Head JAGUAR XF 2009 1.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 391, PDF Size: 19.32 MB

Page 163 of 391

163

Adaptive cruise control (ACC)

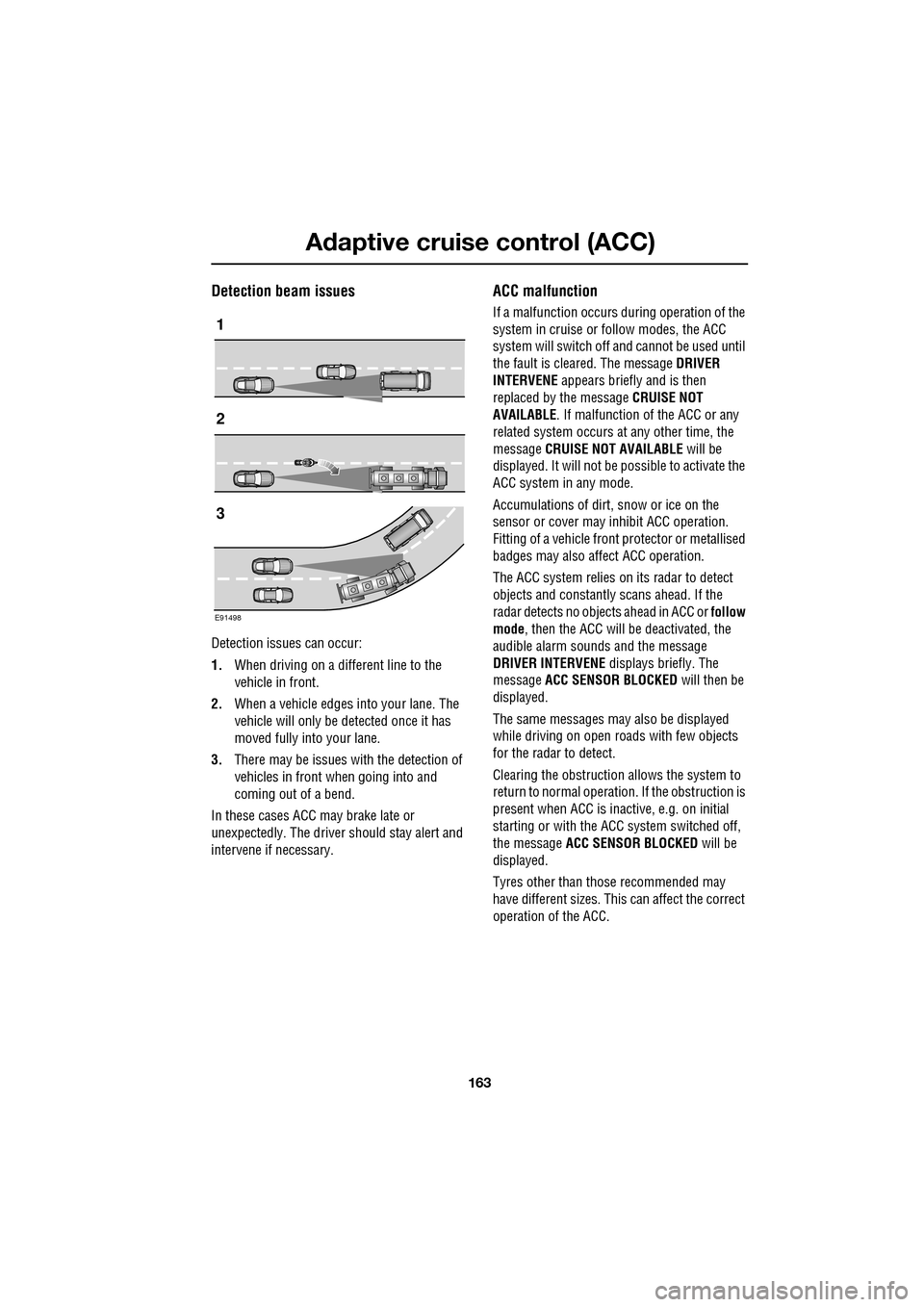

Detection beam issues

Detection issues can occur:

1.When driving on a different line to the

vehicle in front.

2. When a vehicle edges into your lane. The

vehicle will only be detected once it has

moved fully into your lane.

3. There may be issues with the detection of

vehicles in front when going into and

coming out of a bend.

In these cases ACC may brake late or

unexpectedly. The driver should stay alert and

intervene if necessary.

