Transmission mount JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 292 of 3039

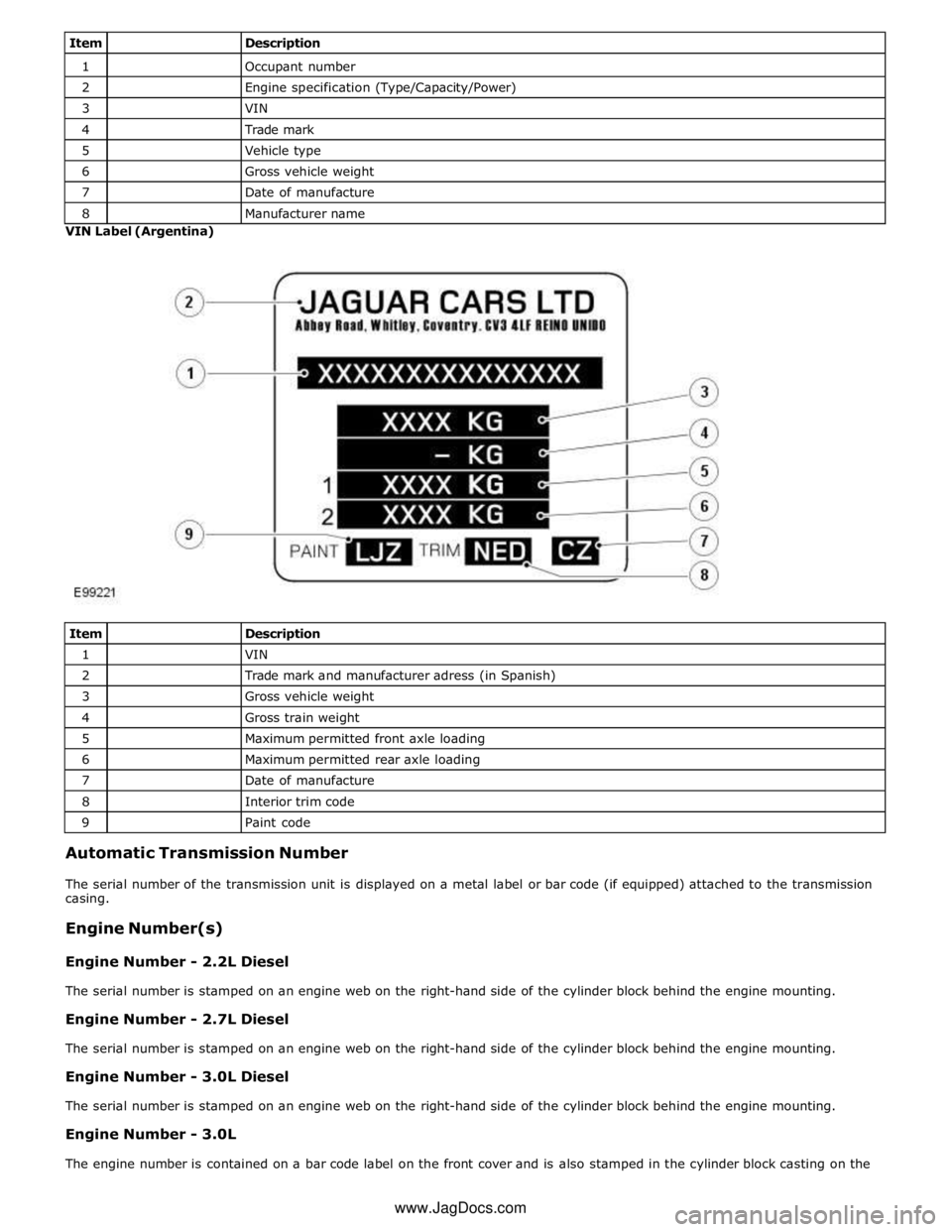

1

Occupant number 2

Engine specification (Type/Capacity/Power) 3

VIN 4

Trade mark 5

Vehicle type 6

Gross vehicle weight 7

Date of manufacture 8

Manufacturer name VIN Label (Argentina)

Item

Description 1

VIN 2

Trade mark and manufacturer adress (in Spanish) 3

Gross vehicle weight 4

Gross train weight 5

Maximum permitted front axle loading 6

Maximum permitted rear axle loading 7

Date of manufacture 8

Interior trim code 9

Paint code Automatic Transmission Number

The serial number of the transmission unit is displayed on a metal label or bar code (if equipped) attached to the transmission

casing.

Engine Number(s)

Engine Number - 2.2L Diesel

The serial number is stamped on an engine web on the right-hand side of the cylinder block behind the engine mounting.

Engine Number - 2.7L Diesel

The serial number is stamped on an engine web on the right-hand side of the cylinder block behind the engine mounting.

Engine Number - 3.0L Diesel

The serial number is stamped on an engine web on the right-hand side of the cylinder block behind the engine mounting.

Engine Number - 3.0L

The engine number is contained on a bar code label on the front cover and is also stamped in the cylinder block casting on the www.JagDocs.com

Page 293 of 3039

left-hand side of the engine below the engine mounting.

Engine Number - 4.2L and 4.2L Supercharged

The serial number is stamped on an engine web on the left-hand side of the cylinder block behind the engine mounting. The

emission code is also located here, on the transmission flange.

Engine Number - 5.0L and 5.0L Supercharged

The serial number is stamped on an engine web on the left-hand side of the cylinder block behind the engine mounting.

