Locking JAGUAR XF 2009 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 391, PDF Size: 19.32 MB

Page 47 of 391

47

Seats

Raising the rear seats

The process for raising the rear seat is the

reverse of folding.

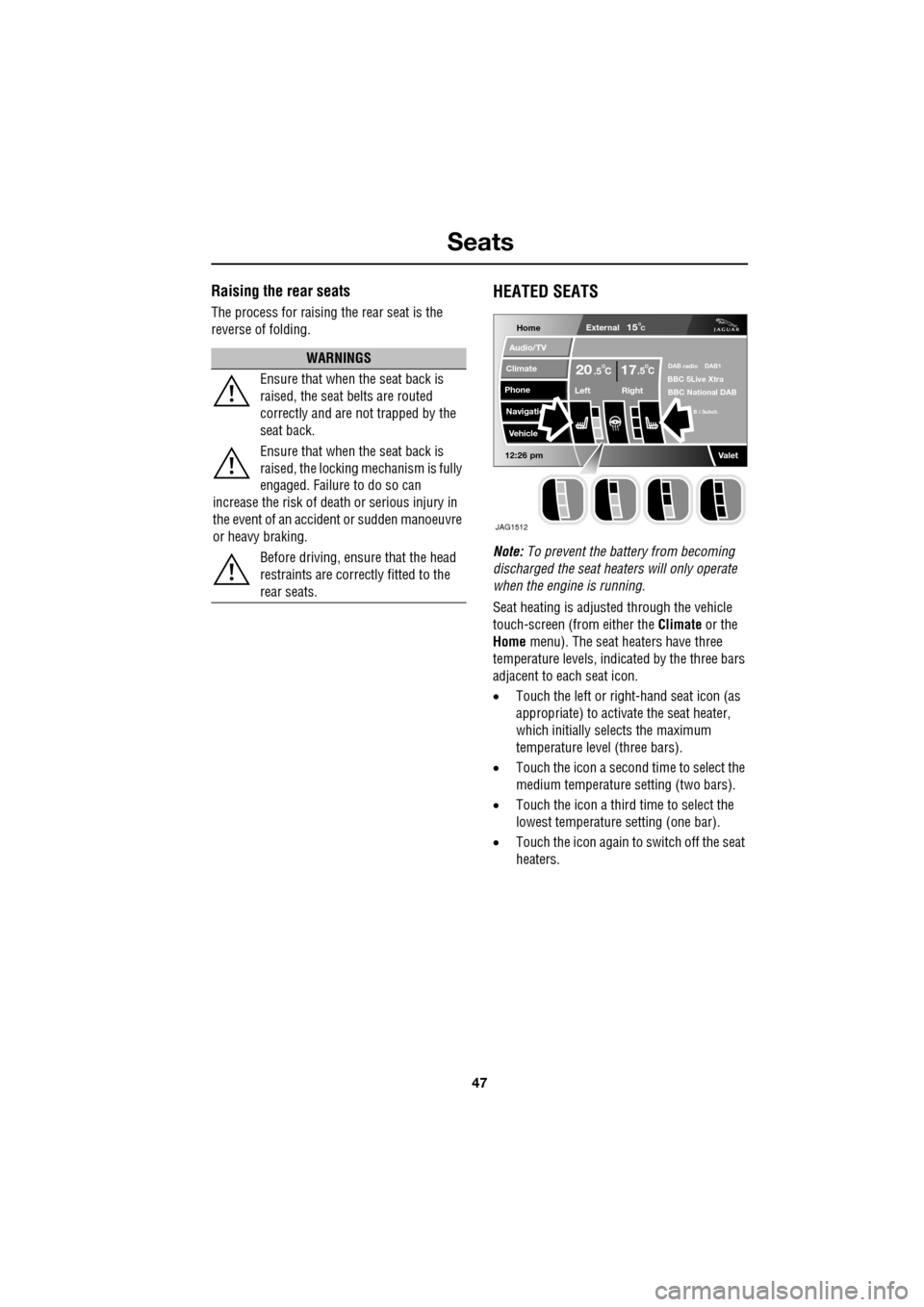

HEATED SEATS

Note: To prevent the battery from becoming

discharged the seat heaters will only operate

when the engine is running.

Seat heating is adjusted through the vehicle

touch-screen (from either the Climate or the

Home menu). The seat heaters have three

temperature levels, indica ted by the three bars

adjacent to each seat icon.

• Touch the left or right -hand seat icon (as

appropriate) to activate the seat heater,

which initially selects the maximum

temperature level (three bars).

• Touch the icon a second time to select the

medium temperature setting (two bars).

• Touch the icon a third time to select the

lowest temperature setting (one bar).

• Touch the icon again to switch off the seat

heaters.

WARNINGS

Ensure that when the seat back is

raised, the seat belts are routed

correctly and are not trapped by the

seat back.

Ensure that when the seat back is

raised, the locking mechanism is fully

engaged. Failure to do so can

increase the risk of death or serious injury in

the event of an accident or sudden manoeuvre

or heavy braking.

Before driving, ensure that the head

restraints are correctly fitted to the

rear seats.

Home

Audio/TV

Climate

Phone

Navigatio

Vehicle

Left Right

20 17CC.5 .5

Valet12:26 pm

External15C

DAB radio DAB1BBC 5Live Xtra

BBC National DAB

B i Subch.

