Engine JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 811 of 3039

Engine System - General Information - Engine 5.0L

Diagnosis and Testing

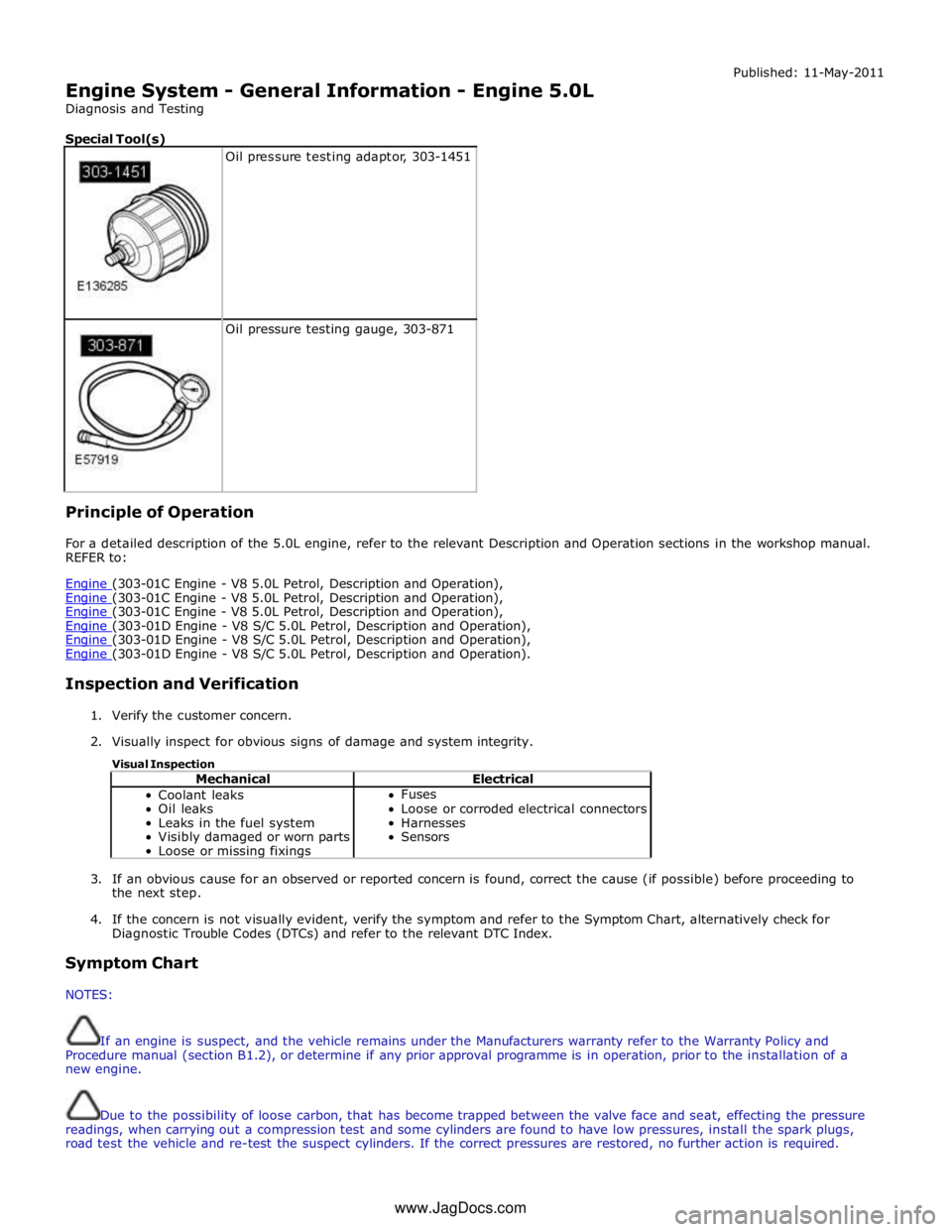

Special Tool(s)