Page 298 of 3039

Published: 11-May-2011

Noise, Vibration and Harshness - Noise, Vibration and Harshness (NVH)

Description and Operation

Noise, vibration and harshness (NVH) is becoming more important as vehicles become more sophisticated and passenger

comfort levels increase. This section is designed to aid in the diagnosis, testing and repair of NVH concerns.

Noise is defined as sounds not associated with the operation of passenger compartment equipment that interface with

customer satisfaction.

Vibration is defined as impulses felt by the customer that are not caused by road surface changes.

Harshness is a ride quality issue where the customer feels that the vehicle response to the road surface is sharply

transmitted to the customer.

Diagnostic Theory

Diagnosis is more than just following a series of interrelated steps in order to find the solution to the specific condition. It is a

way of looking at systems that are not functioning the way they should and finding out why. Also it is knowing how the system

should work and whether it is working correctly.

There are basic rules for diagnosis. If these rules are followed, the cause of the condition is usually found the first time

through the system.

Know the System

Know how the parts go together.

Know how the system operates as well as its limits and what happens when the system goes wrong.

Sometimes this means checking the system against one that is known to be working correctly.

Know the History of the System

A clue in any one of these areas may save time:

How old or new is the system?

What kind of treatment has it had?

Has it been repaired in the past in such a manner that might relate to the present condition?

What is the repair history?

Know the History of the Condition

Did it start suddenly or appear gradually?

Was it related to some other occurrence such as a collision or previous part renewal?

Know how the condition made itself known; it may be an important clue to the cause.

Know the Probability of Certain Conditions Developing

Look for the simple rather than the complex.

For example:

- Electrical conditions usually occur at connections rather than components.

- An engine no-start is more likely to be caused by a loose wire or small adjustment rather than a sheared-off

camshaft.

Know the difference between impossible and improbable. Certain failures in a system can be improbable but still

happen.

New parts are just that, new. It does not mean they are always good functioning parts.

Do Not Cure the Symptom and Leave the Cause

Lowering the pressure in a front tire may correct the condition of a vehicle leaning to one side, but it does not correct the

original condition.

Be Positive the Cause is Found

Double check the findings.

What caused a worn component?

A loose transmission or engine mount could indicate that other mounts are also loose.

Diagnostic Charts

Charts are a simple way of expressing the relationship between basic logic and a physical system of components. They help

discover the cause of a condition in the least time. Diagnostic charts combine many areas of diagnosis into one visual display:

probability of certain things occurring in a system

speed of checking certain components or functions before others

simplicity of carrying out certain tests before others

elimination of checking huge portions of a system by carrying out simple tests

certainty of narrowing down the search to a small portion before carrying out in-depth testing

The fastest way to find a condition is to work with the tools that are available. This means working with proven diagnostic

charts and the correct special equipment for the system.

Page 300 of 3039

Noise Conditions

Gear noise is typically a howling or whining due to gear damage or incorrect bearing preload. It can occur at various

speeds and driving conditions, or it can be continuous

Chuckle is a particular rattling noise that sounds like a stick against the spokes of a spinning bicycle wheel. It occurs

while decelerating from approximately 64 km/h (40 miles/h) and can usually be heard all the way to a stop. The

frequency varies with vehicle speed

Knock is very similar to chuckle, though it may be louder and occurs on acceleration or deceleration. The tear down will

disclose what has to be corrected

Check and rule out tires, exhaust and trim items before disassembling the transmission to diagnose and correct gear noise.

The noises described under Road Test usually have specific causes that can be diagnosed by observation as the unit is

disassembled. The initial clues are the type of noise heard on the road test and the driving conditions.

Vibration Conditions

wear. NOTE: New Constant Velocity (CV) joints should not be installed unless disassembly and inspection revealed unusual

Clicking, popping or grinding noises may be caused by the following:

Cut or damaged CV joint boots resulting in inadequate or contaminated lubricant in the outboard or inboard CV joint

bearing housings

Loose CV joint boot clamps

Another component contacting the rear drive half shaft

Worn, damaged or incorrectly installed wheel bearing, suspension or brake component

Vibration at highway speeds may be caused by the following:

Out-of-balance front or rear wheels

Out-of-round tires

Driveline imbalance

Driveline run-out (alignment)

NOTE: Rear drive half shafts are not balanced and are not likely to contribute to rotational vibration disturbance.

Shudder or vibration during acceleration (including from rest) may be caused by the following:

Driveline alignment

Excessively worn or damaged outboard or inboard CV joint bearing housing

Excessively high CV joint operating angles caused by incorrect ride height. Check ride height, verify correct spring rate

and check items under Inoperative Conditions

Excessively worn driveshaft components

Leakage Conditions

1. Inspect the CV joint boots for evidence of cracks, tears or splits.

2. Inspect the underbody for any indication of grease splatter in the vicinity of the rear drive half shaft, outboard and

inboard CV joint boot locations, which is an indication of CV joint boot or CV joint boot clamp damage.

3. Inspect the inboard CV joint bearing housing seal for leakage.

Inoperative Conditions

If a CV joint or rear drive half shaft pull-out occurs, check the following:

suspension components for correct location, damage or wear

bushings for wear

subframe for damage

bent or worn components

- Stabilizer bar link

- Left-hand rear suspension lower arm and bushing

- Right-hand rear suspension lower arm and bushing

- Rear wheel hub and rear drive half shaft

Road Test

A gear-driven unit will produce a certain amount of noise. Some noise is acceptable and may be audible at certain speeds or

under various driving conditions as on a newly paved blacktop road. The slight noise is in no way detrimental and must be

considered normal.

