine Management System

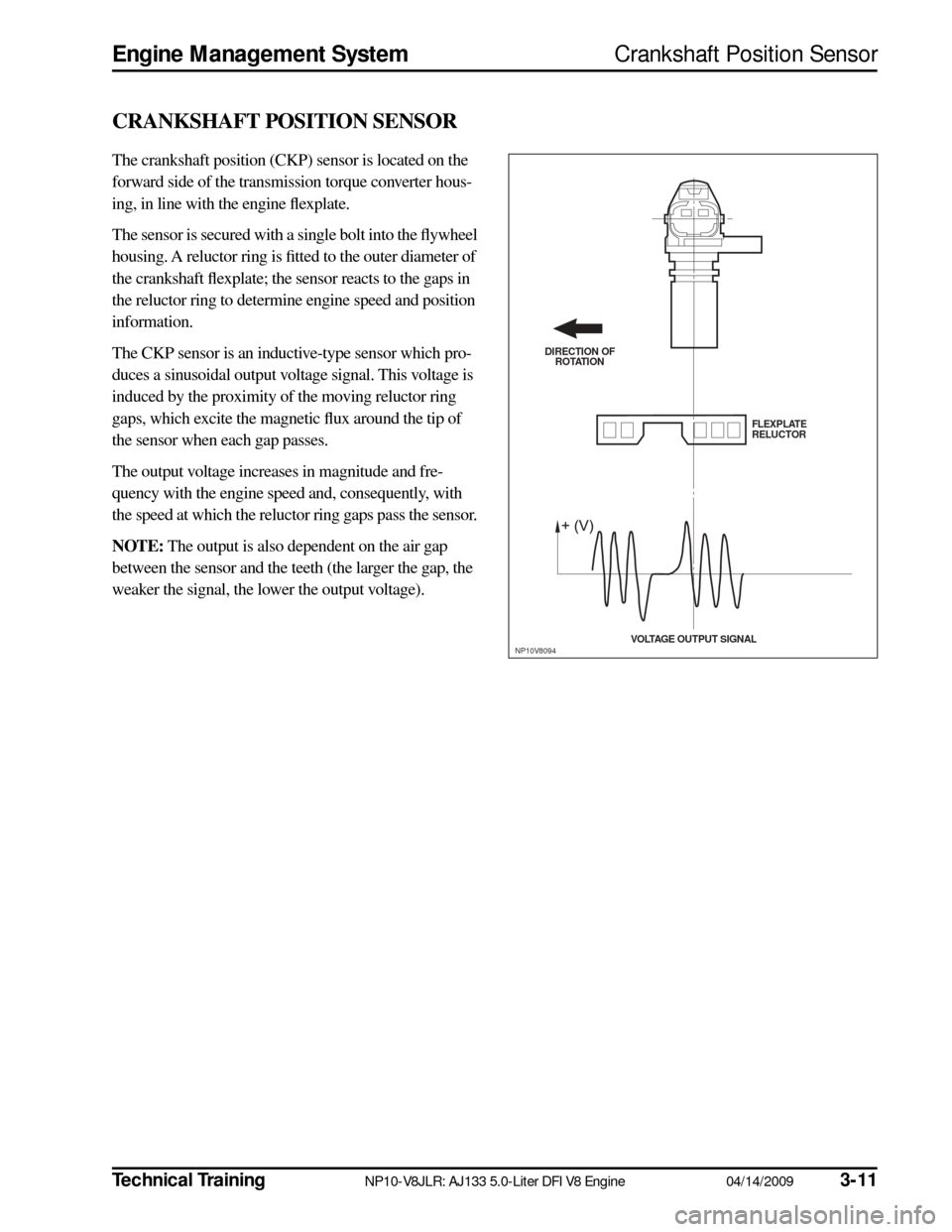

The reluctor is manufactured to have a ‘tooth’ pattern

based on 60 – 2 pattern, where there are 58 teeth in total

at 6° intervals. The two teeth are removed to provide a

hardware reference mark, with a centerline that is 21°

BTDC on cylinder 1, RH bank. The signal voltage can be as low as 0.1V at low engine

speeds and up to 100V at high engine speeds. The ECM

does not react to the output voltage (unless the voltage is

extremely low or high); instead it measures the time

intervals between each pulse (signal frequency).

