Start JAGUAR XF 2009 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 391, PDF Size: 19.32 MB

Page 202 of 391

Maintenance

202

Oil level warnings

Warnings will be displayed in the message

centre if the oil level is not maintained within

the safe operating le vels (minimum and

maximum). A warning will also be displayed if

there is a fault with the oil level monitoring

system.

• ENGINE OIL LOW (amber): The oil is at the

minimum level for sa fe operation. Top-up

with 1 litre (1.8 pints) of oil.

• ENGINE OIL HIGH (amber): This warning

is displayed when the e ngine is started, if

the oil is above the maximum level for safe

operation. Seek qualified assistance to

have the engine oil drained, before driving

the vehicle.

• ENGINE OIL CRITICALLY LOW (red): The

oil is below the minimum level for safe

operation. Stop the vehicle as soon as

safety permits and top-up with 1.5 litres

(2.6 pints) of oil. Wait for 5 minutes,

recheck the oil level reading and top-up

again if necessary.

• ENGINE OIL LEVEL MONITOR SYSTEM

FAULT (amber): A fault with the oil level

monitoring system is indicated. Seek

qualified assistance as soon as possible.

Checking the oil level

The engine oil level is automatically monitored

and is displayed in the trip computer area of the

message centre.

The current oil level can be viewed with the

ignition on, with the engine stopped and the

transmission in Park (P ).

To view the current oil level, allow 5 minutes

after stopping the engine (to allow the oil level

to stabilise), then press the TRIP button on the

end of the left column stalk repeatedly, until the

oil can icon is displayed at the bottom of the

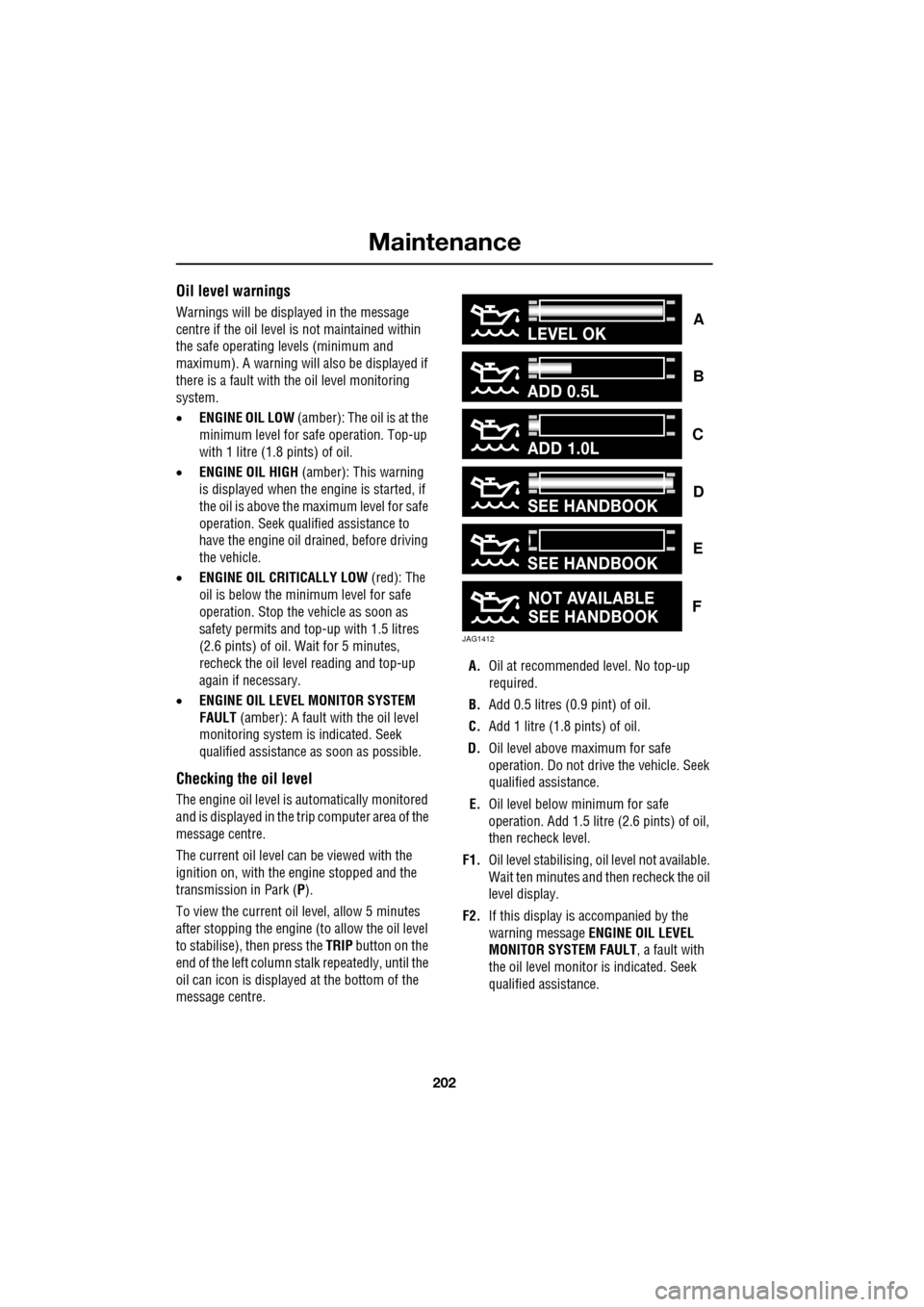

message centre. A.