Oil pressure testing adaptor, 303-1451

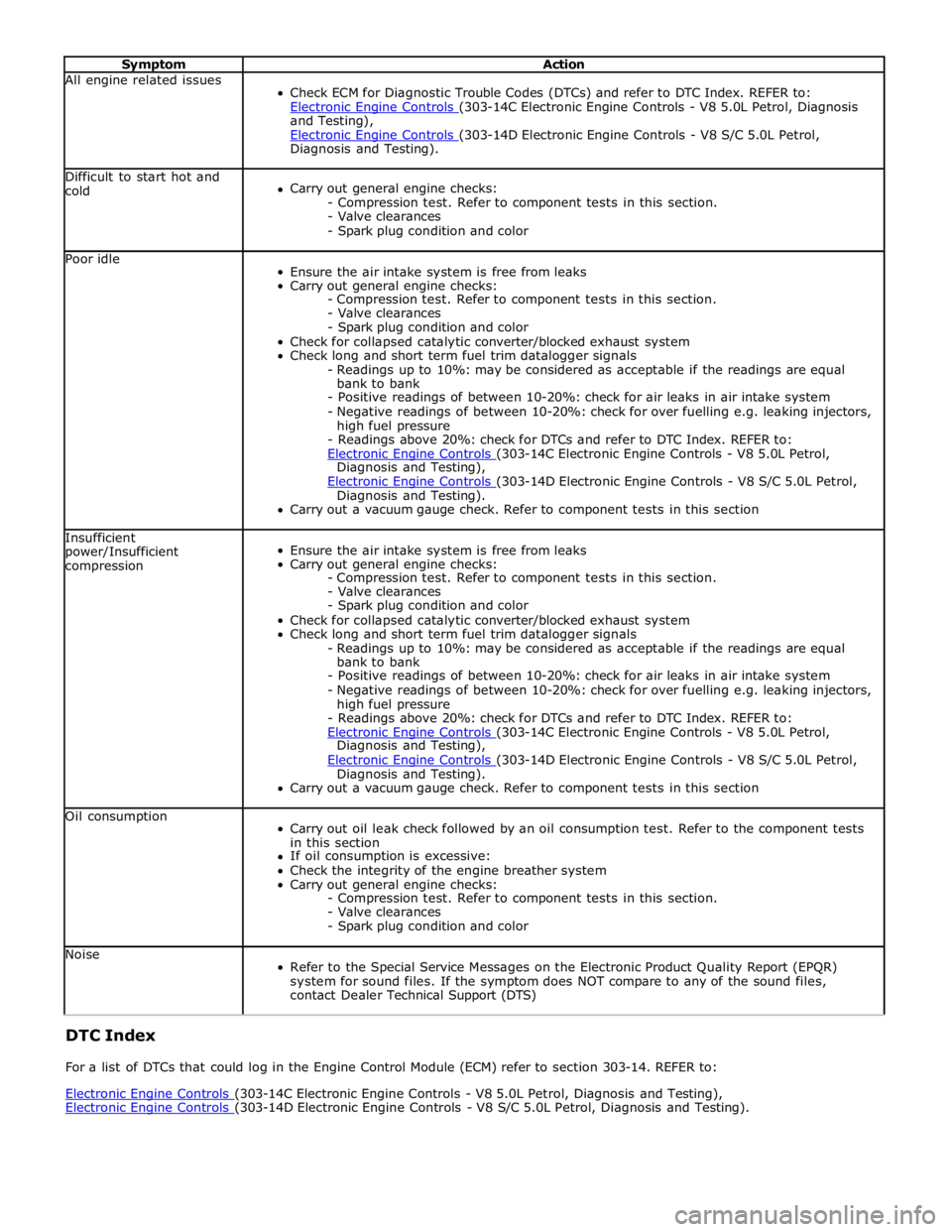

Oil pressure testing gauge, 303-871 Principle of Operation Published: 11-May-2011

For a detailed description of the 5.0L engine, refer to the relevant Description and Operation sections in the workshop manual.

