sensor JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 703 of 3039

Published: 09-Jul-2014

Anti-Lock Control - Stability Assist - Anti-Lock Control - Stability Assist

Diagnosis and Testing

Principle of Operation

For a detailed description of the Anti-Lock Control - Stability Assist system, refer to the relevant Description and Operation

sections in the workshop manual. REFER to: (206-09 Anti-Lock Control - Stability Assist)

Anti-Lock Control - Stability Assist (Description and Operation), Anti-Lock Control - Stability Assist (Description and Operation), Anti-Lock Control - Stability Assist (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Confirm if the Anti-Lock Brake System (ABS) warning light was illuminated, or still is.

NOTE: An intermittent fault may allow the warning light to go off. This does not necessarily mean the fault is not

present. Some warnings will appear to clear when the ignition is cycled. This is often because the warning has flagged as a

result of one of the vehicle's on-board diagnostic routines having run to detect the fault. If the same routine is not run when

the ignition status is set to ON, the warning will not re-flag until the routine does run.

3. Visually inspect for obvious signs of damage and system integrity.

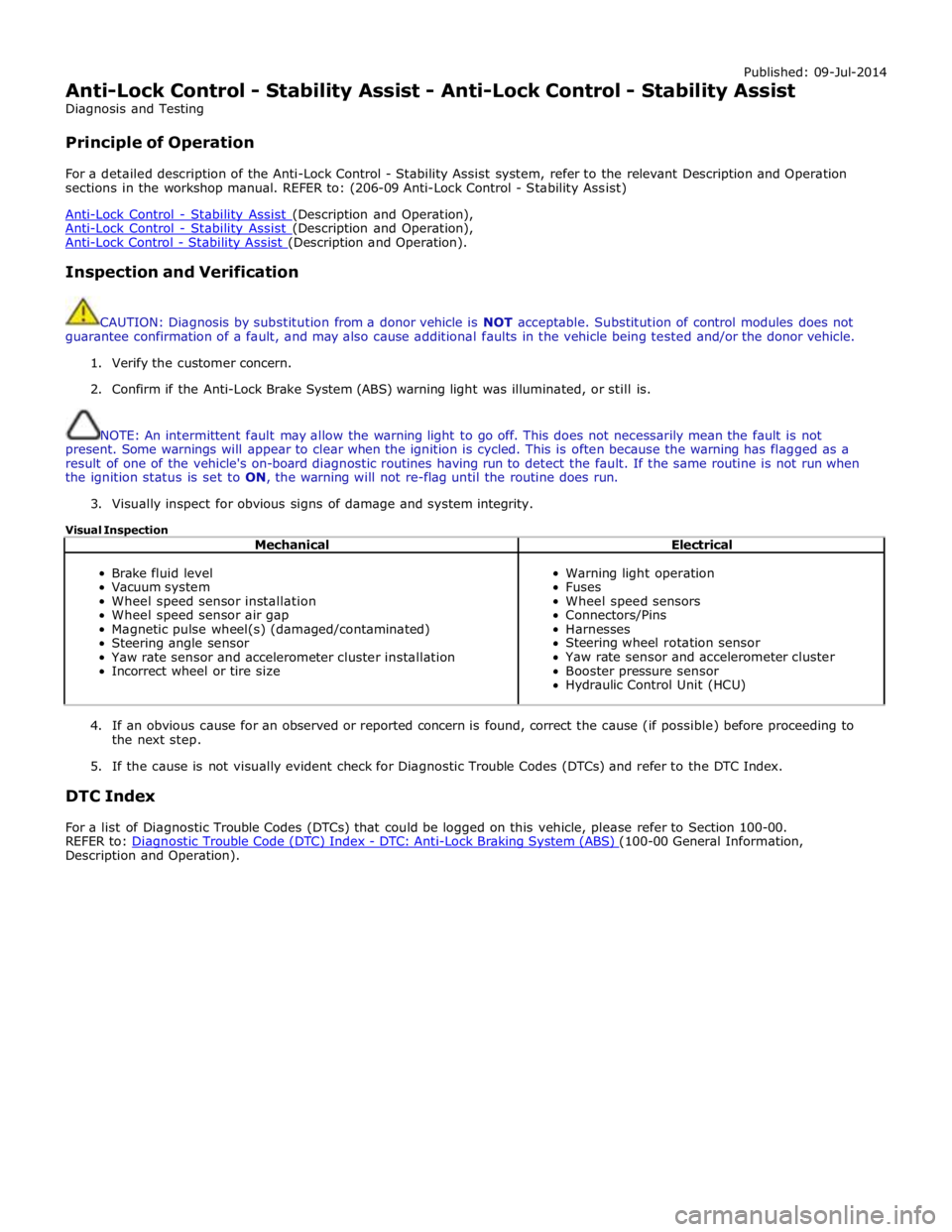

Visual Inspection

Mechanical Electrical

Brake fluid level

Vacuum system

Wheel speed sensor installation

Wheel speed sensor air gap

Magnetic pulse wheel(s) (damaged/contaminated)

Steering angle sensor

Yaw rate sensor and accelerometer cluster installation

Incorrect wheel or tire size

Warning light operation

Fuses

Wheel speed sensors

Connectors/Pins

Harnesses

Steering wheel rotation sensor

Yaw rate sensor and accelerometer cluster

Booster pressure sensor

Hydraulic Control Unit (HCU)

4. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

5. If the cause is not visually evident check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Anti-Lock Braking System (ABS) (100-00 General Information, Description and Operation).