Safety Precautions CAUTIONS:

• Before installing the CKP sensor, check that no ferrous material has been attracted to

the device by its internal magnet.

• Ensure that the air gap is correct.

• Due to the location and orientation of the sensor, ensure that it is not damaged during

engine installation or by any debris that

may be picked up from the road. Failure Modes

• Sensor assembly loose

• Incorrect air gap – Nominal air gap 1.5mm (This is normally pre-set unless there is damage to the

mounting)

• Short/open circuit

• Mounting and integrity of the sensor

• Water/coolant ingress within connector

• Inability of the ECM to detect the software reference point

• Ferrous contamination of CKP sensor pin/reluctor

Failure Symptoms

• Engine will start picking up a signal from the CMP sensors (long crank time)

• Default 3000rpm (limp home mode)

REFERENCE EDGE

S

ENS OR OUTPUT

ECM INTERNAL

COMPARATOR OUTPUT 0V

MISSING TEETH

NP10V8095

Page 15 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-13

Engine Management System

Camshaft Position Sensor

CAMSHAFT POSITION SENSOR

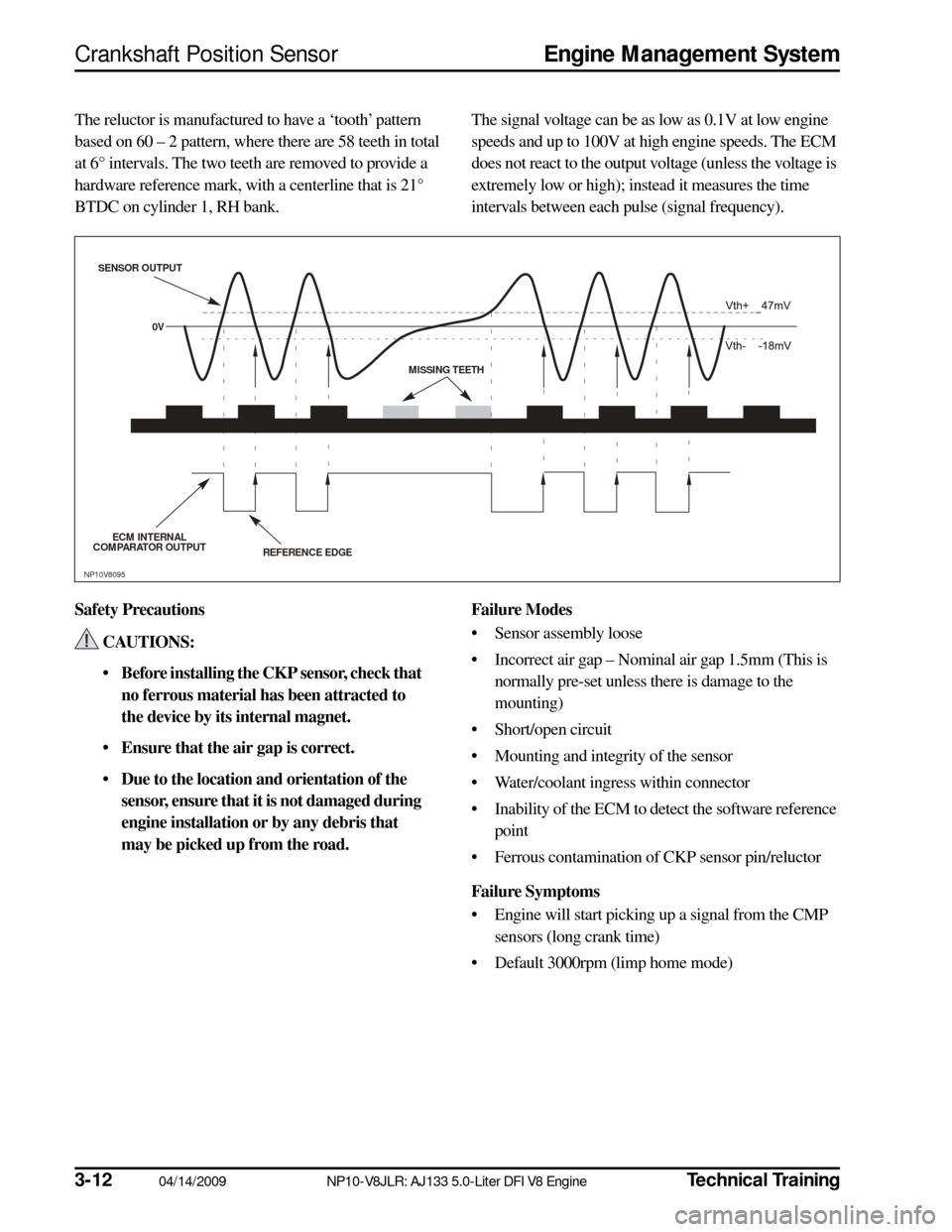

The camshaft position (CMP) sensors are magneto-

resistive element (MRE) sensors, which have digital out-

put with zero speed recognition. They show a high signal

if the camshaft position target is directly in front of the

sensor, and low if the camshaft position target is not in

front of the sensor.

There are four common sensors, one per camshaft.

Failure Modes

• Sensor open circuit

• Short circuit to vehicle battery supply or ground

• Mechanical fitting and integrity of the sensor

• Camshaft wheel tolerances/camshaft end float excessive

• Camshaft and crankshaft misalignment/valve timing error

• Camshaft wheel magnetized/residual magnetism

• Speed signal correlation with crankshaft sensor input

• Incorrect air gap between camshaft and sensor

NOTE:

If both the CKP sensor and the CMP sensor fail,

the engine will stall or not start.

Failure Symptoms

• Ignition timing reverting to the base mapping, with no cylinder correction

• VCT is disabled

NP10V8096

NP10V8097

NP10V8098

43.40°43.40°43.40° 91.60°

91.60°

133.40°133.40°

91.60°

133.40°

91.60°

91.60°91.60°

Specification

Function

Pin 1 Supply

Pin 2 Ground

Pin 3 Signal

Operating voltage 4.5 to 7 V

Maximum supply current 22 mA

Page 16 of 36

3-14

04/14/2009 NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine

Technical Training

Engine Coolant Temperature Sensor

Engine Management System

