lock JAGUAR XF 2009 1.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 391, PDF Size: 19.32 MB

Page 232 of 391

Wheels and tyres

232

Using the Jaguar tyre repair kit

Note: All vehicle drivers and occupants should

be made aware that a temporary repair has

been made to a tyre fitted to the vehicle. They

should also be made aware of the special

driving conditions im posed when using a

repaired tyre.

Repair procedure

1. Open the tyre repair kit and peel off the

maximum speed label. Attach the label to

the fascia in the driver's field of vision.

Take care not to obstruct any of the

instruments or warning lights.

2. Uncoil the compressor power cable and

the inflation hose.

3. Unscrew the orange cap from the sealant

bottle receiver and the sealant bottle cap.

4. Screw the sealant bottle into the receiver

(clockwise) until tight.

•Screwing the bottle onto the receiver will

pierce the bottle's se al. Do not unscrew

a full, or partly us ed bottle from the

receiver. Doing so will result in sealant

leaking from the bottle.

5. Remove the valve cap from the damaged

tyre.

6. Remove the protective cap from the

inflation hose and connect the inflation

hose to the tyre valve. Ensure that the hose

is screwed on firmly.

7. Ensure that the compressor switch is in

the off (0) position.

8. Insert the power cable connector into the

auxiliary power socket. See AUXILIARY

POWER SOCKETS (page 125).

WARNINGS

Avoid skin contact with the sealant

which contains natu ral rubber latex.

If the tyre inflati on pressure does not

reach 1.8 bar (26 lbf/in², 180 kPa)

within seven minutes, the tyre may

have suffered excessive damage. A temporary

repair will not be poss ible, and the vehicle

should not be driven until the tyre has been

replaced.

CAUTIONS

Before attempting a ty re repair, ensure

that the vehicle is parked safely, as far

away from passing traffic as possible.

Ensure that the parki ng brake is applied

and P (Park) is selected.

Do not attempt to remove foreign

objects such as nails, screws, etc. from

the tyre.

Always run the engine when using the

compressor, unless the vehicle is in an

enclosed or poorly ventil ated space, as this

may cause asphyxiation.

To prevent overheating, do not operate

the compressor continuously for longer

than ten minutes.

WARNING

Check the tyre sidewall prior to

inflation. If there are any cracks,

bumps or similar damage, do not

attempt to inflate the tyre. Do not stand

directly beside the tyre while the compressor

is pumping. Watch the ty re sidewall. If any

cracks, bumps or simila r damage appear, turn

off the compressor and let the air out by

means of the pressure relief valve. Do not

continue to use the tyre.

Page 233 of 391

233

Wheels and tyres

9.Unless the vehicle is in an enclosed area,

start the engine.

10. Set the compressor switch to the on ( I)

position.

11. Inflate the tyre to a minimum of 1.9 bar

(26 lbf/in²) and a maximum of 3.5 bar

(51 lbf/in²).

•When pumping the sealant through the

tyre valve, the pressure may rise up to 6

bar (87 lbf/in²). The pressure will drop

again after approximately 30 seconds.

12. During the inflation, switch the

compressor off briefly, to check the tyre

pressure using the gauge mounted on the

compressor.

• It should not take longer than seven

minutes to inflate the tyre. If, after seven

minutes, the tyre has not yet reached

minimum pressure, the tyre should not

be used.

13. Once the tyre has been inflated, switch off

the compressor. If desired, the engine may

be turned off after the compressor has

been turned off.

14. Remove the power connector from the

auxiliary power socket.

15. Remove the inflation hose from the tyre

valve, by unscrewing it as quickly as

possible (count er-clockwise).

16. Replace the inflation hose protective cap

and the tyre valve cap.

17. Do not remove the sealant bottle from the

receiver.

18. Ensure that the tyre repair kit (including

the bottle and receiver caps) are placed

securely in the vehicle. You will need to

use the kit to check the tyre pressure after

approximately 3 km (2 miles), so ensure

they are easily accessible. 19.

Immediately drive the vehicle for

approximately 3 km (2 miles), to allow the

sealant to coat the inner surface of the tyre

and form a seal at the puncture.

Checking the tyre pressure after a repair

1.Drive the vehicle for 3 km (2 miles) then

stop in a safe place. Carry out a visual

examination of the tyres condition.

2. Make sure that the sealant container

section is in its original position.

3. Screw the inflation hos e connector firmly

onto the tyre valve.

4. Read the tyre pressure from the gauge.

5. If the pressure of the sealant filled tyre is

above 1.3 bar (19 lb/in²) adjust the

pressure to the correct value. See TYRE

CARE (page 217).

6. Ensure that the compressor switch is in

the off (O ) position and insert the power

cable connector into the auxiliary power

socket.

If the vehicle is in a well ventilated area,

start the engine.

WARNINGS

When driving the vehicle, if you

experience vibr ations, abnormal

steering, or noises, reduce speed

immediately. Drive with extreme caution and

reduced speed, to the first safe place to stop

the vehicle. Visually examine the tyre and

check its pressure. If there are any signs of

damage or deformity to the tyre, or the tyre

pressure is below 1.3 bar (19 lb/in²), do not

continue driving.

Consult a tyre repair centre or your

Dealer/Authorised Repairer, for

advice concerning the replacement of

a tyre after using a tyre repair kit.