Page 705 of 3039

Anti-Lock Control - Stability Assist - Front Wheel Speed Sensor

Removal and Installation

Removal Published: 11-May-2011

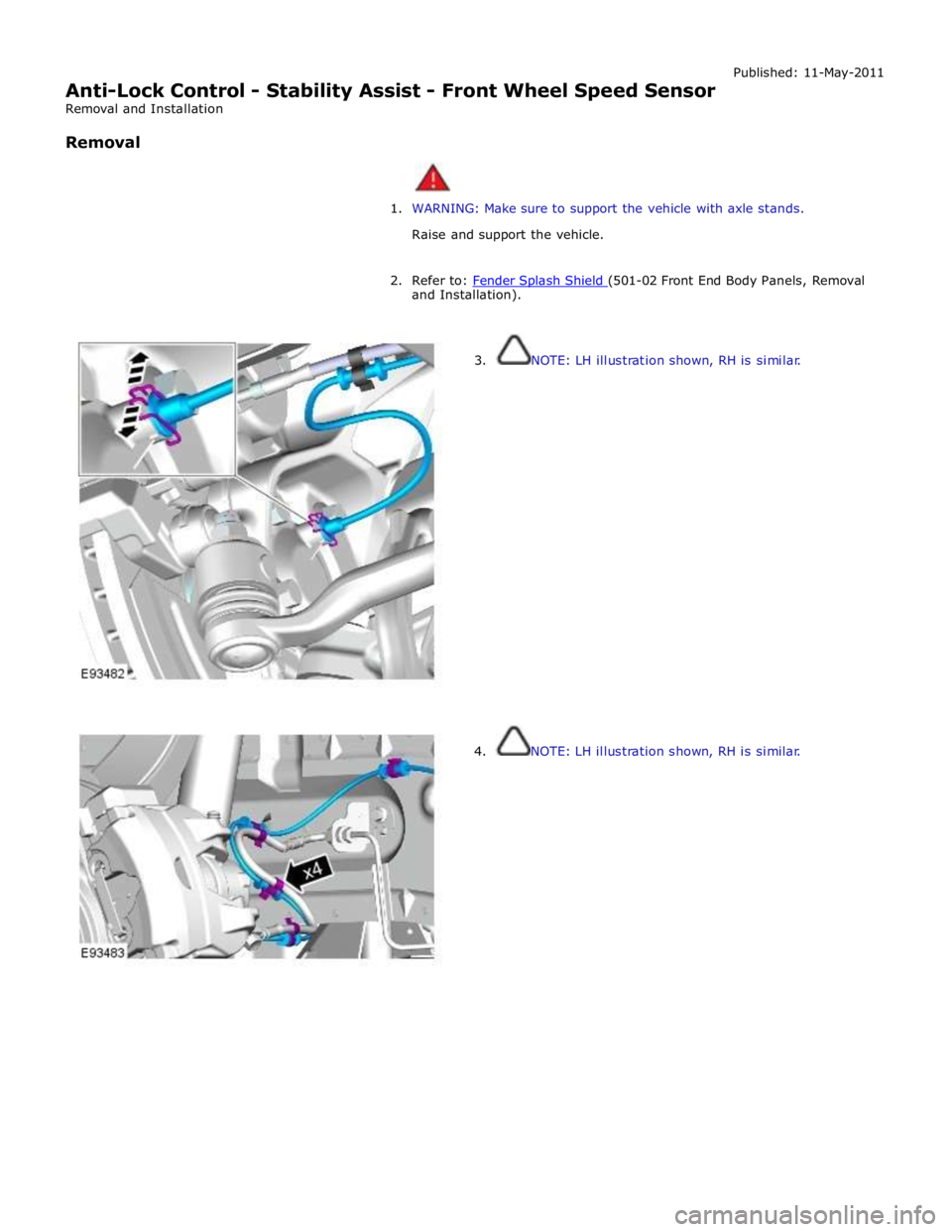

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

3. NOTE: LH illustration shown, RH is similar.

4. NOTE: LH illustration shown, RH is similar.

Page 712 of 3039

Anti-Lock Control - Stability Assist - Rear Wheel Speed Sensor