JAG1512

Page 52 of 391

Seat belts

52

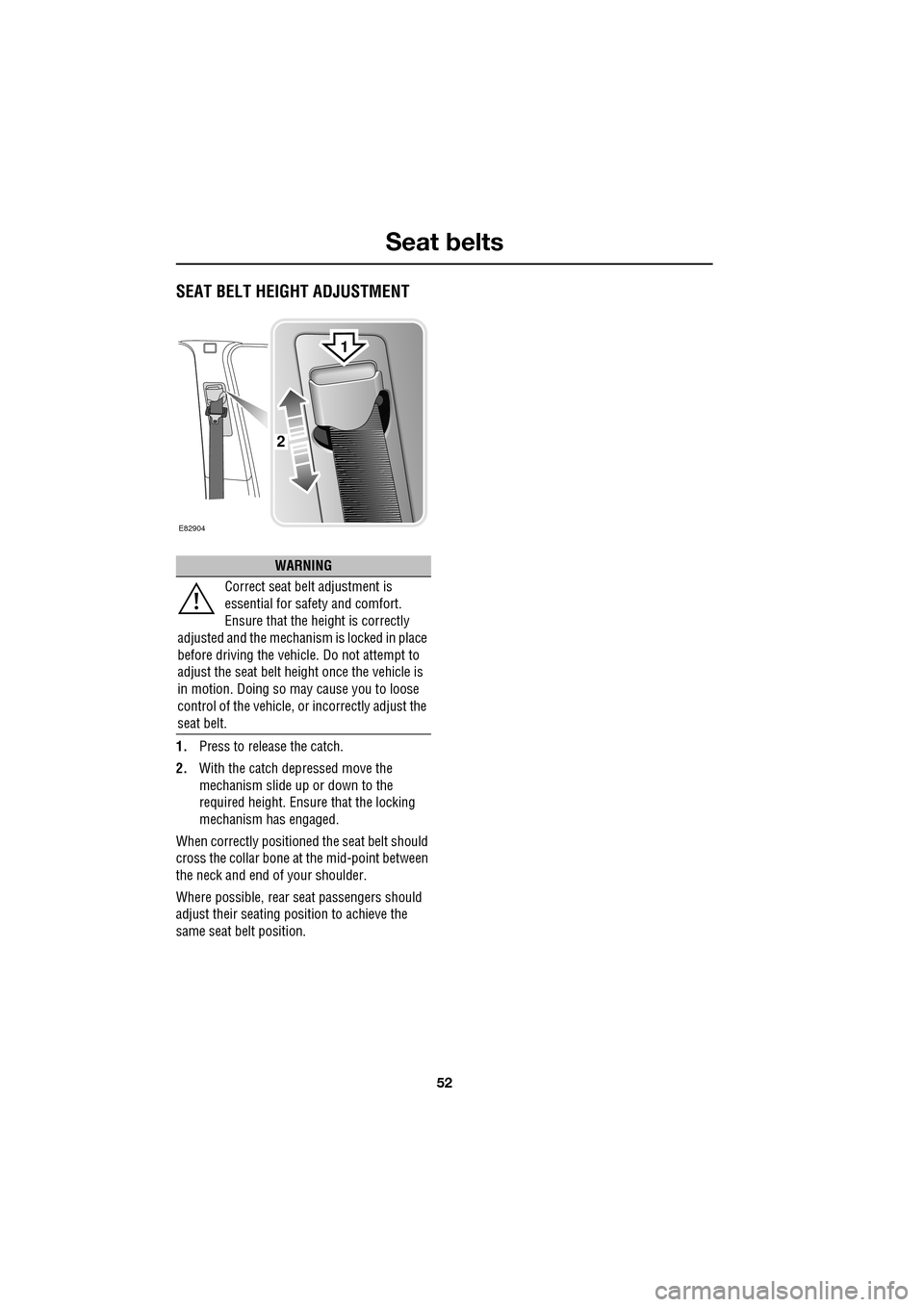

SEAT BELT HEIGHT ADJUSTMENT

1.Press to release the catch.

2. With the catch depressed move the

mechanism slide up or down to the

required height. Ensure that the locking

mechanism has engaged.

When correctly positione d the seat belt should

cross the collar bone at the mid-point between

the neck and end of your shoulder.

Where possible, rear seat passengers should

adjust their seating pos ition to achieve the

same seat belt position.

WARNING

Correct seat belt adjustment is

essential for safety and comfort.

Ensure that the height is correctly

adjusted and the mechanism is locked in place

before driving the vehicl e. Do not attempt to

adjust the seat belt height once the vehicle is

in motion. Doing so may cause you to loose

control of the vehicle, or incorrectly adjust the

seat belt.

E82904

2

1

Page 63 of 391

63

Child safety

ISOFIX child seats

•IUF = Suitable for ISOFIX forward child

restraint systems of universal category

approved for use in the mass group.

• IL = These ISOFIX child restraint systems

are of the specific vehicle, restricted or

semi-universal categories.

• * = Child seats suitable for use in these

locations are Britax Cosy-Tot Premium

Infant carrier and Br itax Duo Plus child

seat.

Note: Ages given are approximate. In case of

doubt, the child’s weight, not age, should be

used when considering an appropriate child

seat.