ACC malfunction

If a malfunction occurs during operation of the

system in cruise or follow modes, the ACC

system will switch off a nd cannot be used until

the fault is cleared. The message DRIVER

INTERVENE appears briefly and is then

replaced by the message CRUISE NOT

AVAILABLE . If malfunction of the ACC or any

related system occurs at any other time, the

message CRUISE NOT AVAILABLE will be

displayed. It will not be possible to activate the

ACC system in any mode.

Accumulations of dirt, snow or ice on the

sensor or cover may inhibit ACC operation.

Fitting of a vehicle front protector or metallised

badges may also affect ACC operation.

The ACC system relies on its radar to detect

objects and constantly scans ahead. If the

radar detects no objects ahead in ACC or follow

mode , then the ACC will be deactivated, the

audible alarm sounds and the message

DRIVER INTERVENE displays briefly. The

message ACC SENSOR BLOCKED will then be

displayed.

The same messages may also be displayed

while driving on open roads with few objects

for the radar to detect.

Clearing the obstruction allows the system to

return to normal operation. If the obstruction is

present when ACC is inac tive, e.g. on initial

starting or with the ACC system switched off,

the message ACC SENSOR BLOCKED will be

displayed.

Tyres other than those recommended may

have different sizes. This can affect the correct

operation of the ACC.1

2

3

E91498

Page 164 of 391

Adaptive cruise control (ACC)

164

Adverse weather conditions

During adverse weather conditions such as

heavy rain or snowfall, the sensitivity of radar

blockage detection is incr eased, so that it can

correctly detect any reduced performance

caused by a blocked sensor.

During these conditions, the warning message

ACC SENSOR BLOCKED may be displayed

more frequently, especially in areas where

there are few roadside objects for the radar to

detect.

