Transmission mount JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1535 of 3039

Published: 11-May-2011

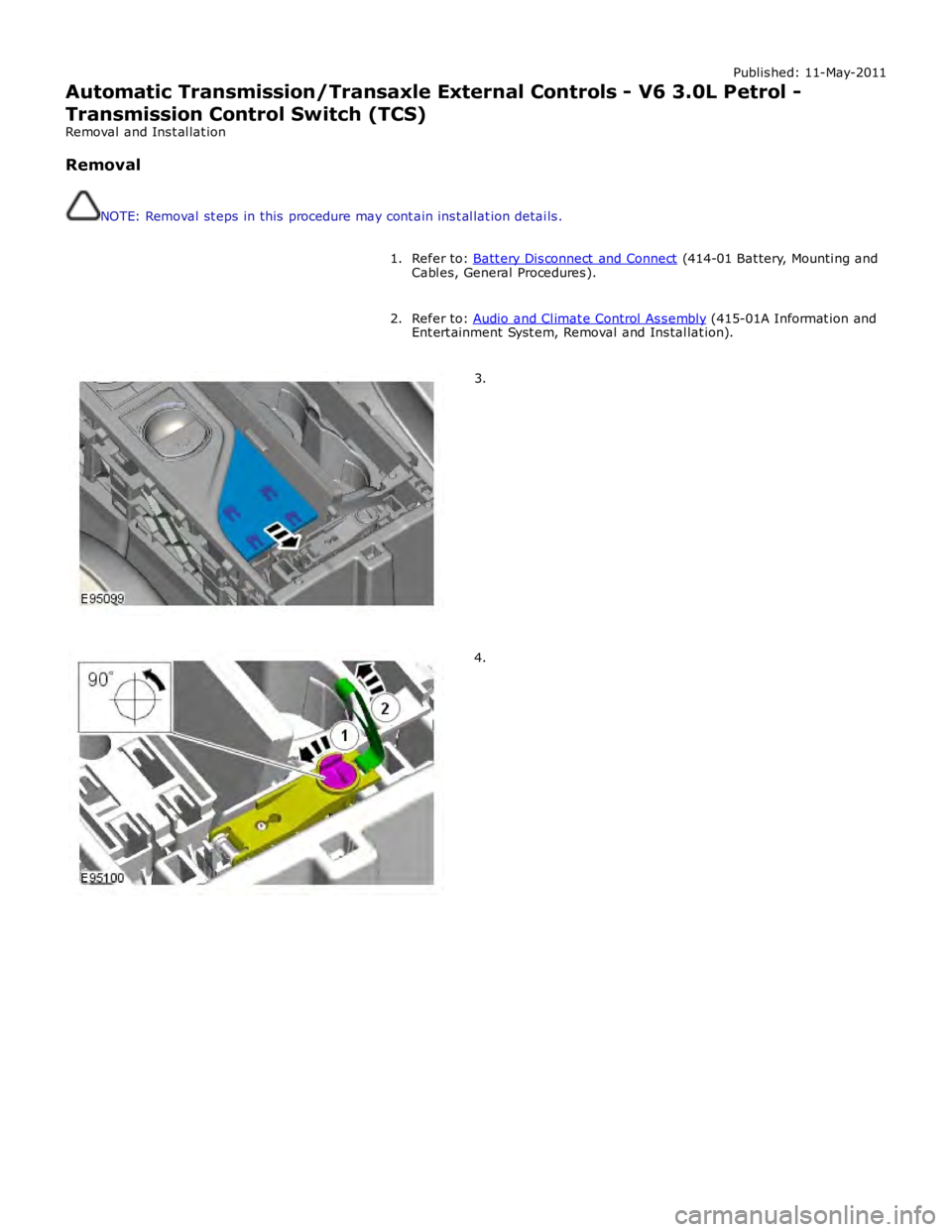

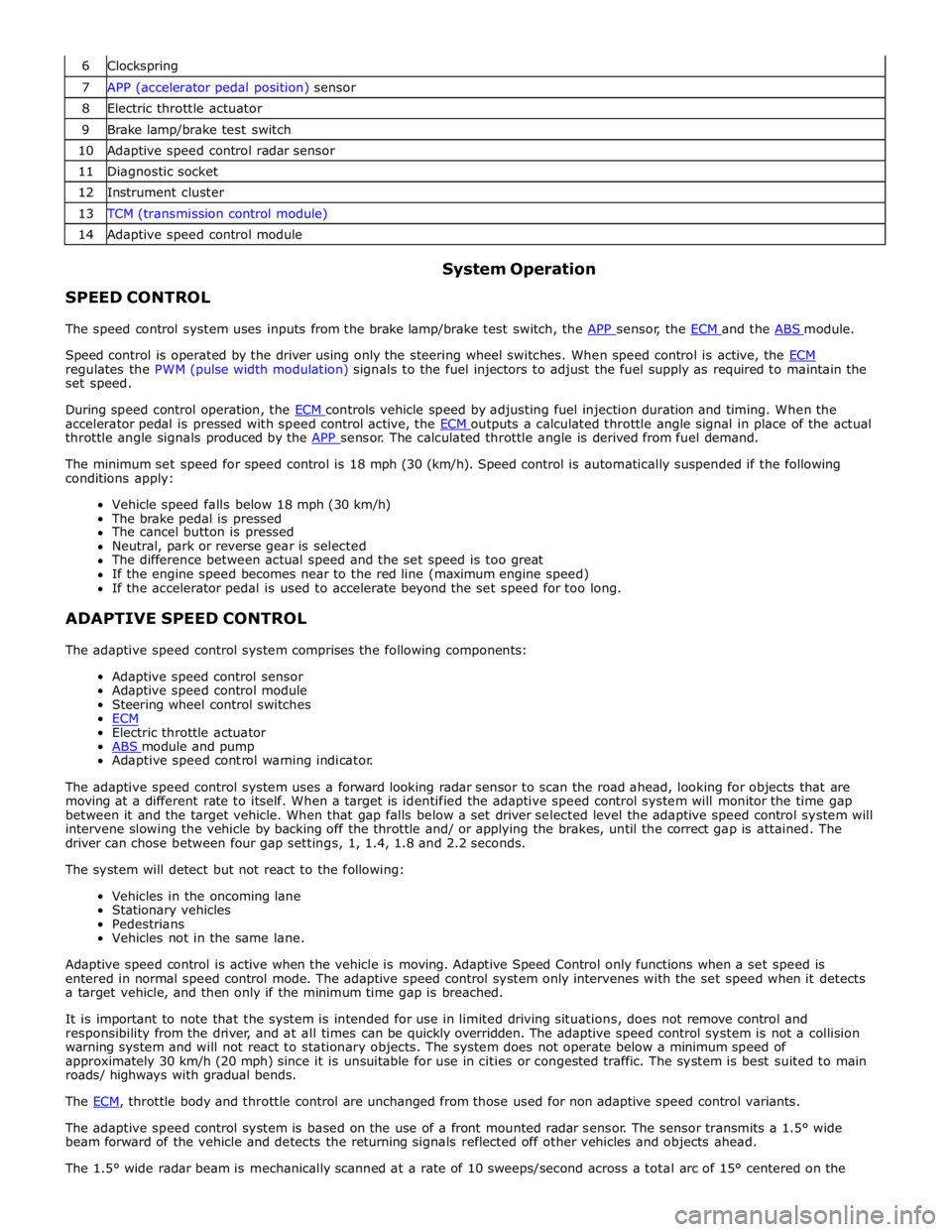

Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol -

Transmission Control Switch (TCS)

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain inst allation details.

Refer to: Batt ery Disconnect and Connect (414-01 Battery, Mounting and

Cables, General Procedures). 1.

Refer to: Audio and Climate Control Assembly (415-01A Informat ion and

Entert ainment Syst em, Removal and Installat ion). 2.3.4.

Page 1539 of 3039

Published: 11-May-2011

Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol -

Emergency Park Position Release Lever

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain inst allation details.

Refer to: Batt ery Disconnect and Connect (414-01 Battery, Mounting and

Cables, General Procedures). 1.

Refer to: Air Deflector (501-02, Removal and Installation). 2.

Refer to: Engine Rear Undershield (501-02 Front End Body Panels,

Removal and Installation). 3.

Refer to: Floor Console Side Trim Panel (501-12 Inst rument Panel and

Console, Removal and Installation). 4.WARNING: Make sure to support the vehicle with axle

stands.

T orque: 11 Nm 5.

Page 1641 of 3039

6 Clockspring 7 APP (accelerator pedal position) sensor 8 Electric throttle actuator 9 Brake lamp/brake test switch 10 Adaptive speed control radar sensor 11 Diagnostic socket 12 Instrument cluster 13 TCM (transmission control module) 14 Adaptive speed control module

SPEED CONTROL System Operation

The speed control system uses inputs from the brake lamp/brake test switch, the APP sensor, the ECM and the ABS module.

Speed control is operated by the driver using only the steering wheel switches. When speed control is active, the ECM regulates the PWM (pulse width modulation) signals to the fuel injectors to adjust the fuel supply as required to maintain the

set speed.

During speed control operation, the ECM controls vehicle speed by adjusting fuel injection duration and timing. When the accelerator pedal is pressed with speed control active, the ECM outputs a calculated throttle angle signal in place of the actual throttle angle signals produced by the APP sensor. The calculated throttle angle is derived from fuel demand.

The minimum set speed for speed control is 18 mph (30 (km/h). Speed control is automatically suspended if the following

conditions apply:

Vehicle speed falls below 18 mph (30 km/h)

