engine JAGUAR XF 2009 1.G AJ133 5.0L Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 36, PDF Size: 0.38 MB

Page 32 of 36

3-3004/14/2009NP10-V8JLR: AJ133 5.0-Liter DFI V8 EngineTechnical Training

Controller Area Network Engine Management System

CONTROLLER AREA NETWORK

The Controller Area Network (CAN) is a high-speed

serial interface for sharing dynamic signals between elec-

tronic control modules. CAN communications are ‘self-

checked’ for errors, and if an error is detected the message

is ignored by the receiving electronic control module.

Due to the high rate of information exchange, the system

has a high degree of latency. This allows for a high num-

ber of errors to be present without reducing the data

transfer rate. In practice, this is a very reliable system.

Each CAN message is transmitted by one electronic con-

trol module and received by all other electronic control

modules on the CAN bus. Each message contains a fixed

structure of signals. The data exchanged is used so that

each electronic control module does not need to have a

hardwired sensor for each input. The CAN message iden-

tifiers are arranged by a network tool, which can guarantee

that all messages meet their specified timing needs.

Signal Overview

The CAN communication system is a differential bus

using a twisted pair that is normally very reliable. If either

or both of the wires of the twisted pair CAN bus is open-

or short-circuited, a CAN time-out fault will occur.

Below is a list of additional electronic control modules that

the ECM will communicate with on the CAN network:

• Instrument cluster

• Steering angle sensor

•TCM

• Active rear locking differential, if equipped

• Adaptive cruise control

• Electronic parking brake

Failure Modes

• CAN bus wiring short circuit or open circuit

• Incompatible software and message versions

Page 33 of 36

Technical TrainingNP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine04/14/20093-31

Engine Management SystemOn-Board Diagnostic Monitoring

ON-BOARD DIAGNOSTIC MONITORING

Some OBD monitors are continuous, that is they operate

all the time the ignition is on.

Some OBD monitors have conditions that must be met

before the monitor is allowed to operate, such as engine

speed 1000 – 4000 rpm and engine airflow 10 – 100 g/

sec and intake air temperature -10 – +50°C, in order to

ensure the vehicle is operating in such a manner that the

failure may be correctly diagnosed. For this reason it

may be possible for a failure to be present on the vehicle

but remain undetected by the module.

Most OBD monitors use 2-trip detection: if on the first

occasion the failure is detected, a pending DTC is

recorded. If the failure is again detected on the next drive

cycle, then a confirmed DTC is logged and the MIL may

be illuminated.

A few OBD monitors operate on a single-trip basis

where the MIL is illuminated as soon as the failure is

diagnosed.

Detection of a failure may prevent the operation of other

OBD monitors. This is to prevent the logging of multiple

DTCs for a single. However, the system is not infallible,

and a single fault may result in two or more failures

being detected, with two or more DTCs being recorded.

