JAGUAR XF 2009 1.G Manual Online

Manufacturer: JAGUAR, Model Year: 2009, Model line: XF, Model: JAGUAR XF 2009 1.GPages: 391, PDF Size: 19.32 MB

Page 81 of 391

81

Lighting

Note: For lamps controlled by proximity

sensors, the wearing of gloves may interfere

with operation. If you are wearing gloves, it

may be necessary to touch the proximity

switch to operate the lamps.

Ambience lighting

Ambience lighting. Automatically illuminates

when the headlamps are on. Ambience lighting

creates a blue glow ar ound the centre console

and front door armrests.

Luggage compartment lamp

Automatically illuminates when the luggage

compartment is opened.

APPROACH LAMPS

This feature is activated by pressing

the headlamp icon button on the

Jaguar Smart Key. See USING THE

REMOTE CONTROL (page 17). The headlamps

will remain on for 25 seconds or until the

button is pressed again, or until the engine

START/STOP button is pressed.

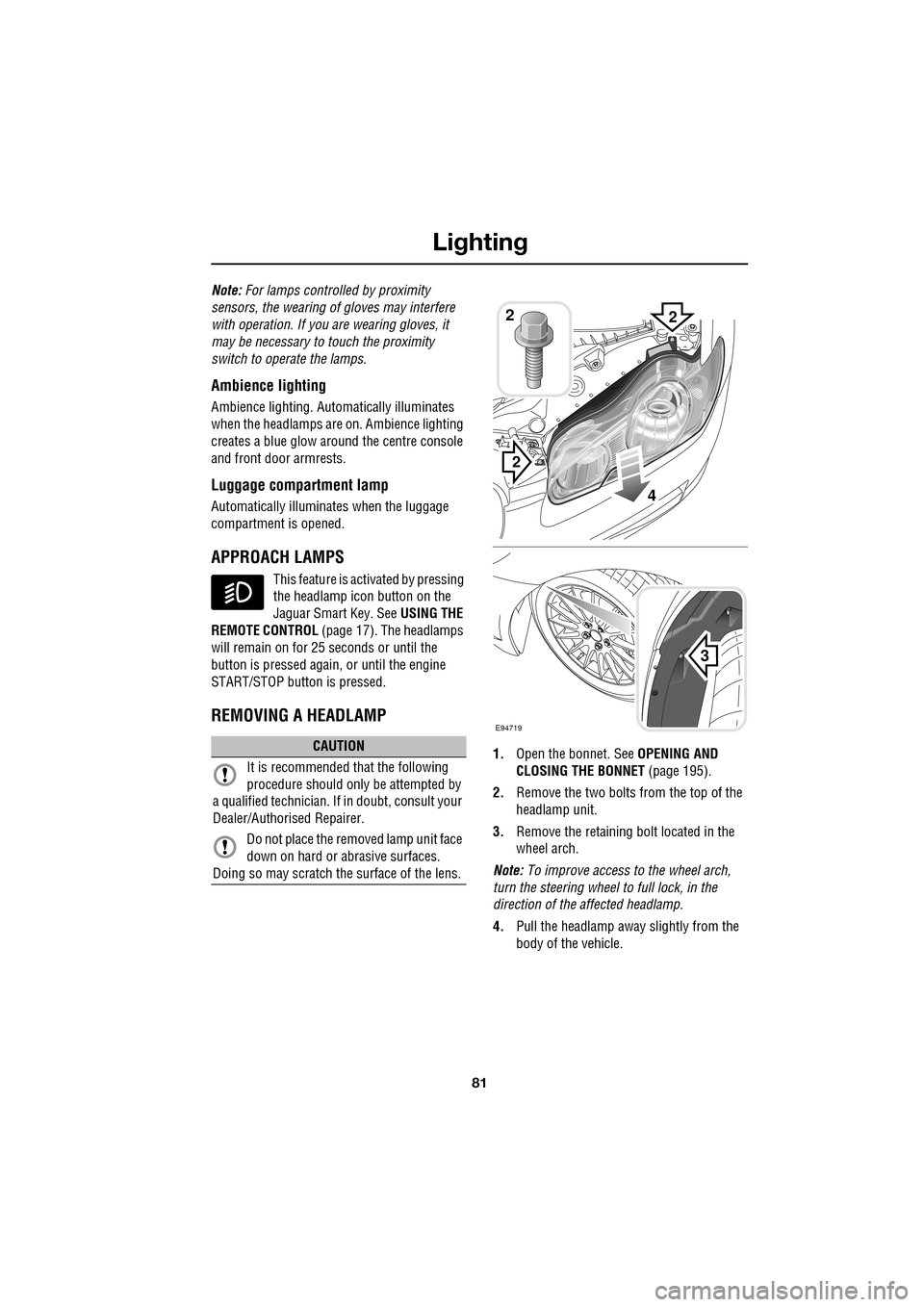

REMOVING A HEADLAMP

1. Open the bonnet. See OPENING AND

CLOSING THE BONNET (page 195).

2. Remove the two bolts from the top of the

headlamp unit.

3. Remove the retaining bolt located in the

wheel arch.

Note: To improve access to the wheel arch,

turn the steering wheel to full lock, in the

direction of the affected headlamp.

4. Pull the headlamp away slightly from the

body of the vehicle.CAUTION

It is recommended that the following

procedure should only be attempted by

a qualified technician. If in doubt, consult your

Dealer/Authorised Repairer.

Do not place the removed lamp unit face

down on hard or abrasive surfaces.

Doing so may scratch the surface of the lens.

