parking JAGUAR XF 2009 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 391, PDF Size: 19.32 MB

Page 150 of 391

Parking aid

150

Front and rear parking aid

When both front and rear parking aids are

fitted, a switch is located in the overhead

console.

Pressing the switch turns both the front and

rear parking aids on or off. The switch warning

indicator will come on when the system is

turned on. A switch is not provided when only

a rear parking aid is fitted.

Note: The front parking aid will also operate

when reverse gear is selected.

The front parking aid provides an audible

proximity warning when driving forwards or

reversing.

The front and rear sensors only operate within

a fixed speed range in forward gears and are

not effective when moving forwards above

15 km/h (9 mph). Objects are detected within the approximate

operating range from the

front of the vehicle,

as shown in the illustration above:

1. 600 mm (24 inches).

2. 1800 mm (71 inches).

3. 800 mm (31 inches).

If an obstacle is detected at the front or rear of

the vehicle, a warning tone will be heard from

the front or rear speaker respectively.

Note: The outer rear sensors ( 1) will show

visual detection on the touch-screen, before

the audible warning is given.

The warning tone increa ses in rate as the

vehicle approaches the obstacle.

CAUTION

The parking aid system automatically

switches off when the vehicle is moving

above 15 km/h (9 mph) in D, and will need to

be reselected when moving below 15 km/h

(9 mph).

E94141

E94142

3

2

1

1

Page 151 of 391

151

Parking aid

The front or rear warning tone will become

continuous when the obstacle is detected at or

within 300 mm (12 inches) from the vehicle.

Note: The outer front and rear sensors will

switch off if the distance to an object increases

or remains constant for 3 seconds. The

sensors will reactivate automatically if a new

object is detected with in the operating range,

or if the distance to the original object reduces.

Rear fitted accessories

Particular care must be taken when reversing

with rear fitted accessories e.g. bicycle carrier,

as the rear park assist will only indicate the

distance from the bumper to the obstacle.

Cleaning the sensors

Do not clean the sensors with abrasive or sharp

objects or materials.

For reliable operation, th e sensors in the front

and rear bumpers should be kept free from ice,

frost and grime.

When using a high pressure spray the sensors

should only be sprayed br iefly and not from a

distance of less than 200 mm (8 inches).

System fault

If the system has a fault when engaging reverse

gear or turning on the ignition, then a single,

three second tone will be heard (only once per

ignition cycle) and a pop-up warning will

appear on the touch-scre en. If both front and

rear parking aids are fitted, the warning

indicator in the parking aid switch will flash for

three seconds and then switch off, if a fault is

detected.

If a fault is detected, the system is

automatically disabled.

The parking aid may sound spurious tones if it

detects a frequency tone using the same band

as the sensors (e.g. air brakes).

Page 152 of 391

Rear view camera

152

PRINCIPLE OF OPERATION

The system provides a rear view image to

assist in reversing the vehicle.

The camera is positioned centrally and

unobtrusively, just above the rear license plate.

When reverse gear (R) is selected, the rear

view camera displays a wide-angle, colour view

from the rear of the vehicle, displayed on the

touch-screen. The camera display also incorporates graphic

overlays to aid the driver in assessing vehicle

direction, width and pr

oximity to surrounding

objects. These are detailed under Camera

overlays later in this section.

The camera display on the touch-screen has

priority over the parki ng aid display. To view

the parking aid display instead, touch the

touch-screen.

If a parking aid sensor is activated with the

camera in use, a corresponding red shaded

area will appear on the camera display to

identify which sensor has been activated.

To cancel the rear view camera display at any

time, touch the touch-screen.

The camera image will not be displayed when

any of the following apply:

• D is selected and the vehicle speed is

greater than 16 km/h (10 mph).

• D is selected for longer than 2 seconds and

the vehicle speed is less than 16 km/h

(10 mph).

WARNINGS

It remains the driver's responsibility

to detect obstacles and estimate the

vehicle's distance from them when

reversing. Some ov erhanging objects or

barriers, which could possibly cause damage

to the vehicle, may not be detected by the

camera.

Always be vigilant when reversing.