Page 235 of 391

235

Wheels and tyres

Note: Different types of tyre may affect the

performance of the TPM system. Always

replace tyres in accordance with

recommendations. See TYRE

SPECIFICATIONS - ARDUOUS TERRAIN

(page 239).

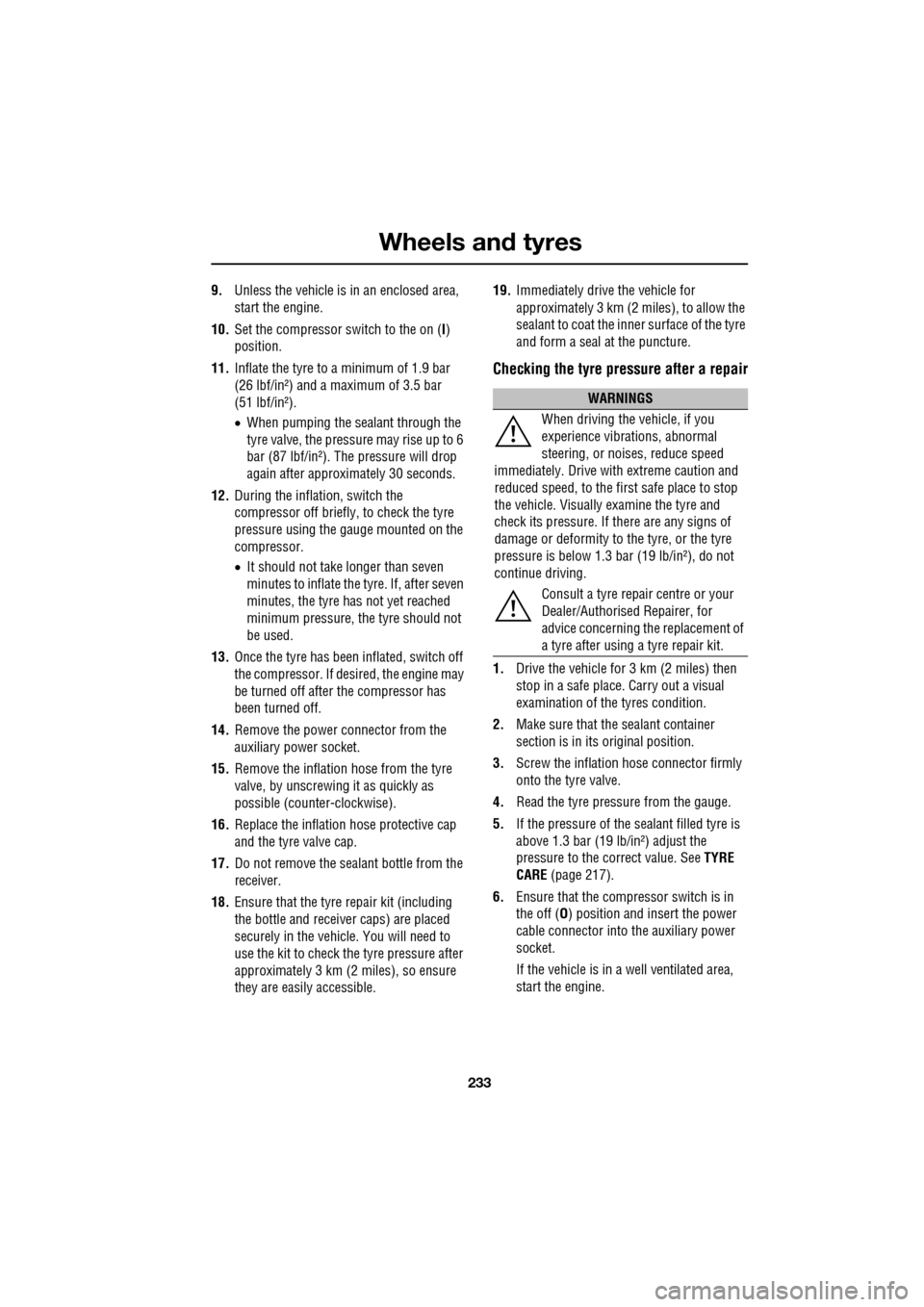

Your vehicle may be equipped with a TPM

System which monitors pressure in each tyre

(temporary use spare wheels are not fitted with

sensors and are conseque ntly not monitored).

Wheels fitted with a TPM system can be easily

visually identified by the external metal lock nut

and valve ( 1). All Jaguar n on-TPM system

wheels have a rubber valve fitted (2).

TPM system operation

The TPM system monitors pressure of the

tyres via sensors located in each wheel and a

receiver located within the vehicle.

Communication between se nsor and receiver

is via Radio Frequency (RF) signals.