The brake pedal is pressed

The cancel button is pressed

Neutral, park or reverse gear is selected

The difference between actual speed and the set speed is too great

If the engine speed becomes near to the red line (maximum engine speed)

If the accelerator pedal is used to accelerate beyond the set speed for too long.

ADAPTIVE SPEED CONTROL

The adaptive speed control system comprises the following components:

Adaptive speed control sensor

Adaptive speed control module

Steering wheel control switches

ECM

Electric throttle actuator

ABS module and pump Adaptive speed control warning indicator.

The adaptive speed control system uses a forward looking radar sensor to scan the road ahead, looking for objects that are

moving at a different rate to itself. When a target is identified the adaptive speed control system will monitor the time gap

between it and the target vehicle. When that gap falls below a set driver selected level the adaptive speed control system will

intervene slowing the vehicle by backing off the throttle and/ or applying the brakes, until the correct gap is attained. The

driver can chose between four gap settings, 1, 1.4, 1.8 and 2.2 seconds.

The system will detect but not react to the following:

Vehicles in the oncoming lane

Stationary vehicles

Pedestrians

Vehicles not in the same lane.

Adaptive speed control is active when the vehicle is moving. Adaptive Speed Control only functions when a set speed is

entered in normal speed control mode. The adaptive speed control system only intervenes with the set speed when it detects

a target vehicle, and then only if the minimum time gap is breached.

It is important to note that the system is intended for use in limited driving situations, does not remove control and

responsibility from the driver, and at all times can be quickly overridden. The adaptive speed control system is not a collision

warning system and will not react to stationary objects. The system does not operate below a minimum speed of

approximately 30 km/h (20 mph) since it is unsuitable for use in cities or congested traffic. The system is best suited to main

roads/ highways with gradual bends.

The ECM, throttle body and throttle control are unchanged from those used for non adaptive speed control variants.

The adaptive speed control system is based on the use of a front mounted radar sensor. The sensor transmits a 1.5° wide

beam forward of the vehicle and detects the returning signals reflected off other vehicles and objects ahead.