REFER to:

Engine (303-01C Engine - V8 5.0L Petrol, Description and Operation), Engine (303-01C Engine - V8 5.0L Petrol, Description and Operation), Engine (303-01C Engine - V8 5.0L Petrol, Description and Operation), Engine (303-01D Engine - V8 S/C 5.0L Petrol, Description and Operation), Engine (303-01D Engine - V8 S/C 5.0L Petrol, Description and Operation), Engine (303-01D Engine - V8 S/C 5.0L Petrol, Description and Operation).

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical Coolant leaks

Oil leaks

Leaks in the fuel system

Visibly damaged or worn parts

Loose or missing fixings Fuses

Loose or corroded electrical connectors

Harnesses

Sensors

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the concern is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the relevant DTC Index.

Symptom Chart

NOTES:

If an engine is suspect, and the vehicle remains under the Manufacturers warranty refer to the Warranty Policy and

Procedure manual (section B1.2), or determine if any prior approval programme is in operation, prior to the installation of a

new engine.

Due to the possibility of loose carbon, that has become trapped between the valve face and seat, effecting the pressure

readings, when carrying out a compression test and some cylinders are found to have low pressures, install the spark plugs,

road test the vehicle and re-test the suspect cylinders. If the correct pressures are restored, no further action is required. www.JagDocs.com

Page 812 of 3039

Symptom Action All engine related issues

Check ECM for Diagnostic Trouble Codes (DTCs) and refer to DTC Index. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing),

Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing). Difficult to start hot and

cold

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color Poor idle

Ensure the air intake system is free from leaks

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color

Check for collapsed catalytic converter/blocked exhaust system

Check long and short term fuel trim datalogger signals

- Readings up to 10%: may be considered as acceptable if the readings are equal

bank to bank

- Positive readings of between 10-20%: check for air leaks in air intake system

- Negative readings of between 10-20%: check for over fuelling e.g. leaking injectors,

high fuel pressure

- Readings above 20%: check for DTCs and refer to DTC Index. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing),

Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Carry out a vacuum gauge check. Refer to component tests in this section Insufficient

power/Insufficient

compression

Ensure the air intake system is free from leaks

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color

Check for collapsed catalytic converter/blocked exhaust system

Check long and short term fuel trim datalogger signals

- Readings up to 10%: may be considered as acceptable if the readings are equal

bank to bank

- Positive readings of between 10-20%: check for air leaks in air intake system

- Negative readings of between 10-20%: check for over fuelling e.g. leaking injectors,

high fuel pressure

- Readings above 20%: check for DTCs and refer to DTC Index. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing),

Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Carry out a vacuum gauge check. Refer to component tests in this section Oil consumption

Carry out oil leak check followed by an oil consumption test. Refer to the component tests

in this section

If oil consumption is excessive:

Check the integrity of the engine breather system

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color Noise

Refer to the Special Service Messages on the Electronic Product Quality Report (EPQR)

system for sound files. If the symptom does NOT compare to any of the sound files,

contact Dealer Technical Support (DTS) DTC Index

For a list of DTCs that could log in the Engine Control Module (ECM) refer to section 303-14. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing), Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Page 813 of 3039

Component Tests

Engine Oil Leaks

NOTE: Before installing new gaskets or oil seals, make sure that the fault is clearly established.

If the oil leak cannot be identified clearly by a visual inspection, carry out an Ultraviolet test:

Fluorescent Oil Additive Method

1. Clean the engine with a suitable cleaning fluid (brake cleaner).

2. Drain the engine oil and refill with recommended oil, premixed with Diesel Engine Oil Dye or equivalent. Use a minimum

14.8 ml (0.5 ounce) to a maximum 29.6 ml (1 ounce) of fluorescent additive to all engines. If oil is not premixed,

fluorescent additive must first be added to the crankcase.

3. Run engine for 15 minutes. Stop the engine and inspect all seal and gasket areas for leaks using a 12 Volt Master UV

Diagnostic Inspection Kit or equivalent. A clear bright yellow or orange area will identify leak. For extremely small

leaks, several hours may be required for the leak to appear.