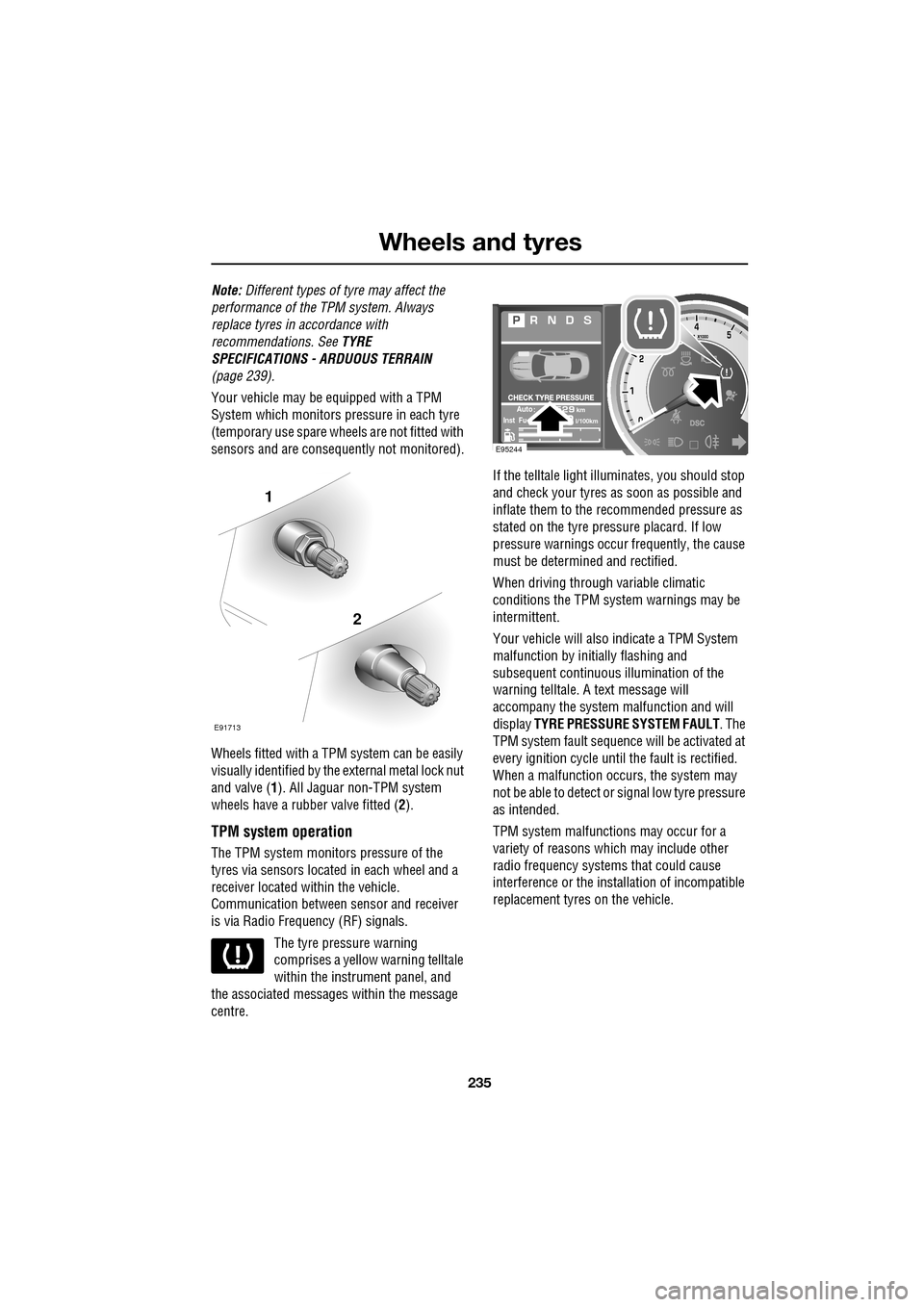

The tyre pressure warning

comprises a yellow warning telltale

within the instrument panel, and

the associated messages within the message

centre. If the telltale light illu

minates, you should stop

and check your tyres as soon as possible and

inflate them to the recommended pressure as

stated on the tyre pressure placard. If low

pressure warnings occur frequently, the cause

must be determined and rectified.

When driving through variable climatic

conditions the TPM syst em warnings may be

intermittent.

Your vehicle will also indicate a TPM System

malfunction by initially flashing and

subsequent continuous illumination of the

warning telltale. A text message will

accompany the system malfunction and will

display TYRE PRESSURE SYSTEM FAULT . The

TPM system fault sequence will be activated at

every ignition cycle until the fault is rectified.

When a malfunction occurs, the system may

not be able to de tect or signal low tyre pressure

as intended.

TPM system malfuncti ons may occur for a

variety of reasons which may include other

radio frequency systems that could cause

interference or the installation of incompatible

replacement tyres on the vehicle.

1

2

E91713

AutokmInst Ful/100km

E95244

Page 236 of 391

Wheels and tyres

236

Tyre pressure warning with speed

If the vehicle is to be driven at speeds in excess

of 160 km/h (100 mph), the tyre pressures

should be increased as stated in this handbook

or on the placard label. Failure to increase the

tyre pressures and driving in excess of

160 km/h (100 mph), will illuminate the yellow

warning telltale and display a text message

TYRE PRESSURES LOW FOR SPEED . In the

event of this warning be ing displayed, vehicle

speed should be reduced

Temporary use spare wheel and tyre

change

If the temporary use spare wheel is fitted the

system will automatically recognise the change

in wheel positions. The n after approximately

ten minutes of driv ing above 25 km/h

(18 mph), a message TYRE NOT MONITORED

will be displayed accompanied by illumination

of the warning telltale and the corresponding

block in the vehicle graphic.

The warning telltale will initially flash and will

subsequently revert to continuous illumination.

Extended use of the temporary use spare wheel

will produce an additional text message TYRE

PRESSURE SYSTEM FAULT .