The 1.5° wide radar beam is mechanically scanned at a rate of 10 sweeps/second across a total arc of 15° centered on the

Page 1822 of 3039

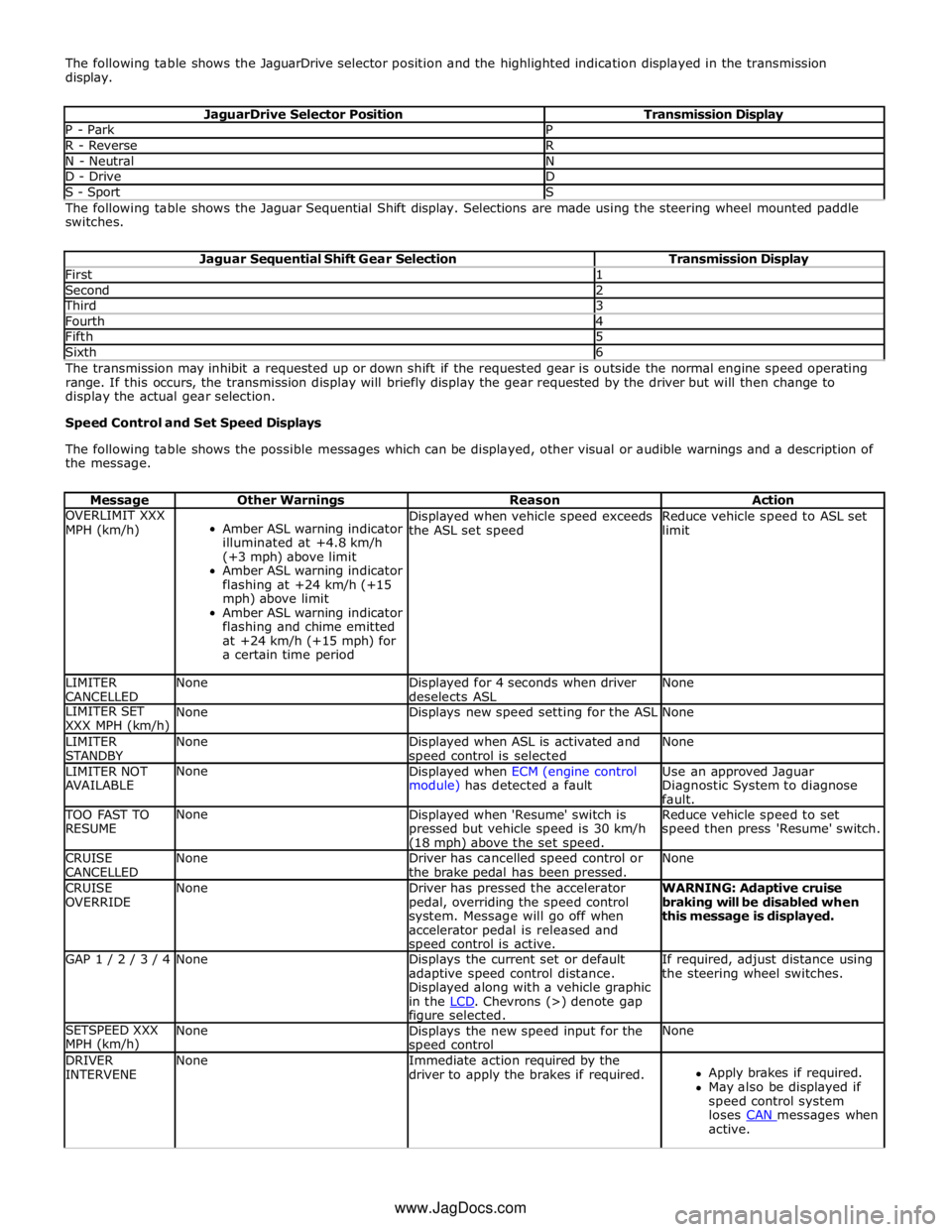

The following table shows the JaguarDrive selector position and the highlighted indication displayed in the transmission

display.

JaguarDrive Selector Position Transmission Display P - Park P R - Reverse R N - Neutral N D - Drive D S - Sport S The following table shows the Jaguar Sequential Shift display. Selections are made using the steering wheel mounted paddle

switches.

Jaguar Sequential Shift Gear Selection Transmission Display First 1 Second 2 Third 3 Fourth 4 Fifth 5 Sixth 6 The transmission may inhibit a requested up or down shift if the requested gear is outside the normal engine speed operating

range. If this occurs, the transmission display will briefly display the gear requested by the driver but will then change to

display the actual gear selection.

Speed Control and Set Speed Displays

The following table shows the possible messages which can be displayed, other visual or audible warnings and a description of

the message.

Message Other Warnings Reason Action OVERLIMIT XXX

MPH (km/h)

Amber ASL warning indicator

illuminated at +4.8 km/h

(+3 mph) above limit

Amber ASL warning indicator

flashing at +24 km/h (+15

mph) above limit

Amber ASL warning indicator

flashing and chime emitted

at +24 km/h (+15 mph) for

a certain time period Displayed when vehicle speed exceeds

the ASL set speed Reduce vehicle speed to ASL set

limit LIMITER

CANCELLED None

Displayed for 4 seconds when driver

deselects ASL None LIMITER SET

XXX MPH (km/h) None Displays new speed setting for the ASL None LIMITER

STANDBY None

Displayed when ASL is activated and speed control is selected None LIMITER NOT

AVAILABLE None

Displayed when ECM (engine control

module) has detected a fault Use an approved Jaguar

Diagnostic System to diagnose

fault. TOO FAST TO

RESUME None

Displayed when 'Resume' switch is

pressed but vehicle speed is 30 km/h (18 mph) above the set speed. Reduce vehicle speed to set

speed then press 'Resume' switch. CRUISE

CANCELLED None

Driver has cancelled speed control or

the brake pedal has been pressed. None CRUISE

OVERRIDE None

Driver has pressed the accelerator

pedal, overriding the speed control

system. Message will go off when

accelerator pedal is released and speed control is active. WARNING: Adaptive cruise

braking will be disabled when

this message is displayed. GAP 1 / 2 / 3 / 4 None

Displays the current set or default

adaptive speed control distance.