Oil at recommended level. No top-up

required.

B. Add 0.5 litres (0.9 pint) of oil.

C. Add 1 litre (1.8 pints) of oil.

D. Oil level above maximum for safe

operation. Do not driv e the vehicle. Seek

qualified assistance.

E. Oil level below minimum for safe

operation. Add 1.5 litre (2.6 pints) of oil,

then recheck level.

F1. Oil level stabilising, oil level not available.

Wait ten minutes and then recheck the oil

level display.

F2. If this display is accompanied by the

warning message ENGINE OIL LEVEL

MONITOR SYSTEM FAULT , a fault with

the oil level monitor is indicated. Seek

qualified assistance.

ADD 0.5L

ADD 1.0L

LEVEL OK

JAG1412

SEE HANDBOOK

NOT AVAILABLE

SEE HANDBOOK

SEE HANDBOOK

C

B

A

F

E

D

Page 208 of 391

Maintenance

208

POWER STEERING FLUID CHECK

Checking the fluid level

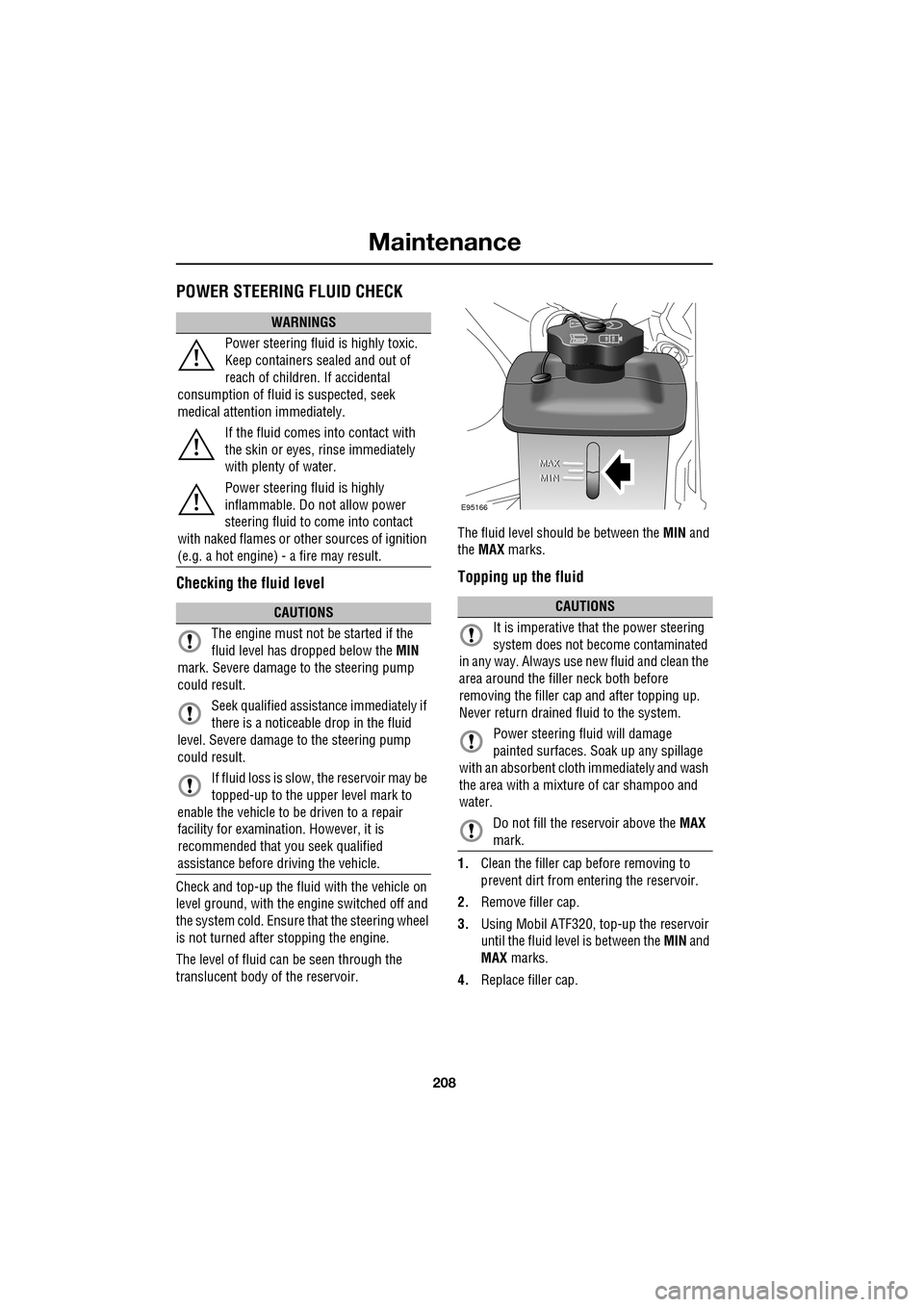

Check and top-up the fluid with the vehicle on

level ground, with the e ngine switched off and

the system cold. Ensure that the steering wheel

is not turned after stopping the engine.