Removal and Installation Published: 11-May-2011

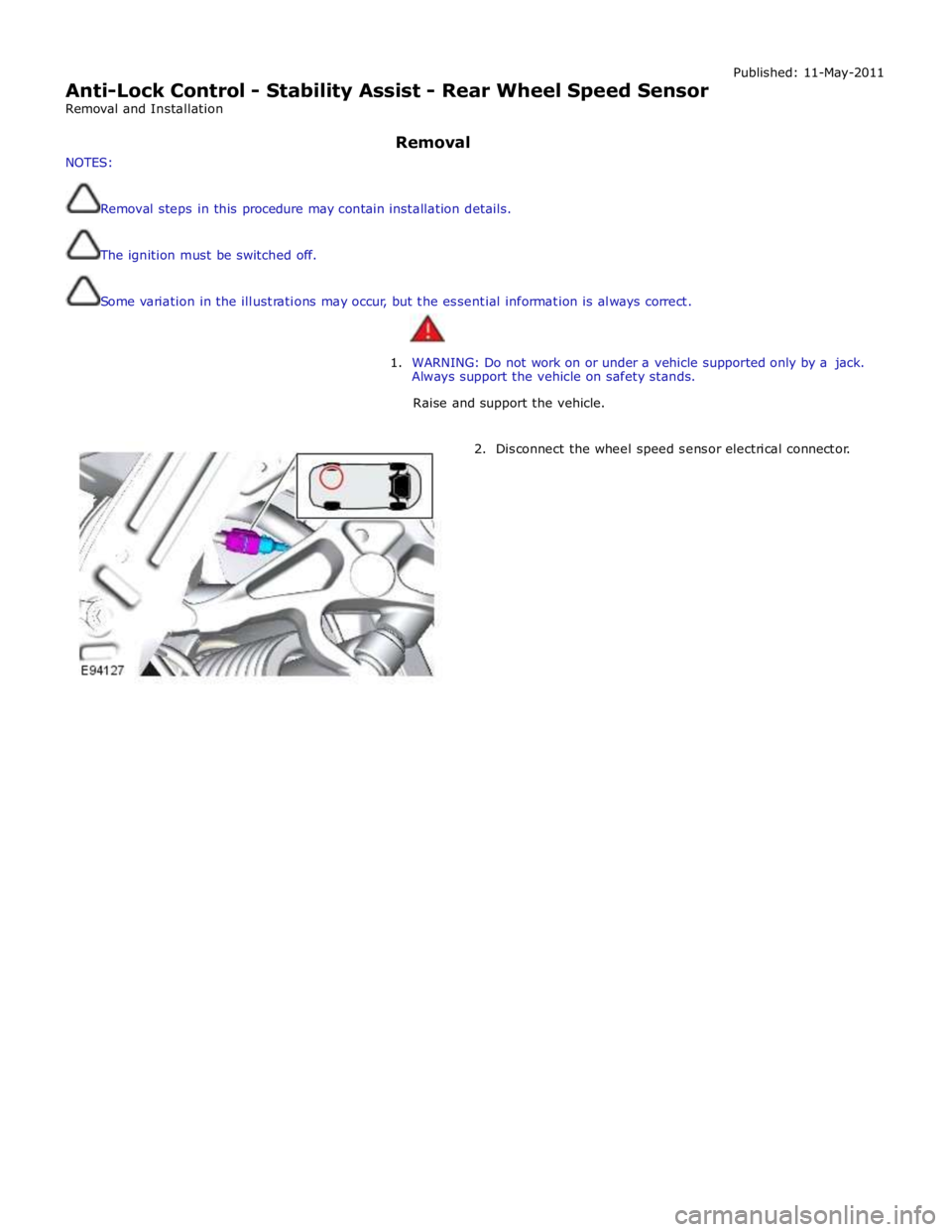

NOTES: Removal

Removal steps in this procedure may contain installation details.

The ignition must be switched off.

Some variation in the illustrations may occur, but the essential information is always correct.

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Disconnect the wheel speed sensor electrical connector.