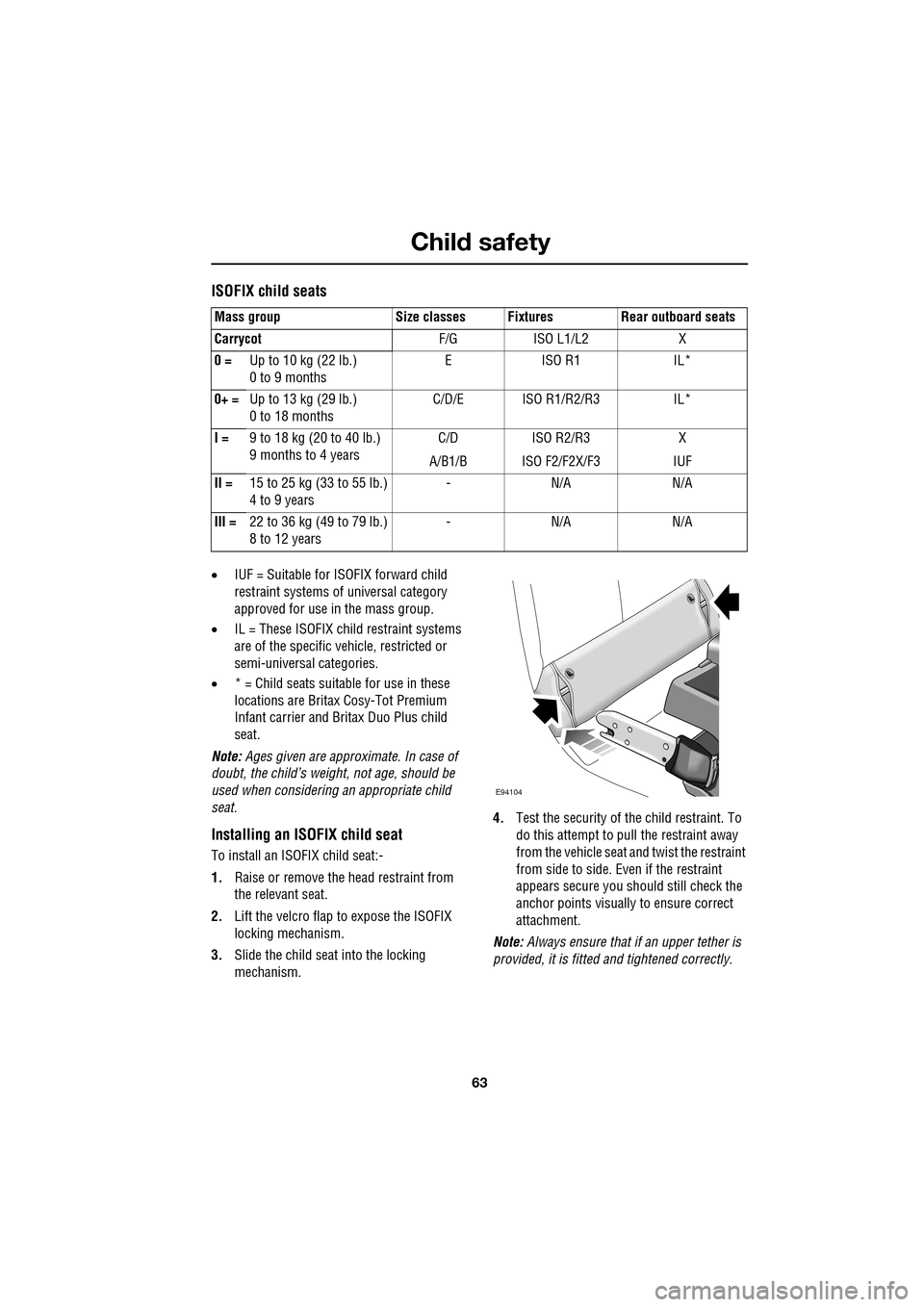

Installing an ISOFIX child seat

To install an ISOFIX child seat:-

1. Raise or remove the head restraint from

the relevant seat.

2. Lift the velcro flap to expose the ISOFIX

locking mechanism.

3. Slide the child seat into the locking

mechanism. 4.

Test the security of the child restraint. To

do this attempt to pull the restraint away

from the vehicle seat and twist the restraint

from side to side. Even if the restraint

appears secure you s hould still check the

anchor points visually to ensure correct

attachment.

Note: Always ensure that if an upper tether is

provided, it is fitted and tightened correctly.

Mass group Size classes Fixtures Rear outboard seats

Carrycot

F/G ISO L1/L2 X

0 = Up to 10 kg (22 lb.)

0 to 9 months EISO R1 IL*

0+ = Up to 13 kg (29 lb.)

0 to 18 months C/D/E ISO R1/R2/R3 IL*

I = 9 to 18 kg (20 to 40 lb.)

9 months to 4 years C/D

A/B1/B ISO R2/R3

ISO F2/F2X/F3 X

IUF

II = 15 to 25 kg (33 to 55 lb.)

4 to 9 years -N/A N/A

III = 22 to 36 kg (49 to 79 lb.)

8 to 12 years -N/A N/A

E94104

Page 90 of 391

Wipers and washers

90

Low screen wash

If the low washer fluid warning is on, the

windscreen wipers will not operate when the

wash/wipe is activated, even though there may

be washer fluid remaining in the reservoir

which is sprayed onto the screen. This is to

prevent damage to the wiper blades, scratching

of the glass or smearing dirt across the screen.

Normal, fast or single wipe can be selected

manually, to clear any spray from the

windscreen.

Timed jet function

If the timed jet func tion is configured,

the washer jets will only operate on the

up stroke of the wipers.

This function can be enabled/disabled by your

Dealer/Authorised Repairer.

Drip wipe

If the drip wipe function is configured,

the wipers will operate four seconds

after a wash wipe cycle has finished, to

clear any remaining drips from the windscreen.

This function can be enabled/disabled by your

Dealer/Authorised Repairer.

Blocked jets

If a washer jet becomes blocked, use a thin

strand of wire to unblock the jet by inserting

the wire into the jet. Ensure that the wire is

completely remove d after unblocking.

HEADLAMP WASHERS

Headlamp power wash operates automatically

with the windscreen wash, and will only

operate if the headlamps are switched on and

there is sufficient washer fluid in the reservoir.

Headlamp wash operates with every fourth

operation of the screen wa shers, provided that

ten minutes have elapsed since the last

operation of the headlamp washers.

Note: The power wash sequence is reset when

the headlamps or the ignition are turned off.

Note: Headlamp power wash is inhibited when

the low washer fluid warning is on.