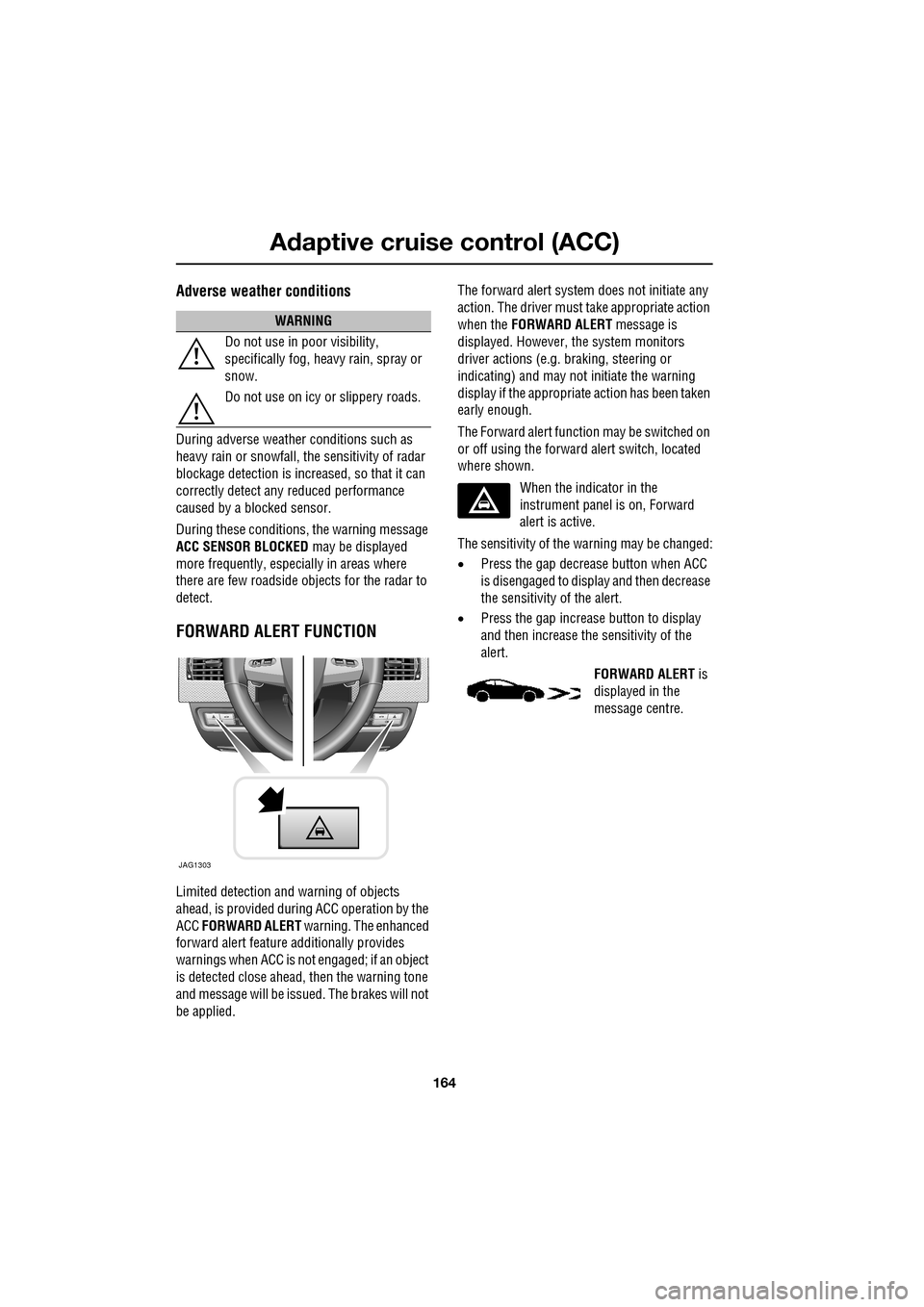

FORWARD ALERT FUNCTION

Limited detection and warning of objects

ahead, is provided during ACC operation by the

ACC FORWARD ALERT warning. The enhanced

forward alert feature additionally provides

warnings when ACC is not engaged; if an object

is detected close ahead, then the warning tone

and message will be issued. The brakes will not

be applied. The forward alert system does not initiate any

action. The driver must

take appropriate action

when the FORWARD ALERT message is

displayed. However, the system monitors

driver actions (e.g. braking, steering or

indicating) and may not initiate the warning

display if the appropriate action has been taken

early enough.

The Forward alert function may be switched on

or off using the forward alert switch, located

where shown.

When the indicator in the

instrument panel is on, Forward

alert is active.

The sensitivity of the warning may be changed:

• Press the gap decrease button when ACC

is disengaged to displa y and then decrease

the sensitivity of the alert.

• Press the gap increase button to display

and then increase the sensitivity of the

alert.

FORWARD ALERT is

displayed in the

message centre.

WARNING

Do not use in poor visibility,

specifically fog, heavy rain, spray or

snow.

Do not use on icy or slippery roads.

JAG1303

Page 165 of 391

165

Adaptive cruise control (ACC)

ADVANCED EMERGENCY BRAKE

ASSIST

On vehicles fitted with Advanced Emergency

Brake Assist, brake response is improved

during emergency braking when a moving

vehicle is detected close ahead.

Advanced Emergency Brake Assist activates If

the risk of collision increases after the

FORWARD ALERT warning is displayed.

See FORWARD ALERT FUNCTION (page 164).

The brakes are automatica lly applied gently in

preparation for rapid braking (which may be

noticeable). If the brake pedal is then pressed

quickly, then braking is implemented fully,

even if the pressure on the pedal is light.

See HINTS ON DRIVING WITH ABS

(page 144).

Advanced Emergency Brake Assist is available

at speeds above approximately 7 km/h (5 mph)

and will function even if Forward Alert and

Adaptive Cruise Control are switched off. A

fault with the system will be indicated by the

warning FORWARD ALER T UNAVAILABLE

appearing in the mess age centre. Advanced

Emergency Brake Assist will not be available

until the fault is rectified.

WARNING

Advanced Emergency Brake Assist, is

an additional safety system and is not

intended to relieve the driver of the

responsibility for exer cising due care and

attention when driving.

CAUTION

The system may not react to slow

moving vehicles and will not react to

stationary vehicles or vehicles not

travelling in the same direction as your vehicle.

Advanced Emergency Brake Assist can

only improve braking performance if the

driver applies the brakes.

Warnings may not appear if the distance

to the vehicle ahead is very small or if

steering wheel and pedal movements

are large (e.g. to avoid a collision).

Advanced Emergency Brake Assist

utilises the same radar sensor as

Adaptive Cruise Control and Forward

Alert - the same limita tions of performance

apply.

See PRINCIPLE OF OPERATION (page 159).

See USING ACC (page 159).

See FORWARD ALERT FUNCTION

(page 164).

Page 209 of 391

209

Maintenance

WASHER FLUID CHECK

The washer reservoir supplies the windscreen

and headlamp washer jets.

Check and top-up the reservoir level at least

every week.

Fill with Jaguar Windscreen Washer Fluid,

diluted with clean water, as specified in the

instructions on the bottle. Using a

non-approved fluid may adversely affect the

wiper blade rubber, resulting in ineffectual and

noisy wiping.

Operate the washer switches periodically to

check that the nozzles are clear and properly

directed.

Topping up the fluid

1. Clean the filler cap before removing to

prevent dirt from entering the reservoir.

2. Open filler cap.

3. Top-up the reservoir until the fluid is

visible in the filler neck.