The road test and customer interview (if available) provide information needed to identify the condition and give direction to

the correct starting point for diagnosis.

1. Make notes throughout the diagnosis routine. Make sure to write down even the smallest piece of information, because

Page 302 of 3039

and drive half shaft failure, which could cause serious personal injury and extensive vehicle damage. Failure to follow these

instructions may result in personal injury.

CAUTION: The suspension should not be allowed to hang free. When the CV joint is run at a very high angle, extra

vibration as well as damage to the seals and joints can occur.

The rear suspension lower arm should be supported as far outboard as possible. To bring the vehicle to its correct ride height,

the full weight of the vehicle should be supported in the rear by floor jacks. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

1. Raise and support the vehicle. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

2. Explore the speed range of interest using the Road Test Quick Checks as previously described.

3. Carry out a coast down in neutral. If the vehicle is free of vibration when operating at a steady indicated speed and

behaves very differently in drive and coast, a transmission concern is likely.

Note, however, that a test on the lift may produce different vibrations and noises than a road test because of the effect of the

lift. It is not unusual to find vibrations on the lift that were not found in the road test. If the condition found on the road can

be duplicated on the lift, carrying out experiments on the lift may save a great deal of time.

Exhaust Neutralization Procedure

1. Raise vehicle on lift and slacken all exhaust fixings.

2. With all fixings loose, neutralize the exhaust system.

3. Tighten all fixings to correct torque, starting at the rear-most point working towards the front of the vehicle.

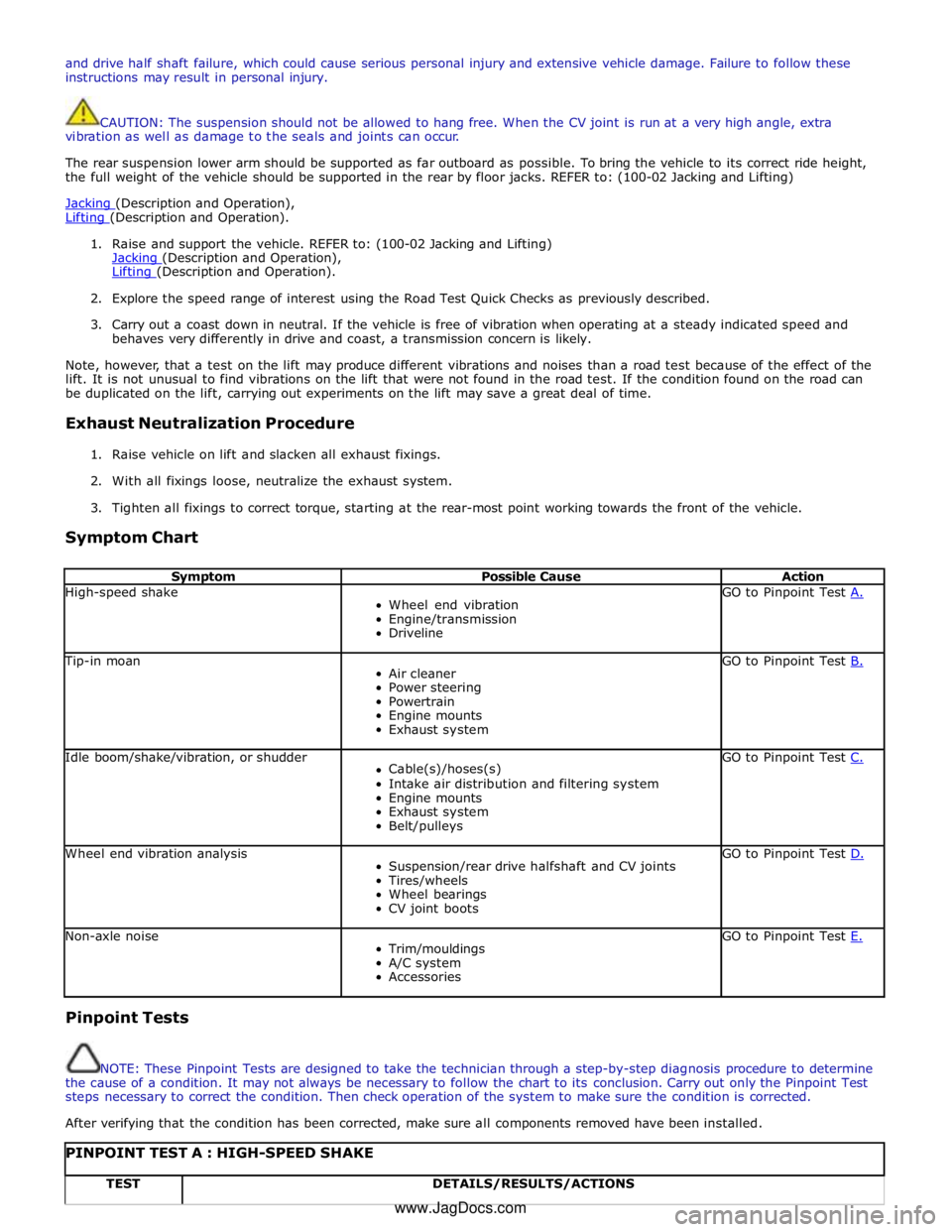

Symptom Chart

Symptom Possible Cause Action High-speed shake

Wheel end vibration

Engine/transmission

Driveline GO to Pinpoint Test A. Tip-in moan

Air cleaner

Power steering

Powertrain

Engine mounts

Exhaust system GO to Pinpoint Test B. Idle boom/shake/vibration, or shudder

Cable(s)/hoses(s)

Intake air distribution and filtering system

Engine mounts

Exhaust system

Belt/pulleys GO to Pinpoint Test C. Wheel end vibration analysis

Suspension/rear drive halfshaft and CV joints

Tires/wheels

Wheel bearings

CV joint boots GO to Pinpoint Test D. Non-axle noise

Trim/mouldings

A/C system

Accessories GO to Pinpoint Test E. Pinpoint Tests

NOTE: These Pinpoint Tests are designed to take the technician through a step-by-step diagnosis procedure to determine

the cause of a condition. It may not always be necessary to follow the chart to its conclusion. Carry out only the Pinpoint Test

steps necessary to correct the condition. Then check operation of the system to make sure the condition is corrected.