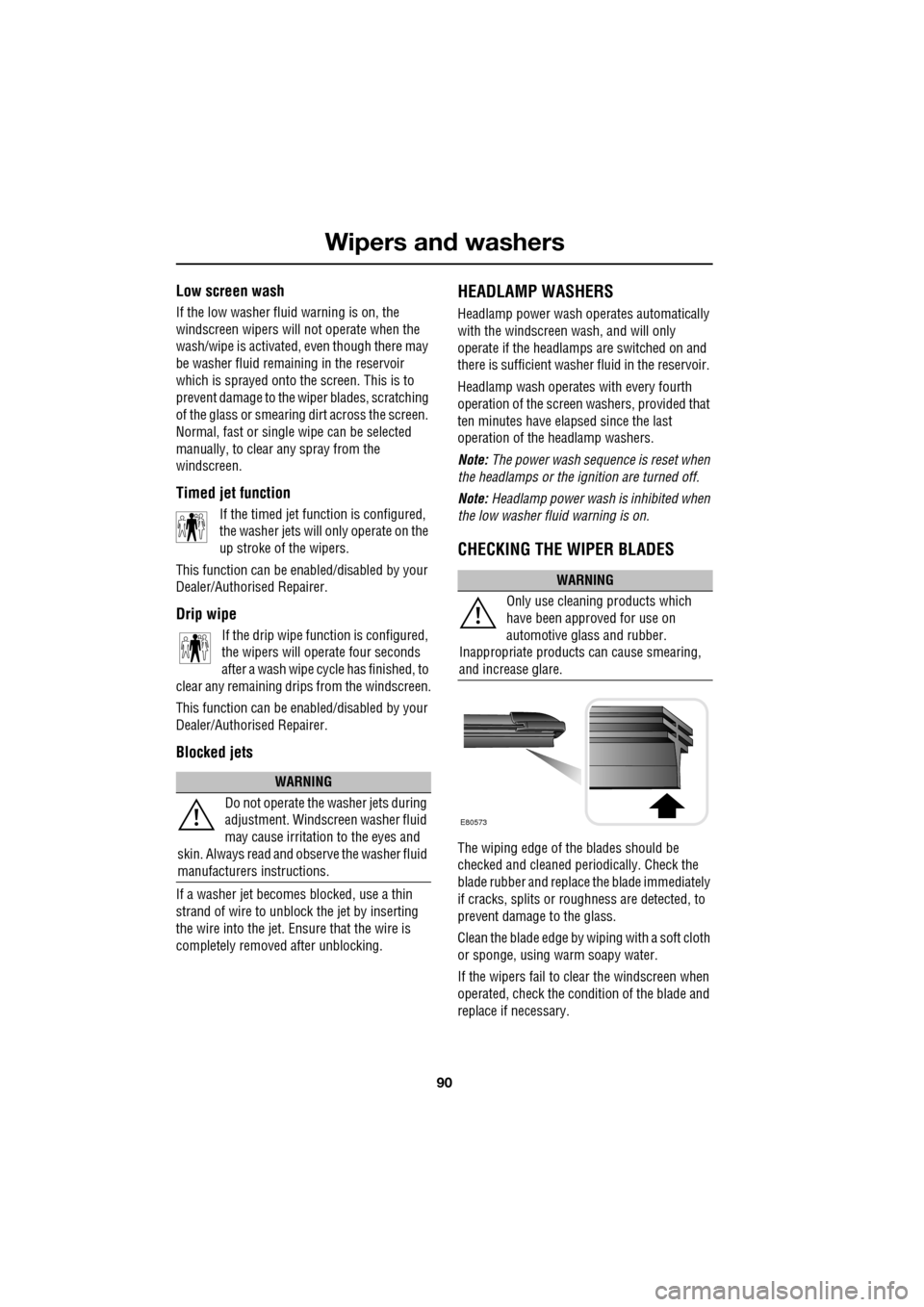

CHECKING THE WIPER BLADES

The wiping edge of the blades should be

checked and cleaned periodically. Check the

blade rubber and replace the blade immediately

if cracks, splits or roughness are detected, to

prevent damage to the glass.

Clean the blade edge by wiping with a soft cloth

or sponge, using wa rm soapy water.

If the wipers fail to clear the windscreen when

operated, check the cond ition of the blade and

replace if necessary.

WARNING

Do not operate the washer jets during

adjustment. Windscreen washer fluid

may cause irritation to the eyes and

skin. Always read and observe the washer fluid

manufacturers instructions.

WARNING

Only use cleani ng products which

have been approved for use on

automotive glass and rubber.

Inappropriate products can cause smearing,

and increase glare.

E80573

Page 144 of 391

Brakes

144

PRINCIPLE OF OPERATION

Brake pads

Brake pads require a period of bedding in when

new. Drive with extra caution for the first

500 km (300 miles) to avoid the need for heavy

braking.

Brake pad wear warning

When the brake pads are wearing low, the

warning message BRAKE PADS LOW is

displayed in the message centre. Arrange for

your vehicle to be se en by your Dealer/

Authorised Repairer at the earliest opportunity.

Wet conditions

Driving through heavy ra in or water can have

an adverse effect on braking efficiency. Under

such circumstances, it is recommended that

you lightly a pply the brakes intermittently to

dry the brakes.

ABS warning indicator

If this amber warning indicator

illuminates while driving and/or

ABS FAULT is displayed in the

message centre, drive with extra caution, avoid

heavy braking where possible, and seek

qualified assistance as soon as possible.

If this red warning indicator

illuminates while driving and/or the

message LOW BRAKE FLUID is

displayed in the message centre, check the

brake fluid level at the earliest opportunity and

top-up as required. See BRAKE FLUID CHECK

(page 206).

HINTS ON DRIVING WITH ABS

ABS (Anti-Lock Braking System) allows

maximum brake pressure, and thus maximum

braking efficiency, to be applied, and prevents

the road wheels locking. This allows the driver

to retain steering control during heavy braking

under most road conditions.

ABS optimises tyre to road adhesion under

maximum braking conditions, though it cannot

provide increased cornering ability.

WARNINGS

Do not rest your foot on the brake

pedal whilst the vehicle is in motion.

This may cause a light application of

the brakes, which can result in overheating,

reduced brake performance, and excessive

brake wear.

Never allow the vehicle to coast

(freewheel) with the engine turned

off. The engine must be running to

provide full braking assistance. The brakes will

still function with the e ngine off, but far more

pressure will be required to operate them.

If the red brake warning indicator

illuminates, safely bring the vehicle to

a stop, as quickly as possible. Seek

qualified assistance before proceeding.

Never place non-approved floor

matting or any ot her obstructions

under the brake pedal. This restricts

pedal travel and braking efficiency.

WARNINGS

ABS cannot overcome the physical

limitations of braking distance. Nor

can it overcome the lack of grip on a

road surface (e.g. aquaplaning on water).

Braking distance is increased on a

slippery surface. This applies to all

vehicles, even those fitted with ABS.

The driver should not be tempted to

take risks when driving, in the hope

that ABS will correct errors of

judgement. In all cases it remains the driver's

responsibility to driv e with due care and

attention, payi ng particular attention to the

effects of speed, weather, road conditions etc.

Page 224 of 391

Wheels and tyres

224

RUN FLAT TYRES

Run-flat tyres can be identified by the lettering

RSC on the sidewall. The tyre construction

utilises a specially reinforced sidewall, which

allows the vehicle to be driven at restricted

speeds, even when the tyre is depressurised.

Run-flat tyres can only be fitted to special rims,

constructed for ru n-flat tyre use.

A tyre pressure monitoring system is

mandatory when the vehicle is fitted with

run-flat tyres. See TYRE PRESSURE

MONITORING SYSTEM (page 234).

If the tyre has deflated, the vehicle should be

driven with caution, as handling characteristics

will be different compared to a fully inflated

tyre.

If the vehicle is fully la den with passengers and

luggage, the maximum di stance that can be

completed on a fully deflated tyre, is

approximately 80 kilo metres (50 miles).

Stop immediately if the tyre construction

begins to break down or if the tyre dislodges

from the wheel rim. Typi cally, this will be

accompanied by excessive vibration.

A tyre driven in a defl ated condition must be

replaced as s oon as possible. Vehicles fitted with run-flat tyres are not fitted

with a spare wheel or jacking equipment.

Therefore, run-flat tyre

s should be replaced

with the same type of tyre.