Page 713 of 3039

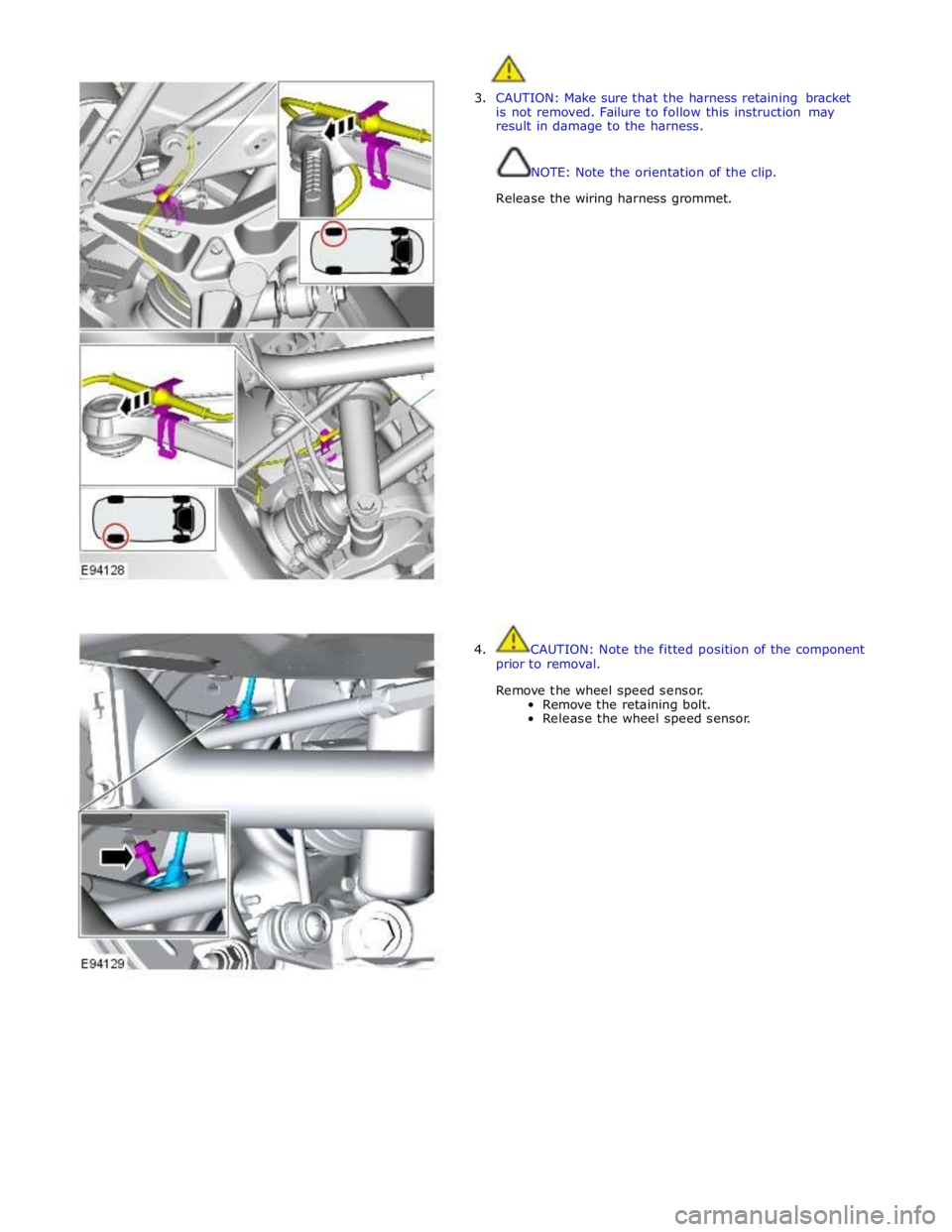

3. CAUTION: Make sure that the harness retaining bracket

is not removed. Failure to follow this instruction may

result in damage to the harness.

NOTE: Note the orientation of the clip.

Release the wiring harness grommet.

4. CAUTION: Note the fitted position of the component

prior to removal.

Remove the wheel speed sensor.

Remove the retaining bolt.

Release the wheel speed sensor.

Page 715 of 3039

Published: 11-May-2011

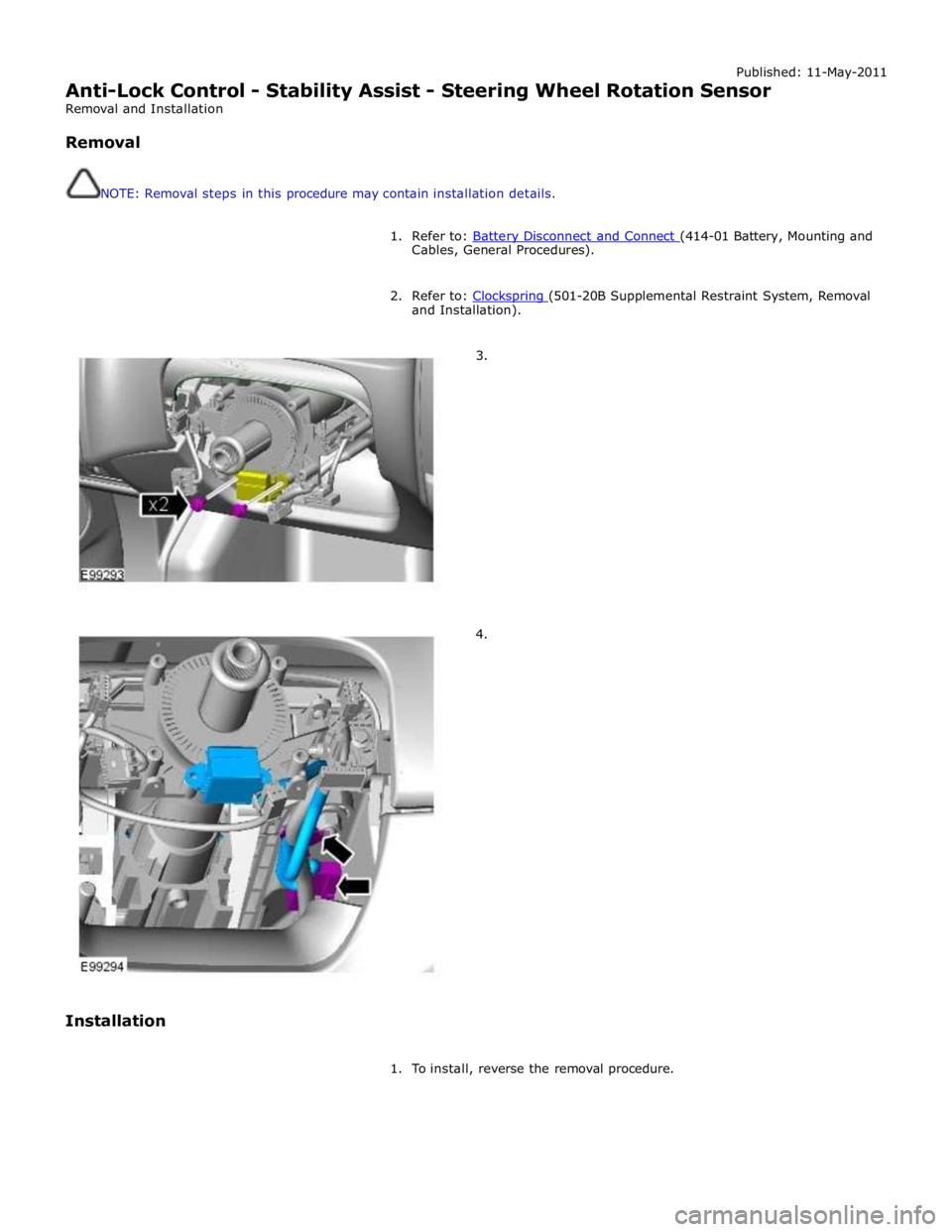

Anti-Lock Control - Stability Assist - Steering Wheel Rotation Sensor

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Clockspring (501-20B Supplemental Restraint System, Removal and Installation).