The level of fluid can be seen through the

translucent body of the reservoir. The fluid level shoul

d be between the MIN and

the MAX marks.

Topping up the fluid

1.Clean the filler cap before removing to

prevent dirt from entering the reservoir.

2. Remove filler cap.

3. Using Mobil ATF320, top-up the reservoir

until the fluid level is between the MIN and

MAX marks.

4. Replace filler cap.

WARNINGS

Power steering fluid is highly toxic.

Keep containers sealed and out of

reach of children. If accidental

consumption of fluid is suspected, seek

medical attenti on immediately.

If the fluid comes into contact with

the skin or eyes, rinse immediately

with plenty of water.

Power steering fluid is highly

inflammable. Do not allow power

steering fluid to come into contact

with naked flames or other sources of ignition

(e.g. a hot engine) - a fire may result.

CAUTIONS

The engine must not be started if the

fluid level has dropped below the MIN

mark. Severe damage to the steering pump

could result.

Seek qualified assistance immediately if

there is a noticeable drop in the fluid

level. Severe damage to the steering pump

could result.

If fluid loss is slow, the reservoir may be

topped-up to the upper level mark to

enable the vehicle to be driven to a repair

facility for examination. However, it is

recommended that you seek qualified

assistance before driving the vehicle.CAUTIONS

It is imperative that the power steering

system does not beco me contaminated

in any way. Always use new fluid and clean the

area around the filler neck both before

removing the filler ca p and after topping up.

Never return drained fluid to the system.

Power steering fluid will damage

painted surfaces. So ak up any spillage

with an absorbent cloth immediately and wash

the area with a mixture of car shampoo and

water.

Do not fill the reservoir above the MAX

mark.

E95166

Page 212 of 391

Vehicle battery

212

BATTERY WARNING SYMBOLS

BATTERY CARE

Do not allow any naked flames,

or other sources of ignition near

the battery as the battery may

emit explosive gasses.

Ensure that when working near,

or handling the battery, suitable

eye protection is worn. This will

reduce the risk of eye damage

caused by acid splashes.

To prevent risk of injury, do not

allow children near the battery.

Be aware that the battery may

emit explosive gasses.

The battery contains acid which

is extremely corrosive, and toxic.

WARNINGS

Do not allow the battery electrolyte

(fluid) to come into contact with your

skin or eyes. It is both corrosive and

toxic, and the resulting injuries can be severe.

If any electrolyte does come into contact with

your skin or eyes, immediately rinse the

affected area with clean, cold water.

Immediate medical advice will be required.

If battery electrolyte comes into

contact with your skin and/or clothes

you should remove the affected

clothing and flush the skin with copious

amounts of water. Seek medical assistance

immediately.

If battery electrolyte comes into

contact with your eyes, flush with

copious amounts of clean cold water.

Seek medical assistance immediately, and

continue to flush with water.

If swallowed, battery electrolyte can

be fatal. If electrolyte is swallowed,

seek medical assistance immediately.

Do not connect any 12 volt equipment

directly to the battery terminals.

Doing so may cause a spark, which

can result in an explosion.

The cell plugs and vent pipe must be

in place at all times when the battery

is connected to the vehicle. Ensure

that the vent pipe is clear of obstructions and

not kinked. Failure to do so may cause a

pressure build up in the battery, resulting in an

explosion.

Do not expose the battery to a naked

flame or spark as the battery

produces explosive , flammable gas.

Never jump start (boost) or charge, a

frozen battery. Doing so can result in

an explosion.

Remove all metal jewellery before

working on, or near , the battery, and

never allow metal tools or vehicle

components to come into contact with the

battery terminals. Metal objects can cause

sparks and/or short circuits, resulting in an

explosion.

Do not allow the battery posts or

terminals to come into contact with

your skin. They cont ain lead and lead

compounds, which are toxic. Always wash

your hands thoroughly after handling the

battery.

WARNINGS

Page 214 of 391

Vehicle battery

214

USING BOOSTER CABLES

Note: Before connecti ng booster cables,

ensure that the battery connections on the

disabled vehicle are correct and that all

electrical equipment has been switched off.

1. Connect one end of the positive booster

cable to the positive terminal on the donor

vehicle's battery.

2. Connect the other end of the positive

booster cable to the positive terminal on

the disabled vehicle's battery. 3.

Connect one end of th e negative booster

cable to the earth point of the donor vehicle

that is recommended for jump starting by

the manufacturer.

4. Connect the other end of the negative

booster cable to a suitable earth point on

the disabled vehicle. The earth point

should be at least 0.5 metres (20 inches)

away from the battery and as far as

possible from any fu el or brake pipes.