4. As necessary, pressurize the main oil gallery system to locate leaks due to incorrectly sealed, loose or cocked plugs. If

the flywheel bolts leak oil, look for sealer on the threads.

5. Repair all leaks as necessary.

Compression Test General Remarks

NOTES:

Removing fuses and disconnecting electrical components may cause the Engine Control Module (ECM) to log Diagnostic

Trouble Codes (DTCs). After the measurements have been carried out, DTCs should be cleared from memory by connecting to

the Manufacturer Approved Diagnostic System.

Only check the compression pressure with the valves set to the prescribed clearance (if this can be adjusted).

The compression pressure should be checked with the engine at normal operating temperature.

Check the Compression Pressure

WARNING: Move gear selector lever to 'P' position. Failure to follow this instruction may result in personal injury.

1. Remove the fuel pump relay.

2. Start the engine - the engine will start, run for a few seconds then stall.

3. Remove the spark plugs.

4. Install the compression tester.

5. Install an auxiliary starter switch in the starting circuit. With the ignition switch OFF, using the auxiliary starter switch,

crank the engine a minimum of five compression strokes and record the highest reading. Note the approximate number

of compression strokes required to obtain the highest reading.

6. Repeat the test on each cylinder, cranking the engine approximately the same number of compression strokes.

7. Install the removed components in reverse order, observing the specified tightening torques.

8. Clear all DTCs from the ECM.

Interpretation of the Results

NOTE: Due to the possibility of loose carbon that has become trapped between the valve face and seat effecting the

pressure readings, when carrying out a compression test and cylinders are found to have low pressures, install the spark plugs,

road test the vehicle and re-test the suspect cylinders. If the correct pressures are restored, no further action is required.

The indicated compression pressures are considered within specification if the lowest reading cylinder is within 75% of the

highest reading.

If the cylinder pressures are found to be low, carry out a leakdown test to determine the location of the fault (if any leakback

can be heard through the engine breather system suspect the piston rings, if any leakback can be heard through the inlet

system suspect the inlet valve or seat, if any leakback can be heard through the exhaust manifold suspect the exhaust valve

or seat. If the measurements for two cylinders next to each other are both too low then it is very likely that the cylinder head

gasket between them is burnt through. This can also be recognized by traces of engine oil in the coolant and/or coolant in the

Page 814 of 3039

engine oil).

Oil Consumption Test

The amount of oil an engine uses will vary with the way the vehicle is driven in addition to normal engine-to-engine variation.

This is especially true during the first 16,100 km (10,000 miles) when a new engine is being broken in or until certain internal

components become conditioned. Vehicles used in heavy-duty operation may use more oil. The following are examples of

heavy-duty operation:

Trailer towing applications

Severe loading applications

Sustained high speed operation

Engines need oil to lubricate the following internal components:

Cylinder block cylinder walls

Pistons and piston rings

Intake and exhaust valve stems

Intake and exhaust valve guides

All internal engine components

When the pistons move downward, a thin film of oil is left on the cylinder walls. As the vehicle is operated, some oil is also

drawn into the combustion chambers past the intake and exhaust valve stem seals and burned.

The following are examples of conditions that can affect oil consumption rates:

Engine size

Operator driving habits

Ambient temperatures

Quality and viscosity of oil

Engine is being run in an overfilled condition (check the oil level at least five minutes after a hot shutdown with the

vehicle parked on a level surface. The oil level should not be above the top of the cross-hatched area and the letter "F"

in FULL).

Operation under varying conditions can frequently be misleading. A vehicle that has been run for several thousand miles on

short trips or in below-freezing ambient temperatures may have consumed a "normal" amount of oil. However, when checking

the engine oil level, it may measure up to the full mark on the oil level indicator due to dilution (condensation and fuel) in the

engine crankcase. The vehicle then might be driven at high speeds on the highway where the condensation and fuel boil off.