E96469

Page 153 of 391

153

Rear view camera

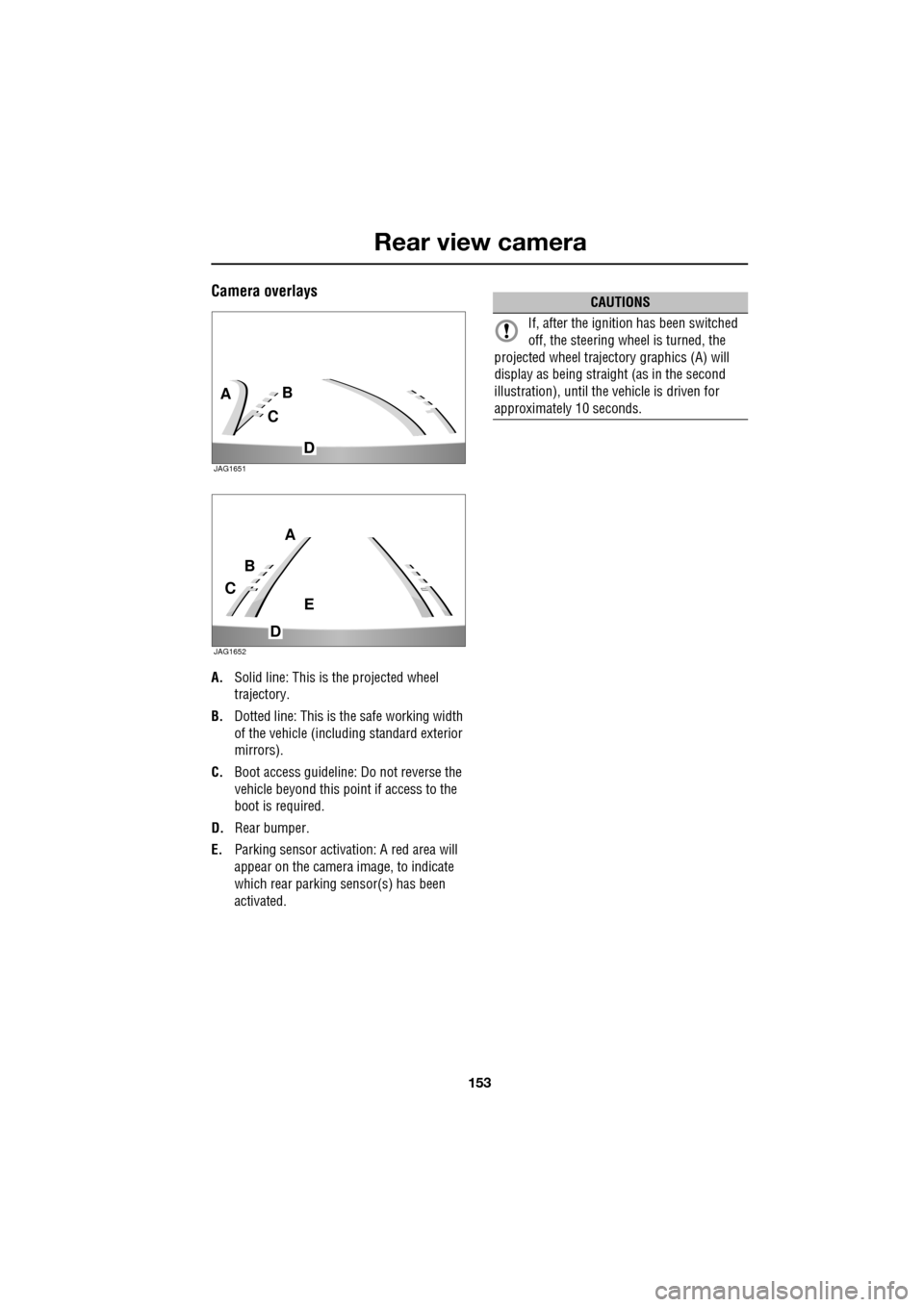

Camera overlays

A.Solid line: This is the projected wheel

trajectory.

B. Dotted line: This is the safe working width

of the vehicle (includi ng standard exterior

mirrors).

C. Boot access guideline: Do not reverse the

vehicle beyond this point if access to the

boot is required.

D. Rear bumper.

E. Parking sensor activa tion: A red area will

appear on the camera image, to indicate

which rear parking sensor(s) has been

activated.

C

BA

D

JAG1651

C

B

A

D

E

JAG1652

CAUTIONS

If, after the ignition has been switched

off, the steering wheel is turned, the

projected wheel trajecto ry graphics (A) will

display as being straight (as in the second

illustration), until the vehicle is driven for

approximately 10 seconds.