• Check that all cables are clear of any

moving components and that all four

connections are secure.

5. Start the engine of the donor vehicle, and

allow it to idle for a few minutes.

6. Start the engine of the disabled vehicle.

7. Allow both vehicles to idle for two minutes.

8. Switch off the donor vehicle.

Disconnecting the cables

Note: Do not switch on any electrical

equipment until after th e cables have been

disconnected.

The engine should be running on the

previously disabled ve hicle and the engine

switched off on the donor vehicle. Disconnect

the booster cables in the exact reverse order of

that used for connection.

WARNINGS

Always wear appropriate eye

protection when working with

batteries.

During normal use, batteries emit

explosive hydrogen gas - ensure

sparks and naked lights are kept away

from the luggage compartment.

Do not attempt to start the vehicle if

the electrolyte in the battery is

suspected of being frozen.

Make sure both batt eries are of the 12

volt type and that the booster cables

have insulated clamps and are

approved for use with 12 volt batteries.

Do not disconnect the discharged

battery.

Do not connect posit ive (+) terminals

to negative (-) terminals and ensure

booster cables are kept away from

any moving parts in the engine compartment.

Do not connect a booster cable to the

negative (-) terminal of the battery.

Always connect to the recommended

earthing point.

WARNING

To avoid serious in jury use extreme

caution when removing the booster

cables as the engine will be running

on the previously disabl ed vehicle. This means

that you may be workin g close to components

which are moving at high speed, carry high

voltage, or may be hot.

Page 219 of 391

219

Wheels and tyres

The following procedure should be used to

check and adjust the tyres pressures.

1.Remove the valve cap.

2. Firmly attach a tyre pressure gauge/inflator

to the valve.

3. Read the tyre pressure from the gauge,

and add air if required.

4. If air is added to the tyre, remove the gauge

and re-attach it be fore reading the

pressure. Failure to do so may result in an

inaccurate reading.

5. If the tyre pressure is too high, remove the

gauge and allow air out of the tyre by

pressing the centre of the valve. Refit the

gauge to the valve and check the pressure.

6. Repeat the process a dding or removing air

as required until the correct tyre pressure

is reached.

7. Refit the valve cap.

Note: It is an offence in certain countries to

drive a vehicle with incorrect tyre pressures.

Note: It is the driver's responsibility to ensure

that the tyre pressures are correct.

Tyre valves

Keep the valve caps screwed down firmly to

prevent water or dirt entering the valve. Check

the valves for leaks when checking the tyre

pressures.