The next time the engine oil is checked it may appear that a liter of oil was used in about 160 km (100 miles). Oil

consumption rate is about one liter per 2,400 km (1,500 miles).

Make sure the selected engine oil meets Jaguar specification and the recommended API performance category "SG" and SAE

viscosity grade as shown in the vehicle Owner's Guide. It is also important that the engine oil is changed at the intervals

specified for the typical operating conditions.

The following diagnostic procedure is used to determine the source of excessive oil consumption.

NOTE: Oil use is normally greater during the first 16,100 km (10,000 miles) of service. As mileage increases, oil use

decreases. High speed driving, towing, high ambient temperature and other factors may result in greater oil use.

1. Define excessive consumption, such as the number of miles driven per liter of oil used. Also determine customers

driving habits, such as sustained high speed operation, towing, extended idle and other considerations.

2. Verify that the engine has no external oil leaks as described under Engine Oil Leaks in this section.

3. Carry out an oil consumption test:

Run the engine to normal operating temperature. Switch engine OFF and allow oil to drain back for at least five

minutes .

With vehicle parked on level surface, check the engine oil level.

If required, add engine oil to set level exactly to the FULL mark.

Record the vehicle mileage.

Instruct the customer to return for a level check after driving the vehicle as usual for 1,610 km (1000 miles).

Check the oil level under the same conditions and at the same location as the initial check.

NOTE: If the oil consumption rate is unacceptable go to Step 4.

4. Check the Positive Crankcase Ventilation (PCV) system. Make sure the system is not plugged.

5. Check for plugged oil drain-back holes in the cylinder head and cylinder block.

6. If the condition still exists after carrying out the above tests go to step 9.

7. Carry out a cylinder compression test. Refer to the Compression Test procedure in this section. This can help determine

the source of oil consumption such as valves, piston rings or other areas.

8. Check valve guides for excessive guide clearance. Install new valve stem seals after verifying valve guide clearance.

9. Worn or damaged internal engine components can cause excessive oil consumption. Small deposits of oil on the tips of

the spark plugs can be a clue to internal oil consumption.

Page 816 of 3039

9. WEAK VALVE SPRINGS: When the needle oscillation becomes more violent as engine RPM is increased, weak valve

springs are indicated. The reading at idle could be relatively steady.

10. LATE VALVE TIMING: A steady but low reading could be caused by late valve timing.

11.

IGNITION TIMING RETARDED: Retarded ignition timing will produce a steady but somewhat low reading.

12.

INSUFFICIENT SPARK PLUG GAP: When spark plugs are gapped too close, a regular, small pulsation of the needle can

occur.

13. INTAKE LEAK: A low, steady reading can be caused by an intake manifold or throttle body gasket leak.

14.

BLOWN HEAD GASKET: A regular drop of fair magnitude can be caused by a blown head gasket or warped cylinder head

to cylinder block surface.

15.

RESTRICTED EXHAUST SYSTEM: When the engine is first started and is idled, the reading may be normal, but as the

engine RPM is increased, the back pressure caused by a clogged muffler, kinked tail pipe or other concerns will cause

the needle to slowly drop to 0 kPa (0 in-Hg). The needle then may slowly rise. Excessive exhaust clogging will cause

the needle to drop to a low point even if the engine is only idling.

When vacuum leaks are indicated, search out and correct the cause. Excess air leaking into the system will upset the fuel

mixture and cause concerns such as rough idle, missing on acceleration or burned valves. If the leak exists in an accessory

such as the power brake booster, the unit will not function correctly. Always repair vacuum leaks.

Engine Oil Pressure Check

NOTE: Prior to checking the engine oil pressure, a road test of 6 miles (10 kilometres), must be carried out. Do not

attempt to attain engine normal operating temperature by allowing the engine to idle.

1. Disconnect the battery ground cable. Refer to section 414-00 - Charging System - General Information of the workshop

manual

2. WARNINGS:

The spilling of hot engine oil is unavoidable during this procedure, care must be taken to prevent scalding.