Page 184 of 391

Towing

184

Diesel engine vehicles

The diesel engine management system

incorporates sensors to determine optimum

performance. It is also designed to protect the

engine when arduous conditions are

encountered during towing. When ambient

temperature exceeds 40°C (104°F), the engine

coolant temperature may increase above

normal operating level. If this occurs, the

management system will initiate a series of

actions to restore norma l operating conditions.

The actions may include:

• A message centre message.

• Engine performance reduction.

• Air conditioning syst em cycling. The

system temperature output will fluctuate

between hot and cold, in order to dissipate

engine heat. If engine overheat persists,

the air conditioning will move to

continuous heat output.

It is advisable to bring the vehicle and trailer to

a convenient stop and allow the engine to idle

until normal temperature is restored. Do not

turn off the engine.

Trailer electrical connection

Note: The rear parking sensors are

automatically disabled when the trailer

electrical conne ction is made using Jaguar

approved towing equipment.

The vehicle's electrical system has been

designed to support all towing requirements,

and comply with legal requirements for the

specific territory in which the vehicle is first

sold.

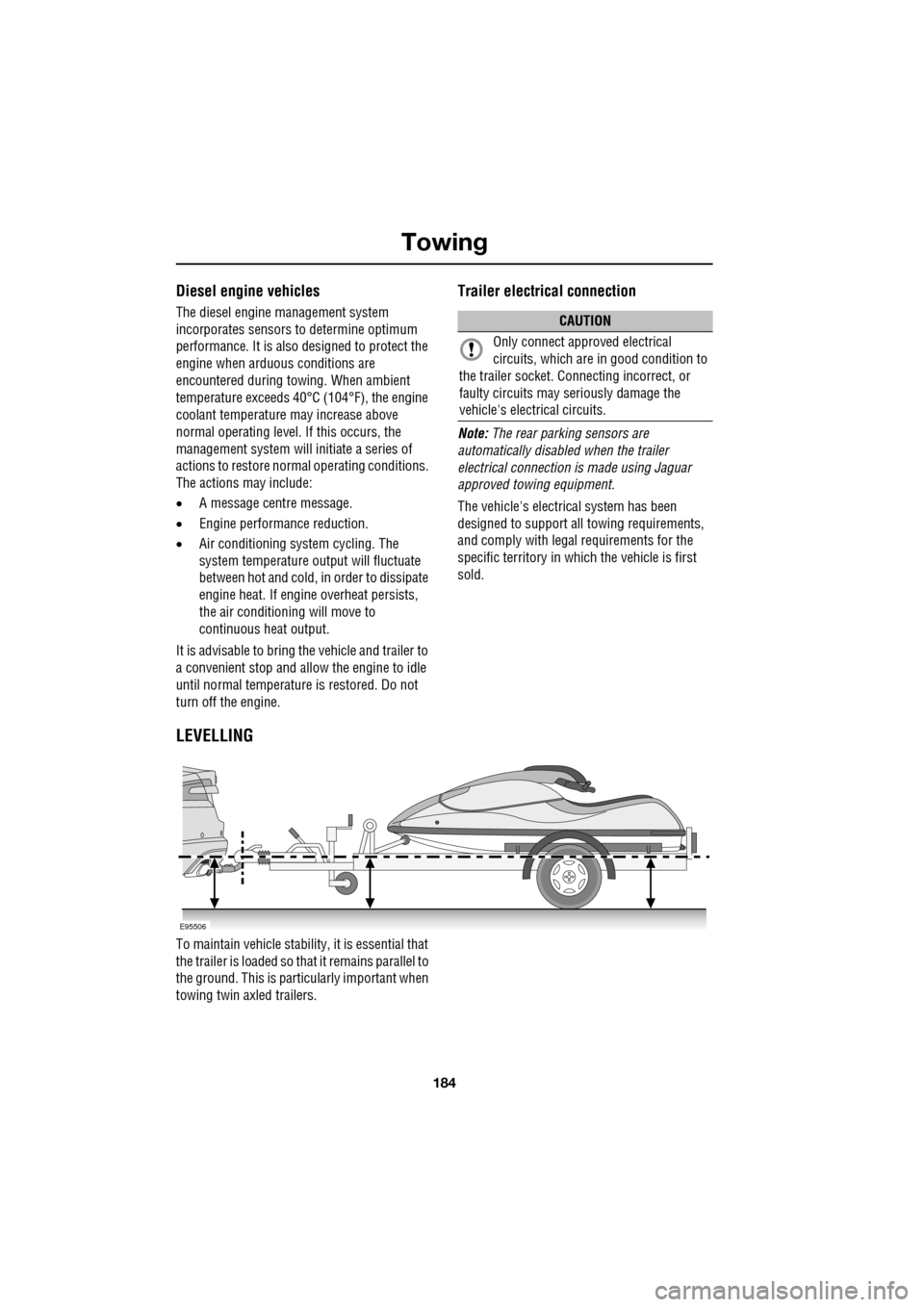

LEVELLING

To maintain vehicle stabilit y, it is essential that

the trailer is loaded so that it remains parallel to

the ground. This is particularly important when

towing twin axled trailers.

CAUTION

Only connect appr oved electrical

circuits, which are in good condition to

the trailer socket. Connecting incorrect, or

faulty circuits may seriously damage the

vehicle's electrical circuits.

E95506

Page 209 of 391

209

Maintenance

WASHER FLUID CHECK

The washer reservoir supplies the windscreen

and headlamp washer jets.

Check and top-up the reservoir level at least

every week.

Fill with Jaguar Windscreen Washer Fluid,

diluted with clean water, as specified in the

instructions on the bottle. Using a

non-approved fluid may adversely affect the

wiper blade rubber, resulting in ineffectual and

noisy wiping.

Operate the washer switches periodically to

check that the nozzles are clear and properly

directed.

Topping up the fluid

1. Clean the filler cap before removing to

prevent dirt from entering the reservoir.

2. Open filler cap.

3. Top-up the reservoir until the fluid is

visible in the filler neck.

4. Close filler cap.

WARNINGS

Some screen washer products are

inflammable, particularly if high or

undiluted concentrations are exposed

to sparking. Do not allow screen washer fluid

to come into contact with naked flames or

sources of ignition.