Displayed along with a vehicle graphic

in the LCD. Chevrons (>) denote gap figure selected. If required, adjust distance using

the steering wheel switches. SETSPEED XXX

MPH (km/h) None

Displays the new speed input for the speed control None DRIVER

INTERVENE None

Immediate action required by the

driver to apply the brakes if required.

Apply brakes if required.

May also be displayed if

speed control system

loses CAN messages when active. www.JagDocs.com

Page 2294 of 3039

8 LH door module 9 Exterior mirror control switches

System Operation

The rear view mirrors comprise an interior mirror mounted to the windshield, and an exterior mirror mounted on each front door

cheater. The types of mirrors and associated operating functions installed depend on the specification and trim level of the

vehicle.

Interior Mirrors

The interior rear view mirror is provided as a manual dimming or an electrically operated automatic dimming type.

The manual dimming mirror comprises a prismatic glass housed within a surrounding case that is attached with a ball joint

connector to the mirror stem. Manual dimming of the mirror is achieved using the lever mounted on the underside of the mirror

body. Operating the lever will tilt the mirror head from the 'day' position to the 'night' position.

The automatic dimming mirror comprises an electro-chromatic glass housed within a surrounding case that is attached with a

ball joint connector to the mirror stem. The mirror stem incorporates an 8-pin electrical connector that is connected to the roof

panel wiring harness. The wiring harness provides hardwired and a LIN connection to the CJB.

Light sensors are mounted on the front and rear of the mirror surround case. The sensors control the automatic dimming

feature to reduce glare from the headlights of following vehicles.

The automatic dimming function is permanently active when the ignition is in power mode 4 (Accessory) and power mode 6

(Ignition). The forward facing light sensor monitors the ambient light level at the front of the vehicle; the rearward facing light

sensor monitors the light level coming from the rear of the vehicle. When light from the rear of the vehicle exceeds the

ambient light level from the front of the vehicle, the automatic dimming circuit darkens the interior mirror surface.

Automatic dimming is inhibited when reverse gear is selected to provide the driver with maximum vision. On vehicles with

automatic transmission, the reverse gear signal is provided by the TCM (transmission control module) via the high speed CAN bus to the CJB. The CJB then provides a power feed to the mirror. On vehicles with manual transmission, the reverse gear signal is provided by a transmission switch that is hardwired to the CJB.

Exterior Mirrors

Electrically operated and heated exterior mirrors are installed as standard. Depending on the specification and trim level of the

vehicle, the following options are available:

Power fold (switch pack operated feature) and auto fold (remote handset operated feature)

Memory recall

Reverse gear mirror dip

Mirror heating

Exterior mirror lamps.

The power fold/auto fold feature is available only when power fold mirrors are installed to the vehicle.

The mirrors can be configured to automatically fold when the vehicle is locked and unfold when unlocked. This feature can be

enabled or disabled via the Vehicle settings area of the touch screen:

Select 'Settings' from the touch screen Home menu.

Select ' Security/Vehicle'

Select 'Windows/Mirrors'

Select Power Fold 'On' or 'Off' as appropriate.

The pasenger side mirror can be configured to automatically dip when reverse gear is selected. This feature can be enabled or

disabled via the Vehicle settings area of the touch screen:

Select 'Settings' from the touch screen Home menu.

Select ' Security/Vehicle'

Select 'Windows/Mirrors'

Select Reverse dip 'On' or 'Off' as appropriate.

The LH door mirror incorporates an ambient air temperature sensor that is hardwired to the ECM (engine control module). The ECM is connected to the CJB and other control modules via the high speed CAN bus. The sensor provides information to the ECM that is then transmitted on the medium speed CAN bus for use by other control modules. On vehicles installed with a high-line instrument cluster, the CJB transmits the temperature signal to the instrument cluster that provides a display of the ambient temperature to the driver.

The exterior mirror lamps are controlled by the interior lighting function.

The door mirrors are controlled using a switch pack located on the driver's door. The switch pack contains 2 non-latching mirror

select switches labeled 'L' and 'R' and a 4-way directional joystick. The switch pack is connected to the driver door control

module via the LIN bus. The driver and front passenger door control modules are connected via the medium speed CAN bus. A hardwired connection between each door control module and the corresponding door mirror, provides the supply and ground

paths for the mirror motors.

Each exterior door mirror incorporates 2 motors to control horizontal (left/right) and vertical (up/down) adjustments. www.JagDocs.com