3

2

2

E94719

2

4

Page 82 of 391

Lighting

82

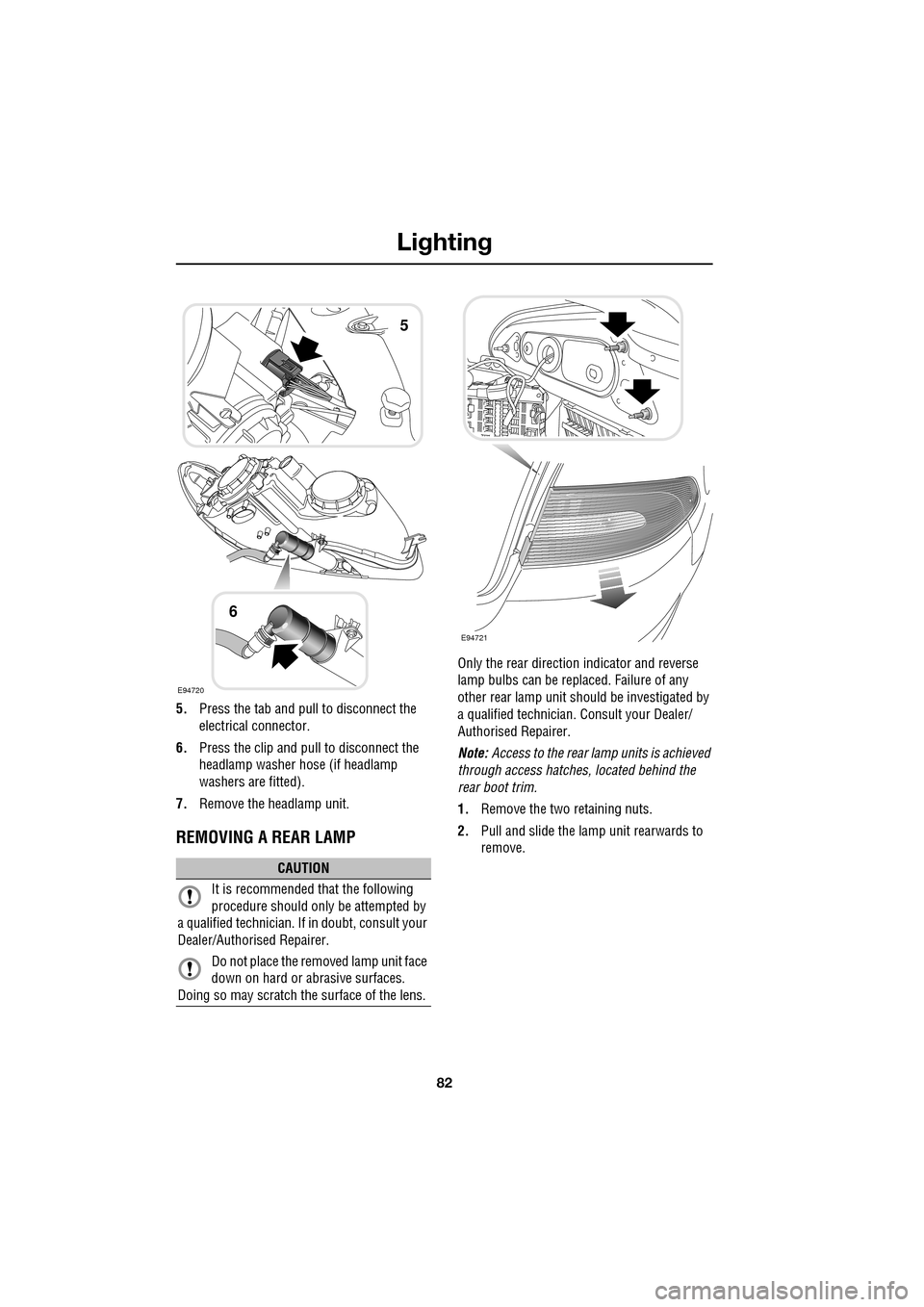

5.Press the tab and pull to disconnect the

electrical connector.

6. Press the clip and pull to disconnect the

headlamp washer hose (if headlamp

washers are fitted).

7. Remove the headlamp unit.

REMOVING A REAR LAMP

Only the rear directio n indicator and reverse

lamp bulbs can be repl aced. Failure of any

other rear lamp unit should be investigated by

a qualified technician. Consult your Dealer/

Authorised Repairer.

Note: Access to the rear lamp units is achieved

through access hatche s, located behind the

rear boot trim.

1. Remove the two retaining nuts.

2. Pull and slide the lamp unit rearwards to

remove.

CAUTION

It is recommended that the following

procedure should only be attempted by

a qualified technician. If in doubt, consult your

Dealer/Authorised Repairer.

Do not place the removed lamp unit face

down on hard or abrasive surfaces.

Doing so may scratch the surface of the lens.

E94720

5

6

E94721

Page 83 of 391

83

Lighting

CHANGING A BULB

General information

Note: In certain markets its a legal requirement

to carry spare bulbs. A replacement bulb kit is

available as an approved accessory from your

Dealer/Authorised Repairer.

Halogen bulbs

Halogen bulbs are used for main beam and

dipped beam headlamps. Take care not to

touch the glass part of the bulb with your

fingers; always use a cl oth to handle the bulb.

If necessary use methylated spirits to remove

finger prints.

Xenon lamps

Seek advice about the correct

disposal of Xenon lamp units from

your Dealer/Authorised Repairer, or

your local authority.