If the vehicle is operated in

temperatures below 4°C (40°F), use a

washer fluid with frost protection. In

cold weather, failure to use a washer fluid with

frost protection, could result in impaired

vision and increase the risk of a vehicle crash.

CAUTIONS

Do not use an antifreeze or

vinegar/water solution in the washer

reservoir - antifreeze will damage painted

surfaces, while vinegar can damage the

windscreen washer pump.

Body panels may suffer discolouration

as a result of screen washer fluid

spillage. Take care to avoid spillage,

particularly if an undiluted or high

concentration is being us ed. If spillage occurs,

wash the affected area immediately with water.

E95174

Page 220 of 391

Wheels and tyres

220

Tyre pressure compensation chart - high

ambient temperatures

Tyre pressures during long term vehicle

storage

To minimise the possibility and effects of flat

spots during storage, the tyres may be inflated

to the maximum pressure indicated on the tyre

wall.

Note: Before using the st ored vehicle on the

road again, ensure that correct tyre pressures

are restored.

Flat spots

If the vehicle is stati onary for a long period,

when the ambient temperature is high, the

tyres may form flat spots. When the vehicle is

driven, these flat spots will cause a vibration

which will steadily disappear as the tyres warm

up and regain their original shape. In order to minimise flat spotting, the tyre

pressures can be increa

sed. Tyre pressures

should be increased by 0.14 bar/14 kPa (2

lbf/in²) for each 10°C (20°F) temperature

increase above 20°C (68°F)

Long term storage

Flat spotting can be minimised during long

term storage, by increasing the tyre pressures

to the maximum indicated on the tyre sidewall.

Note: The tyre pressures s hould be reduced to

the correct pressure before the vehicle is

driven.

Tyre wear

Good driving practise will improve the mileage

you obtain from your tyres, and avoid

unnecessary damage.

• Always ensure that the tyre pressures are

correctly adjusted.

• Always observe the posted speed limits,

and advisory speeds for bends.

• Avoid pulling away quickly, or hard

acceleration.

• Avoid making fast turns or braking

sharply.

• Wherever possible, avoid potholes, or

obstacles on the road.

• Do not drive up kerbs, or rub the tyres

against them when parking.

Tyre pressure temperature compensation

Ambient

temperature -

°C (°F) Pressure

compensation -

bar (lbf/in², kPa)

20 (68) use placard label

30 (86) + 0.14 (2, 14)

40 (104) + 0.28 (4, 28)

50 (122) + 0.41 (6, 41)

E80322

Page 227 of 391

227

Wheels and tyres

Wheel changing safety

Before raising the vehicle, or changing a wheel

ensure that you read, and comply with the

following warnings.