Wear protective gloves.

Remove the engine oil filter element

REFER to: Oil Filter Element (303-01C Engine - V8 5.0L Petrol, Removal and Installation).

NOTE: Ensure the oil filter element is not contaminated during this procedure

3. Install the oil filter element into special tool (Oil filter adapter number 303-1451)

4. Install the special tool (Oil filter adapter number 303-1451) to the engine. Torque: 25 Nm

5. Install the special tool (Oil pressure testing gauge, 303-871) and tighten the union

6. Connect the battery ground cable

7. Refer to owner hand book, check and top-up the engine oil if required

8. Start and run the engine

9. Note the oil pressure readings with the engine running at idle and 3500 RPM

10.

Turn off the engine

11.

Disconnect the battery ground cable

12. Remove the special tools

1. Clean the components

13.

Install the engine oil filter element

REFER to: Oil Filter Element (303-01C Engine - V8 5.0L Petrol, Removal and Installation).

NOTE: Ensure the oil filter element is not contaminated during this procedure

14.

Connect the battery ground cable

15. Refer to owner hand book, check and top-up the engine oil if required

www.JagDocs.com

Page 819 of 3039

Engine System - General Information - Camshaft End Play

General Procedures Published: 11-May-2011

1. NOTE: Make sure that the camshaft is to specification.

Using the special tool, measure the end play.

Slide the camshaft in both directions. Read and note

the maximum and minimum values on the dial indicator

gauge. 1. End play = maximum value minus minimum value.

If the measurement is out of specification, install new

components.

Page 822 of 3039

Published: 11-May-2011

Engine System - General Information - Connecting Rod Cleaning

General Procedures

1. CAUTION: Do not use a caustic cleaning solution or damage to

connecting rods may occur.

Mark and separate the parts and clean with solvent. Clean the oil

passages. www.JagDocs.com

Page 825 of 3039

Published: 11-May-2011

Engine System - General Information - Cylinder Bore Out-of-Round

General Procedures

1. NOTE: The main bearing caps or lower crankcase must be in

place and tightened to the specified torque; however, the bearing

shells should not be installed.

Measure the cylinder bore with an internal micrometer.

Carry out the measurements in different directions and at

different heights to determine if there is any out-of-

roundness or tapering.

If the measurement is out of the specified range, hone out

the cylinder block or install a new block.

Page 826 of 3039

Published: 11-May-2011

Engine System - General Information - Exhaust Manifold Cleaning and

Inspection

General Procedures

1. Inspect the cylinder head joining flanges of the exhaust manifold for

evidence of exhaust gas leaks.

2. Inspect the exhaust manifold for cracks, damaged gasket surfaces, or

other damage that would make it unfit for further use.

Page 827 of 3039

Published: 02-Jun-2011

Engine System - General Information - Leakage Test Using Smoke Test Equipment

General Procedures

CAUTION: The compressed air line supply pressure must be between 3.5 and 12 bar (50 and 175 psi) for the smoke test

equipment to function correctly. Do not exceed this pressure. Failure to follow this instruction may result in damage to the

smoke test equipment.

NOTES:

The vehicle battery must be in good condition and fully charged before carrying out this procedure.

On vehicles with 3.0L TDV6, it will be necessary to insert smoke at both air cleaner outlet pipes independently if the right

hand turbocharger and associated hoses are to be tested.

In some cases it may be necessary to remove undertrays, trim or engine covers to obtain access to all potential leak

locations.

Some variation in the illustrations may occur, but the essential information is always correct.

For further information regarding operation of the test equipment refer to the manufacturers operators manual supplied

with the kit.