After verifying that the condition has been corrected, make sure all components removed have been installed.

PINPOINT TEST A : HIGH-SPEED SHAKE TEST DETAILS/RESULTS/ACTIONS www.JagDocs.com

Page 303 of 3039

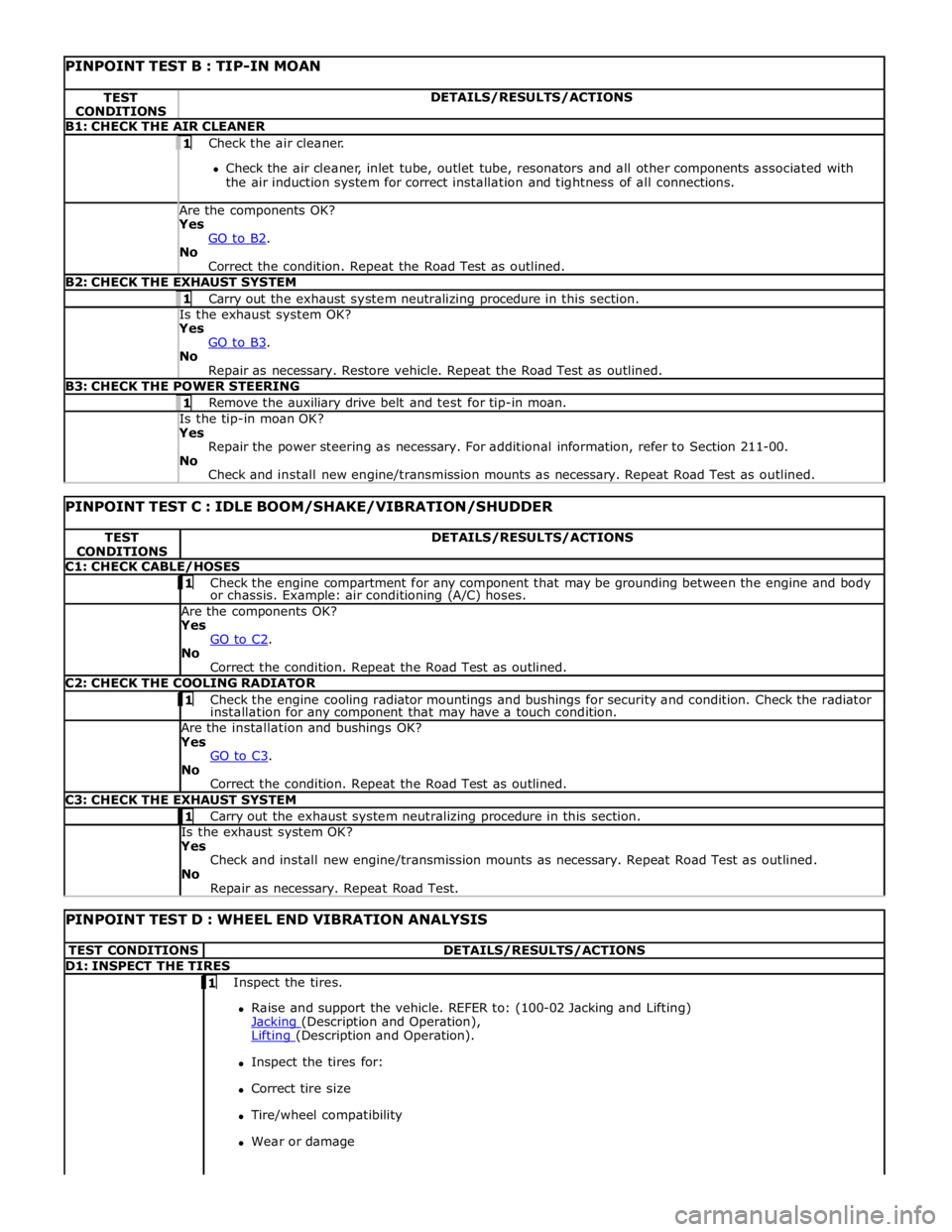

PINPOINT TEST B : TIP-IN MOAN TEST

CONDITIONS DETAILS/RESULTS/ACTIONS B1: CHECK THE AIR CLEANER 1 Check the air cleaner.

Check the air cleaner, inlet tube, outlet tube, resonators and all other components associated with

the air induction system for correct installation and tightness of all connections. Are the components OK? Yes

GO to B2. No

Correct the condition. Repeat the Road Test as outlined. B2: CHECK THE EXHAUST SYSTEM 1 Carry out the exhaust system neutralizing procedure in this section. Is the exhaust system OK? Yes

GO to B3. No

Repair as necessary. Restore vehicle. Repeat the Road Test as outlined. B3: CHECK THE POWER STEERING 1 Remove the auxiliary drive belt and test for tip-in moan. Is the tip-in moan OK? Yes

Repair the power steering as necessary. For additional information, refer to Section 211-00.