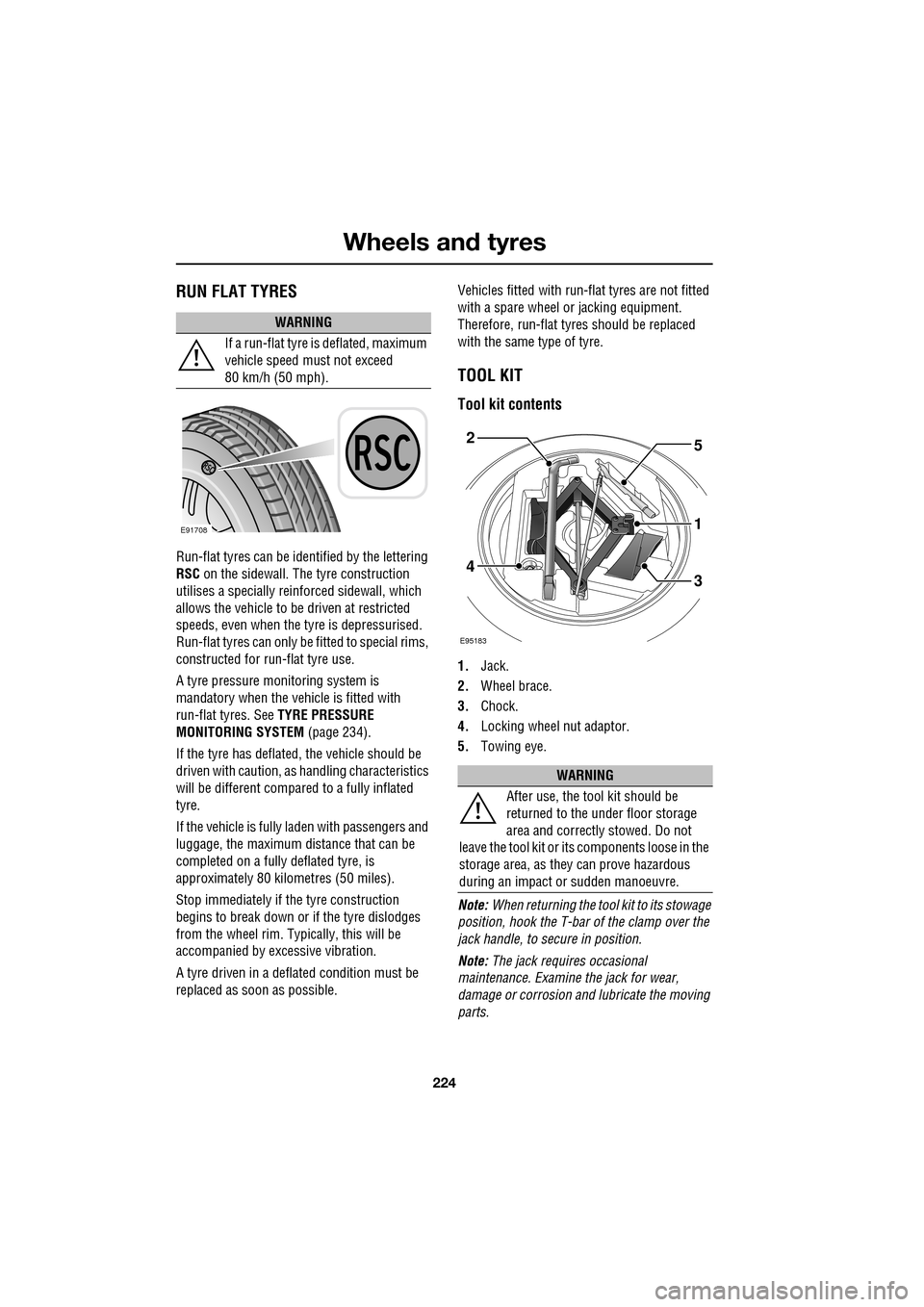

TOOL KIT

Tool kit contents

1. Jack.

2. Wheel brace.

3. Chock.

4. Locking wheel nut adaptor.

5. Towing eye.

Note: When returning the tool kit to its stowage

position, hook the T-bar of the clamp over the

jack handle, to se cure in position.

Note: The jack requi res occasional

maintenance. Examine the jack for wear,

damage or corrosion and lubricate the moving

parts.

WARNING

If a run-flat tyre is deflated, maximum

vehicle speed must not exceed

80 km/h (50 mph).

E91708

WARNING

After use, the tool kit should be

returned to the under floor storage

area and correctly stowed. Do not

leave the tool kit or it s components loose in the

storage area, as they can prove hazardous

during an impact or sudden manoeuvre.

E95183

5

1

34

2

Page 226 of 391

Wheels and tyres

226

Locking wheel nuts

Vehicles may be equipped with a locking wheel

nut on each wheel. These are similar to

standard wheel nuts, and can only be removed

using the special adaptor provided with the

jacking equipment.

1. Insert the adaptor firmly onto the locking

wheel nut.

2. Using the wheel brace, unscrew the wheel

nut and adaptor.

3. Return the locking wheel nut adaptor to the

correct storage position.

Note: A code number is stam ped on the side of

the locking nut. Ensure the number is recorded

on the Security Card supplied with the

literature pack. Quot e this number if a

replacement is require d. Do not keep the

Security Card in the vehicle.