4. Close filler cap.

WARNINGS

Some screen washer products are

inflammable, particularly if high or

undiluted concentrations are exposed

to sparking. Do not allow screen washer fluid

to come into contact with naked flames or

sources of ignition.

If the vehicle is operated in

temperatures below 4°C (40°F), use a

washer fluid with frost protection. In

cold weather, failure to use a washer fluid with

frost protection, could result in impaired

vision and increase the risk of a vehicle crash.

CAUTIONS

Do not use an antifreeze or

vinegar/water solution in the washer

reservoir - antifreeze will damage painted

surfaces, while vinegar can damage the

windscreen washer pump.

Body panels may suffer discolouration

as a result of screen washer fluid

spillage. Take care to avoid spillage,

particularly if an undiluted or high

concentration is being us ed. If spillage occurs,

wash the affected area immediately with water.

E95174

Page 211 of 391

211

Maintenance

Capacities

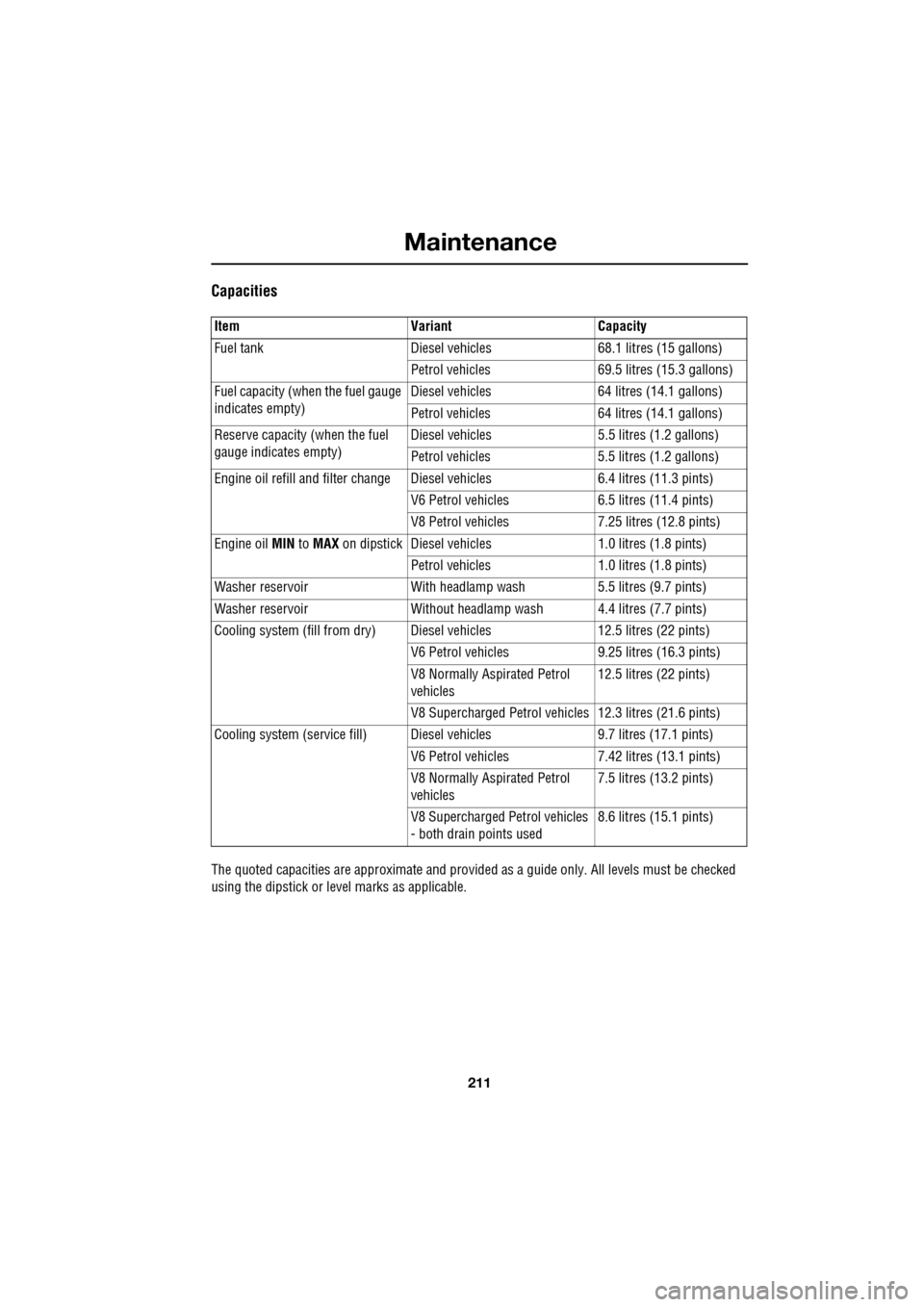

The quoted capacities are approximate and provided as a guide only. All levels must be checked

using the dipstick or le vel marks as applicable.