No

Check and install new engine/transmission mounts as necessary. Repeat Road Test as outlined.

PINPOINT TEST C : IDLE BOOM/SHAKE/VIBRATION/SHUDDER TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: CHECK CABLE/HOSES 1 Check the engine compartment for any component that may be grounding between the engine and body or chassis. Example: air conditioning (A/C) hoses. Are the components OK? Yes

GO to C2. No

Correct the condition. Repeat the Road Test as outlined. C2: CHECK THE COOLING RADIATOR 1 Check the engine cooling radiator mountings and bushings for security and condition. Check the radiator installation for any component that may have a touch condition. Are the installation and bushings OK? Yes

GO to C3. No

Correct the condition. Repeat the Road Test as outlined. C3: CHECK THE EXHAUST SYSTEM 1 Carry out the exhaust system neutralizing procedure in this section. Is the exhaust system OK? Yes

Check and install new engine/transmission mounts as necessary. Repeat Road Test as outlined.

No

Repair as necessary. Repeat Road Test.

PINPOINT TEST D : WHEEL END VIBRATION ANALYSIS TEST CONDITIONS DETAILS/RESULTS/ACTIONS D1: INSPECT THE TIRES 1 Inspect the tires.

Raise and support the vehicle. REFER to: (100-02 Jacking and Lifting)

Jacking (Description and Operation), Lifting (Description and Operation).

Inspect the tires for:

Correct tire size

Tire/wheel compatibility

Wear or damage

Page 495 of 3039

Published: 11-May-2011

Ride and Handling Optimization - Ride and Handling Optimization - System

Operation and Component Description

Description and Operation

JAGUARDRIVE CONTROL OPERATION

Engine Management System System Operation

The Engine Management System (EMS) varies the accelerator pedal maps to change the amount of torque per percentage of

pedal travel. The EMS can also change the accelerator pedal response to control the allowed torque change relative to the

speed of pedal travel.

Each driving mode uses a combination of operating parameters for each sub-system. Changing between driving modes initiates

a different set of operating characteristics, which will be noticeable to the driver. The driver will notice differences in engine

response when, for example, the accelerator pedal is held in a constant position and the driving mode is changed from Winter

to Dynamic, the driver will notice the torque and engine speed increase. Similarly, if the mode is changed from Normal or

Dynamic to Winter the driver will notice a reduction in torque and engine speed.

NOTE: The change in torque and engine speed can take approximately 30 seconds and care must be taken not to confuse

the JaguarDrive Control system operation with an EMS fault.

Transmission Control

The TCM (transmission control module) changes the shift maps for the JaguarDrive Control mode selected. This changes the

shift points providing early or late upshifts and downshifts. For example, on slippery surfaces in Winter mode the transmission

will select 2nd gear for starting from a standstill on a flat surface to minimize wheel slip.

Anti-lock Braking System Control

The ABS (anti-lock brake system) module controls several vehicle functions and adjusts the operating parameters of these

functions to optimize the selected JaguarDrive Control mode. Traction control uses different slip/acceleration thresholds to

improve traction and vehicle composure. For example, the system sensitivity is increased on slippery surfaces to reduce wheel

spin.

If TracDSC is selected or DSC is switched off, then subsequently the JaguarDrive Control mode is changed, DSC is automatically

switched back on (or to TracDSC for Dynamic mode).

The stability control uses different threshold values for the selected mode, reducing the requirement for the driver to change

the DSC system mode for optimum performance in various driving scenarios.

Incorrect Mode Usage

Selection of an inappropriate mode is discouraged in the following ways:

The active mode icon is continually displayed in the instrument cluster message center

In any special mode, when the ignition has been in the off position continuously for more than 6 hours, the JaguarDrive

Control system defaults to the special modes off (DSC on).

Selection of an inappropriate mode for the conditions will not endanger the driver or immediately cause damage to the vehicle.

Continued use of an inappropriate mode may reduce the life of some components. The driver may notice a different vehicle

response, with the engine and transmission responses being different than in the special modes off.

Driver Information

The instrument cluster contains a message center, which displays vehicle information to the driver. The message center

contains the JaguarDrive Control mode icons, which display the currently selected mode. If no symbol is displayed, no special

mode is selected and the system is in special modes off.

Any required changes to the subsystems are also passed to the driver in the form of warning illumination in the instrument

cluster or appropriate messages in the message center, DSC off for example.

In Dynamic mode when the transmission is in manual mode, the gear information is displayed in amber when the appropriate

engine speed is reached for optimum sporty change point.

DIAGNOSTICS

JaguarDrive Control relies on the correct functionality of the sub-systems. If one of the sub-systems develops a fault, the

JaguarDrive Control system will not function, even though the fault is not in the JaguarDrive Control system.

The JaguarDrive Selector module and rotary control should only be investigated if there are no apparent faults in any of the

sub-systems. If a fault in a sub-system is subsequently corrected, the JaguarDrive Control system will function normally after

an ignition on and off cycle.