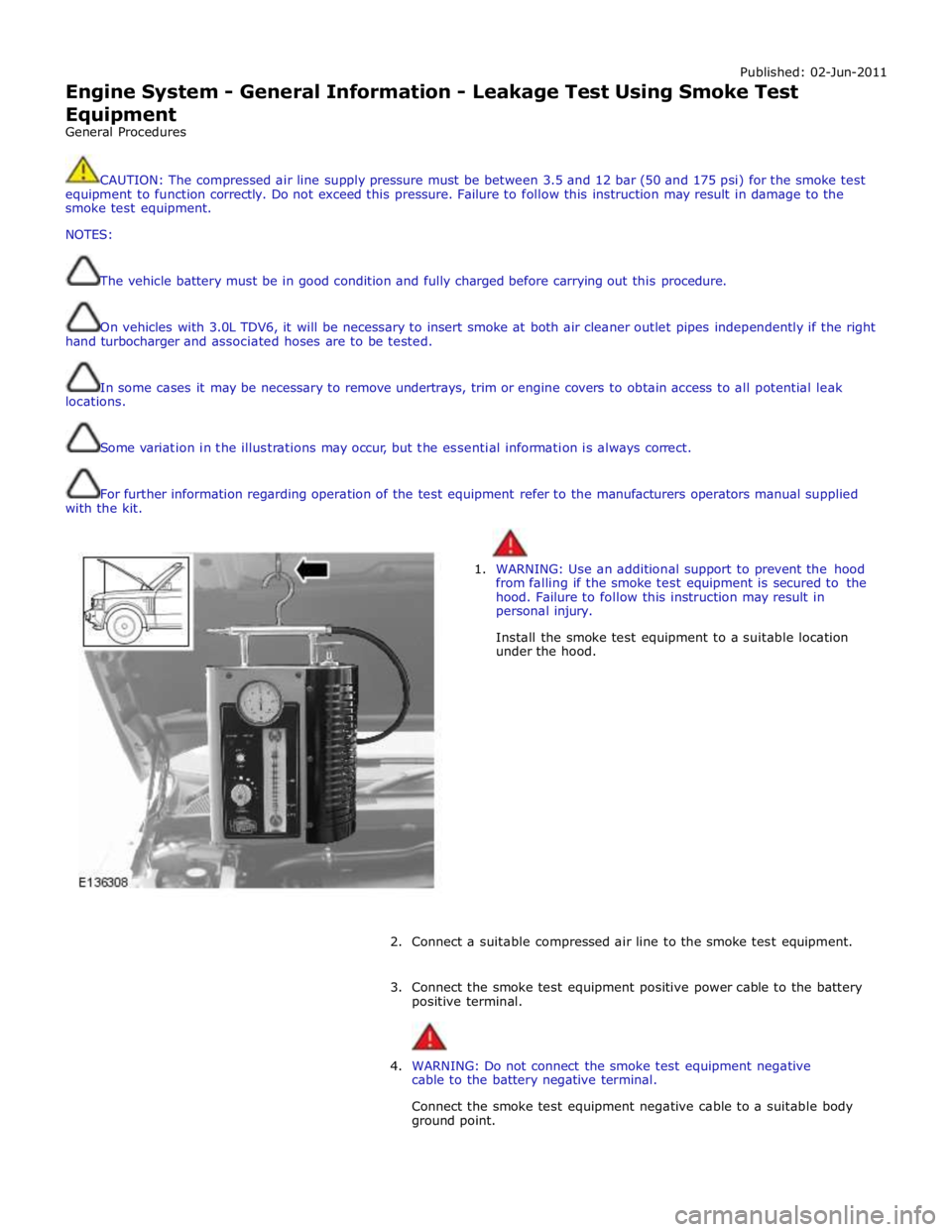

1. WARNING: Use an additional support to prevent the hood

from falling if the smoke test equipment is secured to the

hood. Failure to follow this instruction may result in

personal injury.

Install the smoke test equipment to a suitable location

under the hood.

2. Connect a suitable compressed air line to the smoke test equipment.

3. Connect the smoke test equipment positive power cable to the battery

positive terminal.

4. WARNING: Do not connect the smoke test equipment negative

cable to the battery negative terminal.

Connect the smoke test equipment negative cable to a suitable body

ground point.