This TPM system display sequence will be

activated at every ignition cycle until the

temporary use spare wheel is replaced by a

fully operational full size wheel and tyre

assembly.

Always replace the temporary use wheel before

having TPM system faults investigated. The

fault may well be rectified with the fitment of a

fully operational full size running tyre in lieu of

the temporary use spare wheel assembly.

Tyre changing

Always have your tyres serviced or changed by

a qualified engineer.

Care must be taken to avoid contact between

the bead of the tyre and the sensor during

removal and refitting of the tyre, otherwise the

sensor may become damaged and or

inoperable.

Sensors can be removed from the wheel by the

unscrewing of the va lve retention nut.

Replacement sensor

Should the sensor require replacing, it should

be carried out by a Dealer/Authorised Repairer.

A replacement sensor must be fitted to a

running wheel in order to be recognised by the

system. The vehicle needs to be stationary for

15 minutes during the se nsor fitment before

the system is ready to detect the new sensor.

The vehicle must be driven for a minimum of

fifteen minutes after the sensor change, and

then remain stationary for fifteen minutes to

activate full TPM system operation.

If the TPM system warning for any wheel does

not clear, even after ensuring correct inflation

and driving for more than ten minutes above

25 km/h (18 mph), you should seek qualified

assistance as soon as possible.

CAUTION

Valve stem seal, washer, nut, valve core

and cap should be replaced at every tyre

change. Valve stem seal, washer and nut must

be replaced if valve re tention nut is loosened.

Sensor units and nuts must be refitted using

correct torque figures and associated profile.

Damage to the vehicle may result if these

precautions are not taken.

Page 245 of 391

245

Fuses

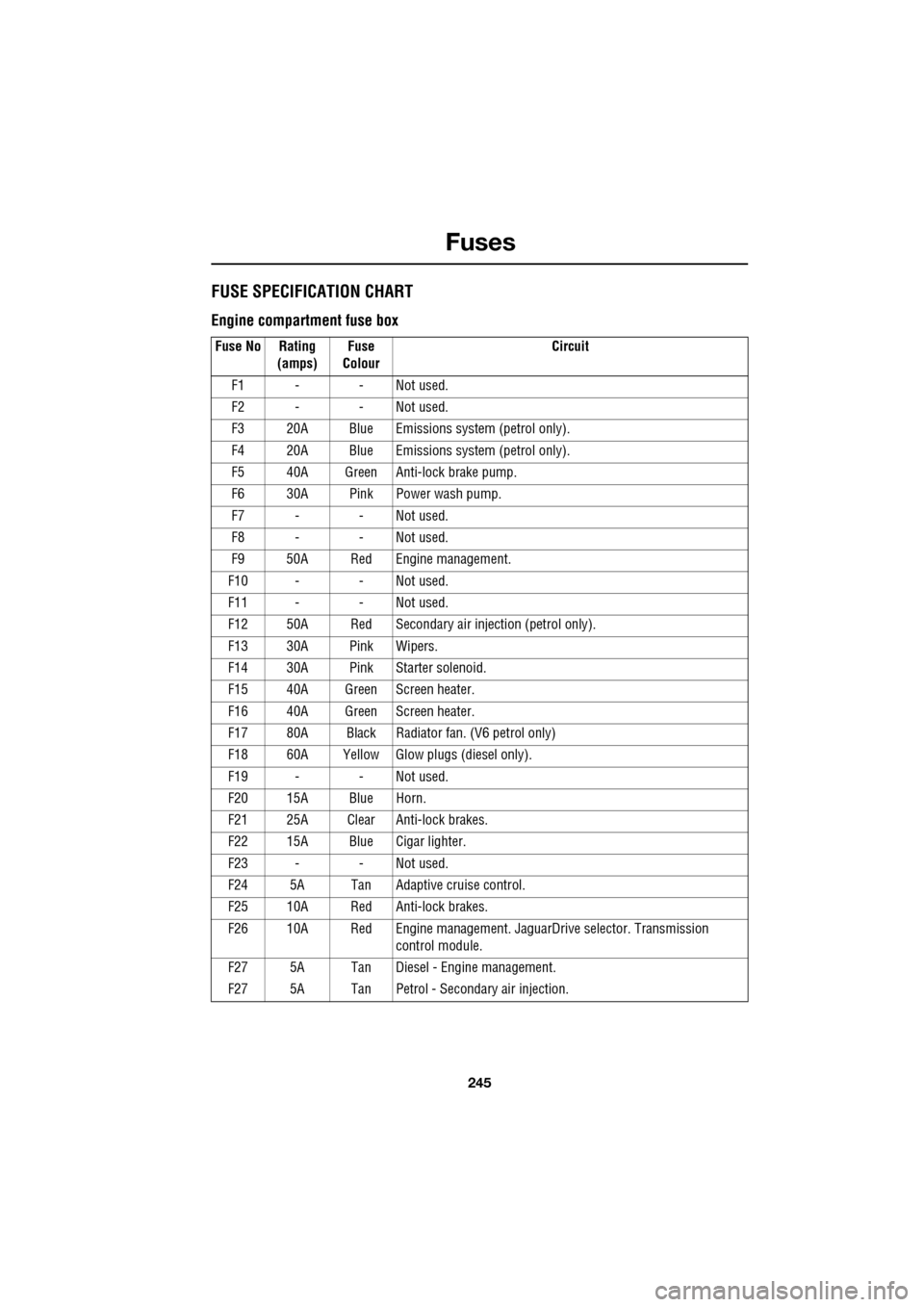

FUSE SPECIFICATION CHART

Engine compartment fuse box

Fuse No Rating (amps) Fuse

Colour Circuit

F1 - - Not used.