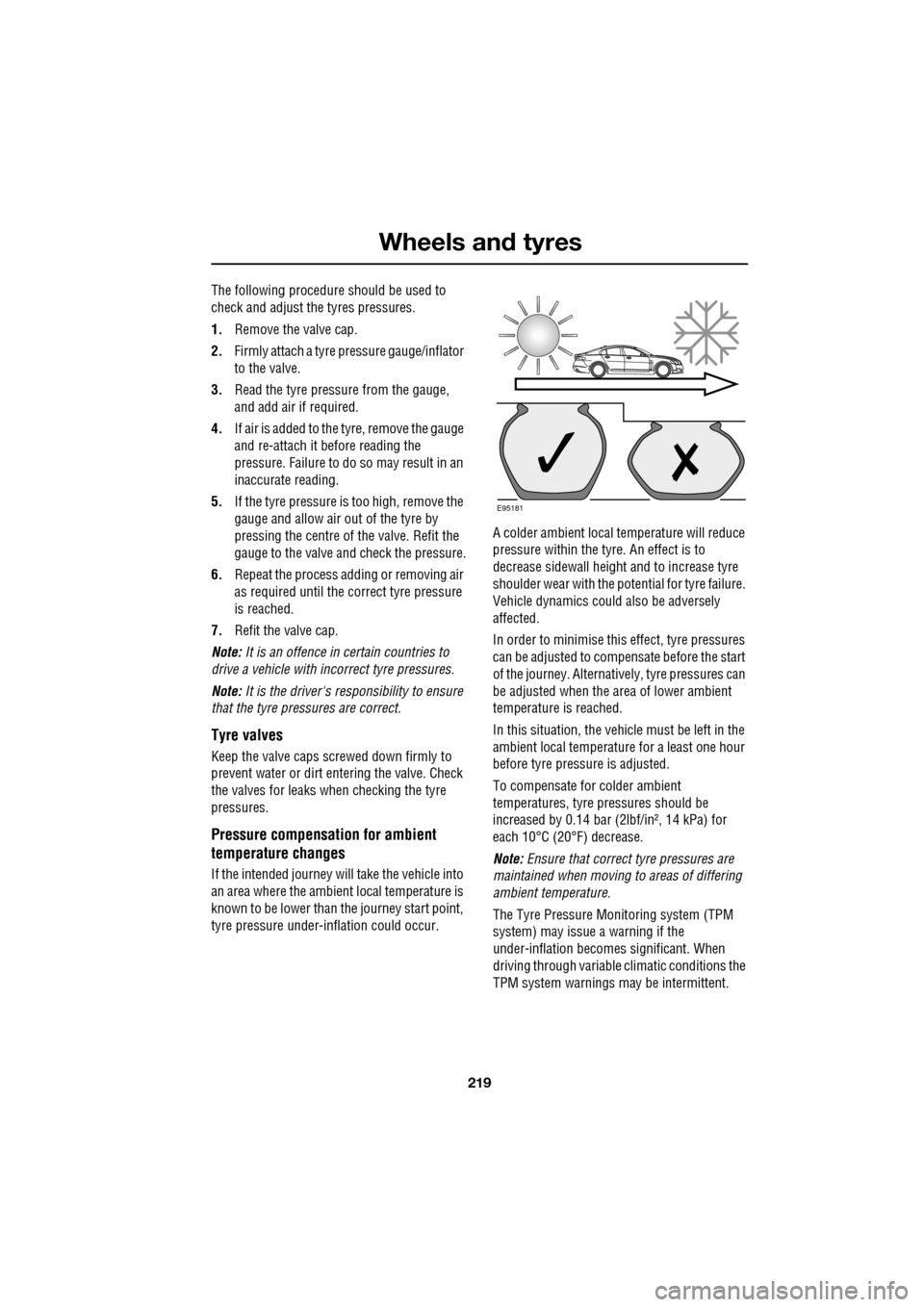

Pressure compensation for ambient

temperature changes

If the intended journey will take the vehicle into

an area where the ambien t local temperature is

known to be lower than the journey start point,

tyre pressure under-i nflation could occur. A colder ambient local temperature will reduce

pressure within the tyre. An effect is to

decrease sidewall height

and to increase tyre

shoulder wear with the potential for tyre failure.

Vehicle dynamics could also be adversely

affected.

In order to minimise this effect, tyre pressures

can be adjusted to compensate before the start

of the journey. Alternatively, tyre pressures can

be adjusted when the area of lower ambient

temperature is reached.

In this situation, the vehicle must be left in the

ambient local temperature for a least one hour

before tyre pressu re is adjusted.

To compensate for colder ambient

temperatures, tyre pressures should be

increased by 0.14 bar (2lbf/in², 14 kPa) for

each 10°C (20°F) decrease.

Note: Ensure that correct tyre pressures are

maintained when moving to areas of differing

ambient temperature.

The Tyre Pressure M onitoring system (TPM

system) may issue a warning if the

under-inflation becomes significant. When

driving through variable climatic conditions the

TPM system warnings may be intermittent.