Page 501 of 3039

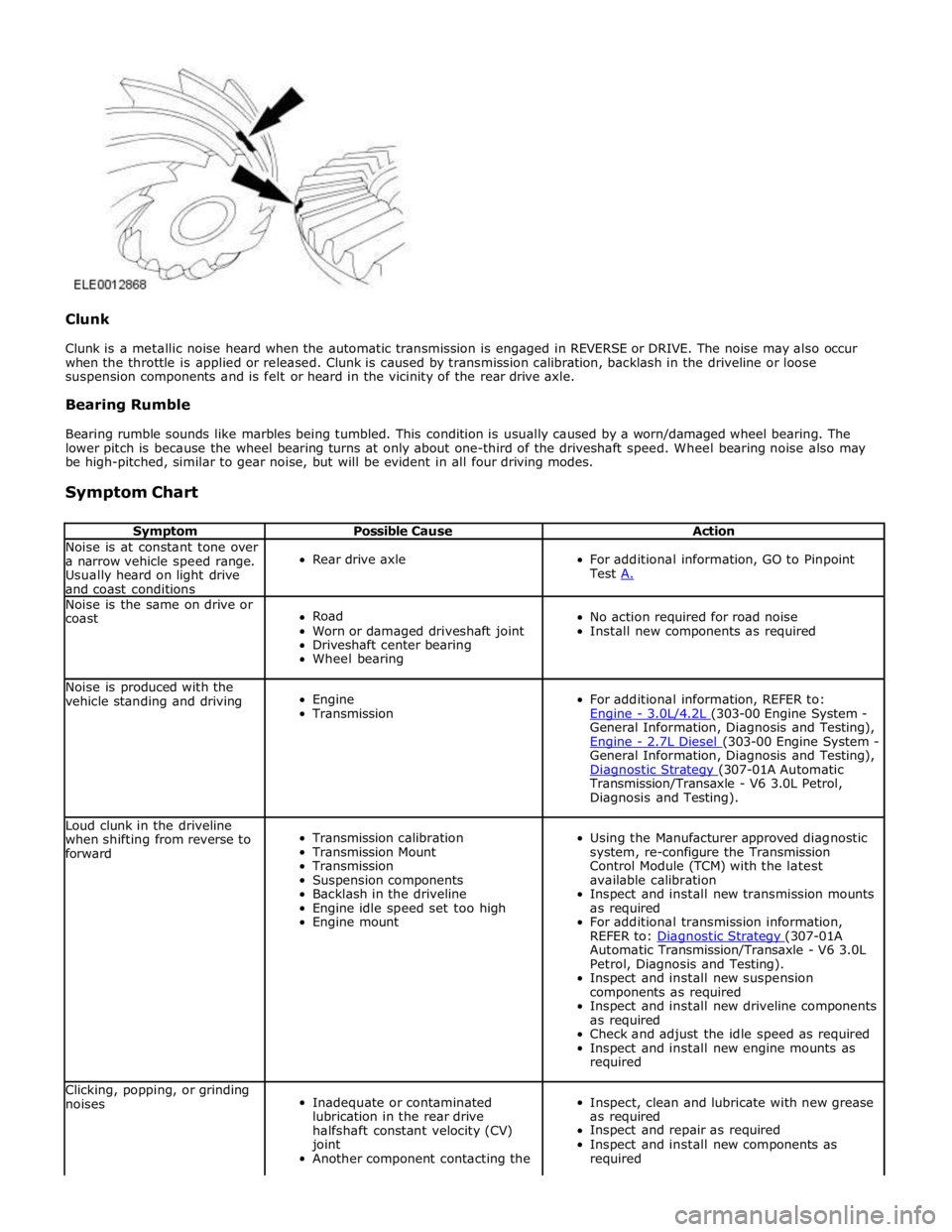

Clunk

Clunk is a metallic noise heard when the automatic transmission is engaged in REVERSE or DRIVE. The noise may also occur

when the throttle is applied or released. Clunk is caused by transmission calibration, backlash in the driveline or loose

suspension components and is felt or heard in the vicinity of the rear drive axle.

Bearing Rumble

Bearing rumble sounds like marbles being tumbled. This condition is usually caused by a worn/damaged wheel bearing. The

lower pitch is because the wheel bearing turns at only about one-third of the driveshaft speed. Wheel bearing noise also may

be high-pitched, similar to gear noise, but will be evident in all four driving modes.