F2 - - Not used.

F3 20A Blue Emissions system (petrol only).

F4 20A Blue Emissions system (petrol only).

F5 40A Green Anti-lock brake pump.

F6 30A Pink Power wash pump.

F7 - - Not used.

F8 - - Not used.

F9 50A Red Engine management.

F10 - - Not used.

F11 - - Not used.

F12 50A Red Secondary air in jection (petrol only).

F13 30A Pink Wipers.

F14 30A Pink Starter solenoid.

F15 40A Green Screen heater.

F16 40A Green Screen heater.

F17 80A Black Radiator fan. (V6 petrol only)

F18 60A Yellow Glow plugs (diesel only).

F19 - - Not used.

F20 15A Blue Horn.

F21 25A Clear Anti-lock brakes.

F22 15A Blue Cigar lighter.

F23 - - Not used.

F24 5A Tan Adaptive cruise control.

F25 10A Red Anti-lock brakes.

F26 10A Red Engine manage ment. JaguarDrive selector. Transmission

control module.

F27 5A Tan Diesel - Engine management.

F27 5A Tan Petrol - Secondary air injection.

Page 251 of 391

251

Status after a collision

DRIVING AFTER A COLLISION

Before starting or driving

If the vehicle has been involved in an accident

it should be checked thoroughly before

attempting to start the engine or drive the

vehicle.

Check for:-

• Fuel leaks.

• Fluid leaks.

• Battery damage.

• Damage to wiring.

• Damage to lights.

• Damage to steering, suspension, wheels

or tyres.

• Sharp or protruding bodywork.

• Operation of doors and locks.

• Condition and operation of seat belts and

SRS components.

• Activation of the pe destrian protection

system.

• Condition of chil d seats and their

mounting/attach ment points.

Note: This list is not exhaustive.

Resetting the fuel cut-off

The fuel system cut-off forms part of the Safety

and Restraint System (SRS) fitted to your

vehicle. Following an impact, and depending on

the severity, the fuel pump may be switched

off.

1.Switch the ignition off, and wait for 10

seconds.

2. Without pressing the brake pedal, press

the engine START/STOP button, to switch

the electrical circuits on. Wait for 30

seconds.

3. Check the vehicle thoroughly for fuel leaks.

If a leak is detected switch the ignition off

immediately.

•The vehicle must not be started if a leak

is present. Seek qualified advice, and

have the vehicle recovered.

4. If no leaks are detected, start the engine.

WARNING

If the vehicle is involved in a collision

it should be checked by a Dealer/

Authorised repairer, or suitably

qualified personnel, before starting or driving.

WARNING

The fuel cut-off should never be reset

if you can smell fuel, or a leak can be

seen. Doing so can lead to a fire

which may cause personal injury or death.