Item Variant Capacity

Fuel tank Diesel vehicles 68.1 litres (15 gallons)

Petrol vehicles 69.5 litres (15.3 gallons)

Fuel capacity (when the fuel gauge

indicates empty) Diesel vehicles 64

litres (14.1 gallons)

Petrol vehicles 64 litres (14.1 gallons)

Reserve capacity (when the fuel

gauge indicates empty) Diesel vehicles 5.5 litres (1.2 gallons)

Petrol vehicles 5.5 li

tres (1.2 gallons)

Engine oil refill and filter change Diesel vehicles 6.4 litres (11.3 pints)

V6 Petrol vehicles 6.5 litres (11.4 pints)

V8 Petrol vehicles 7.25 litres (12.8 pints)

Engine oil MIN to MAX on dipstick Diesel vehicl es1.0 litres (1.8 pints)

Petrol vehicles 1.0 litres (1.8 pints)

Washer reservoir With headlamp wash 5.5 litres (9.7 pints)

Washer reservoir Without headlamp wash 4.4 litres (7.7 pints)

Cooling system (fill from dry) Diesel vehicles 12.5 litres (22 pints)

V6 Petrol vehicles 9.25 litres (16.3 pints)

V8 Normally As pirated Petrol

vehicles 12.5 litres (22 pints)

V8 Supercharged Petrol vehi cles 12.3 litres (21.6 pints)

Cooling system (service fill) Diesel vehicles 9.7 litres (17.1 pints)

V6 Petrol vehicles 7.42 litres (13.1 pints)

V8 Normally As pirated Petrol

vehicles 7.5 litres (13.2 pints)

V8 Supercharged Petrol vehicles

- both drain points used 8.6 litres (15.1 pints)

Page 227 of 391

227

Wheels and tyres

Wheel changing safety

Before raising the vehicle, or changing a wheel

ensure that you read, and comply with the

following warnings.

WARNINGS

Always find a safe place to stop, off

the highway and away from traffic.

Ensure that the vehicle is on firm level

ground.

Disconnect traile r/caravan from

vehicle.

Switch on the hazard warning lamps.

Ensure that all passengers, and

animals, are out of the vehicle and in

a safe place away from the highway.

Place a warning triangle at a suitable

distance behind th e vehicle, facing

towards oncoming traffic.

Ensure that the front wheels are in the

straight ahead position, and engage

the steering lock.

Apply the parking br ake, and engage

Park (P).

Ensure that the jack is on firm level

ground.

Never place anything between the

jack and the ground, or the jack and

the vehicle.

When one rear wheel is lifted off the

ground the selection P (Park) position

will not prevent the vehicle from

moving and possibly slipping off the jack as

the park brake only operates on the rear

wheels.

Do not start or run the engine while

the vehicle is supported only by a

jack.

The jack is designed for use when

changing a wheel only. Never work

beneath the vehicle with the jack as

the only means of s upport - use vehicle

support stands.

Always chock the wheel diagonally

opposite the wheel to be changed,

using the wheel chock supplied in the

tool kit. Chock the front of a front wheel, or the

rear of a rear wheel.

If jacking the vehicle on a slight slope

is unavoidable, place chocks on the

downhill side of the two opposite

wheels. An additional chock will be

needed.

Take care when lifting the spare

wheel, and removing the punctured

wheel. The wheels are heavy, and can

cause injuries if not handled

correctly.

Remove the spare wheel prior to

jacking the vehicle. To avoid

destabilising the vehicle when raised.

Take care when loosening the wheel

nuts. The wheel brace may slip off if

not properly attached, and the wheel

nuts may give way suddenly. Either

unexpected movement ma y cause an injury.