3.

4.

Installation

1. To install, reverse the removal procedure.

Page 716 of 3039

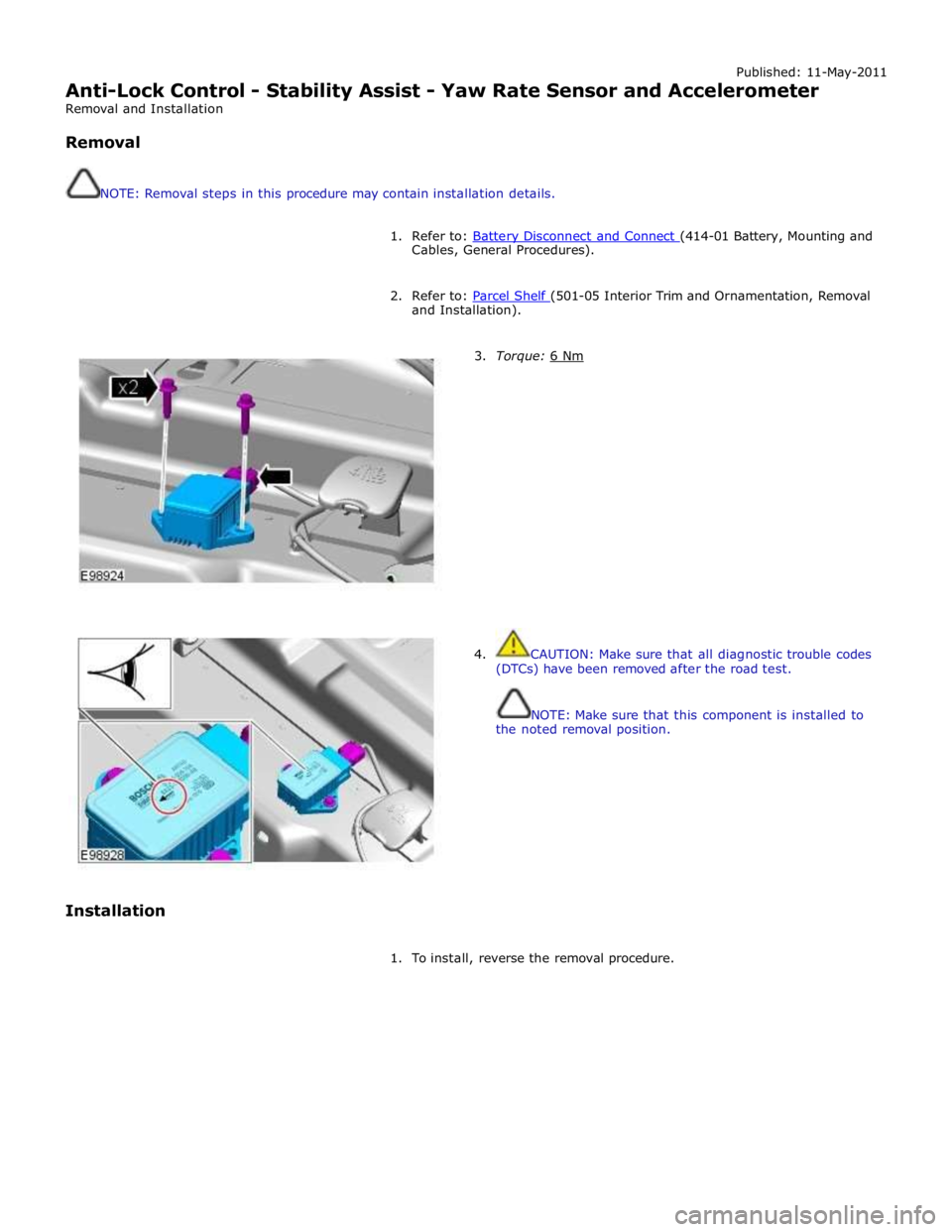

Published: 11-May-2011

Anti-Lock Control - Stability Assist - Yaw Rate Sensor and Accelerometer

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Parcel Shelf (501-05 Interior Trim and Ornamentation, Removal and Installation).

Installation

3. Torque: 6 Nm

4. CAUTION: Make sure that all diagnostic trouble codes

(DTCs) have been removed after the road test.

NOTE: Make sure that this component is installed to

the noted removal position.

1. To install, reverse the removal procedure.

Page 777 of 3039

Steering Column - Steering Column - Overview

Description and Operation

OVERVIEW Published: 11-May-2011

The steering column comprises the upper column assembly, the lower column assembly and the steering wheel. The 3

components are positively connected together to pass driver rotary input from the steering wheel to a linear output of the

steering rack.

The upper column assembly contains electrical adjustment for steering wheel reach and rake, the electric steering lock

mechanism and the steering angle sensor. Steering adjustment memory positions are stored in the driver's seat module.

The electric steering column is a standard fitment on all models. The upper column assembly contains electrical adjustment for

steering wheel reach and rake, the electric column lock mechanism and the steering angle sensor. Steering adjustment memory

positions are stored in the driver's seat module. The column also features a 'tilt away' function which moves the steering

column away from the driver allowing easier exit and entry to the vehicle.