Page 253 of 391

253

Vehicle recovery

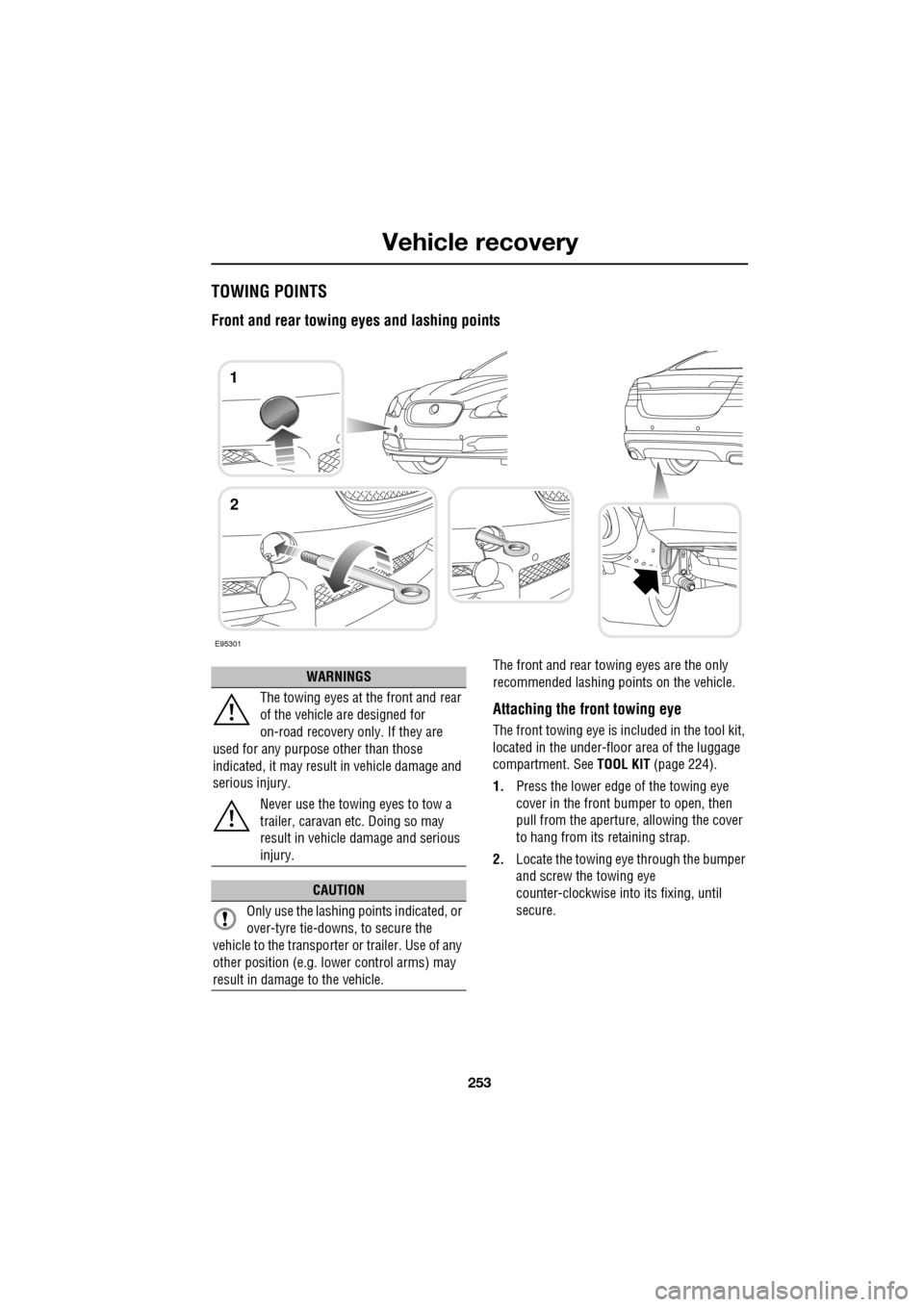

TOWING POINTS

Front and rear towing eyes and lashing points

The front and rear towing eyes are the only

recommended lashing points on the vehicle.

Attaching the front towing eye

The front towing eye is included in the tool kit,

located in the under-floor area of the luggage

compartment. See TOOL KIT (page 224).

1. Press the lower edge of the towing eye

cover in the front bumper to open, then

pull from the aperture, allowing the cover

to hang from its retaining strap.

2. Locate the towing eye through the bumper

and screw the towing eye

counter-clockwise into its fixing, until

secure.

E95301

1

2

WARNINGS

The towing eyes at the front and rear

of the vehicle are designed for

on-road recovery only. If they are

used for any purpose other than those

indicated, it may result in vehicle damage and

serious injury.

Never use the towing eyes to tow a

trailer, caravan etc. Doing so may

result in vehicle damage and serious

injury.

CAUTION

Only use the lashing points indicated, or

over-tyre tie-downs, to secure the

vehicle to the transporter or trailer. Use of any

other position (e.g. lower control arms) may

result in damage to the vehicle.