WARNINGS

Page 228 of 391

Wheels and tyres

228

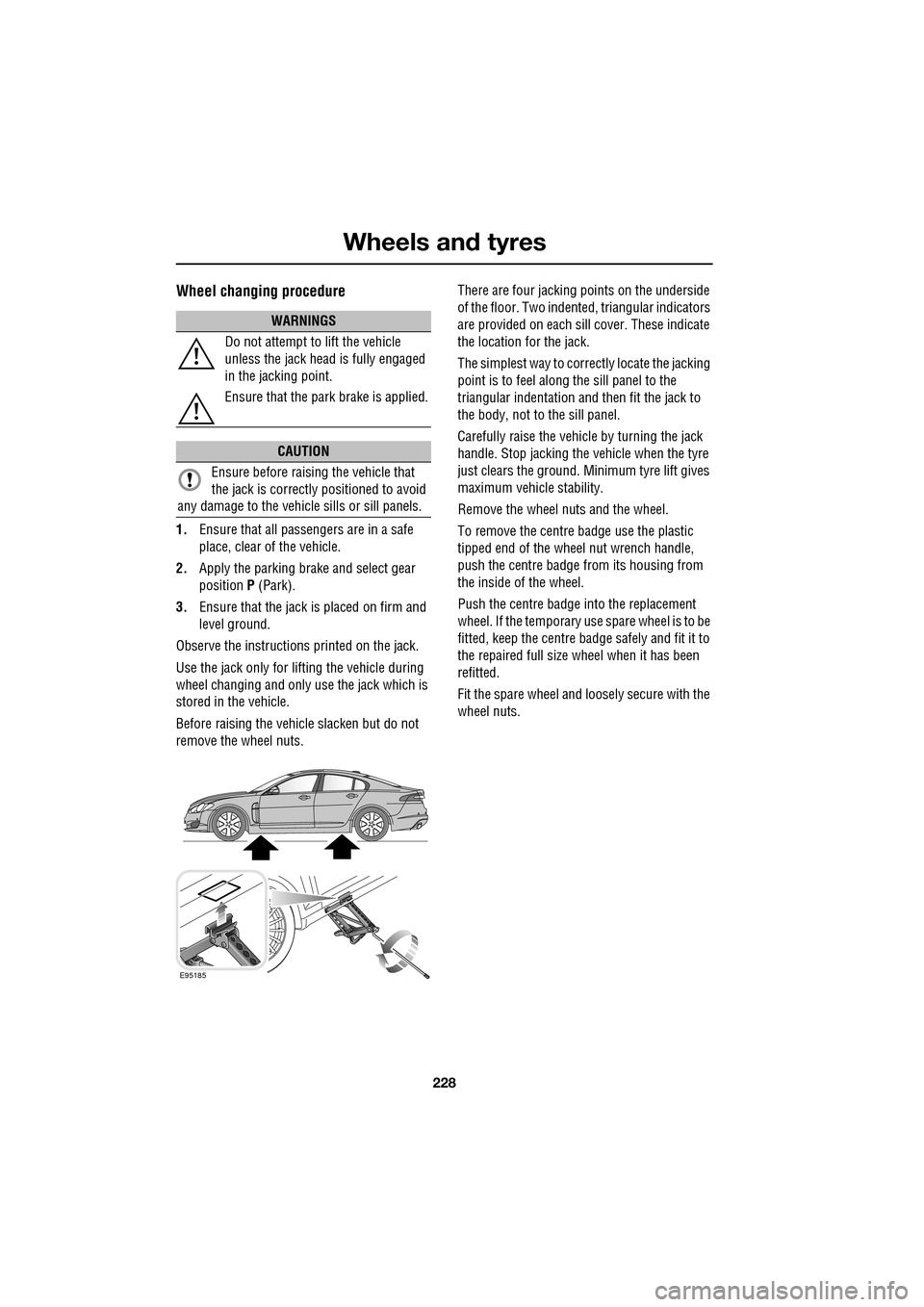

Wheel changing procedure

1.Ensure that all passengers are in a safe

place, clear of the vehicle.

2. Apply the parking brake and select gear

position P (Park).

3. Ensure that the jack is placed on firm and

level ground.

Observe the instructions printed on the jack.

Use the jack only for lifting the vehicle during

wheel changing and only us e the jack which is

stored in the vehicle.

Before raising the vehi cle slacken but do not

remove the wheel nuts. There are four jacking points on the underside

of the floor. Two indented, triangular indicators

are provided on each sill cover. These indicate

the location for the jack.

The simplest way to correctly locate the jacking

point is to feel along

the sill panel to the

triangular indentation and then fit the jack to

the body, not to the sill panel.

Carefully raise the vehicle by turning the jack

handle. Stop jacking the vehicle when the tyre

just clears the ground. Minimum tyre lift gives

maximum vehicle stability.

Remove the wheel nuts and the wheel.

To remove the centre badge use the plastic

tipped end of the wheel nut wrench handle,

push the centre badge from its housing from

the inside of the wheel.

Push the centre badge into the replacement

wheel. If the temporary use spare wheel is to be

fitted, keep the centre badge safely and fit it to

the repaired full size wheel when it has been

refitted.