Page 34 of 36

3-3204/14/2009NP10-V8JLR: AJ133 5.0-Liter DFI V8 EngineTechnical Training

Crankcase Ventilation System Engine Management System

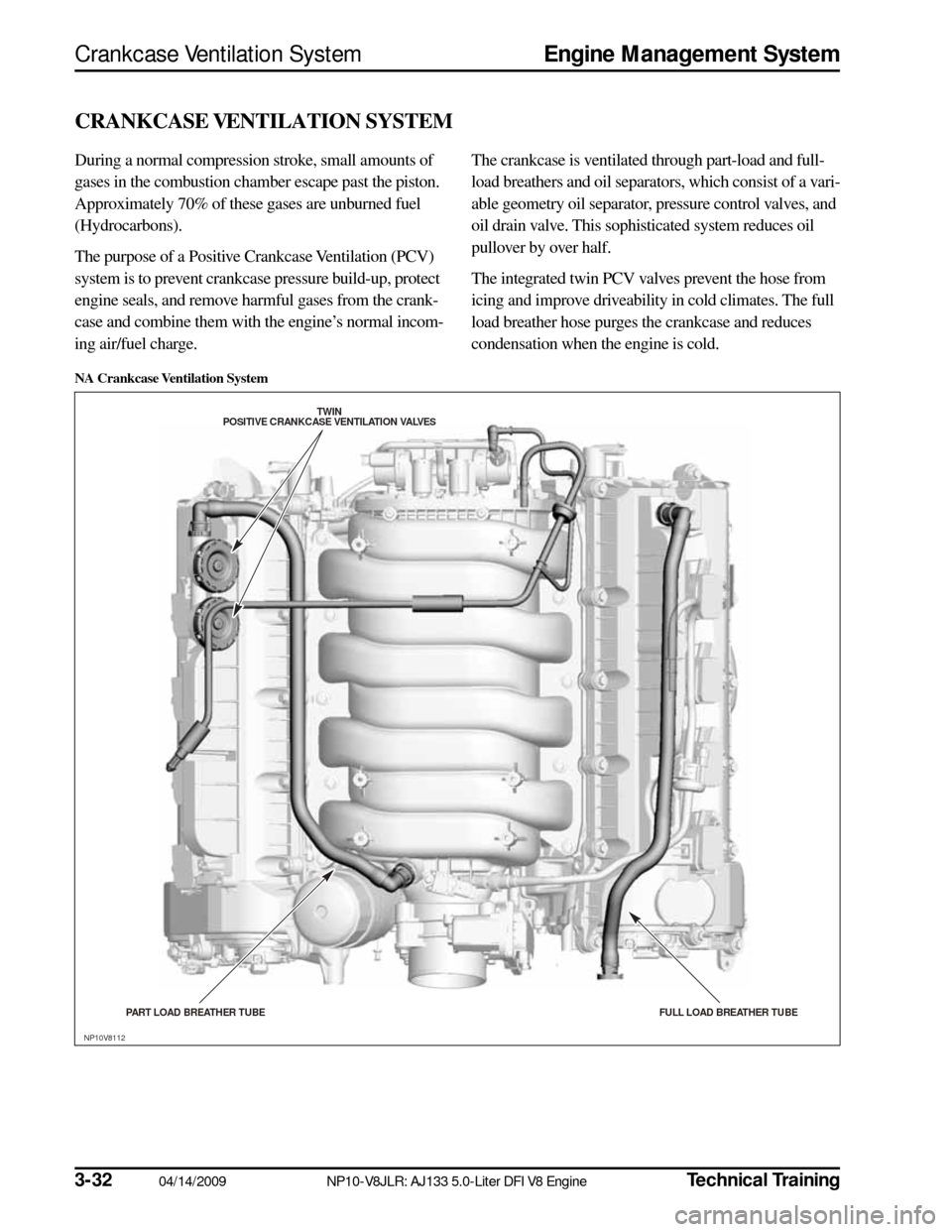

CRANKCASE VENTILATION SYSTEM

During a normal compression stroke, small amounts of

gases in the combustion chamber escape past the piston.

Approximately 70% of these gases are unburned fuel

(Hydrocarbons).

The purpose of a Positive Crankcase Ventilation (PCV)

system is to prevent crankcase pressure build-up, protect

engine seals, and remove harmful gases from the crank-

case and combine them with the engine’s normal incom-

ing air/fuel charge. The crankcase is ventilated through part-load and full-

load breathers and oil separators, which consist of a vari-

able geometry oil separator, pressure control valves, and

oil drain valve. This sophisticated system reduces oil

pullover by over half.

The integrated twin PCV valves prevent the hose from

icing and improve driveability in cold climates. The full

load breather hose purges the crankcase and reduces

condensation when the engine is cold.