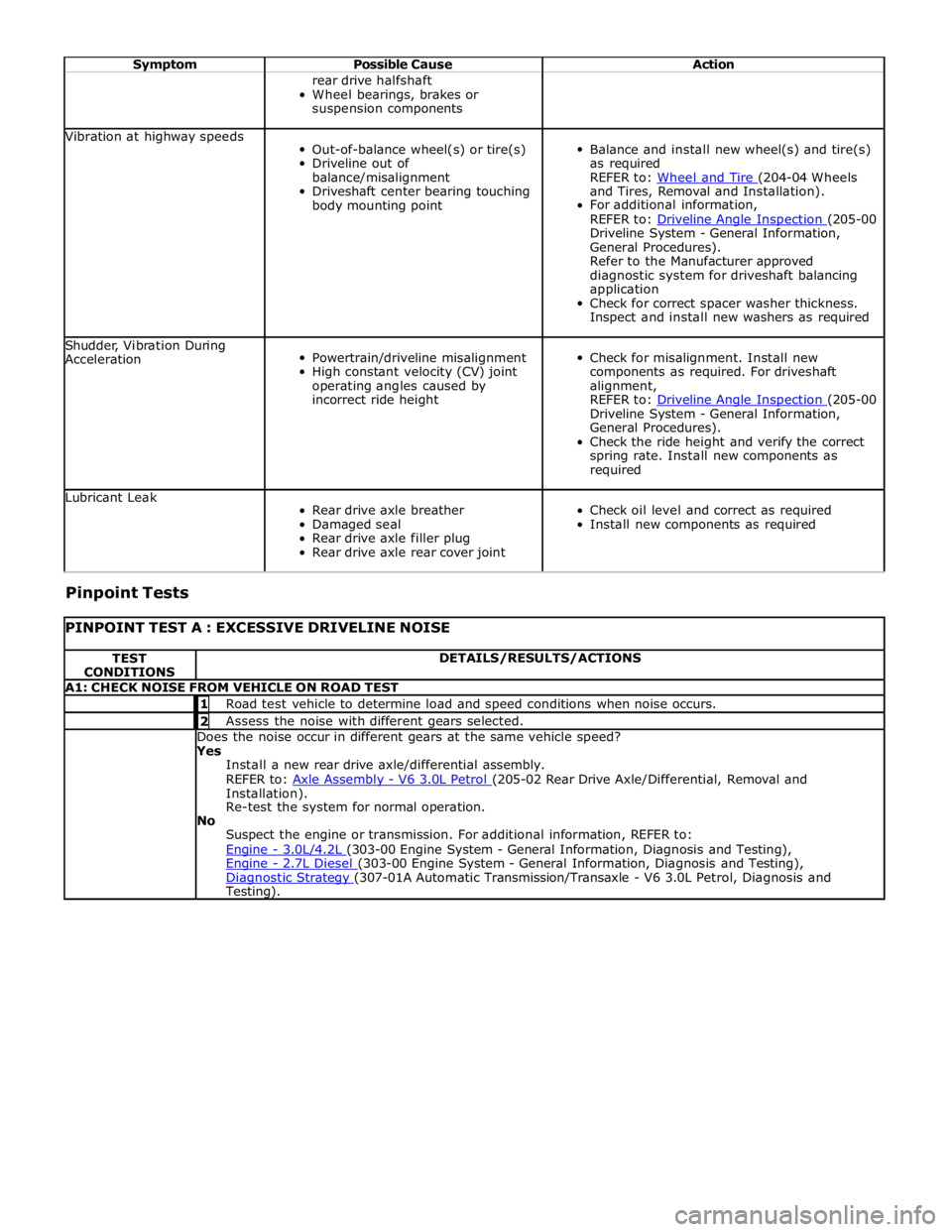

Symptom Chart

Symptom Possible Cause Action Noise is at constant tone over

a narrow vehicle speed range.

Usually heard on light drive

and coast conditions

Rear drive axle

For additional information, GO to Pinpoint

Test A. Noise is the same on drive or

coast

Road

Worn or damaged driveshaft joint

Driveshaft center bearing

Wheel bearing

No action required for road noise

Install new components as required Noise is produced with the

vehicle standing and driving

Engine

Transmission

For additional information, REFER to:

Engine - 3.0L/4.2L (303-00 Engine System - General Information, Diagnosis and Testing),

Engine - 2.7L Diesel (303-00 Engine System - General Information, Diagnosis and Testing),

Diagnostic Strategy (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol,

Diagnosis and Testing). Loud clunk in the driveline

when shifting from reverse to

forward

Transmission calibration

Transmission Mount

Transmission

Suspension components

Backlash in the driveline

Engine idle speed set too high

Engine mount

Using the Manufacturer approved diagnostic

system, re-configure the Transmission

Control Module (TCM) with the latest

available calibration

Inspect and install new transmission mounts

as required

For additional transmission information,

REFER to: Diagnostic Strategy (307-01A Automatic Transmission/Transaxle - V6 3.0L

Petrol, Diagnosis and Testing).

Inspect and install new suspension

components as required

Inspect and install new driveline components

as required

Check and adjust the idle speed as required

Inspect and install new engine mounts as

required Clicking, popping, or grinding

noises

Inadequate or contaminated

lubrication in the rear drive

halfshaft constant velocity (CV)

joint

Another component contacting the

Inspect, clean and lubricate with new grease

as required

Inspect and repair as required

Inspect and install new components as

required

Page 502 of 3039

Symptom Possible Cause Action rear drive halfshaft

Wheel bearings, brakes or

suspension components Vibration at highway speeds

Out-of-balance wheel(s) or tire(s)

Driveline out of

balance/misalignment

Driveshaft center bearing touching

body mounting point

Balance and install new wheel(s) and tire(s)

as required

REFER to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

For additional information,

REFER to: Driveline Angle Inspection (205-00 Driveline System - General Information,

General Procedures).

Refer to the Manufacturer approved

diagnostic system for driveshaft balancing

application

Check for correct spacer washer thickness.

Inspect and install new washers as required Shudder, Vibration During

Acceleration

Powertrain/driveline misalignment

High constant velocity (CV) joint

operating angles caused by

incorrect ride height

Check for misalignment. Install new

components as required. For driveshaft

alignment,

REFER to: Driveline Angle Inspection (205-00 Driveline System - General Information,

General Procedures).

Check the ride height and verify the correct

spring rate. Install new components as

required Lubricant Leak

Rear drive axle breather

Damaged seal

Rear drive axle filler plug

Rear drive axle rear cover joint

Check oil level and correct as required

Install new components as required Pinpoint Tests

PINPOINT TEST A : EXCESSIVE DRIVELINE NOISE TEST

CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK NOISE FROM VEHICLE ON ROAD TEST 1 Road test vehicle to determine load and speed conditions when noise occurs. 2 Assess the noise with different gears selected. Does the noise occur in different gears at the same vehicle speed? Yes

Install a new rear drive axle/differential assembly.

REFER to: Axle Assembly - V6 3.0L Petrol (205-02 Rear Drive Axle/Differential, Removal and Installation).

Re-test the system for normal operation.