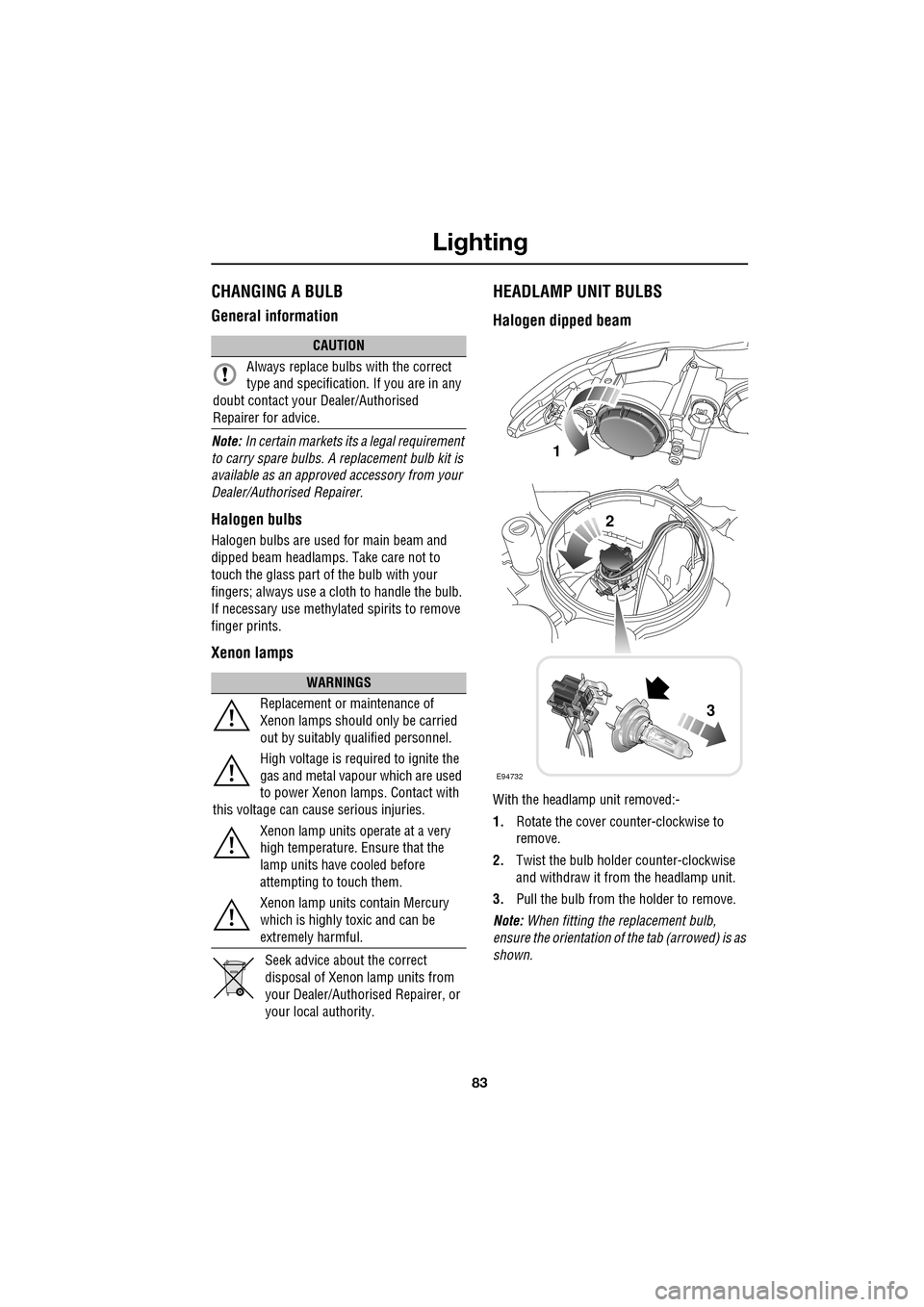

HEADLAMP UNIT BULBS

Halogen dipped beam

With the headlamp unit removed:-

1. Rotate the cover counter-clockwise to

remove.

2. Twist the bulb holder counter-clockwise

and withdraw it from the headlamp unit.

3. Pull the bulb from the holder to remove.

Note: When fitting the replacement bulb,

ensure the orientation of the tab (arrowed) is as

shown.

CAUTION

Always replace bulbs with the correct

type and specification. If you are in any

doubt contact your Dealer/Authorised

Repairer for advice.

WARNINGS

Replacement or maintenance of

Xenon lamps should only be carried

out by suitably qualified personnel.

High voltage is required to ignite the

gas and metal vapour which are used

to power Xenon lamps. Contact with

this voltage can cause serious injuries.

Xenon lamp units operate at a very

high temperature. Ensure that the

lamp units have cooled before

attempting to touch them.

Xenon lamp units contain Mercury

which is highly toxic and can be

extremely harmful.

E94732

1

2

3

Page 84 of 391

Lighting

84

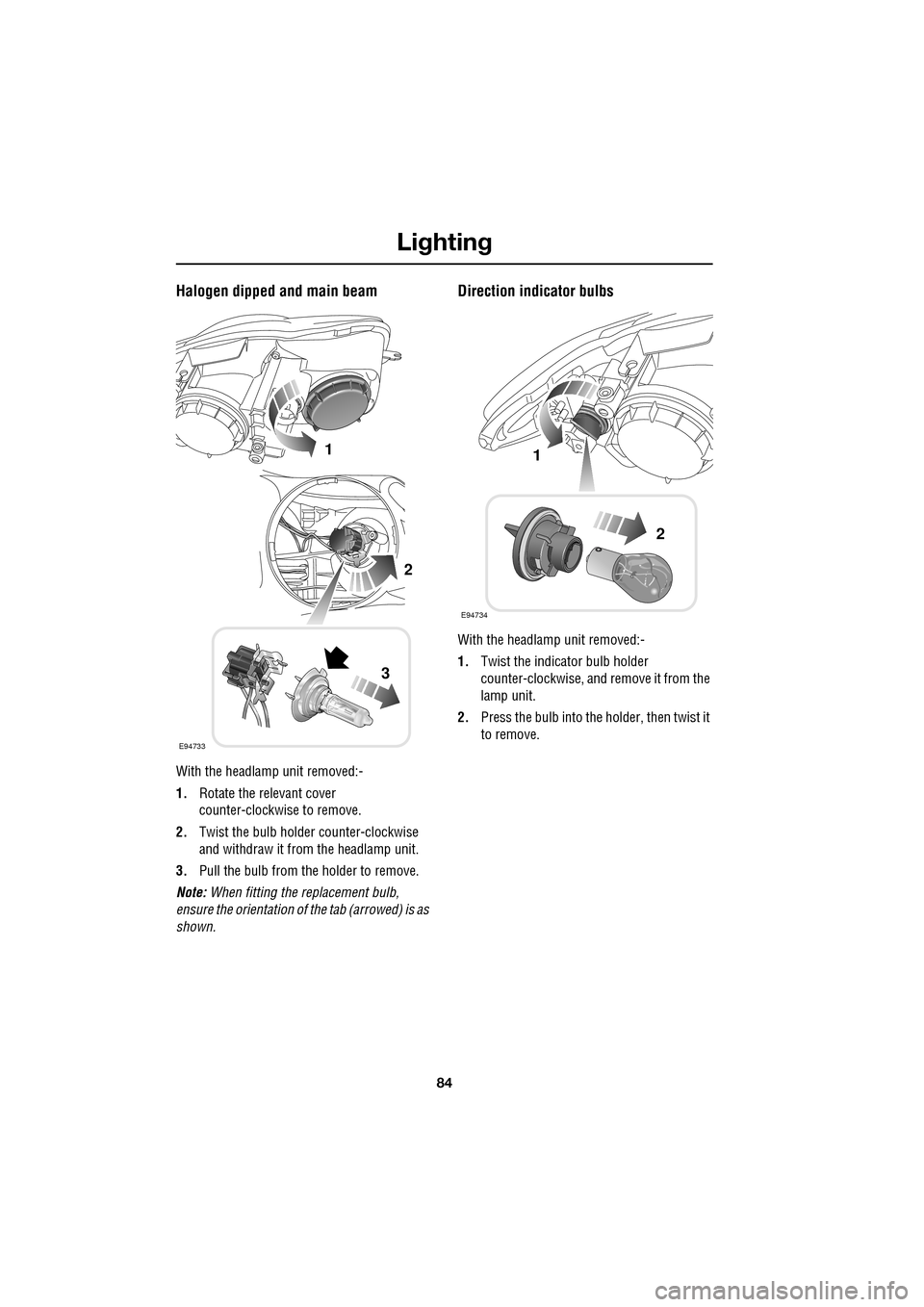

Halogen dipped and main beam

With the headlamp unit removed:-

1.Rotate the relevant cover

counter-clockwise to remove.