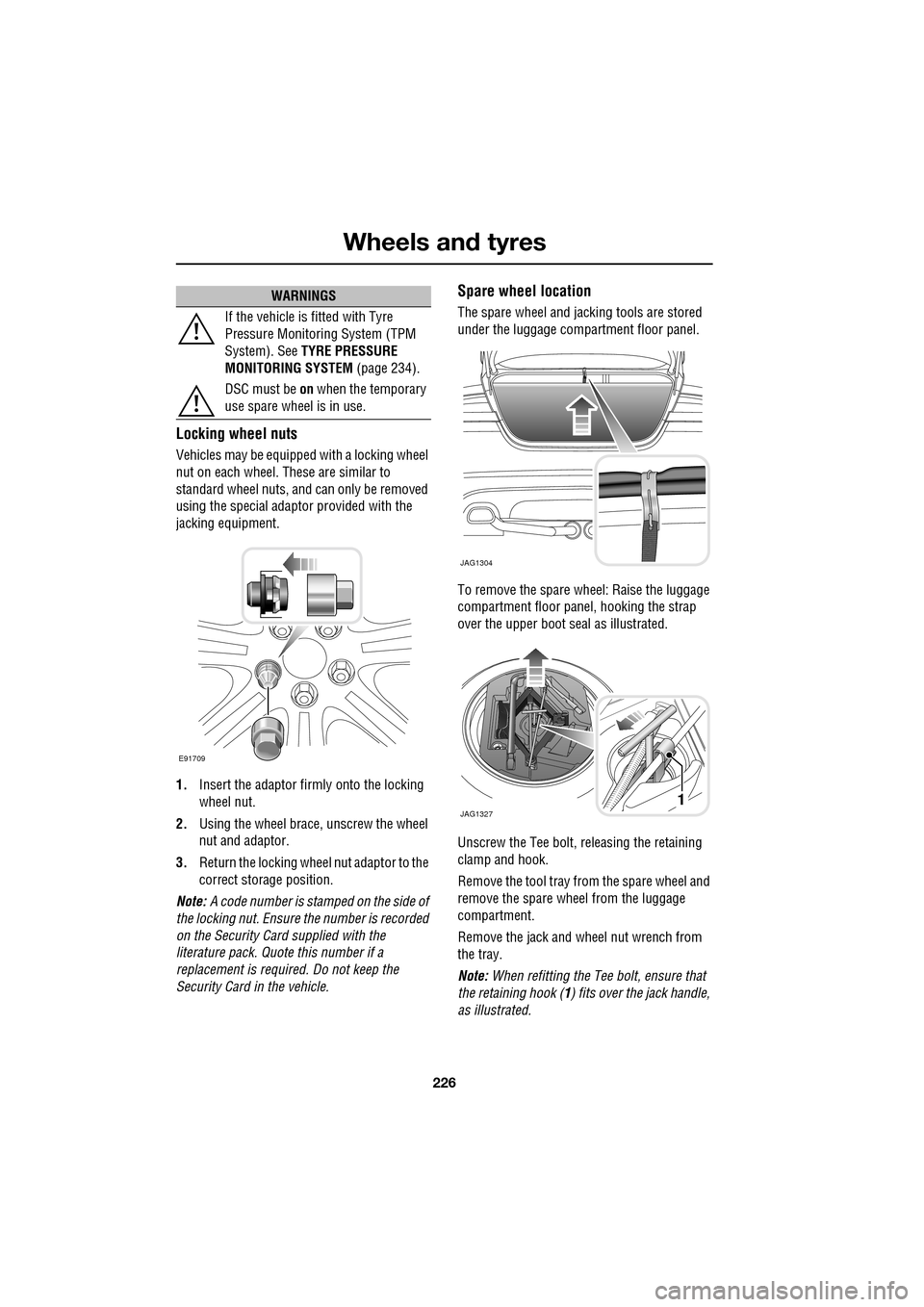

Spare wheel location

The spare wheel and jacking tools are stored

under the luggage compartment floor panel.

To remove the spare wheel: Raise the luggage

compartment floor panel, hooking the strap

over the upper boot seal as illustrated.

Unscrew the Tee bolt, re leasing the retaining

clamp and hook.

Remove the tool tray from the spare wheel and

remove the spare wheel from the luggage

compartment.

Remove the jack and wheel nut wrench from

the tray.

Note: When refitting the Tee bolt, ensure that

the retaining hook ( 1) fits over the jack handle,

as illustrated.

If the vehicle is fitted with Tyre

Pressure Monitoring System (TPM

System). See

TYRE PRESSURE

MONITORING SYSTEM (page 234).

DSC must be on when the temporary

use spare wheel is in use.

WARNINGS

E91709

JAG1304

JAG13271

Page 255 of 391

255

Vehicle recovery

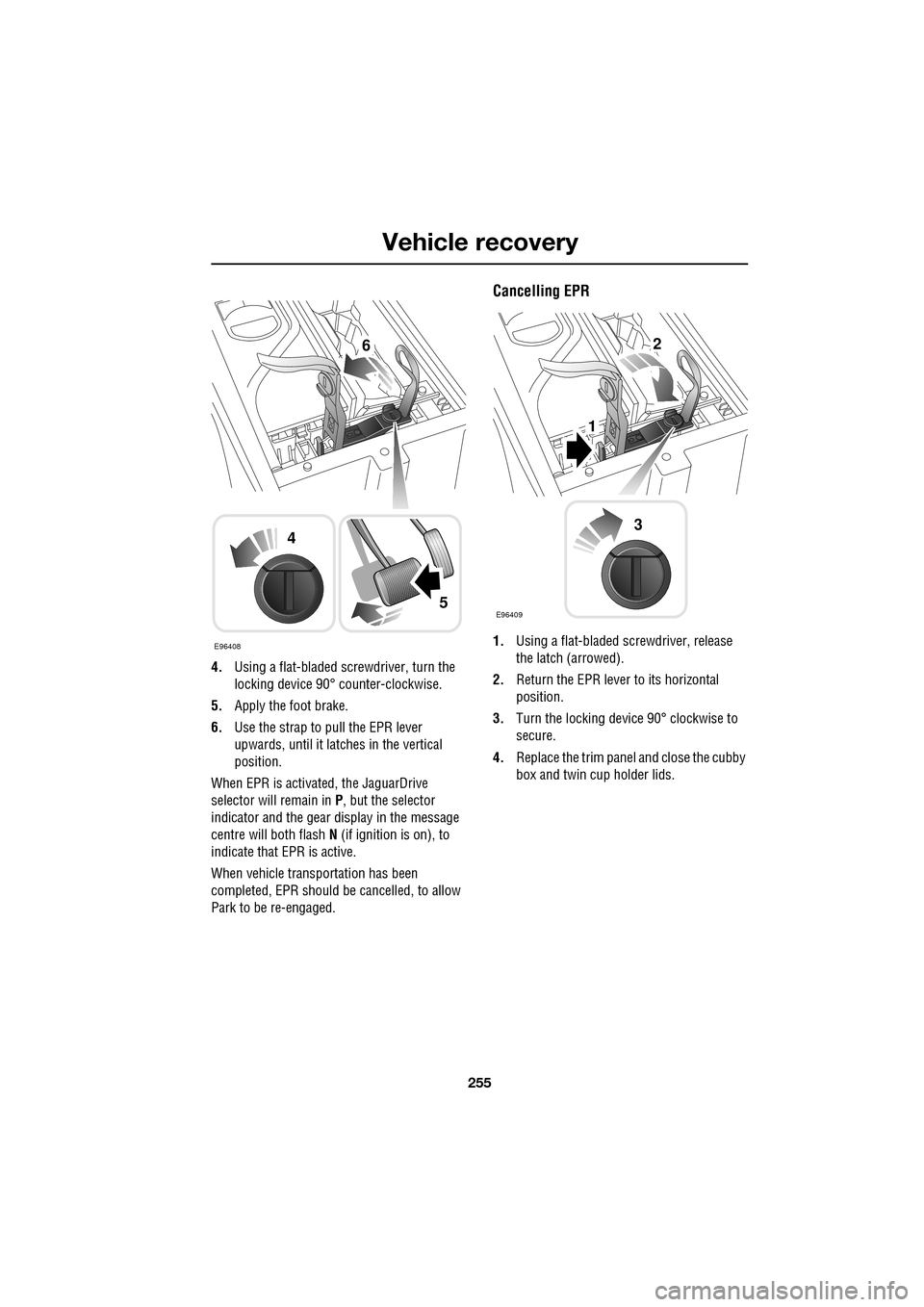

4.Using a flat-bladed screwdriver, turn the

locking device 90° counter-clockwise.