Page 255 of 391

255

Vehicle recovery

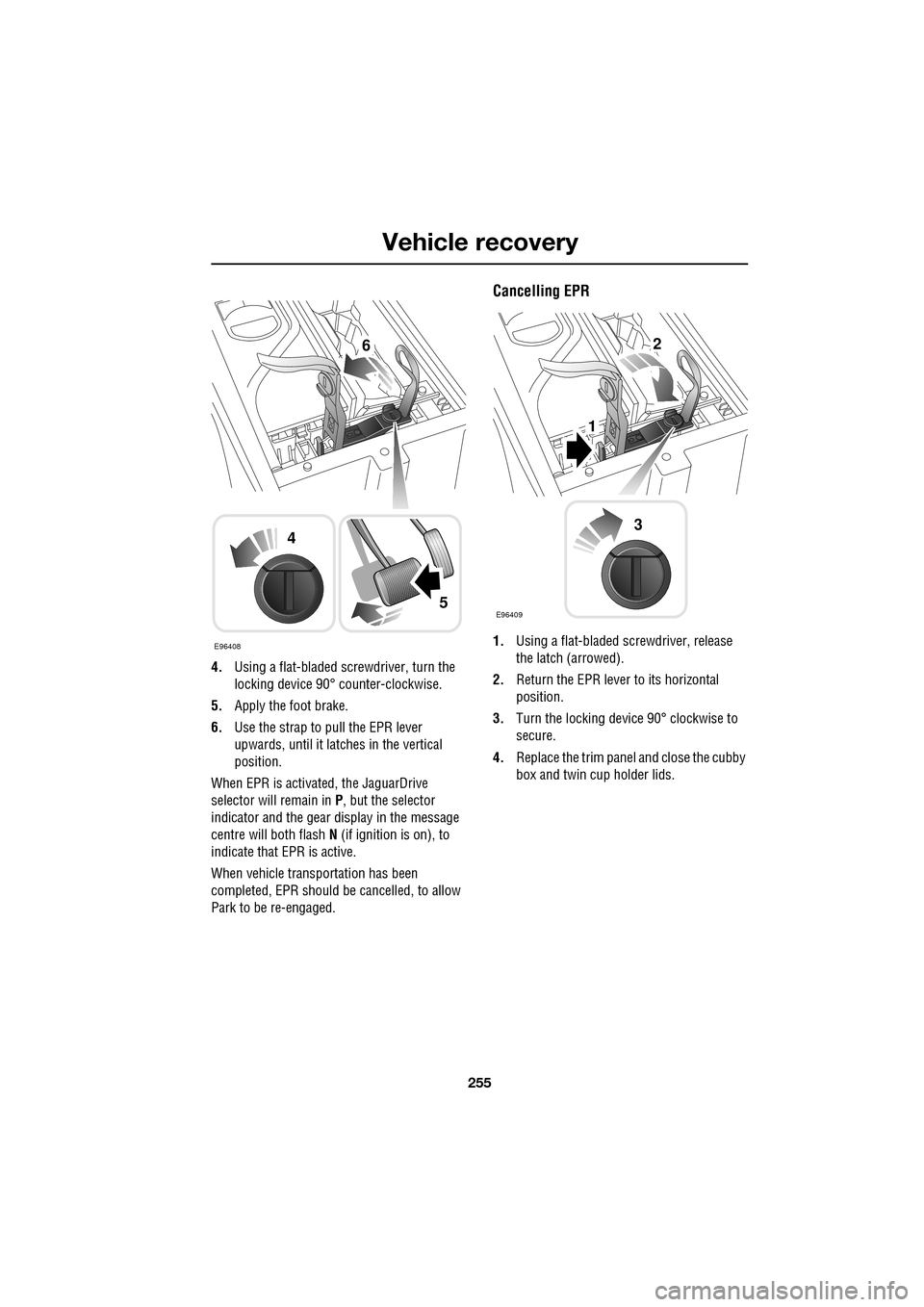

4.Using a flat-bladed screwdriver, turn the

locking device 90° counter-clockwise.

5. Apply the foot brake.

6. Use the strap to pull the EPR lever

upwards, until it latches in the vertical

position.

When EPR is activated, the JaguarDrive

selector will remain in P , but the selector

indicator and the gear display in the message

centre will both flash N (if ignition is on), to

indicate that EPR is active.

When vehicle transportation has been

completed, EPR should be cancelled, to allow

Park to be re-engaged.

Cancelling EPR

1. Using a flat-bladed sc rewdriver, release

the latch (arrowed).

2. Return the EPR lever to its horizontal

position.

3. Turn the locking device 90° clockwise to

secure.

4. Replace the trim pane l and close the cubby

box and twin cup holder lids.E96408

4

5

62

1

E96409

3

Page 256 of 391

Vehicle recovery

256

TOWING THE VEHICLE ON FOUR

WHEELS

Note: The recommended recovery method is

to raise all four wheels.

Towing procedure

1. The vehicle should be parked on firm level

ground, with the parking brake on, and the

gear selector in P (Park).

2. Secure the towing attachment from the

recovery vehicle to the front towing eye.

See TOWING POINTS (page 253).

3. Dock the Jaguar Smart Key and switch on

the ignition. See GENERAL INFORMATION

(page 132). 4.

Apply the foot brake and release the

parking brake.

5. With the foot brake st ill applied, activate

the Emergency Park Release (EPR).

See TRANSPORTING THE VEHICLE

(page 254).

6. The vehicle can now be towed a maximum

of 0.8 km (0.5 miles) at a maximum speed

of 48 kmh (30 mph).

7. Upon arrival at the destination, ensure

wherever possible that the vehicle is

parked on firm level ground.

8. Lower the Emergency Park Release (EPR)

lever, to cancel EP R and to re-engage P

(Park).

9. Apply the parking brake.

10. Switch off the ignition and remove the

Jaguar Smart Key.

11. Remove the towing attachment from the

towing eye.

WARNINGS

Ensure that the remote control

remains docked whilst the vehicle is

being towed. Removing the remote

control will engage the steering lock, which

will prevent the vehicle from steering

correctly.

If the engine cannot be run whilst the

vehicle is being towed, there will be

no power assistance for the steering

or brakes. This will result in greater effort

being required to steer or slow the vehicle, and

greatly increased stopping distances.

CAUTIONS

The vehicle should only be towed in a

forward direction with all four wheels on

the ground.

The vehicle should only be towed for a

maximum of 0.8 km (0.5 miles), at a

maximum speed of 48 km/h (30 mph). Towing

for a greater distance or at a higher speed, may

result in serious damage to the transmission.

CAUTION

Leaving the ignition switched on for

extended periods will cause the battery

to drain.

WARNING

Use extreme caution when detaching

towing equipment. Vehicle movement

is possible which can result in serious

injuries.