Page 2459 of 3039

Published: 11-May-2011

Instrument Panel and Console - Floor Console Double Cup Holder

Removal and Installation

Removal

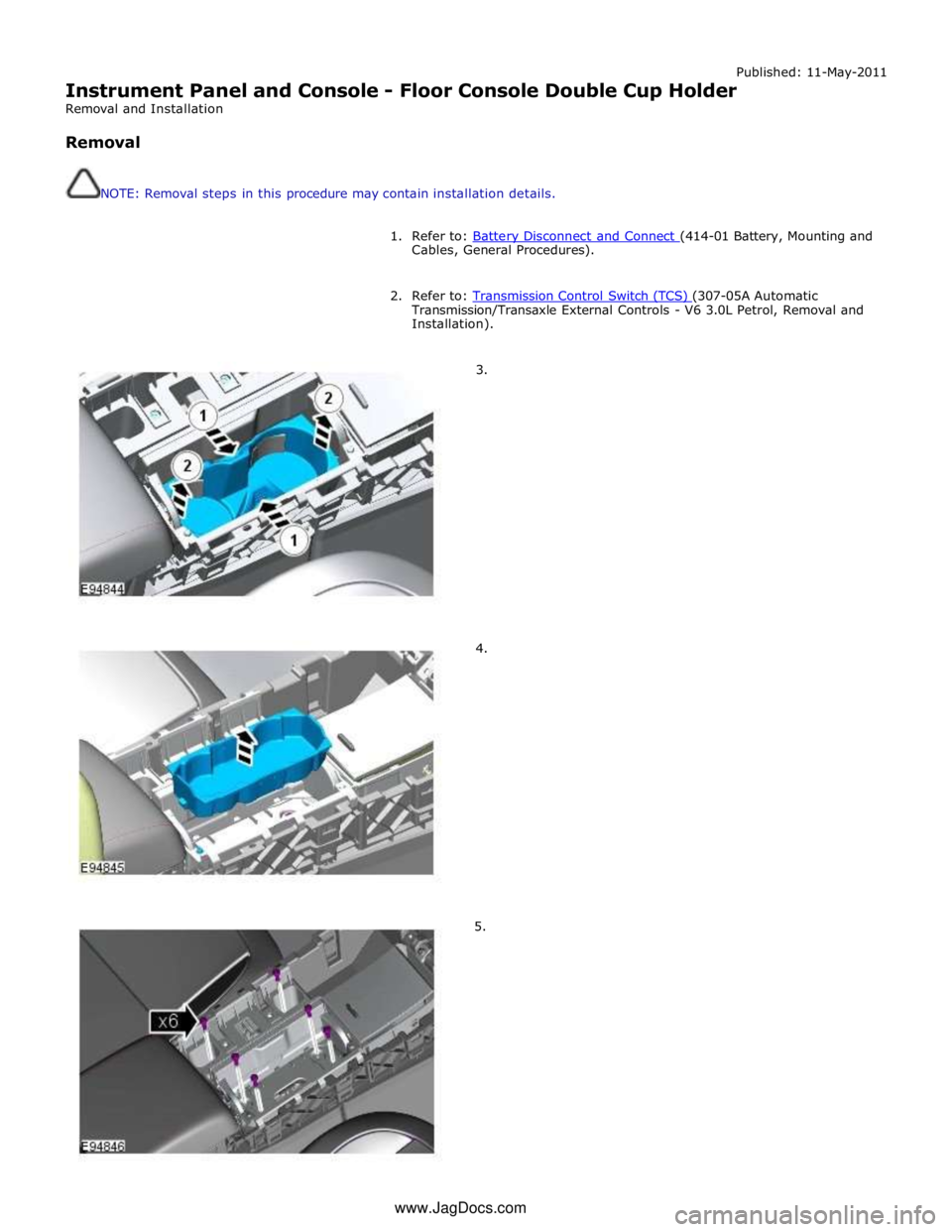

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Transmission Control Switch (TCS) (307-05A Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol, Removal and

Installation).

3.

4.

5. www.JagDocs.com

Page 2707 of 3039

For instance, the crumple zones absorb the bulk of the impact energy. If any unprofessional repair techniques or

methods are used in these areas then this can pose a fundamental threat to vehicle safety.

Hidden damage

As well as looking at external indicators like flaked off paint, it is vital to check for hidden body damage or deformation

that is not visible from the outside. Large attached parts like bumpers and inner fenders often need to be removed to

allow accurate assessment of damage to underlying body parts.