2. Twist the bulb holder counter-clockwise

and withdraw it from the headlamp unit.

3. Pull the bulb from the holder to remove.

Note: When fitting the replacement bulb,

ensure the orientation of the tab (arrowed) is as

shown.

Direction indicator bulbs

With the headlamp unit removed:-

1. Twist the indicator bulb holder

counter-clockwise, and remove it from the

lamp unit.

2. Press the bulb into the holder, then twist it

to remove.

E94733

1

2

3

E94734

1

2

Page 85 of 391

85

Lighting

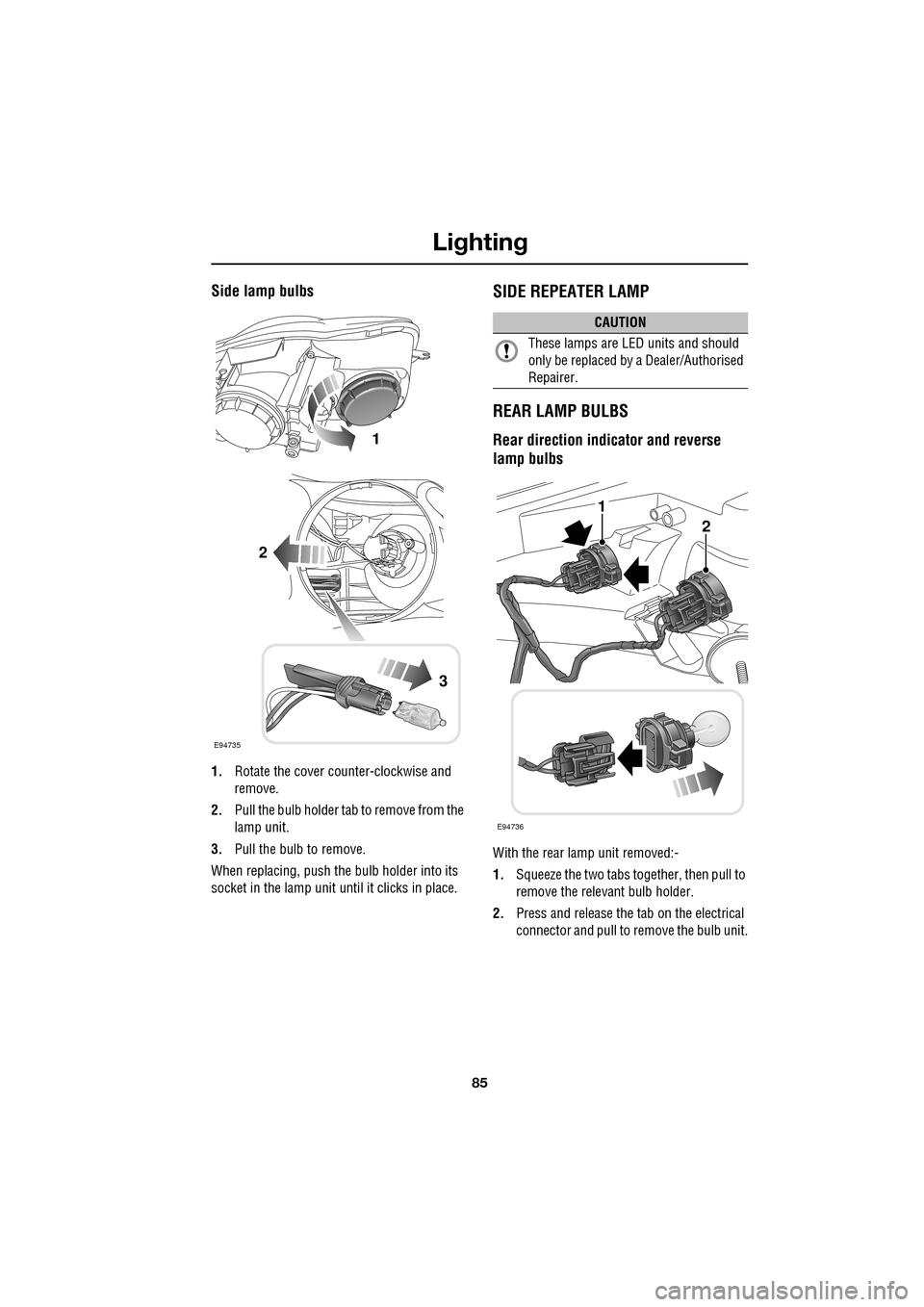

Side lamp bulbs

1.Rotate the cover counter-clockwise and

remove.

2. Pull the bulb holder tab to remove from the

lamp unit.

3. Pull the bulb to remove.

When replacing, push the bulb holder into its

socket in the lamp unit until it clicks in place.

SIDE REPEATER LAMP

REAR LAMP BULBS

Rear direction indicator and reverse

lamp bulbs

With the rear lamp unit removed:-

1.Squeeze the two tabs together, then pull to

remove the relevant bulb holder.

2. Press and release the tab on the electrical

connector and pull to remove the bulb unit.

E94735

1

2

3

CAUTION

These lamps are LED units and should

only be replaced by a Dealer/Authorised

Repairer.