Fit the spare wheel and loosely secure with the

wheel nuts.

WARNINGS

Do not attempt to lift the vehicle

unless the jack head is fully engaged

in the jacking point.

Ensure that the park brake is applied.

CAUTION

Ensure before raising the vehicle that

the jack is correctly positioned to avoid

any damage to the vehicle sills or sill panels.

E95185

Page 234 of 391

Wheels and tyres

234

7.Switch the compressor to on ( I) and inflate

the tyre to the correct pressure.

8. To check the tyre pressure, turn off the

compressor then read the pressure from

the gauge.

9. When the compressor is off, if the tyre

pressure is too high, release the required

amount of pressure using the pressure

relief valve.

10. Once the tyre is inflated to the correct

pressure, switch off the compressor and

remove the power plug from the auxiliary

socket.

•The use of the tyre re pair kit sealant may

lead to error prompts and incorrect

readings of the Tyre Pressure

Monitoring System. Therefore, use the

tyre repair kit pressure gauge to check

and adjust the damaged tyre's inflation

pressure.

11. Unscrew the inflation hose connector from

the tyre valve, replace the tyre valve cap

and the inflation hose connector protective

cap.

12. Ensure that the tyre repair kit is placed

securely in the vehicle.

13. Drive to the nearest tyre repair centre or

Dealer/Authorised Repairer, for a

replacement tyre to be fitted. Ensure that

you make the repair centre aware that the

tyre repair kit has been used before the tyre

is removed.

14. Both the tyre inflation hose, and the sealant

container should be replaced once a new

tyre has been fitted. Only sealant containers which are

completely empty should be

disposed of with normal household

waste. Sealant containe rs which contain some

sealant, and the tyre in flation hose, should be

disposed of by a tyre specialist or your

Dealer/Authorised Repairer, in compliance with

local waste dispos al regulations.

TYRE PRESSURE MONITORING

SYSTEM

Note: Non-approved accessories may interfere

with the system. If this occurs, TYRE

PRESSURE SYSTEM FAULT is displayed in the

message centre.

WARNINGS

The Tyre Pressure Monitoring (TPM)

system is NOT a substitute for

manually checking ty re pressures.

The TPM system only provides a low pressure

warning and does not re-i nflate your tyres.

Tyre pressures should be checked regularly

using an accurate pressure gauge when cold.

Failure to properly maintain your pressures

could increase the risk of tyre failure, with

consequential loss of vehicle control and

personal injury.

The TPM system can NOT register

damage to a tyre. Regularly check the

condition of your tyre s, especially if

the vehicle is driven off-road.

CAUTION

When inflating tyre s, care should be

taken to avoid bend ing or damaging the

TPM system valves. Always ensure correct

alignment of the inflation head to the valve

stem.