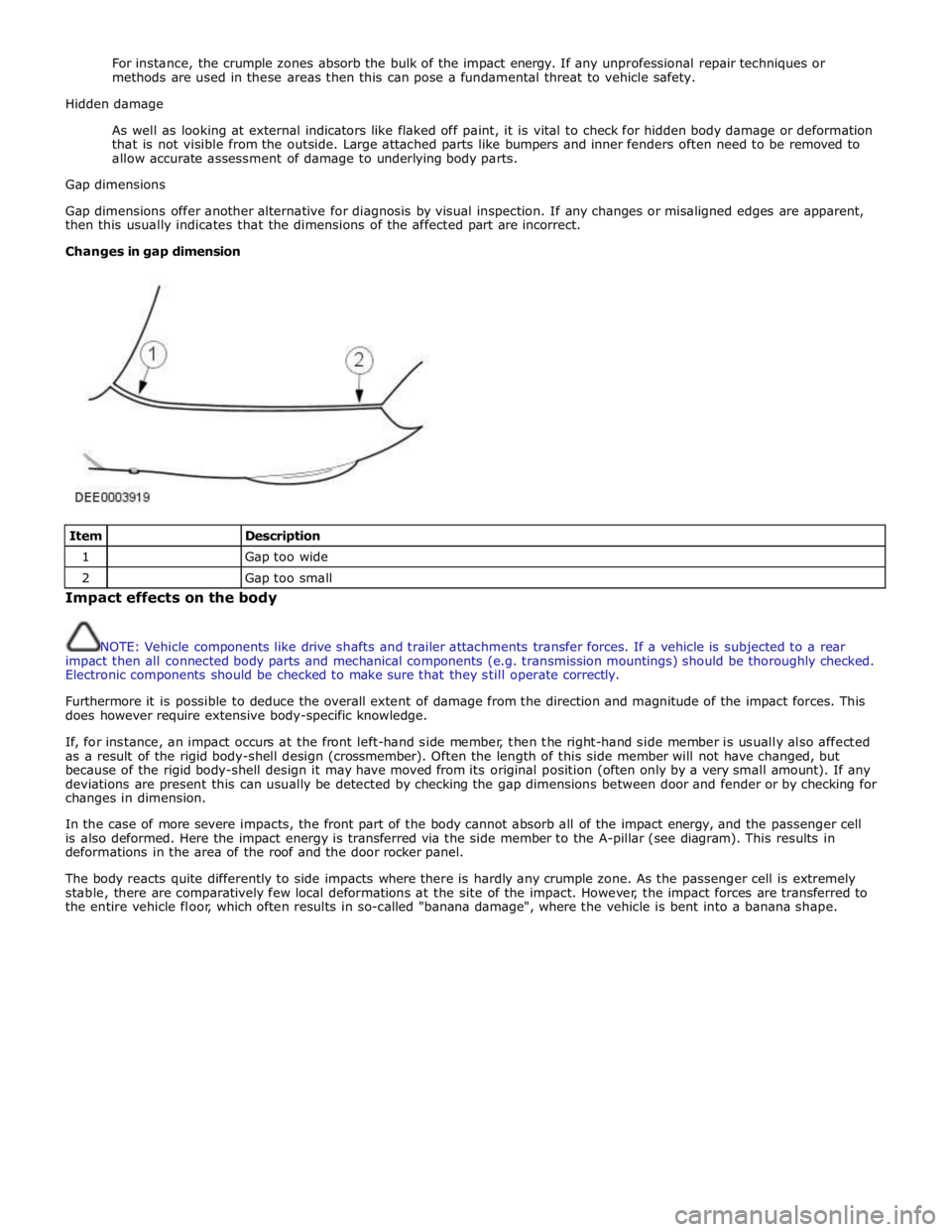

Gap dimensions

Gap dimensions offer another alternative for diagnosis by visual inspection. If any changes or misaligned edges are apparent,

then this usually indicates that the dimensions of the affected part are incorrect.

Changes in gap dimension

Item

Description 1

Gap too wide 2

Gap too small Impact effects on the body

NOTE: Vehicle components like drive shafts and trailer attachments transfer forces. If a vehicle is subjected to a rear

impact then all connected body parts and mechanical components (e.g. transmission mountings) should be thoroughly checked.

Electronic components should be checked to make sure that they still operate correctly.

Furthermore it is possible to deduce the overall extent of damage from the direction and magnitude of the impact forces. This

does however require extensive body-specific knowledge.

If, for instance, an impact occurs at the front left-hand side member, then the right-hand side member is usually also affected

as a result of the rigid body-shell design (crossmember). Often the length of this side member will not have changed, but

because of the rigid body-shell design it may have moved from its original position (often only by a very small amount). If any

deviations are present this can usually be detected by checking the gap dimensions between door and fender or by checking for

changes in dimension.

In the case of more severe impacts, the front part of the body cannot absorb all of the impact energy, and the passenger cell

is also deformed. Here the impact energy is transferred via the side member to the A-pillar (see diagram). This results in

deformations in the area of the roof and the door rocker panel.

The body reacts quite differently to side impacts where there is hardly any crumple zone. As the passenger cell is extremely

stable, there are comparatively few local deformations at the site of the impact. However, the impact forces are transferred to

the entire vehicle floor, which often results in so-called "banana damage", where the vehicle is bent into a banana shape.

Page 2738 of 3039

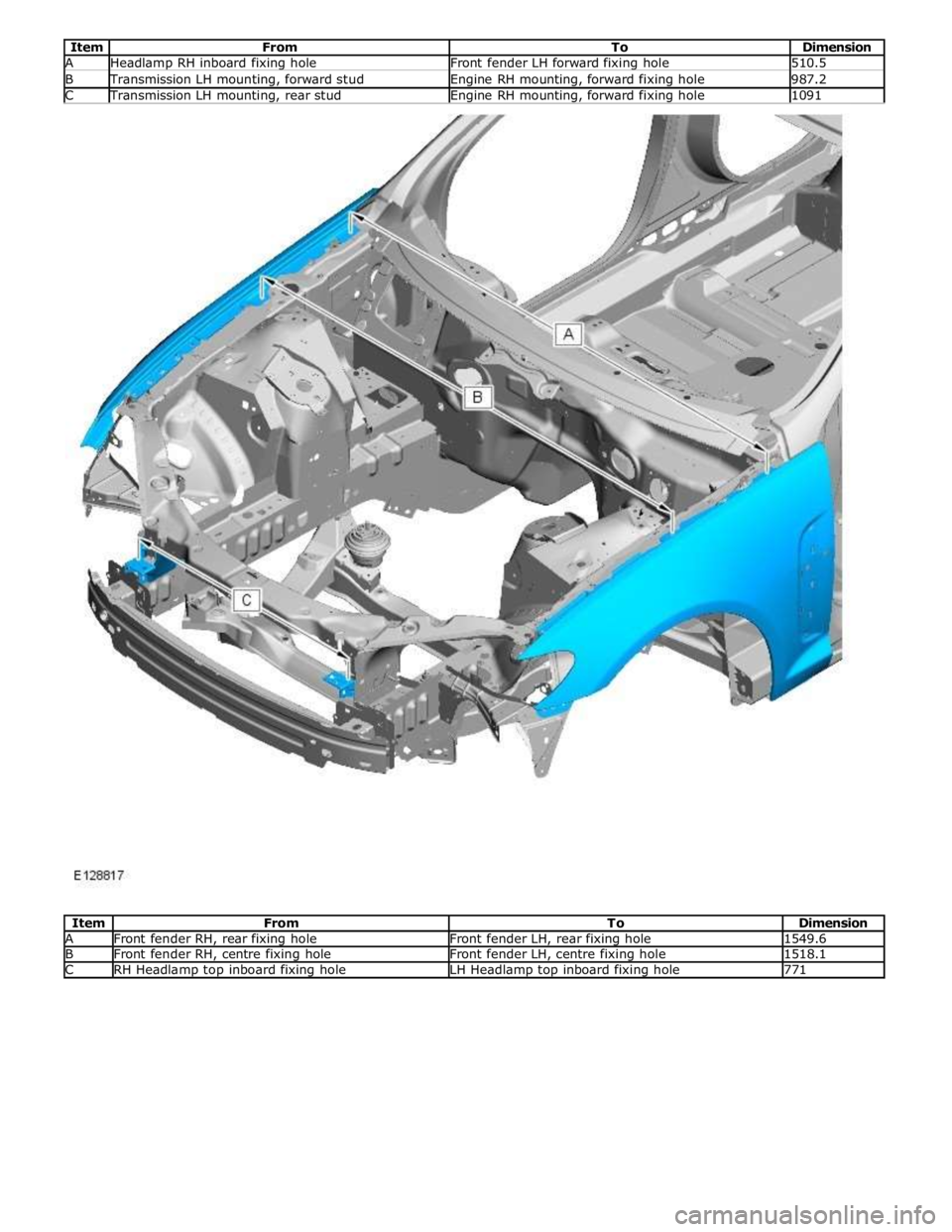

Item From To Dimension A Headlamp RH inboard fixing hole Front fender LH forward fixing hole 510.5 B Transmission LH mounting, forward stud Engine RH mounting, forward fixing hole 987.2 C Transmission LH mounting, rear stud Engine RH mounting, forward fixing hole 1091