Column adjustment is provided by a single motor for both reach and rake adjustment. Operation of the column adjustment is

controlled by a four way joystick type switch located in the column lower shroud. Column adjustment is an integral part of the

driver position memory system.

www.JagDocs.com

Page 780 of 3039

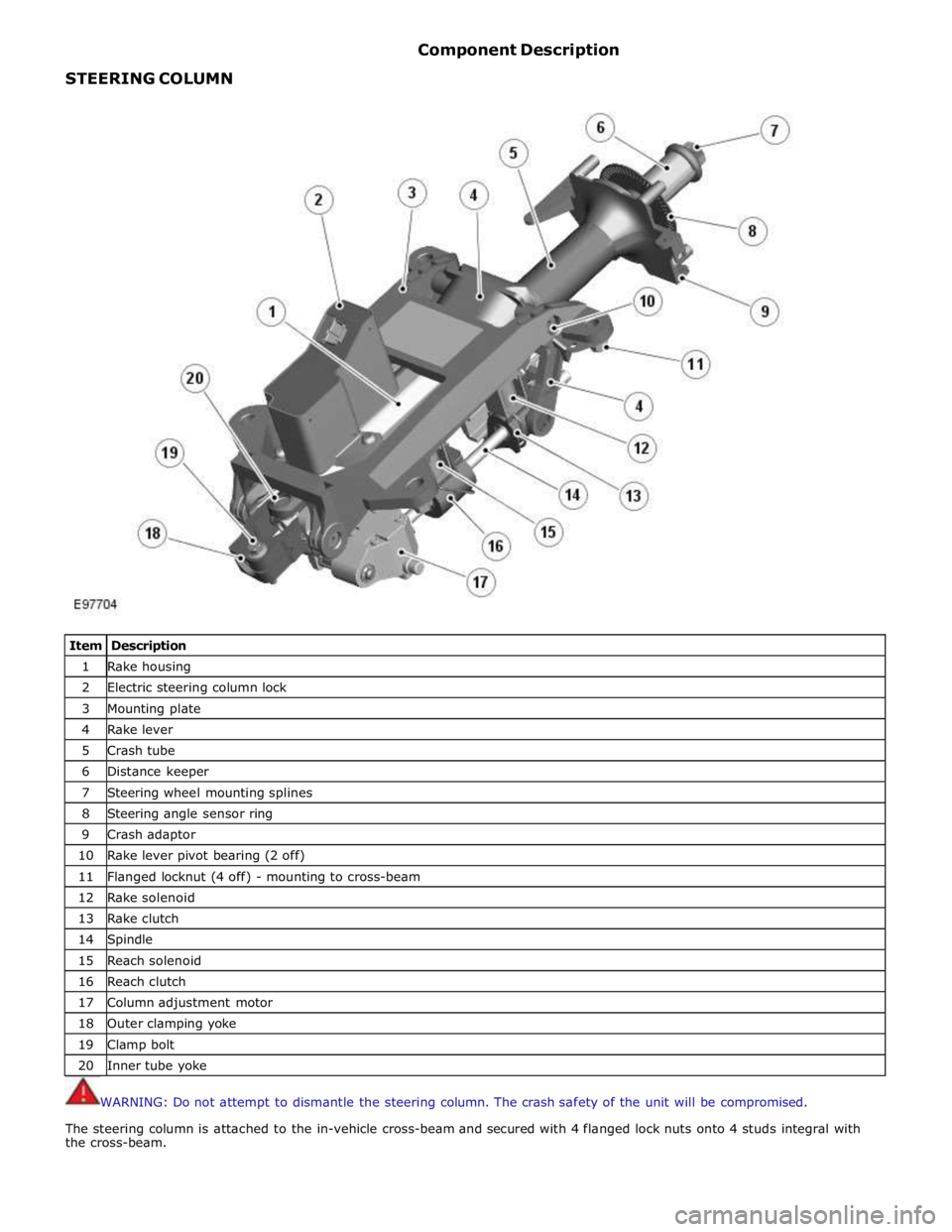

STEERING COLUMN Component Description

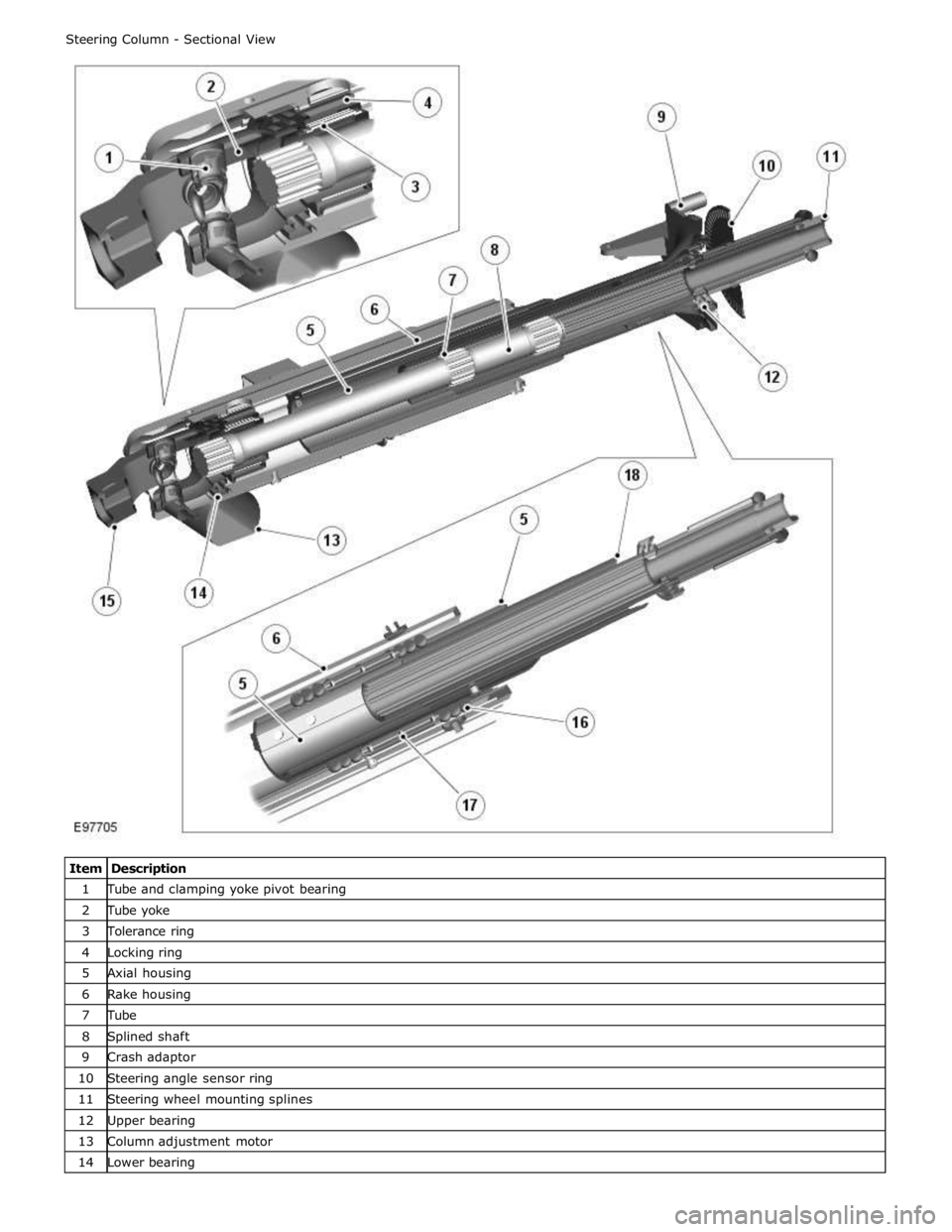

Item Description 1 Rake housing 2 Electric steering column lock 3 Mounting plate 4 Rake lever 5 Crash tube 6 Distance keeper 7 Steering wheel mounting splines 8 Steering angle sensor ring 9 Crash adaptor 10 Rake lever pivot bearing (2 off) 11 Flanged locknut (4 off) - mounting to cross-beam 12 Rake solenoid 13 Rake clutch 14 Spindle 15 Reach solenoid 16 Reach clutch 17 Column adjustment motor 18 Outer clamping yoke 19 Clamp bolt 20 Inner tube yoke

WARNING: Do not attempt to dismantle the steering column. The crash safety of the unit will be compromised.

The steering column is attached to the in-vehicle cross-beam and secured with 4 flanged lock nuts onto 4 studs integral with

the cross-beam.