NA Crankcase Ventilation System

TWIN

POS ITIVE CRANKCAS E VENTILATION VALVES

PART LOAD BREATHER TUBE FULL LOAD BREATHER TUBE

NP10V8112

Page 35 of 36

Technical TrainingNP10-V8JLR: AJ133 5.0-Liter DFI V8 Engine04/14/20093-33

Engine Management SystemCrankcase Ventilation System

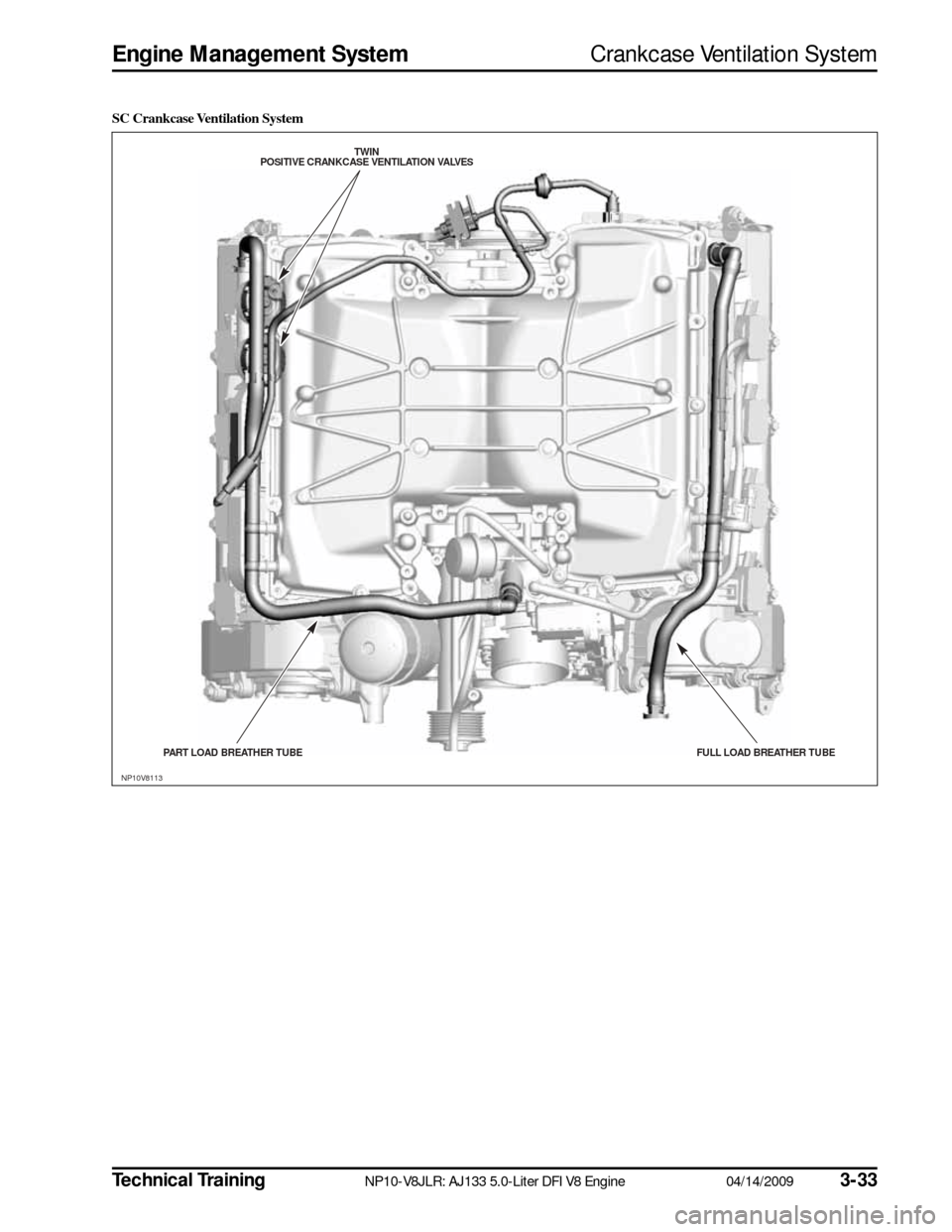

SC Crankcase Ventilation System

TWIN

POS ITIVE CRANKCAS E VENTILATION VALVES

PART LOAD BREATHER TUBE FULL LOAD BREATHER TUBE

NP10V8113

Page 36 of 36

3-3404/14/2009NP10-V8JLR: AJ133 5.0-Liter DFI V8 EngineTechnical Training

THIS PAGE LEFT BLANK INTENTIONALLY.