5. Apply the foot brake.

6. Use the strap to pull the EPR lever

upwards, until it latches in the vertical

position.

When EPR is activated, the JaguarDrive

selector will remain in P , but the selector

indicator and the gear display in the message

centre will both flash N (if ignition is on), to

indicate that EPR is active.

When vehicle transportation has been

completed, EPR should be cancelled, to allow

Park to be re-engaged.

Cancelling EPR

1. Using a flat-bladed sc rewdriver, release

the latch (arrowed).

2. Return the EPR lever to its horizontal

position.

3. Turn the locking device 90° clockwise to

secure.

4. Replace the trim pane l and close the cubby

box and twin cup holder lids.E96408

4

5

62

1

E96409

3

Page 285 of 391

285

Digital audio broadcasting

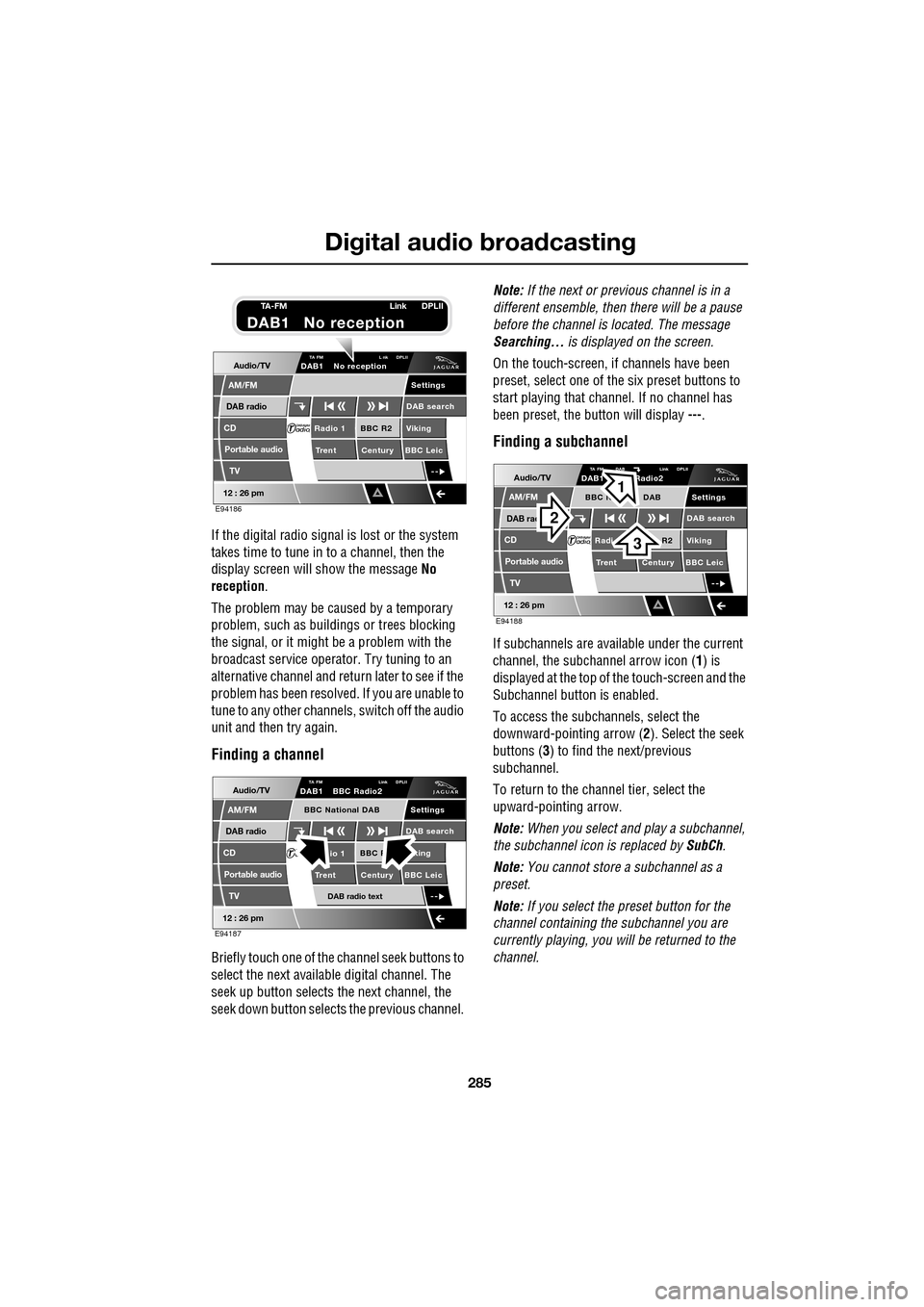

If the digital radio signal is lost or the system

takes time to tune in to a channel, then the

display screen will show the message No

reception.

The problem may be caused by a temporary

problem, such as buildings or trees blocking

the signal, or it might be a problem with the

broadcast servic e operator. Try tuning to an

alternative channel and return later to see if the

problem has been resolved. If you are unable to

tune to any other channe ls, switch off the audio

unit and then try again.

Finding a channel

Briefly touch one of the channel seek buttons to

select the next availabl e digital channel. The

seek up button selects th e next channel, the

seek down button selects the previous channel. Note:

If the next or previous channel is in a

different ensemble, then there will be a pause

before the channel is located. The message

Searching... is displayed on the screen.

On the touch-screen, if channels have been

preset, select one of the six preset buttons to

start playing that channel. If no channel has

been preset, the button will display ---.

Finding a subchannel

If subchannels are available under the current

channel, the subchannel arrow icon ( 1) is

displayed at the top of the touch-screen and the

Subchannel button is enabled.

To access the subchannels, select the

downward-pointing arrow ( 2). Select the seek

buttons ( 3) to find the next/previous

subchannel.