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature (ECT) sensor is a nega-

tive temperature coefficient (NTC) thermistor, used to

monitor engine coolant temperature.

The ECT sensor is vital to the correct running of the

engine, as a richer mixture is required at lower block

temperatures for good quality starts and smooth running,

leaning off as the temperature rises to maintain emis-

sions and performance.

The sensor has a twist-lock design with a latch mecha-

nism, and is located at the rear of the engine in the water

crossover pipe, between the two heads.

Failure Modes

• Uses engine-off time and MAF for calculation

Failure Symptoms

• Poor cold and hot start

• Poor driveability

• Cooling fans on permanently

Sensor Resistance vs. Coolant Temperature

NOTE:

If the ECT sensor fails, the ECM uses a default

value. The electric fan control module is sent a default

coolant temperature value and switches the cooling

fan(s) on permanently.

The voltages shown represent the signal processed by

the ECM. When a defective coolant sensor is detected,

the coolant value defaults to 40°C (104°F) and remains

fixed until the ECM is powered down.

NP10V8099

Specification

Function

Supply voltage 5V ± 0.1V

Operating temperature range -30°C to 125°C

(-22°F – 257°F)

Pin 1 Sensor output signal

Pin 2 Sensor ground

Coolant Temperature

Approx. Resistance

-20°C (-4°F) 15.04 +0.90/-0.83 kOhms 20°C (68°F) 2.45 +0.10/-0.09 kOhms

80°C (176°F) 0.318 ±0.007 k Ohms

110°C (230°F) 0.1471 ±0.0018 k Ohms

Page 17 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-15

Engine Management System

Knock Sensors

KNOCK SENSORS

The ECM uses active knock control, which serves to

prevent engine damaging pre-ignition or detonation

under all operating conditions, enabling the engine to

operate without additional safety margins.

The ECM uses 4 piezo-ceramic knock sensors to determine

the point at which a cylinder is pre-detonating. Two sensors

are mounted on the intake side of each cylinder head.

Each sensor monitors engine knock by converting the

engine block noise into a suitable electrical signal, which

is then transmitted back to the ECM via a twisted-pair

cable. The signal is processed within the ECM to iden-

tify the data that characterizes knocking.

This information is compared to known signal profiles to

determine whether pre-ignition is present. If so, the

closed loop control system retards the ignition on that

cylinder for a number of cycles, after which it gradually

moves back towards its original setting.