WARNINGS

Always find a safe place to stop, off

the highway and away from traffic.

Ensure that the vehicle is on firm level

ground.

Disconnect traile r/caravan from

vehicle.

Switch on the hazard warning lamps.

Ensure that all passengers, and

animals, are out of the vehicle and in

a safe place away from the highway.

Place a warning triangle at a suitable

distance behind th e vehicle, facing

towards oncoming traffic.

Ensure that the front wheels are in the

straight ahead position, and engage

the steering lock.

Apply the parking br ake, and engage

Park (P).

Ensure that the jack is on firm level

ground.

Never place anything between the

jack and the ground, or the jack and

the vehicle.

When one rear wheel is lifted off the

ground the selection P (Park) position

will not prevent the vehicle from

moving and possibly slipping off the jack as

the park brake only operates on the rear

wheels.

Do not start or run the engine while

the vehicle is supported only by a

jack.

The jack is designed for use when

changing a wheel only. Never work

beneath the vehicle with the jack as

the only means of s upport - use vehicle

support stands.

Always chock the wheel diagonally

opposite the wheel to be changed,

using the wheel chock supplied in the

tool kit. Chock the front of a front wheel, or the

rear of a rear wheel.

If jacking the vehicle on a slight slope

is unavoidable, place chocks on the

downhill side of the two opposite

wheels. An additional chock will be

needed.

Take care when lifting the spare

wheel, and removing the punctured

wheel. The wheels are heavy, and can

cause injuries if not handled

correctly.

Remove the spare wheel prior to

jacking the vehicle. To avoid

destabilising the vehicle when raised.

Take care when loosening the wheel

nuts. The wheel brace may slip off if

not properly attached, and the wheel

nuts may give way suddenly. Either

unexpected movement ma y cause an injury.