E94736

1

2

Page 86 of 391

Lighting

86

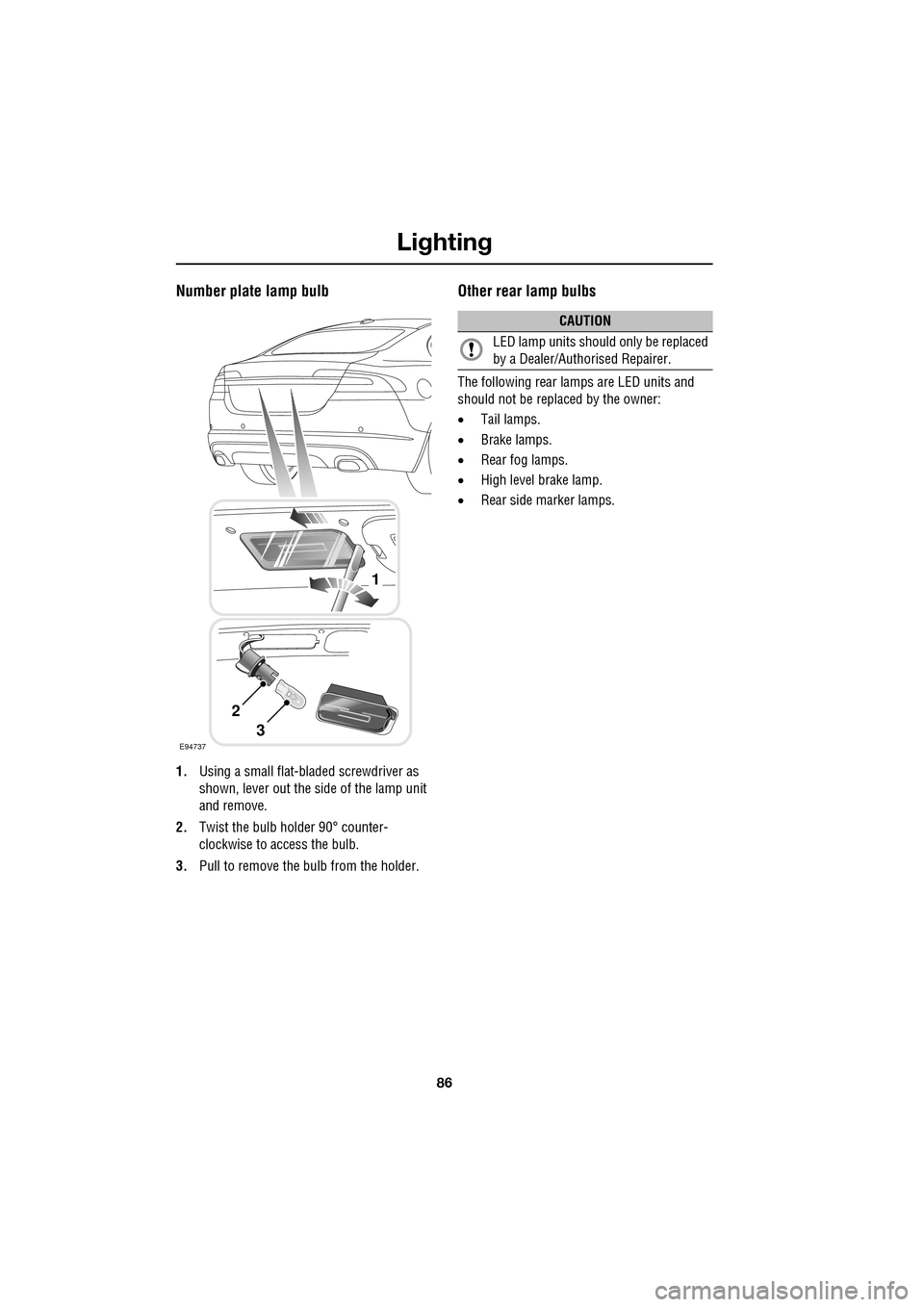

Number plate lamp bulb

1.Using a small flat-bla ded screwdriver as

shown, lever out the si de of the lamp unit

and remove.

2. Twist the bulb holder 90° counter-

clockwise to access the bulb.

3. Pull to remove the bulb from the holder.

Other rear lamp bulbs

The following rear lamps are LED units and

should not be replaced by the owner:

•Tail lamps.

• Brake lamps.

• Rear fog lamps.

• High level brake lamp.

• Rear side marker lamps.

E94737

1

2

3

CAUTION

LED lamp units should only be replaced

by a Dealer/Authorised Repairer.