E95181

Page 221 of 391

221

Wheels and tyres

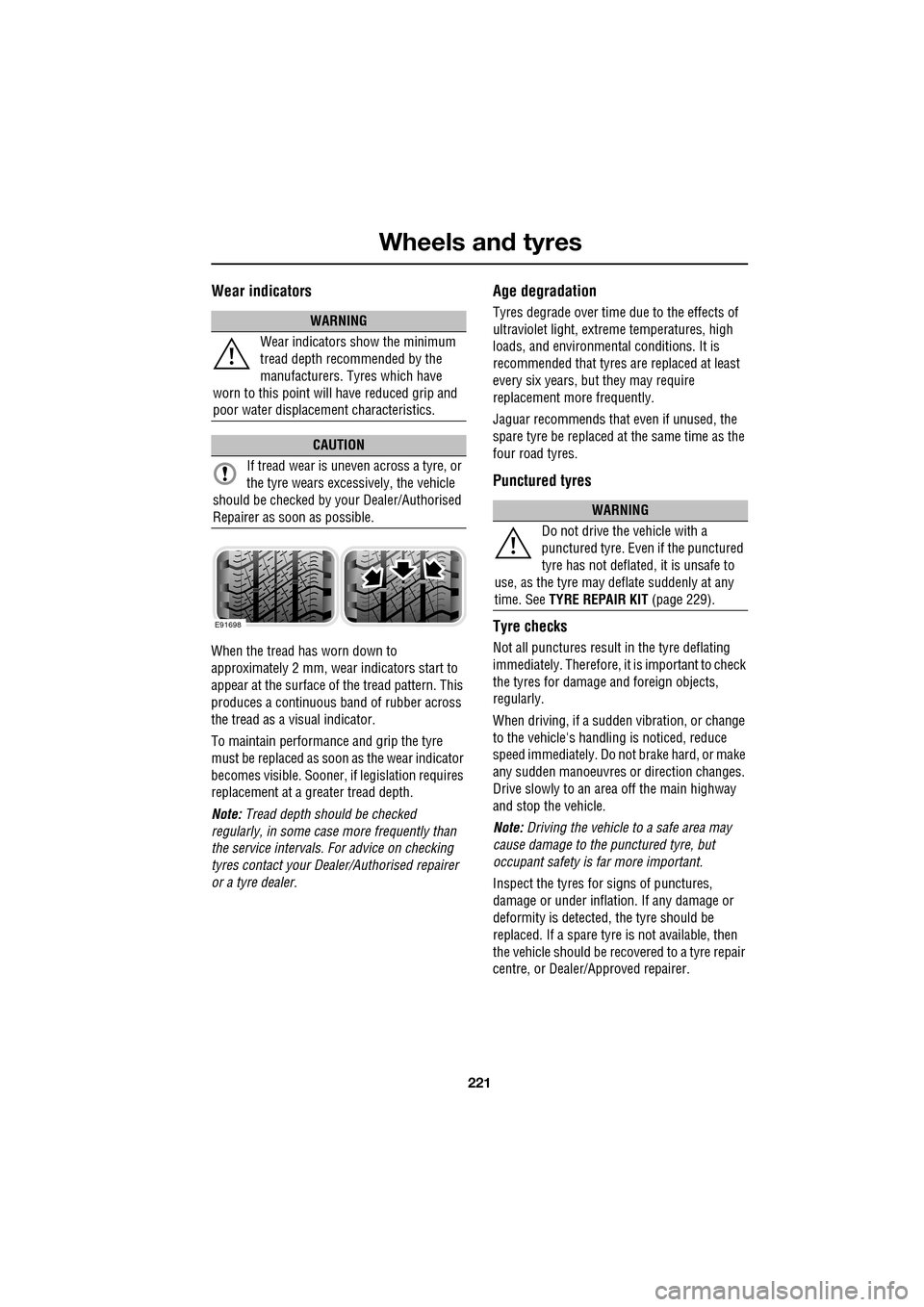

Wear indicators

When the tread has worn down to

approximately 2 mm, wear indicators start to

appear at the surface of the tread pattern. This

produces a continuous band of rubber across

the tread as a visual indicator.

To maintain performance and grip the tyre

must be replaced as soon as the wear indicator

becomes visible. Sooner, if legislation requires

replacement at a greater tread depth.

Note: Tread depth should be checked

regularly, in some case more frequently than

the service intervals. For advice on checking

tyres contact your Dealer/Authorised repairer

or a tyre dealer.

Age degradation

Tyres degrade over time due to the effects of

ultraviolet light, extreme temperatures, high

loads, and environmen tal conditions. It is

recommended that tyres are replaced at least

every six years, but they may require

replacement more frequently.

Jaguar recommends that even if unused, the

spare tyre be replaced at the same time as the

four road tyres.

Punctured tyres

Tyre checks

Not all punctures result in the tyre deflating

immediately. Therefore, it is important to check

the tyres for damage and foreign objects,

regularly.

When driving, if a sudden vibration, or change

to the vehicle's hand ling is noticed, reduce

speed immediately. Do not brake hard, or make

any sudden manoeuvres or direction changes.

Drive slowly to an area off the main highway

and stop the vehicle.

Note: Driving the vehicle to a safe area may

cause damage to th e punctured tyre, but

occupant safety is far more important.

Inspect the tyres for signs of punctures,

damage or under inflati on. If any damage or

deformity is detected, the tyre should be

replaced. If a spare tyre is not available, then

the vehicle should be reco vered to a tyre repair

centre, or Dealer/Approved repairer.

WARNING

Wear indicators show the minimum

tread depth recommended by the

manufacturers. Tyres which have

worn to this point will have reduced grip and

poor water displacement characteristics.

CAUTION

If tread wear is uneve n across a tyre, or

the tyre wears excessively, the vehicle

should be checked by your Dealer/Authorised

Repairer as soon as possible.

E91698

WARNING

Do not drive the vehicle with a

punctured tyre. Even if the punctured

tyre has not deflated, it is unsafe to

use, as the tyre may deflate suddenly at any

time. See TYRE REPAIR KIT (page 229).

Page 227 of 391

227

Wheels and tyres

Wheel changing safety

Before raising the vehicle, or changing a wheel

ensure that you read, and comply with the

following warnings.

WARNINGS

Always find a safe place to stop, off

the highway and away from traffic.

Ensure that the vehicle is on firm level

ground.

Disconnect traile r/caravan from

vehicle.

Switch on the hazard warning lamps.

Ensure that all passengers, and

animals, are out of the vehicle and in

a safe place away from the highway.

Place a warning triangle at a suitable

distance behind th e vehicle, facing

towards oncoming traffic.

Ensure that the front wheels are in the

straight ahead position, and engage

the steering lock.

Apply the parking br ake, and engage

Park (P).

Ensure that the jack is on firm level

ground.

Never place anything between the

jack and the ground, or the jack and

the vehicle.

When one rear wheel is lifted off the

ground the selection P (Park) position

will not prevent the vehicle from

moving and possibly slipping off the jack as

the park brake only operates on the rear

wheels.

Do not start or run the engine while

the vehicle is supported only by a

jack.

The jack is designed for use when

changing a wheel only. Never work

beneath the vehicle with the jack as

the only means of s upport - use vehicle

support stands.

Always chock the wheel diagonally

opposite the wheel to be changed,

using the wheel chock supplied in the

tool kit. Chock the front of a front wheel, or the

rear of a rear wheel.