WARNINGS

Page 228 of 391

Wheels and tyres

228

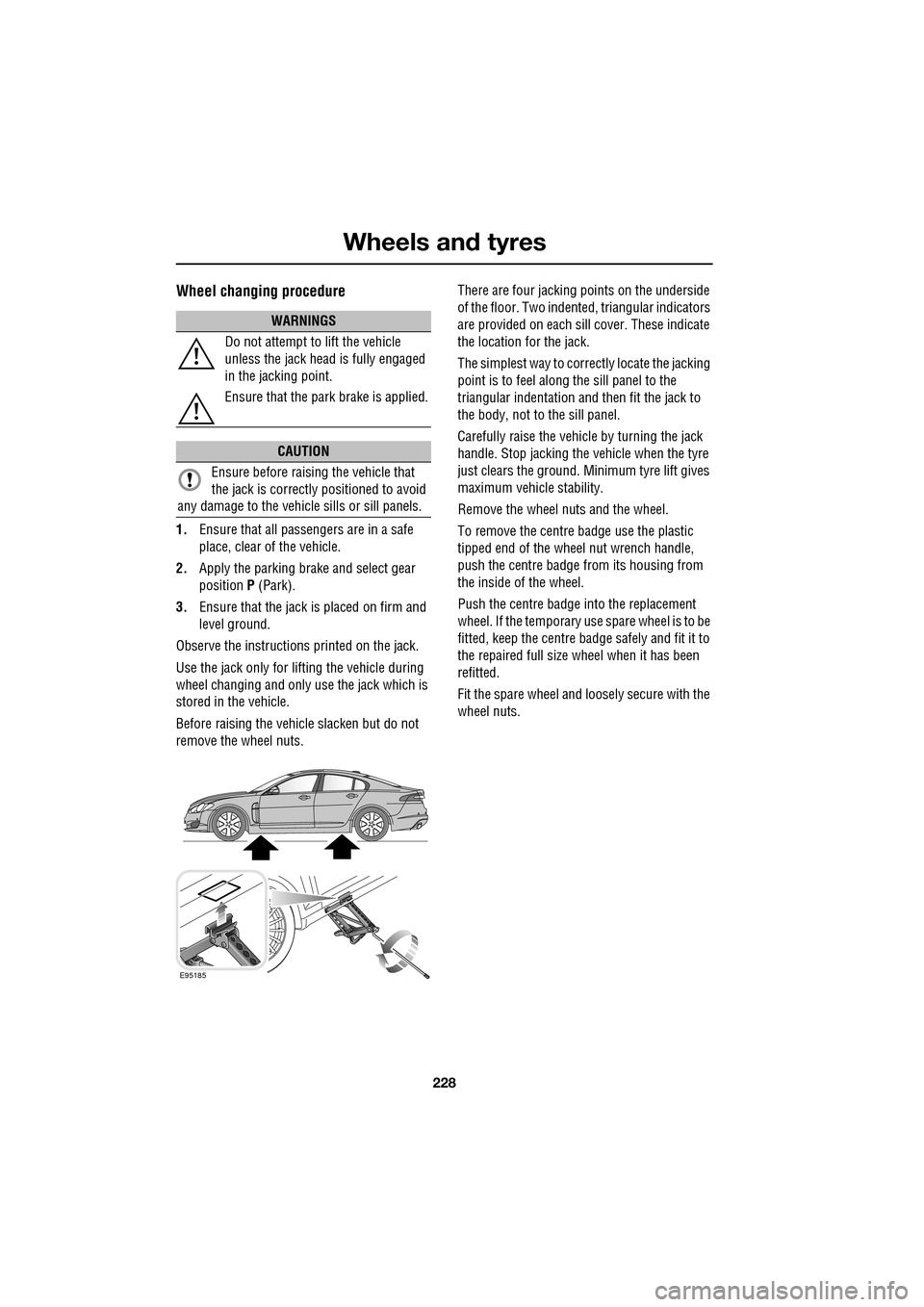

Wheel changing procedure

1.Ensure that all passengers are in a safe

place, clear of the vehicle.

2. Apply the parking brake and select gear

position P (Park).

3. Ensure that the jack is placed on firm and

level ground.

Observe the instructions printed on the jack.

Use the jack only for lifting the vehicle during

wheel changing and only us e the jack which is

stored in the vehicle.

Before raising the vehi cle slacken but do not

remove the wheel nuts. There are four jacking points on the underside

of the floor. Two indented, triangular indicators

are provided on each sill cover. These indicate

the location for the jack.

The simplest way to correctly locate the jacking

point is to feel along

the sill panel to the

triangular indentation and then fit the jack to

the body, not to the sill panel.

Carefully raise the vehicle by turning the jack

handle. Stop jacking the vehicle when the tyre

just clears the ground. Minimum tyre lift gives

maximum vehicle stability.

Remove the wheel nuts and the wheel.

To remove the centre badge use the plastic

tipped end of the wheel nut wrench handle,

push the centre badge from its housing from

the inside of the wheel.

Push the centre badge into the replacement

wheel. If the temporary use spare wheel is to be

fitted, keep the centre badge safely and fit it to

the repaired full size wheel when it has been

refitted.

Fit the spare wheel and loosely secure with the

wheel nuts.

WARNINGS

Do not attempt to lift the vehicle

unless the jack head is fully engaged

in the jacking point.

Ensure that the park brake is applied.

CAUTION

Ensure before raising the vehicle that

the jack is correctly positioned to avoid

any damage to the vehicle sills or sill panels.

E95185

Page 247 of 391

247

Fuses

Passenger compartment fuse box

Fuse No Rating (amps) Fuse

Colour Circuit

F1 - - Not used.

F2 - - Not used.

F3 20A Blue Driver's seat adjustment.

F4 20A Blue Driver's seat adjustment.

F5 - - Not used.

F6 - - Not used.

F7 - - Not used.

F8 20A Blue Front passenger's seat adjustment.

F9 20A Blue Front passenger's seat adjustment.

F10 20A Blue Left-hand rear door controls.

F11 20A Blue Right-hand rear door controls.

F12 - - Not used.

F13 10A Red Steering column adjust.

F14 - - Not used.

F15 - - Not used.

F16 5A Tan Sunblind.

F17 - - Not used.

F18 - - Not used.

F19 - - Not used.

F20 5A Tan Remote control receiver.

F21 5A Tan Foot brake.

F22 5A Tan Electric parking brake.

F23 5A Tan Driver's seat. Audio system. Auto headlamps. Upper centre console switches.

F24 10A Red Front passen ger seat. Electric windows. Mirror adjustment.

F25 20A Yellow Driver's heated/climate seat

F26 15A Blue Trailer power connector. Road pricing system.

F27 20A Yellow Front passenger's heated/climate seat.

F28 15A Blue Auxiliary power socket.

F29 20A Yellow Keyless entry system.

F30 10A Red Air conditioning.