To return to the channel tier, select the

upward-pointing arrow.

Note: When you select and play a subchannel,

the subchannel icon is replaced by SubCh.

Note: You cannot store a subchannel as a

preset.

Note: If you select the preset button for the

channel containing the subchannel you are

currently playing, you will be returned to the

channel.

Audio/TV

DAB radio

CD

AM/FM

12 : 26 pm

BBC R2 Viking

Trent Century BBC LeicRadio 1

Settings

DAB search

TA FM L nk DPLIIDAB1 No reception

Portable audio

TV

E94186

TA-FM Link DPLII

DAB1 No reception

Audio/TV

DAB radio

CD

AM/FM

12 : 26 pm

BBC R king

Trent Century BBC Leicio 1

Settings

DAB search

TA FM Link DPLIIDAB1 BBC Radio2

Portable audio

TV

DAB radio text

BBC National DAB

E94187

Audio/TV

DAB rad

CD

AM/FM

12 : 26 pm

R2 Viking

T

rent Century BBC LeicRadi

Settings

DAB search

TA FM DAB Link DPLIIDAB1 Radio2

Portable audio

TV

BBC N DAB

E94188

2

3

1

Page 382 of 391

Index

382

Bulb changing . . . . . . . . . . . . . . . . . . . . . . 83direction indicator bulb (front) . . . . . . . 84

headlamp unit bulbs . . . . . . . . . . . . . . . 83

high level brake lamp . . . . . . . . . . . . . . 86

number plate lamp bulb . . . . . . . . . . . . 86

rear lamp bulbs . . . . . . . . . . . . . . . . . . . 85

side lamp bulb . . . . . . . . . . . . . . . . . . . 85

side repeater lamp . . . . . . . . . . . . . . . . 85

Bulb specification chart . . . . . . . . . . . . . . . 87

C

Cancel guidance . . . . . . . . . . . . . . . . . . . 350

Car wash . . . . . . . . . . . . . . . . . . . . . . . . . 187

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Changing a bulb . . . . . . . . . . . . . . . . . . . . 83 general information . . . . . . . . . . . . . . . . 83

Changing a fuse. . . . . . . . . . . . . . . . . . . . 241 checking or renewing a blown fuse . . . 241

Changing a road wheel . . . . . . . . . . . . . . 225

locking wheel nuts . . . . . . . . . . . . . . . 226

spare wheel location . . . . . . . . . . . . . . 226

temporary use spare wheel . . . . . . . . . 225

tightening the wheel nuts . . . . . . . . . . 229

wheel changing procedure . . . . . . . . . 228

wheel changing safety. . . . . . . . . . . . . 227

Changing the remote cont rol battery . . . . . 24

Changing the vehicle battery . . . . . . . . . . 215

battery disposal. . . . . . . . . . . . . . . . . . 215

Changing the wiper blades . . . . . . . . . . . . 91 changing the wiper blades . . . . . . . . . . 92

service position . . . . . . . . . . . . . . . . . . . 91

Channel automatic tuning . . . . . . . . . . . . 284

Channel options. . . . . . . . . . . . . . . . . . . . 284 DAB search . . . . . . . . . . . . . . . . . . . . . 286

finding a channel. . . . . . . . . . . . . . . . . 285

finding a subchannel . . . . . . . . . . . . . . 285

finding an ensemble . . . . . . . . . . . . . . 286

Charging the vehicle battery . . . . . . . . . . 215

Checking the wiper blades . . . . . . . . . . . . . 90

Child safety locks . . . . . . . . . . . . . . . . . . . 65

Child seat anchor points . . . . . . . . . . . . . . 62 installing an ISOFIX child seat. . . . . . . . 63

ISOFIX anchor points . . . . . . . . . . . . . . 62

tether anchorage points . . . . . . . . . . . . 64

Child seat positioning . . . . . . . . . . . . . . . . 60 Child seats . . . . . . . . . . . . . . . . . . . . . . . . . 59

child restraint check list . . . . . . . . . . . . . 60

Cleaning the alloy wheels . . . . . . . . . . . . . 187

Cleaning the exterior . . . . . . . . . . . . . . . . . 187

bird droppings . . . . . . . . . . . . . . . . . . . 189

cleaning the rear screen . . . . . . . . . . . . 189

glass surfaces . . . . . . . . . . . . . . . . . . . 189

polishing . . . . . . . . . . . . . . . . . . . . . . . 189

removing grease and tar. . . . . . . . . . . . 189

underbonnet cleaning . . . . . . . . . . . . . . 188

using an automatic wash . . . . . . . . . . . 188

washing the vehicle paintwork . . . . . . . 187

Cleaning the interior . . . . . . . . . . . . . . . . . 189 airbag module covers . . . . . . . . . . . . . . 191

carpet and mats . . . . . . . . . . . . . . . . . . 191

cloth and fabric . . . . . . . . . . . . . . . . . . 190

instrument pack, clock, and audio equipment . . . . . . . . . . . . . . . . . . . . 190

leather . . . . . . . . . . . . . . . . . . . . . . . . . 190

removing stains . . . . . . . . . . . . . . . . . . 190

seat belts . . . . . . . . . . . . . . . . . . . . . . . 191

Climate seats . . . . . . . . . . . . . . . . . . . . . . . 48 backrest ventilation only. . . . . . . . . . . . . 48

cooled ventilation . . . . . . . . . . . . . . . . . . 48

heated ventilation . . . . . . . . . . . . . . . . . . 48

Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 setting the clock as the screensaver . . . 124

Compact disc display options . . . . . . . . . . 296

Compact disc pause . . . . . . . . . . . . . . . . . 295

Compact disc player CD compatibility . . . . . . . . . . . . . . . . . . 292

loading CDs . . . . . . . . . . . . . . . . . . . . . 292

Compact disc selection . . . . . . . . . . . . . . . 294

Compass view. . . . . . . . . . . . . . . . . . . . . . 360

Condensation - lamps . . . . . . . . . . . . . . . . . 76

Controls overview . . . . . . . . . . . . . . . . . . . . 12

Coolant check . . . . . . . . . . . . . . . . . . . . . . 204

Cornering lamps . . . . . . . . . . . . . . . . . . . . . 79

Cruise control . . . . . . . . . . . . . . . . . . . 74, 156

principle of operation . . . . . . . . . . . . . . 156

Cup holders . . . . . . . . . . . . . . . . . . . . . . . 126 twin cup holder . . . . . . . . . . . . . . . . . . 127