No

Suspect the engine or transmission. For additional information, REFER to:

Engine - 3.0L/4.2L (303-00 Engine System - General Information, Diagnosis and Testing), Engine - 2.7L Diesel (303-00 Engine System - General Information, Diagnosis and Testing), Diagnostic Strategy (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol, Diagnosis and Testing).

Page 537 of 3039

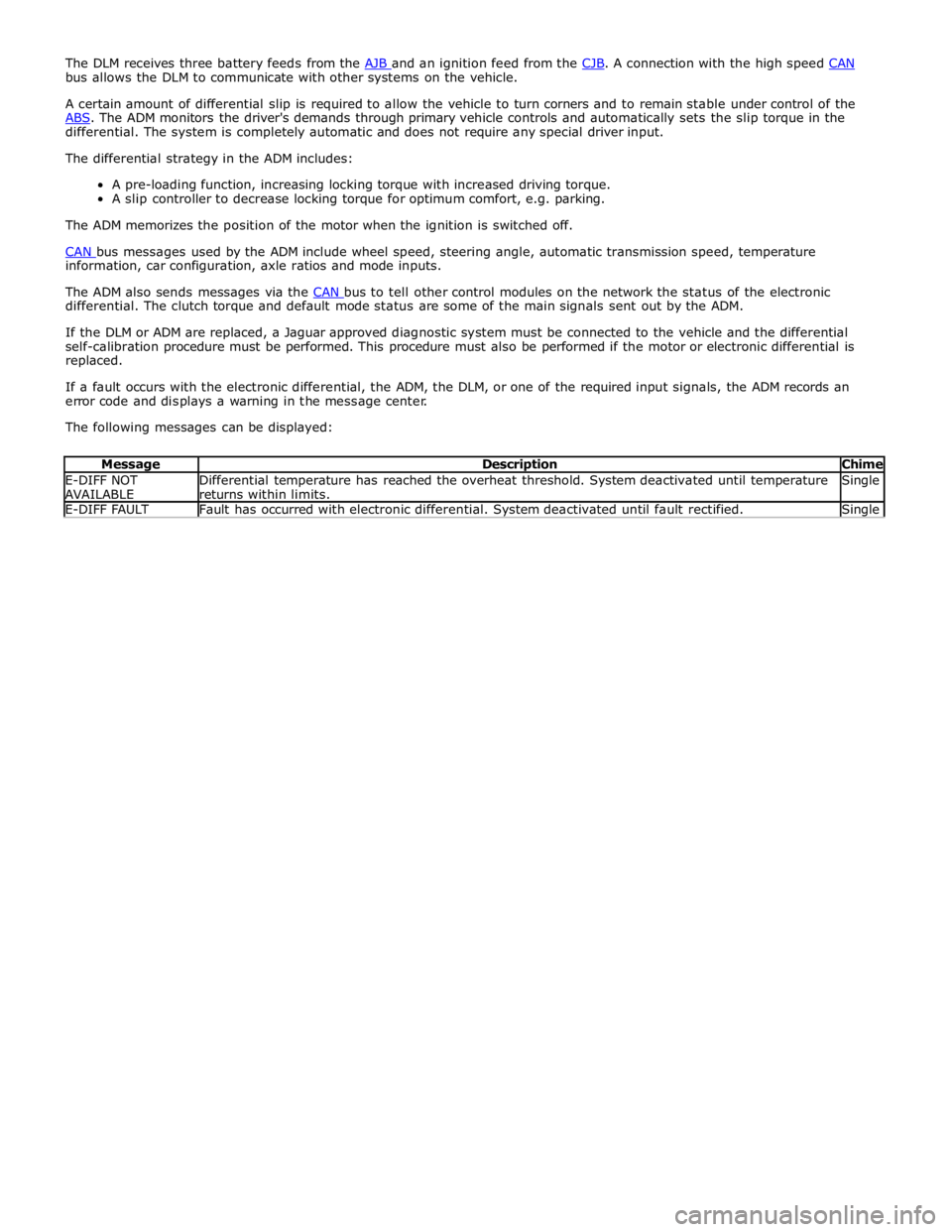

bus allows the DLM to communicate with other systems on the vehicle.

A certain amount of differential slip is required to allow the vehicle to turn corners and to remain stable under control of the

ABS. The ADM monitors the driver's demands through primary vehicle controls and automatically sets the slip torque in the differential. The system is completely automatic and does not require any special driver input.

The differential strategy in the ADM includes:

A pre-loading function, increasing locking torque with increased driving torque.

A slip controller to decrease locking torque for optimum comfort, e.g. parking.

The ADM memorizes the position of the motor when the ignition is switched off.

CAN bus messages used by the ADM include wheel speed, steering angle, automatic transmission speed, temperature information, car configuration, axle ratios and mode inputs.

The ADM also sends messages via the CAN bus to tell other control modules on the network the status of the electronic differential. The clutch torque and default mode status are some of the main signals sent out by the ADM.

If the DLM or ADM are replaced, a Jaguar approved diagnostic system must be connected to the vehicle and the differential

self-calibration procedure must be performed. This procedure must also be performed if the motor or electronic differential is

replaced.

If a fault occurs with the electronic differential, the ADM, the DLM, or one of the required input signals, the ADM records an

error code and displays a warning in the message center.

The following messages can be displayed:

Message Description Chime E-DIFF NOT

AVAILABLE Differential temperature has reached the overheat threshold. System deactivated until temperature

returns within limits. Single E-DIFF FAULT Fault has occurred with electronic differential. System deactivated until fault rectified. Single