If jacking the vehicle on a slight slope

is unavoidable, place chocks on the

downhill side of the two opposite

wheels. An additional chock will be

needed.

Take care when lifting the spare

wheel, and removing the punctured

wheel. The wheels are heavy, and can

cause injuries if not handled

correctly.

Remove the spare wheel prior to

jacking the vehicle. To avoid

destabilising the vehicle when raised.

Take care when loosening the wheel

nuts. The wheel brace may slip off if

not properly attached, and the wheel

nuts may give way suddenly. Either

unexpected movement ma y cause an injury.

WARNINGS

Page 233 of 391

233

Wheels and tyres

9.Unless the vehicle is in an enclosed area,

start the engine.

10. Set the compressor switch to the on ( I)

position.

11. Inflate the tyre to a minimum of 1.9 bar

(26 lbf/in²) and a maximum of 3.5 bar

(51 lbf/in²).

•When pumping the sealant through the

tyre valve, the pressure may rise up to 6

bar (87 lbf/in²). The pressure will drop

again after approximately 30 seconds.

12. During the inflation, switch the

compressor off briefly, to check the tyre

pressure using the gauge mounted on the

compressor.

• It should not take longer than seven

minutes to inflate the tyre. If, after seven

minutes, the tyre has not yet reached

minimum pressure, the tyre should not

be used.

13. Once the tyre has been inflated, switch off

the compressor. If desired, the engine may

be turned off after the compressor has

been turned off.

14. Remove the power connector from the

auxiliary power socket.

15. Remove the inflation hose from the tyre

valve, by unscrewing it as quickly as

possible (count er-clockwise).

16. Replace the inflation hose protective cap

and the tyre valve cap.

17. Do not remove the sealant bottle from the

receiver.

18. Ensure that the tyre repair kit (including

the bottle and receiver caps) are placed

securely in the vehicle. You will need to

use the kit to check the tyre pressure after

approximately 3 km (2 miles), so ensure

they are easily accessible. 19.

Immediately drive the vehicle for

approximately 3 km (2 miles), to allow the

sealant to coat the inner surface of the tyre

and form a seal at the puncture.

Checking the tyre pressure after a repair

1.Drive the vehicle for 3 km (2 miles) then

stop in a safe place. Carry out a visual

examination of the tyres condition.

2. Make sure that the sealant container

section is in its original position.

3. Screw the inflation hos e connector firmly

onto the tyre valve.

4. Read the tyre pressure from the gauge.

5. If the pressure of the sealant filled tyre is

above 1.3 bar (19 lb/in²) adjust the

pressure to the correct value. See TYRE

CARE (page 217).

6. Ensure that the compressor switch is in

the off (O ) position and insert the power

cable connector into the auxiliary power

socket.

If the vehicle is in a well ventilated area,

start the engine.

WARNINGS

When driving the vehicle, if you

experience vibr ations, abnormal

steering, or noises, reduce speed

immediately. Drive with extreme caution and

reduced speed, to the first safe place to stop

the vehicle. Visually examine the tyre and

check its pressure. If there are any signs of

damage or deformity to the tyre, or the tyre

pressure is below 1.3 bar (19 lb/in²), do not

continue driving.

Consult a tyre repair centre or your

Dealer/Authorised Repairer, for

advice concerning the replacement of

a tyre after using a tyre repair kit.