Page 87 of 391

87

Lighting

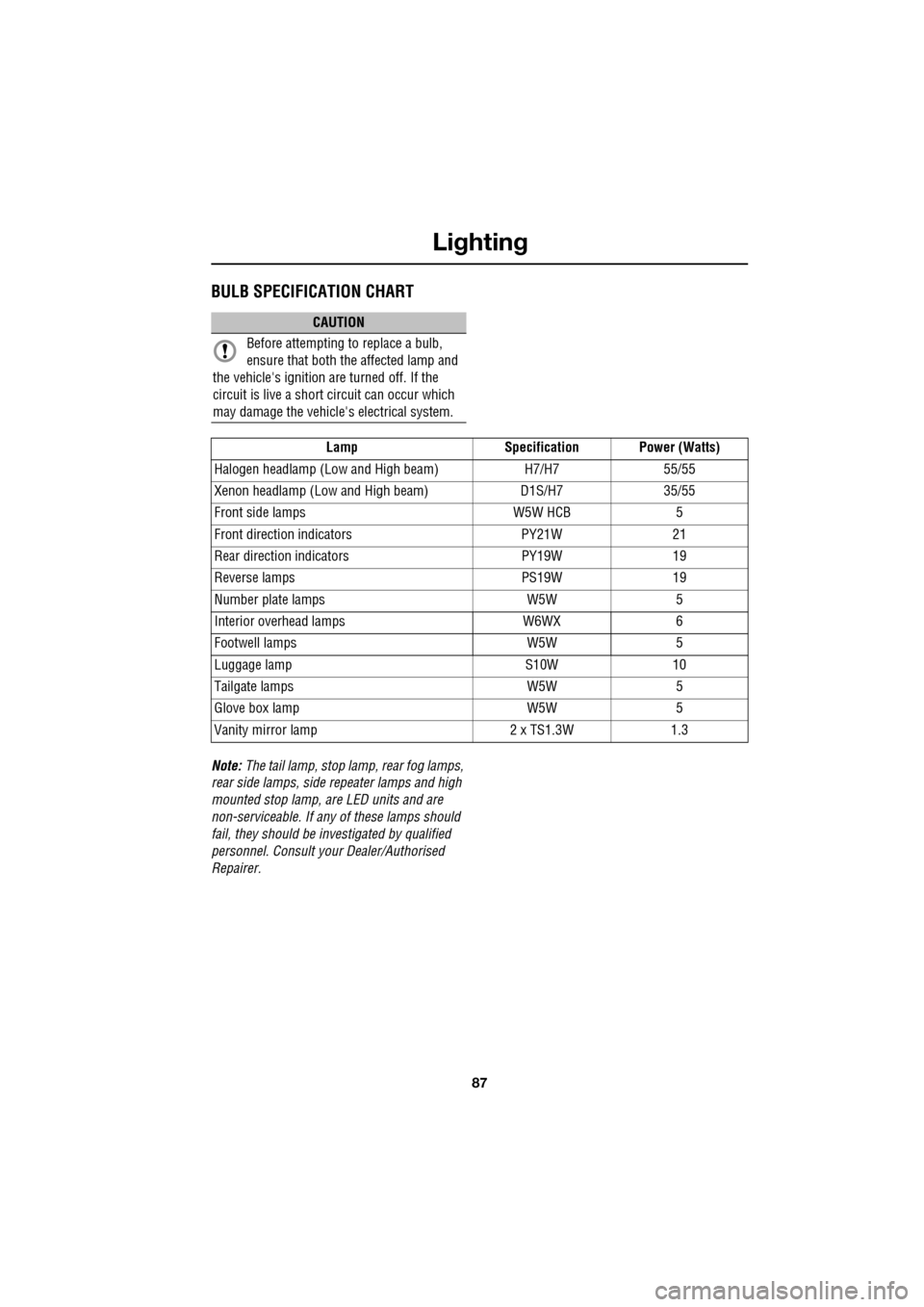

BULB SPECIFICATION CHART

Note: The tail lamp, stop lamp, rear fog lamps,

rear side lamps, side repeater lamps and high

mounted stop lamp, ar e LED units and are

non-serviceable. If an y of these lamps should

fail, they should be investigated by qualified

personnel. Consult your Dealer/Authorised

Repairer.

CAUTION

Before attempting to replace a bulb,

ensure that both the affected lamp and

the vehicle's ignition are turned off. If the

circuit is live a short circuit can occur which

may damage the vehicle's electrical system.

Lamp Specification Power (Watts)

Halogen headlamp (Low and High beam) H7/H755/55

Xenon headlamp (Low and High beam) D1S/H735/55

Front side lamps W5W HCB5

Front direction indicators PY21W21

Rear direction indicators PY19W19

Reverse lamps PS19W19

Number plate lamps W5W5

Interior overhead lamps W6WX6

Footwell lamps W5W5

Luggage lamp S10W10

Tailgate lamps W5W5

Glove box lamp W5W5

Vanity mirror lamp 2 x TS1.3W1.3

Page 88 of 391

Wipers and washers

88

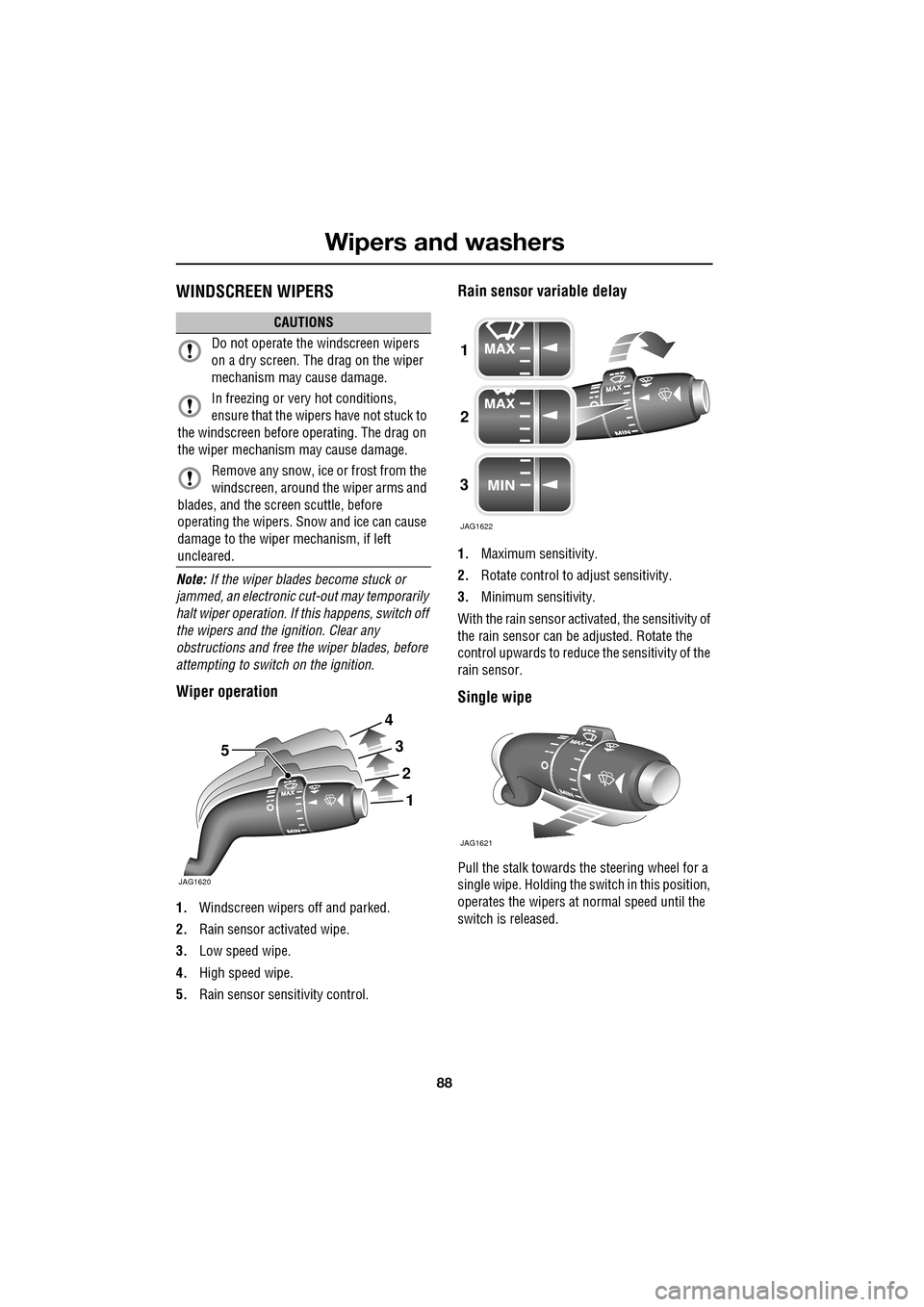

WINDSCREEN WIPERS

Note: If the wiper blades become stuck or

jammed, an electronic cut-out may temporarily

halt wiper operation. If this happens, switch off

the wipers and the ignition. Clear any

obstructions and free th e wiper blades, before

attempting to switch on the ignition.