Item From To Dimension A Front fender RH, rear fixing hole Front fender LH, rear fixing hole 1549.6 B Front fender RH, centre fixing hole Front fender LH, centre fixing hole 1518.1 C RH Headlamp top inboard fixing hole LH Headlamp top inboard fixing hole 771

Page 2784 of 3039

Front End Sheet Metal Repairs - Front Side Member

Removal and Installation

Removal Published: 11-May-2011

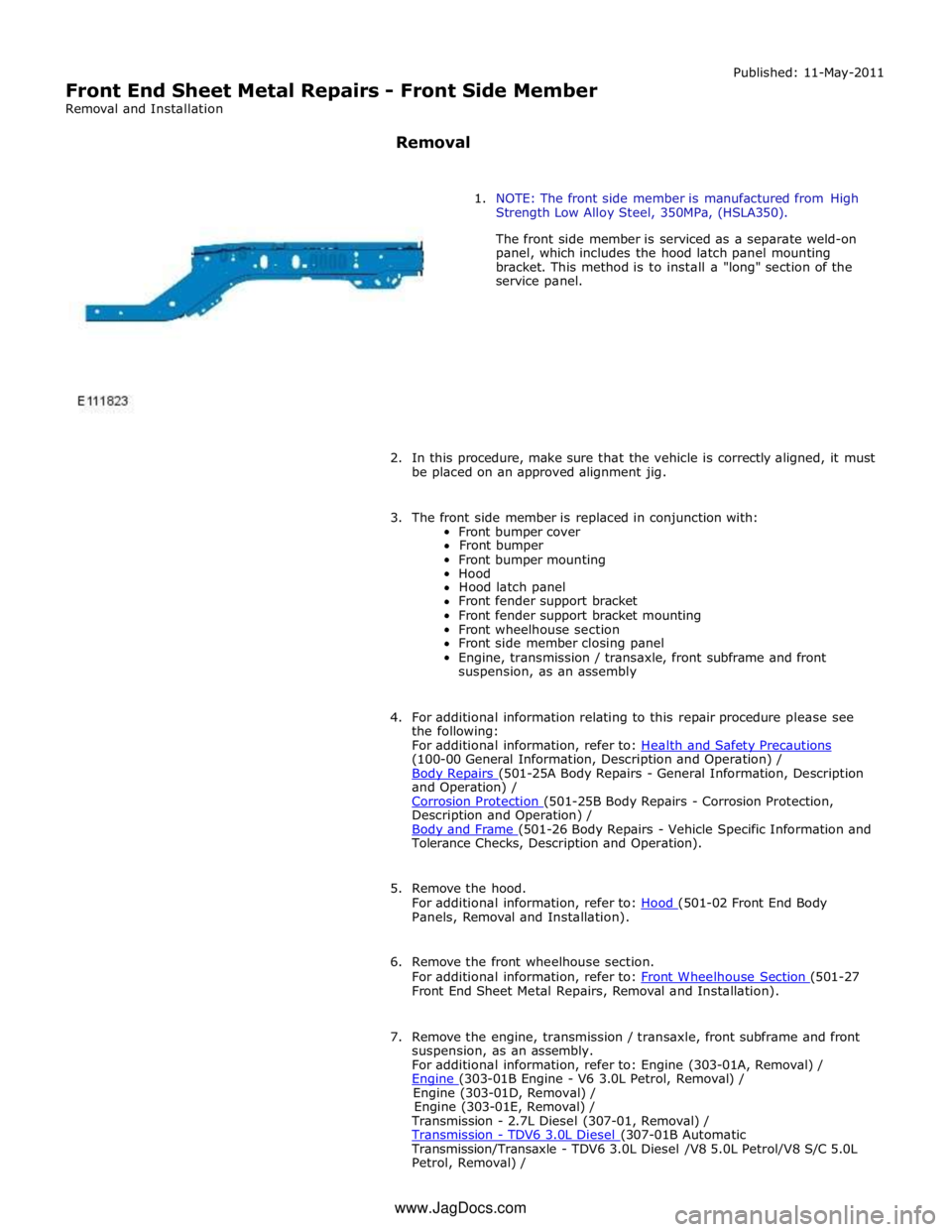

1. NOTE: The front side member is manufactured from High

Strength Low Alloy Steel, 350MPa, (HSLA350).

The front side member is serviced as a separate weld-on

panel, which includes the hood latch panel mounting

bracket. This method is to install a "long" section of the

service panel.

2. In this procedure, make sure that the vehicle is correctly aligned, it must

be placed on an approved alignment jig.

3. The front side member is replaced in conjunction with:

Front bumper cover

Front bumper

Front bumper mounting

Hood

Hood latch panel

Front fender support bracket

Front fender support bracket mounting

Front wheelhouse section

Front side member closing panel

Engine, transmission / transaxle, front subframe and front

suspension, as an assembly

4. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

5. Remove the hood.

For additional information, refer to: Hood (501-02 Front End Body Panels, Removal and Installation).