Safety Precautions CAUTION: Terminals in sensor and connec-

tor are gold plated for corrosion/temperature

resistance. Do not probe connections.

NOTE:

Accurate orientation of the knock sensors on the

cylinder block is required to ensure correct connection to

the vehicle wiring harness.

Failure Modes

• Sensor open circuit

• Short circuit to vehicle ground or battery voltage

• Faulty component or incorrectly torqued / coming loose

• Noise on vehicle 12V supply could look like knock signal causing knock fault

• Min fault usually due to open circuit

• Max fault short circuit to battery voltage or extreme mechanical engine noise/piston slap

• ECM calculates the default value if one sensor fails on each bank of cylinders

Failure Symptoms

• Knock control is disabled and a default ‘safe ignition map’ is used

• Possible rough running and reduced engine perfor- mance

Failure Mode Behaviors

• The vehicle control system constantly checks open circuit of knock sensor. Therefore, the knock sensor

is connected to the power source via pull-up line of

the ECM.

• When short/open circuit occurs to the knock sensor signal circuit, the system detects it, sets failure flag,

and commences maximum retard control on spark

advance.

• As far as the behavior of knock sensor is concerned, however, the above-mentioned failure modes cannot

cause serious outcomes such as heat generation,

smoke emission and/or fire hazard.

NP10V8100

Specification

Function

Power Source N/A

Wiring Type Twisted Pair

Shunt Resistance 4.8M Ohms

Operating Range 3kHz – 22kHz

Mounting Torque 20Nm +/- 3.8Nm

Page 18 of 36

3-16

04/14/2009 NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine

Technical Training

Manifold Absolute Pressure Sensor

Engine Management System

MANIFOLD ABSOLUTE PRESSURE SENSOR

The manifold absolute pressure (MAP) sensor provides

a voltage proportional to the absolute pressure in the

intake manifold. This signal allows the load on the

engine to be calculated and used within the internal cal-

culations of the ECM.

The MAP sensor is mounted on the top of the engine, at

the front behind the throttle body. The purpose of the

sensor is to measure the absolute pressure in the intake

manifold and provide information to the ECM, which

will determine the injection time.

The sensor is a semi-conductor type, which responds to

pressure acting on a membrane within the sensor, alter-

ing the output voltage.

The sensor receives a 5V reference voltage and a ground

from the ECM and returns a signal of between 0.5 – 4.5V

to the ECM. A low pressure returns a low voltage signal to

the ECM and a high pressure returns a high voltage.

The MAP sensor detects quick pressure changes in the

intake manifold after the electronic throttle. The signal is

used in conjunction with the MAF sensor signal to calcu-

late the injection period. The ECM monitors the engine

MAP sensor for faults and can store fault related codes.

Failure Modes

• Sensor open circuit

• Short circuit to battery voltage or ground

• Intake air restricted

• Default value of 1 bar (14.5 psi)

Failure Symptoms

• Rough running

• Difficult starting

• Poor driveability

NP10V8101

Specification

Function

Power Source 5V ±0.25V

Pin 1 Power

Pin 2 Ground

Pin 3 Output Signal

Operating Range 13.3 kPa – 250 kPa

Page 19 of 36

Technical Training

NP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine 04/14/2009

3-17

Engine Management System

Mass Air Flow Sensor

MASS AIR FLOW SENSOR

Mass air flow is determined by the cooling effect of

intake air passing over a ‘hot film’ element contained

within the device. The higher the air flow the greater the

cooling effect and the lower the electrical resistance of

the ‘hot film’ element. The ECM then uses this analog

signal from the mass air flow (MAF) sensor to calculate

the air mass flowing into the engine.

The measured air mass flow is used in determining the

fuel quantity to be injected in order to maintain the sto-

ichiometric air/fuel mixture required for correct opera-

tion of the engine and exhaust catalysts. Should the

device fail, there is a software backup strategy that will

be activated once a fault has been logged.

The intake air temperature (IAT) sensor is integrated into

the MAF sensor. The IAT sensor is an NTC thermistor,

meaning that the sensor resistance decreases as the sen-

sor temperature increases.

The sensor forms part of a voltage divider chain with an

additional resistor in the ECM. The voltage from this device

changes as the sensor resistance changes, thus relating the

air temperature to the voltage measured by the ECM.