Page 245 of 391

245

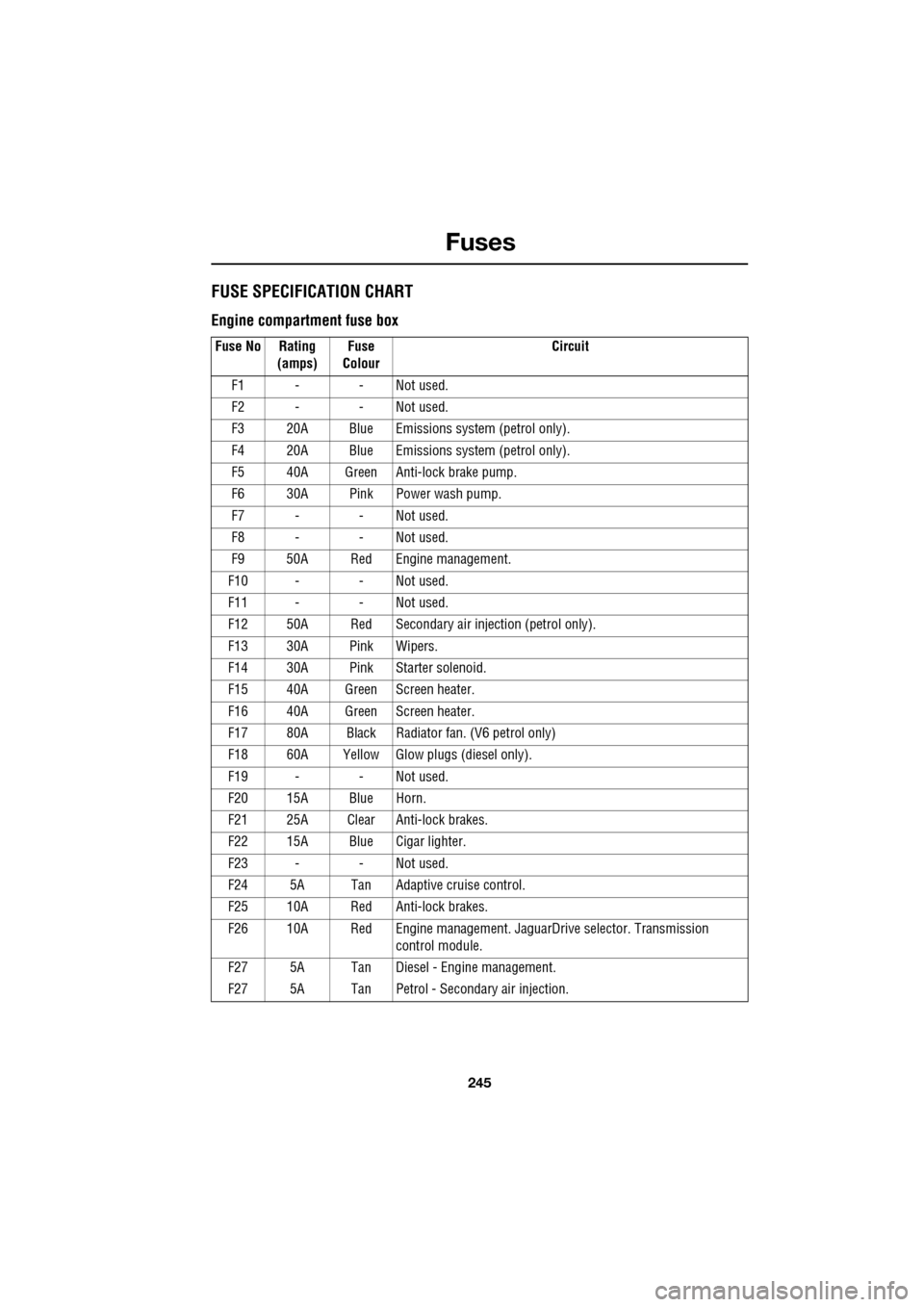

Fuses

FUSE SPECIFICATION CHART

Engine compartment fuse box

Fuse No Rating (amps) Fuse

Colour Circuit

F1 - - Not used.

F2 - - Not used.

F3 20A Blue Emissions system (petrol only).

F4 20A Blue Emissions system (petrol only).

F5 40A Green Anti-lock brake pump.

F6 30A Pink Power wash pump.

F7 - - Not used.

F8 - - Not used.

F9 50A Red Engine management.

F10 - - Not used.

F11 - - Not used.

F12 50A Red Secondary air in jection (petrol only).

F13 30A Pink Wipers.

F14 30A Pink Starter solenoid.

F15 40A Green Screen heater.

F16 40A Green Screen heater.

F17 80A Black Radiator fan. (V6 petrol only)

F18 60A Yellow Glow plugs (diesel only).

F19 - - Not used.

F20 15A Blue Horn.

F21 25A Clear Anti-lock brakes.

F22 15A Blue Cigar lighter.

F23 - - Not used.

F24 5A Tan Adaptive cruise control.

F25 10A Red Anti-lock brakes.

F26 10A Red Engine manage ment. JaguarDrive selector. Transmission

control module.

F27 5A Tan Diesel - Engine management.

F27 5A Tan Petrol - Secondary air injection.

Page 251 of 391

251

Status after a collision

DRIVING AFTER A COLLISION

Before starting or driving

If the vehicle has been involved in an accident

it should be checked thoroughly before

attempting to start the engine or drive the

vehicle.

Check for:-

• Fuel leaks.

• Fluid leaks.

• Battery damage.

• Damage to wiring.

• Damage to lights.

• Damage to steering, suspension, wheels

or tyres.

• Sharp or protruding bodywork.

• Operation of doors and locks.

• Condition and operation of seat belts and

SRS components.

• Activation of the pe destrian protection

system.

• Condition of chil d seats and their

mounting/attach ment points.

Note: This list is not exhaustive.

Resetting the fuel cut-off

The fuel system cut-off forms part of the Safety

and Restraint System (SRS) fitted to your

vehicle. Following an impact, and depending on

the severity, the fuel pump may be switched

off.

1.Switch the ignition off, and wait for 10

seconds.

2. Without pressing the brake pedal, press

the engine START/STOP button, to switch

the electrical circuits on. Wait for 30

seconds.

3. Check the vehicle thoroughly for fuel leaks.

If a leak is detected switch the ignition off

immediately.

•The vehicle must not be started if a leak

is present. Seek qualified advice, and

have the vehicle recovered.

4. If no leaks are detected, start the engine.

WARNING

If the vehicle is involved in a collision

it should be checked by a Dealer/

Authorised repairer, or suitably

qualified personnel, before starting or driving.

WARNING

The fuel cut-off should never be reset

if you can smell fuel, or a leak can be

seen. Doing so can lead to a fire

which may cause personal injury or death.