Page 781 of 3039

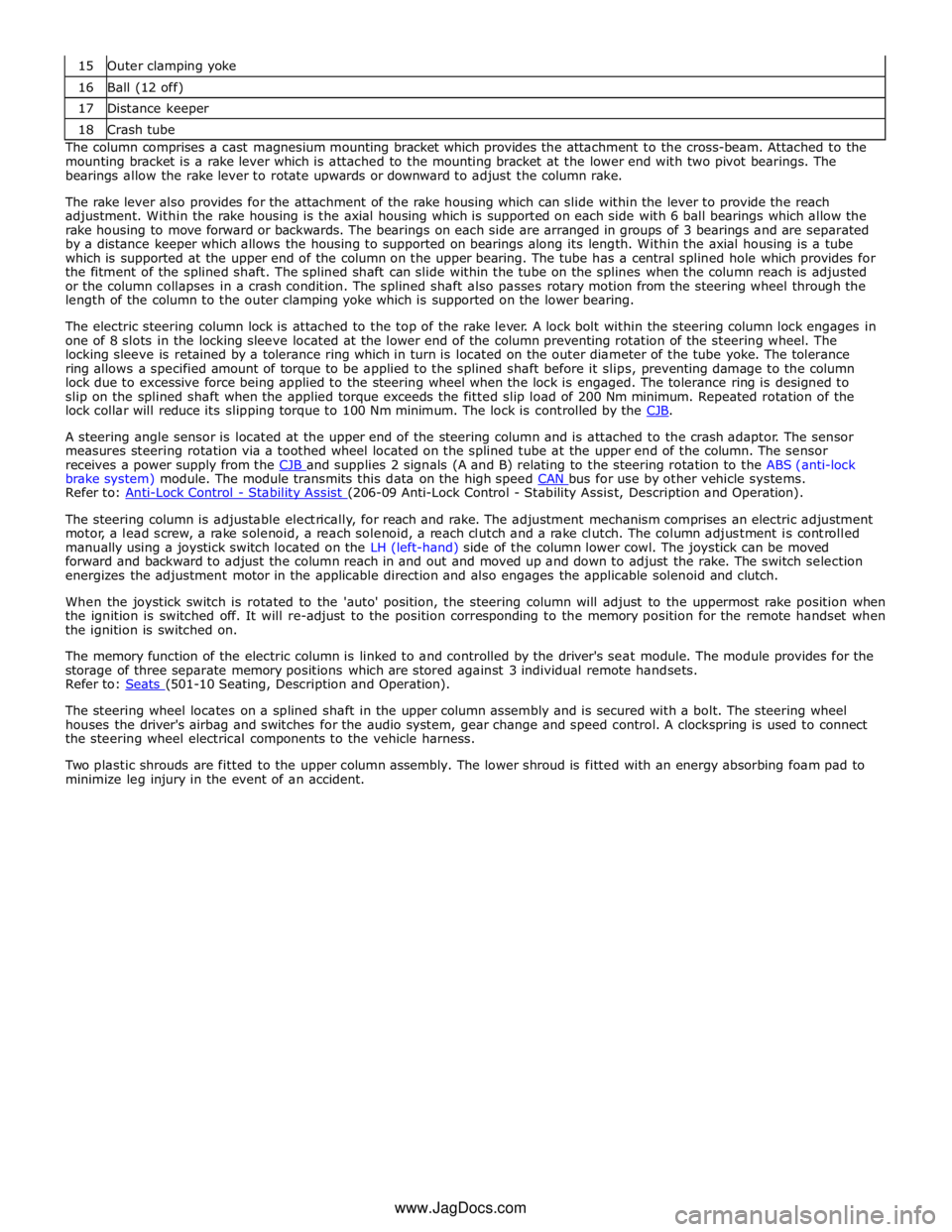

1 Tube and clamping yoke pivot bearing 2 Tube yoke 3 Tolerance ring 4 Locking ring 5 Axial housing 6 Rake housing 7 Tube 8 Splined shaft 9 Crash adaptor 10 Steering angle sensor ring 11 Steering wheel mounting splines 12 Upper bearing 13 Column adjustment motor 14 Lower bearing

Page 782 of 3039

16 Ball (12 off) 17 Distance keeper 18 Crash tube The column comprises a cast magnesium mounting bracket which provides the attachment to the cross-beam. Attached to the

mounting bracket is a rake lever which is attached to the mounting bracket at the lower end with two pivot bearings. The

bearings allow the rake lever to rotate upwards or downward to adjust the column rake.

The rake lever also provides for the attachment of the rake housing which can slide within the lever to provide the reach

adjustment. Within the rake housing is the axial housing which is supported on each side with 6 ball bearings which allow the

rake housing to move forward or backwards. The bearings on each side are arranged in groups of 3 bearings and are separated

by a distance keeper which allows the housing to supported on bearings along its length. Within the axial housing is a tube

which is supported at the upper end of the column on the upper bearing. The tube has a central splined hole which provides for

the fitment of the splined shaft. The splined shaft can slide within the tube on the splines when the column reach is adjusted

or the column collapses in a crash condition. The splined shaft also passes rotary motion from the steering wheel through the

length of the column to the outer clamping yoke which is supported on the lower bearing.

The electric steering column lock is attached to the top of the rake lever. A lock bolt within the steering column lock engages in

one of 8 slots in the locking sleeve located at the lower end of the column preventing rotation of the steering wheel. The

locking sleeve is retained by a tolerance ring which in turn is located on the outer diameter of the tube yoke. The tolerance

ring allows a specified amount of torque to be applied to the splined shaft before it slips, preventing damage to the column

lock due to excessive force being applied to the steering wheel when the lock is engaged. The tolerance ring is designed to

slip on the splined shaft when the applied torque exceeds the fitted slip load of 200 Nm minimum. Repeated rotation of the

lock collar will reduce its slipping torque to 100 Nm minimum. The lock is controlled by the CJB.

A steering angle sensor is located at the upper end of the steering column and is attached to the crash adaptor. The sensor

measures steering rotation via a toothed wheel located on the splined tube at the upper end of the column. The sensor

receives a power supply from the CJB and supplies 2 signals (A and B) relating to the steering rotation to the ABS (anti-lock brake system) module. The module transmits this data on the high speed CAN bus for use by other vehicle systems. Refer to: Anti-Lock Control - Stability Assist (206-09 Anti-Lock Control - Stability Assist, Description and Operation).

The steering column is adjustable electrically, for reach and rake. The adjustment mechanism comprises an electric adjustment

motor, a lead screw, a rake solenoid, a reach solenoid, a reach clutch and a rake clutch. The column adjustment is controlled

manually using a joystick switch located on the LH (left-hand) side of the column lower cowl. The joystick can be moved

forward and backward to adjust the column reach in and out and moved up and down to adjust the rake. The switch selection

energizes the adjustment motor in the applicable direction and also engages the applicable solenoid and clutch.

When the joystick switch is rotated to the 'auto' position, the steering column will adjust to the uppermost rake position when

the ignition is switched off. It will re-adjust to the position corresponding to the memory position for the remote handset when

the ignition is switched on.

The memory function of the electric column is linked to and controlled by the driver's seat module. The module provides for the

storage of three separate memory positions which are stored against 3 individual remote handsets.

Refer to: Seats (501-10 Seating, Description and Operation).

The steering wheel locates on a splined shaft in the upper column assembly and is secured with a bolt. The steering wheel

houses the driver's airbag and switches for the audio system, gear change and speed control. A clockspring is used to connect

the steering wheel electrical components to the vehicle harness.

Two plastic shrouds are fitted to the upper column assembly. The lower shroud is fitted with an energy absorbing foam pad to

minimize leg injury in the event of an accident.

www.JagDocs.com