Because the engine requires a twin air intake induction

system, there are two MAF sensors per vehicle.

Safety Precautions CAUTIONS:

• Component should not be dropped or han-dled roughly.

• Ensure that no contamination enters the device.

• Some terminals in MAF and connector are gold-plated for corrosion resistance – DO

NOT probe.

Failure Modes

• Sensor open circuit

• Short circuit to battery voltage or ground

• Contaminated/damaged sensor element

• Air leak after MAF sensor

• Intake air restricted

• Resistance in the harness, causing signal offset

• Damaged sensor element

Failure Symptoms

• During driving the engine rpm might dip (before recovering)

• Difficulty in starting or start/stall

• Poor throttle response/engine performance

• Emissions incorrect

• Lambda control and idle speed control halted

• MAF signal offset

NP10V8102

SpecificationFunction

Supply Voltage 8 – 14V

(rated supply voltage: 14V)

Pin A Output (Vg)

Pin B Ground for Output (Vg)

Pin C Power Source

Pin D IAT Sensor Ground

Pin E IAT Sensor Output

Page 20 of 36

3-1804/14/2009NP10-V8JLR: AJ133 5.0-Liter DFI V8 EngineTechnical Training

Temperature/Manifold Absolute Pressure Sensor Engine Management System

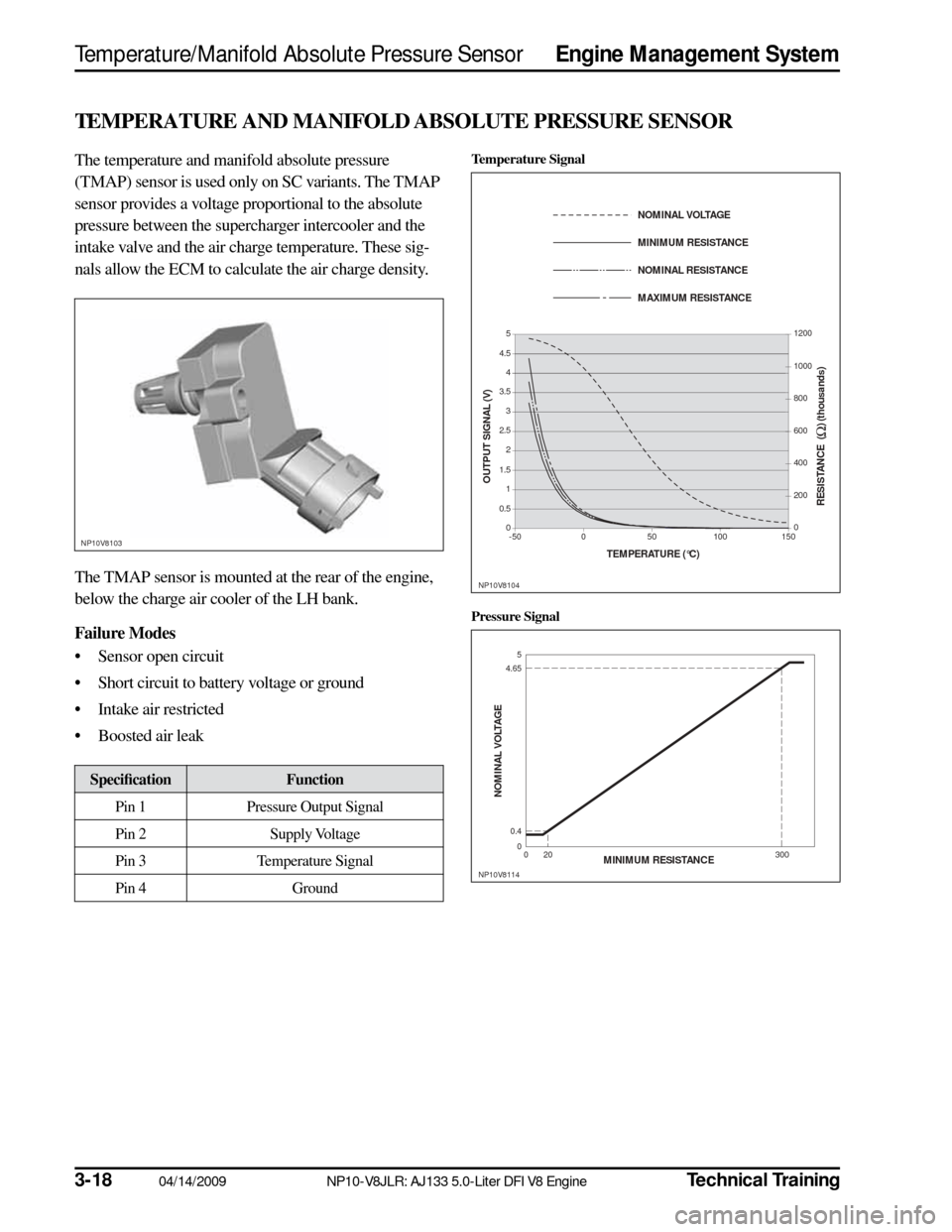

TEMPERATURE AND MANIFOLD ABSOLUTE PRESSURE SENSOR

The temperature and manifold absolute pressure

(TMAP) sensor is used only on SC variants. The TMAP

sensor provides a voltage proportional to the absolute

pressure between the supercharger intercooler and the

intake valve and the air charge temperature. These sig-

nals allow the ECM to calculate the air charge density.

The TMAP sensor is mounted at the rear of the engine,

below the charge air cooler of the LH bank.

Failure Modes

• Sensor open circuit

• Short circuit to battery voltage or ground

• Intake air restricted

• Boosted air leak

SpecificationFunction

Pin 1 Pressure Output Signal

Pin 2 Supply Voltage

Pin 3 Temperature Signal

Pin 4 Ground

NP10V8103

Temperature Signal

Pressure Signal

TEMPERATURE (°C)

OUTPUT SIGNAL (V)

RES IS TANCE (

Ω) (thous ands)

NP10V8104

5

4.5 4

3.5

3

2.5 2

1.5 1

0

0.5

-50 50 0 1001500 200 400 600

800 1000 1200

NOMINAL VOLTAGE

MINIMUM RES

IS TANCE

NOMINAL RES IS TANCE

MAXIMUM RES IS TANCE

NP10V8114

0

0.4

4.65

5

0 20 300