Wiper operation

1. Windscreen wipers off and parked.

2. Rain sensor activated wipe.

3. Low speed wipe.

4. High speed wipe.

5. Rain sensor sensitivity control.

Rain sensor variable delay

1.Maximum sensitivity.

2. Rotate control to adjust sensitivity.

3. Minimum sensitivity.

With the rain sensor acti vated, the sensitivity of

the rain sensor can be adjusted. Rotate the

control upwards to reduce the sensitivity of the

rain sensor.

Single wipe

Pull the stalk towards the steering wheel for a

single wipe. Holding the sw itch in this position,

operates the wipers at normal speed until the

switch is released.

CAUTIONS

Do not operate the windscreen wipers

on a dry screen. The drag on the wiper

mechanism may cause damage.

In freezing or very hot conditions,

ensure that the wipers have not stuck to

the windscreen before operating. The drag on

the wiper mechanism may cause damage.

Remove any snow, ice or frost from the

windscreen, around the wiper arms and

blades, and the screen scuttle, before

operating the wipers. S now and ice can cause

damage to the wiper mechanism, if left

uncleared.

JAG1620

5

1

2

3

4

1

2

3

JAG1622

JAG1621

Page 89 of 391

89

Wipers and washers

Speed-dependent mode

If vehicle speed drops below 2 km/h (1.2 mph)

with the wipers operating, the wiper frequency

automatically reduces. The wipers will switch

to the next lowest speed. When the vehicle’s

speed increases to over 8 km/h (5 mph), the

original wiper speed settings are restored

automatically.

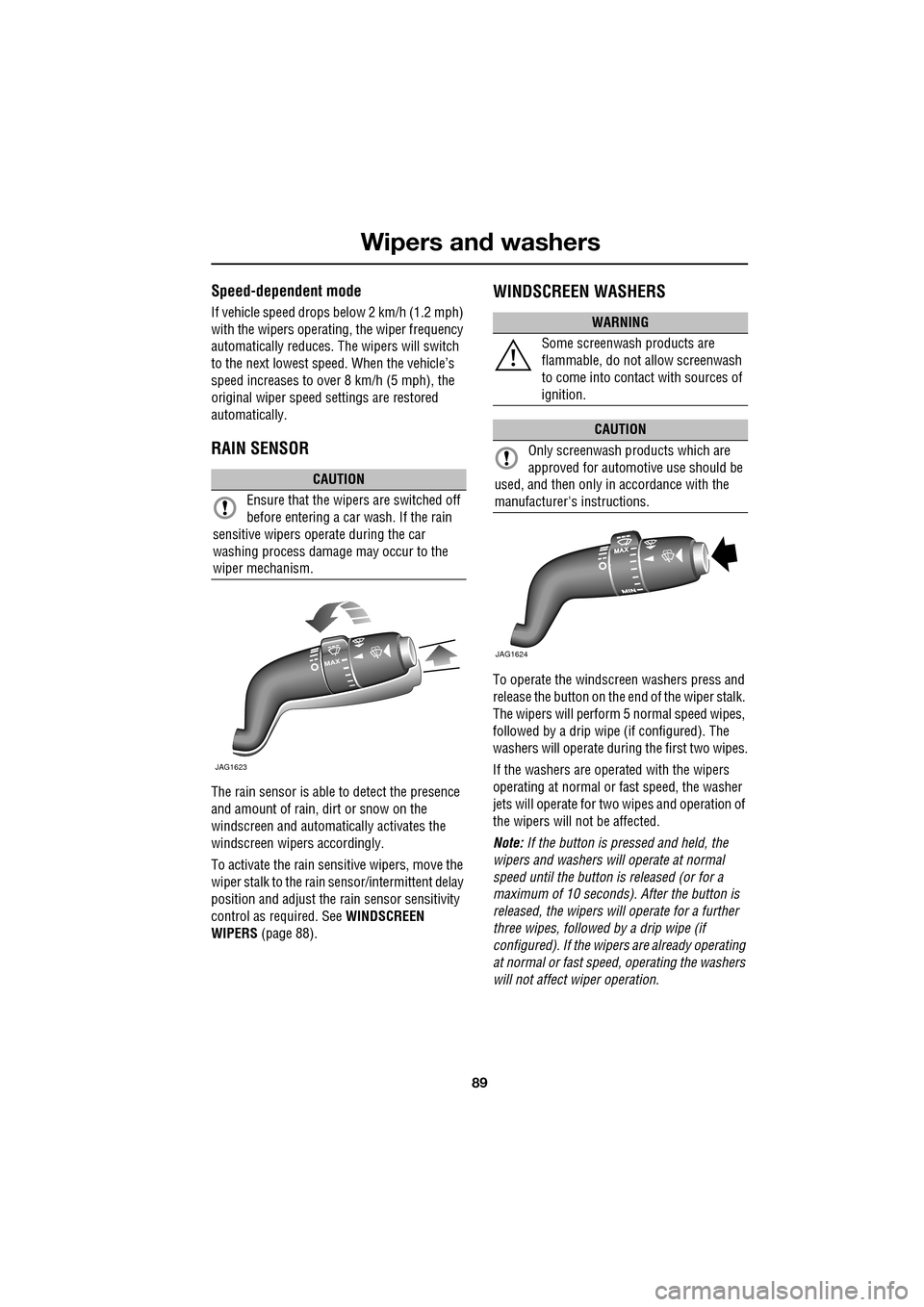

RAIN SENSOR

The rain sensor is able to detect the presence

and amount of rain, dirt or snow on the

windscreen and automatically activates the

windscreen wipers accordingly.

To activate the rain sensitive wipers, move the

wiper stalk to the rain sensor/intermittent delay

position and adjust the ra in sensor sensitivity

control as required. See WINDSCREEN

WIPERS (page 88).