Page 285 of 391

285

Digital audio broadcasting

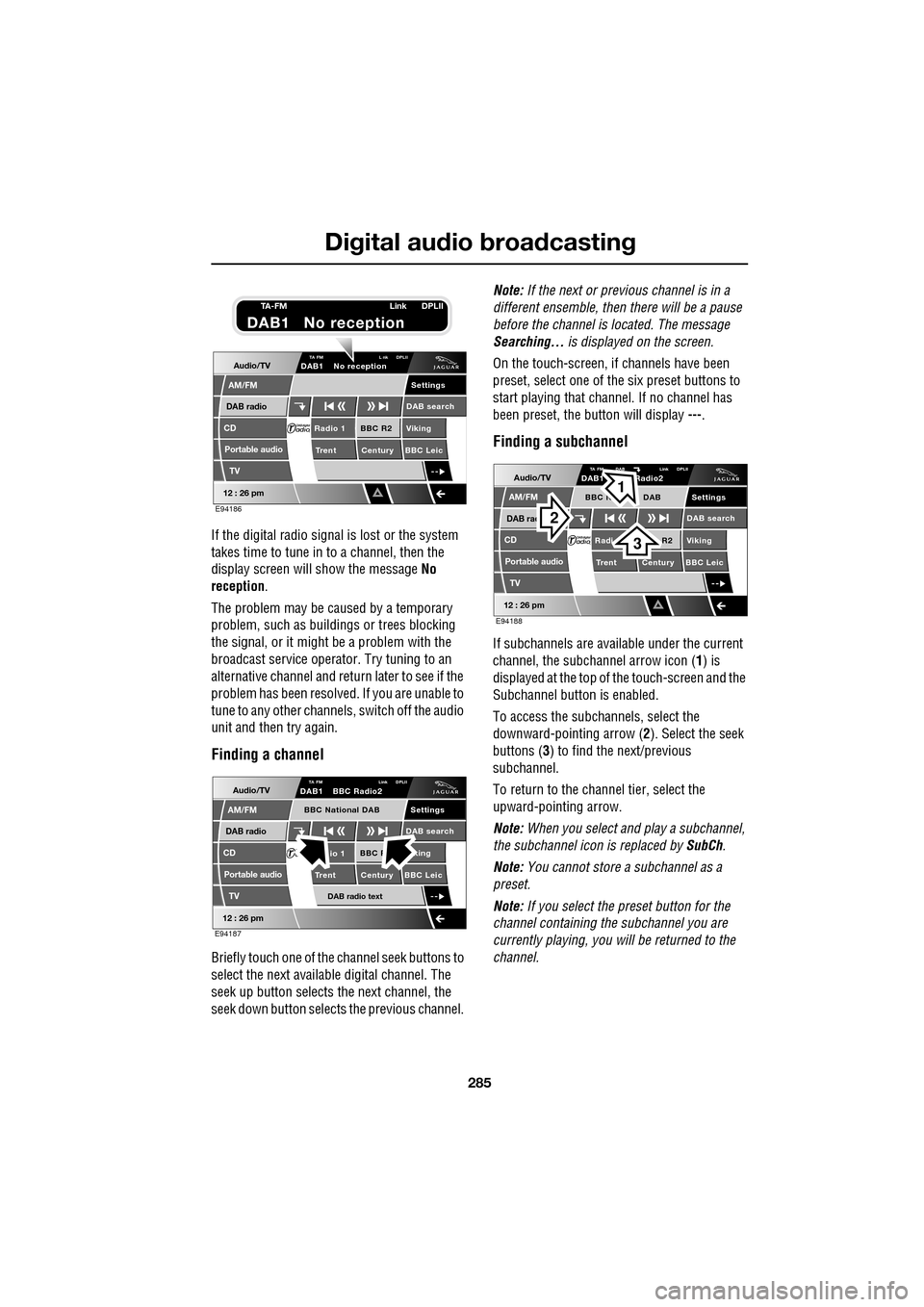

If the digital radio signal is lost or the system

takes time to tune in to a channel, then the

display screen will show the message No

reception.

The problem may be caused by a temporary

problem, such as buildings or trees blocking

the signal, or it might be a problem with the

broadcast servic e operator. Try tuning to an

alternative channel and return later to see if the

problem has been resolved. If you are unable to

tune to any other channe ls, switch off the audio

unit and then try again.

Finding a channel

Briefly touch one of the channel seek buttons to

select the next availabl e digital channel. The

seek up button selects th e next channel, the

seek down button selects the previous channel. Note:

If the next or previous channel is in a

different ensemble, then there will be a pause

before the channel is located. The message

Searching... is displayed on the screen.

On the touch-screen, if channels have been

preset, select one of the six preset buttons to

start playing that channel. If no channel has

been preset, the button will display ---.

Finding a subchannel

If subchannels are available under the current

channel, the subchannel arrow icon ( 1) is

displayed at the top of the touch-screen and the

Subchannel button is enabled.

To access the subchannels, select the

downward-pointing arrow ( 2). Select the seek

buttons ( 3) to find the next/previous

subchannel.

To return to the channel tier, select the

upward-pointing arrow.

Note: When you select and play a subchannel,

the subchannel icon is replaced by SubCh.

Note: You cannot store a subchannel as a

preset.

Note: If you select the preset button for the

channel containing the subchannel you are

currently playing, you will be returned to the

channel.

Audio/TV

DAB radio

CD

AM/FM

12 : 26 pm

BBC R2 Viking

Trent Century BBC LeicRadio 1

Settings

DAB search

TA FM L nk DPLIIDAB1 No reception

Portable audio

TV

E94186

TA-FM Link DPLII

DAB1 No reception

Audio/TV

DAB radio

CD

AM/FM

12 : 26 pm

BBC R king

Trent Century BBC Leicio 1

Settings

DAB search

TA FM Link DPLIIDAB1 BBC Radio2

Portable audio

TV

DAB radio text

BBC National DAB

E94187

Audio/TV

DAB rad

CD

AM/FM

12 : 26 pm

R2 Viking

T

rent Century BBC LeicRadi

Settings

DAB search

TA FM DAB Link DPLIIDAB1 Radio2

Portable audio

TV

BBC N DAB

E94188

2

3

1