NOMINAL VOLTAGE

MINIMUM RESIS TANCE

Page 21 of 36

Technical TrainingNP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine04/14/20093-19

Engine Management SystemThrottle Position Sensor

THROTTLE POSITION SENSOR

The engine torque is regulated via an electronic throttle

body (‘drive-by-wire’ system), where an electronic pedal

assembly determines throttle opening.

The throttle position (TP) sensor is mounted in the inte-

grated cover plate on the throttle body assembly. The

throttle body assembly is mounted at the top front of the

engine, in a similar position for both NA and SC variants.

This value is input into the ECM and the throttle is

opened to the correct angle by means of an electric direct

current (DC) motor integrated into the throttle body.

Movement of the motor is achieved by changing the

PWM signal to the DC motor, allowing it to be operated

in both directions.

The dual-output TP sensor in the throttle body is used to

determine the position of the throttle blade and the rate

of change in its angle.

A software strategy within the ECM enables the throttle

position to be calibrated each ignition cycle. When the

ignition is turned ON, the ECM commands the throttle

to open and close fully, thus performing a self-test and

calibration, learning the position of the full closed hard

stop position.Safety Precautions

CAUTION: Terminals in sensor and connec-

tor are gold-plated for corrosion/temperature

resistance – DO NOT probe.

Failure Modes

• Sensor open circuit

• Short circuit to battery voltage or ground

• If signal failure occurs the ECM will enter a limp home mode where the maximum engine speed is

2000 rpm

• Signal offset

• Vacuum leak

Failure Symptoms

• Poor engine running and throttle response

• Limp home mode – maximum 2000 rpm

• Emission control failure

• No closed loop idle speed control

NP10V8105

SpecificationFunction

Supply voltage 5V ± 0.2 V

Supply current Max. 10 mA/1 output

Tolerance – closed position ±150 mV Tolerance – WOT position ±150 mV

Operating temperature range -40°C – 160°C

(-40°F – 320°F)

Pin 1 Throttle motor valve open:

direction +

Pin 2 Throttle motor valve open:

direction –

Pin 3 Position sensor output 2

(Gold)

Pin 4 Ground (Gold)

Pin 5 Position sensor output 1

(Gold)

Pin 6 Position sensor 5V supply

(Gold)