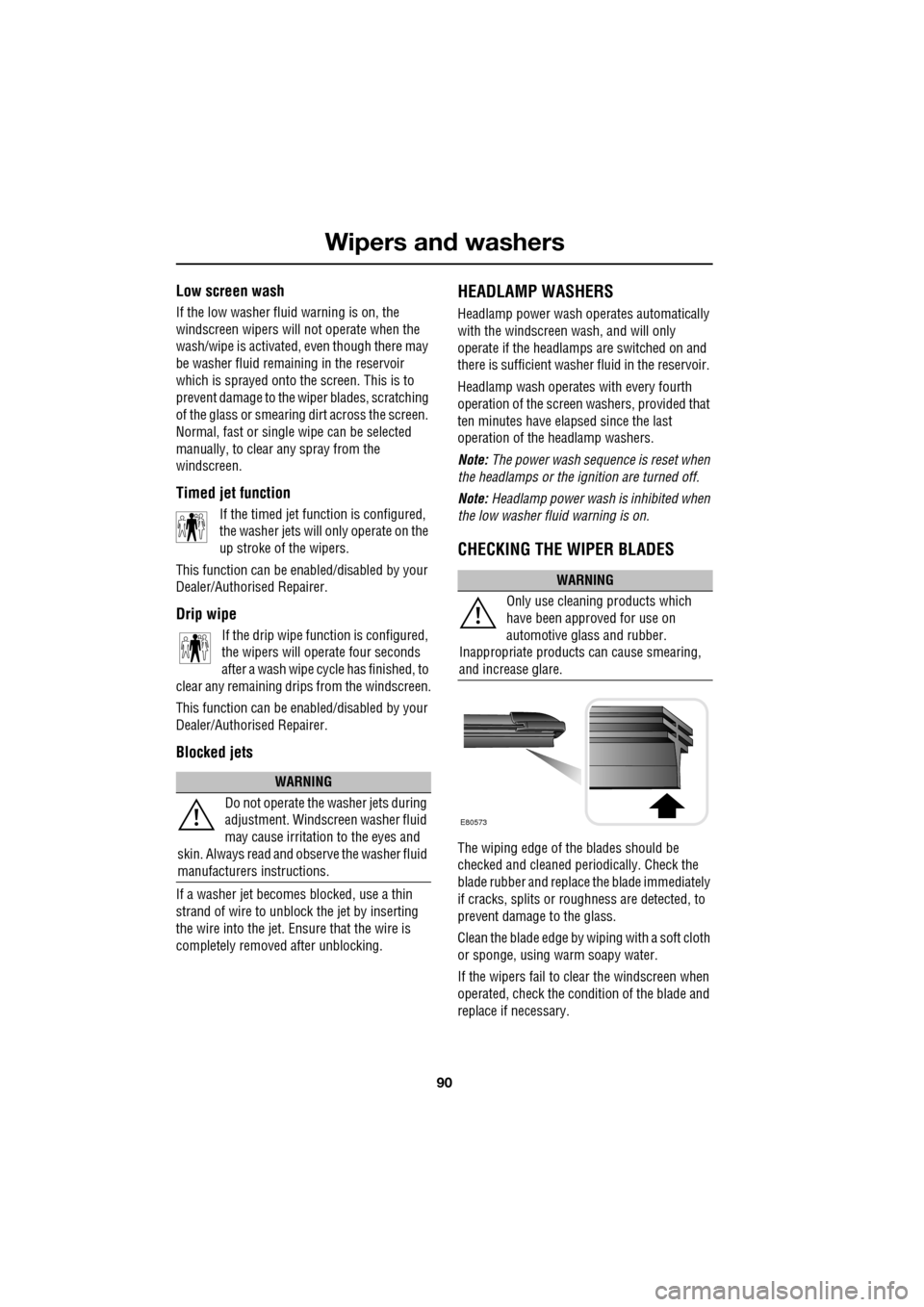

WINDSCREEN WASHERS

To operate the windscreen washers press and

release the button on the e nd of the wiper stalk.

The wipers will perform 5 normal speed wipes,

followed by a drip wipe (if configured). The

washers will operate during the first two wipes.

If the washers are operated with the wipers

operating at normal or fast speed, the washer

jets will operate for tw o wipes and operation of

the wipers will not be affected.

Note: If the button is pressed and held, the

wipers and washers w ill operate at normal

speed until the button is released (or for a

maximum of 10 seconds). After the button is

released, the wipers will operate for a further

three wipes, followed by a drip wipe (if

configured). If the wipe rs are already operating

at normal or fast speed, operating the washers

will not affect wiper operation.

CAUTION

Ensure that the wipers are switched off

before entering a car wash. If the rain

sensitive wipers operate during the car

washing process damage may occur to the

wiper mechanism.

MAX

JAG1623

WARNING

Some screenwash products are

flammable, do not allow screenwash

to come into contact with sources of

ignition.

CAUTION

Only screenwash products which are

approved for automotive use should be

used, and then only in accordance with the

manufacturer's instructions.

JAG1624

Page 90 of 391

Wipers and washers

90

Low screen wash

If the low washer fluid warning is on, the

windscreen wipers will not operate when the

wash/wipe is activated, even though there may

be washer fluid remaining in the reservoir

which is sprayed onto the screen. This is to

prevent damage to the wiper blades, scratching

of the glass or smearing dirt across the screen.

Normal, fast or single wipe can be selected

manually, to clear any spray from the

windscreen.

Timed jet function

If the timed jet func tion is configured,

the washer jets will only operate on the

up stroke of the wipers.

This function can be enabled/disabled by your

Dealer/Authorised Repairer.

Drip wipe

If the drip wipe function is configured,

the wipers will operate four seconds

after a wash wipe cycle has finished, to

clear any remaining drips from the windscreen.

This function can be enabled/disabled by your

Dealer/Authorised Repairer.

Blocked jets

If a washer jet becomes blocked, use a thin

strand of wire to unblock the jet by inserting

the wire into the jet. Ensure that the wire is

completely remove d after unblocking.

HEADLAMP WASHERS

Headlamp power wash operates automatically

with the windscreen wash, and will only

operate if the headlamps are switched on and

there is sufficient washer fluid in the reservoir.

Headlamp wash operates with every fourth

operation of the screen wa shers, provided that

ten minutes have elapsed since the last

operation of the headlamp washers.

Note: The power wash sequence is reset when

the headlamps or the ignition are turned off.

Note: Headlamp power wash is inhibited when

the low washer fluid warning is on.

CHECKING THE WIPER BLADES

The wiping edge of the blades should be

checked and cleaned periodically. Check the

blade rubber and replace the blade immediately

if cracks, splits or roughness are detected, to

prevent damage to the glass.

Clean the blade edge by wiping with a soft cloth

or sponge, using wa rm soapy water.

If the wipers fail to clear the windscreen when

operated, check the cond ition of the blade and

replace if necessary.

WARNING

Do not operate the washer jets during

adjustment. Windscreen washer fluid

may cause irritation to the eyes and

skin. Always read and observe the washer fluid

manufacturers instructions.

WARNING

Only use cleani ng products which

have been approved for use on

automotive glass and rubber.

Inappropriate products can cause smearing,

and increase glare.

E80573