Page 246 of 391

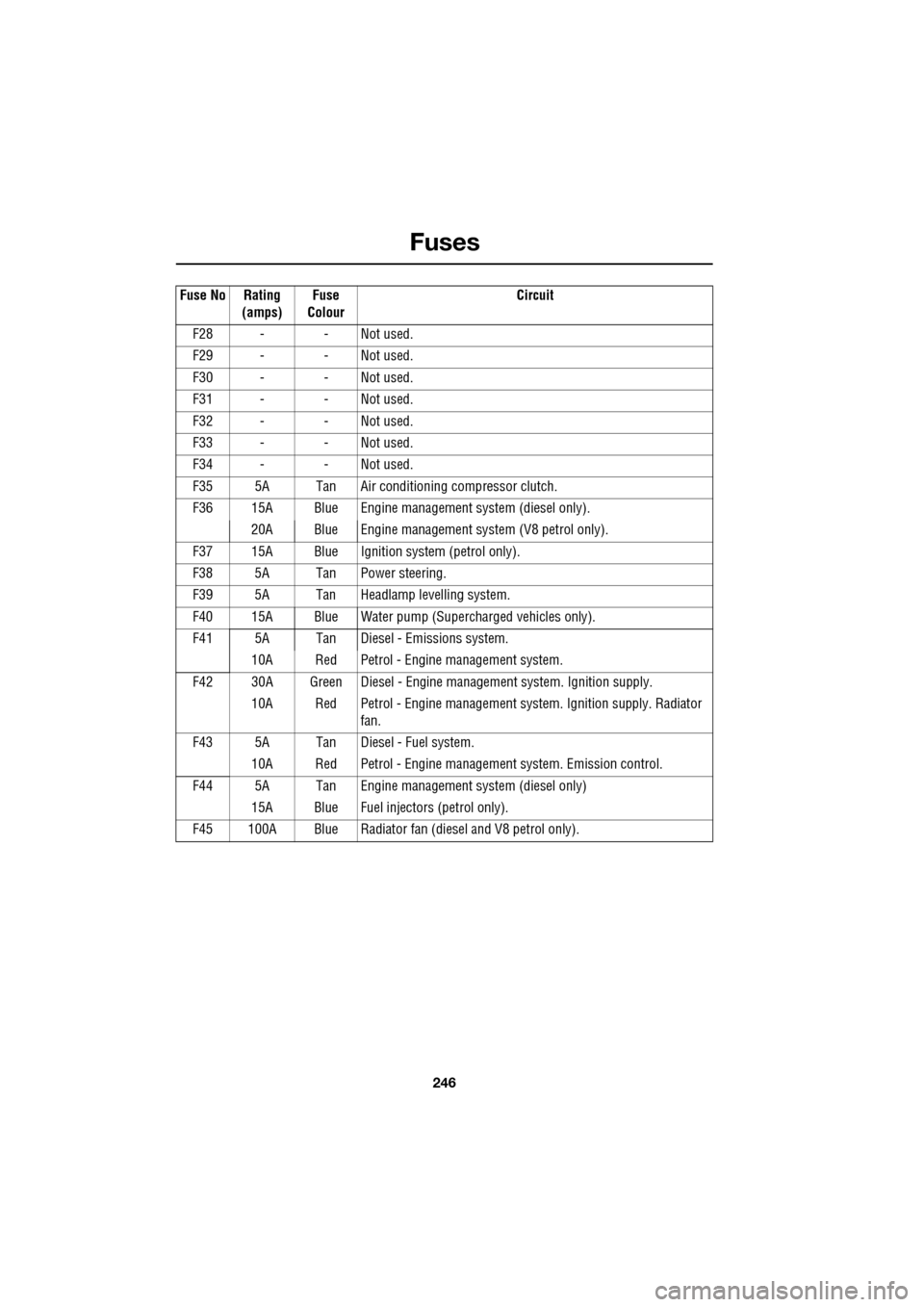

Fuses

246

F28 - - Not used.

F29 - - Not used.

F30 - - Not used.

F31 - - Not used.

F32 - - Not used.

F33 - - Not used.

F34 - - Not used.

F35 5A Tan Air conditioning compressor clutch.

F36 15A Blue Engine management system (diesel only).

20A Blue Engine management sy stem (V8 petrol only).

F37 15A Blue Ignition s ystem (petrol only).

F38 5A Tan Power steering.

F39 5A Tan Headlamp levelling system.

F40 15A Blue Water pump (Superc harged vehicles only).

F41 5A Tan Diesel - Emissions system.

10A Red Petrol - Engine management system.

F42 30A Green Diesel - Engi ne management system. Ignition supply.

10A Red Petrol - Engine management system. Ignition supply. Radiator

fan.

F43 5A Tan Diesel - Fuel system. 10A Red Petrol - Engine manageme nt system. Emission control.

F44 5A Tan Engine management system (diesel only)

15A Blue Fuel injectors (petrol only).

F45 100A Blue Radiator fan (diesel and V8 petrol only).

Fuse No Rating

(amps) Fuse

Colour Circuit

Page 247 of 391

247

Fuses

Passenger compartment fuse box

Fuse No Rating (amps) Fuse

Colour Circuit

F1 - - Not used.

F2 - - Not used.

F3 20A Blue Driver's seat adjustment.

F4 20A Blue Driver's seat adjustment.

F5 - - Not used.

F6 - - Not used.

F7 - - Not used.

F8 20A Blue Front passenger's seat adjustment.

F9 20A Blue Front passenger's seat adjustment.

F10 20A Blue Left-hand rear door controls.

F11 20A Blue Right-hand rear door controls.

F12 - - Not used.

F13 10A Red Steering column adjust.

F14 - - Not used.

F15 - - Not used.

F16 5A Tan Sunblind.

F17 - - Not used.

F18 - - Not used.

F19 - - Not used.

F20 5A Tan Remote control receiver.

F21 5A Tan Foot brake.

F22 5A Tan Electric parking brake.

F23 5A Tan Driver's seat. Audio system. Auto headlamps. Upper centre console switches.

F24 10A Red Front passen ger seat. Electric windows. Mirror adjustment.

F25 20A Yellow Driver's heated/climate seat

F26 15A Blue Trailer power connector. Road pricing system.

F27 20A Yellow Front passenger's heated/climate seat.

F28 15A Blue Auxiliary power socket.

F29 20A Yellow Keyless entry system.

F30 10A Red Air conditioning.