6. Remove the front wheelhouse section.

For additional information, refer to: Front Wheelhouse Section (501-27 Front End Sheet Metal Repairs, Removal and Installation).

7. Remove the engine, transmission / transaxle, front subframe and front

suspension, as an assembly.

For additional information, refer to: Engine (303-01A, Removal) /

Engine (303-01B Engine - V6 3.0L Petrol, Removal) / Engine (303-01D, Removal) /

Engine (303-01E, Removal) /

Transmission - 2.7L Diesel (307-01, Removal) /

Transmission - TDV6 3.0L Diesel (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, Removal) / www.JagDocs.com

Page 2785 of 3039

Transmission (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol, Removal) /

Transmission - 4.2L (307-01, Removal) /

Transmission - V8 5.0L Petrol/V8 S/C 5.0L Petrol (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, Removal) /

Front Shock Absorber (204-01 Front Suspension, Removal and Installation) /

Front Subframe - 2.7L Diesel (502-00, Removal and Installation) /

Front Subframe - V6 3.0L Petrol (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation) /

Front Subframe - 4.2L, Vehicles Without: Supercharger (502-00, Removal

and Installation) /

Front Subframe - 4.2L, Vehicles With: Supercharger (502-00, Removal

and Installation).

8. Remove the pedestrian protection hood actuator.

For additional information, refer to: Pedestrian Protection Hood Actuator LH (501-20C Pedestrian Protection System, Removal and Installation) / Pedestrian Protection Hood Actuator RH (501-20C Pedestrian Protection System, Removal and Installation).

9. If the drivers side front side member and suspension top mount is to be

repaired, remove the brake master cylinder and reservoir.

For additional information, refer to: Brake Master Cylinder (206-06 Hydraulic Brake Actuation, Removal and Installation) /

Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).

10. If the left-hand front side member and suspension top mount assembly

is to be repaired, remove the fuel supply and return lines.

11. Release and position the front side member wiring harness to one side.

12. Remove any remaining miscellaneous components from the repair area.

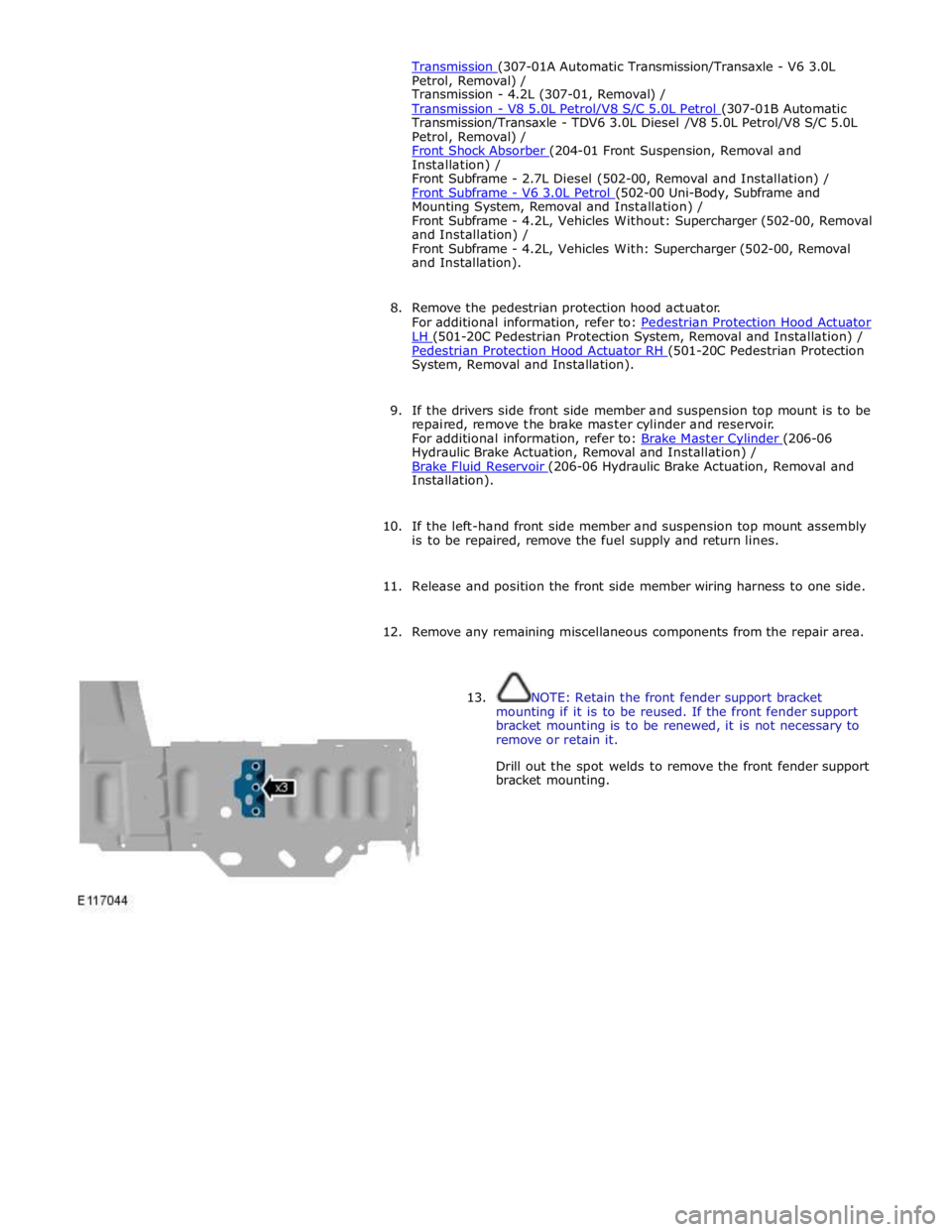

13. NOTE: Retain the front fender support bracket

mounting if it is to be reused. If the front fender support

bracket mounting is to be renewed, it is not necessary to

remove or retain it.

Drill out the spot welds to remove the front fender support

bracket mounting.