battery JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 654 of 3039

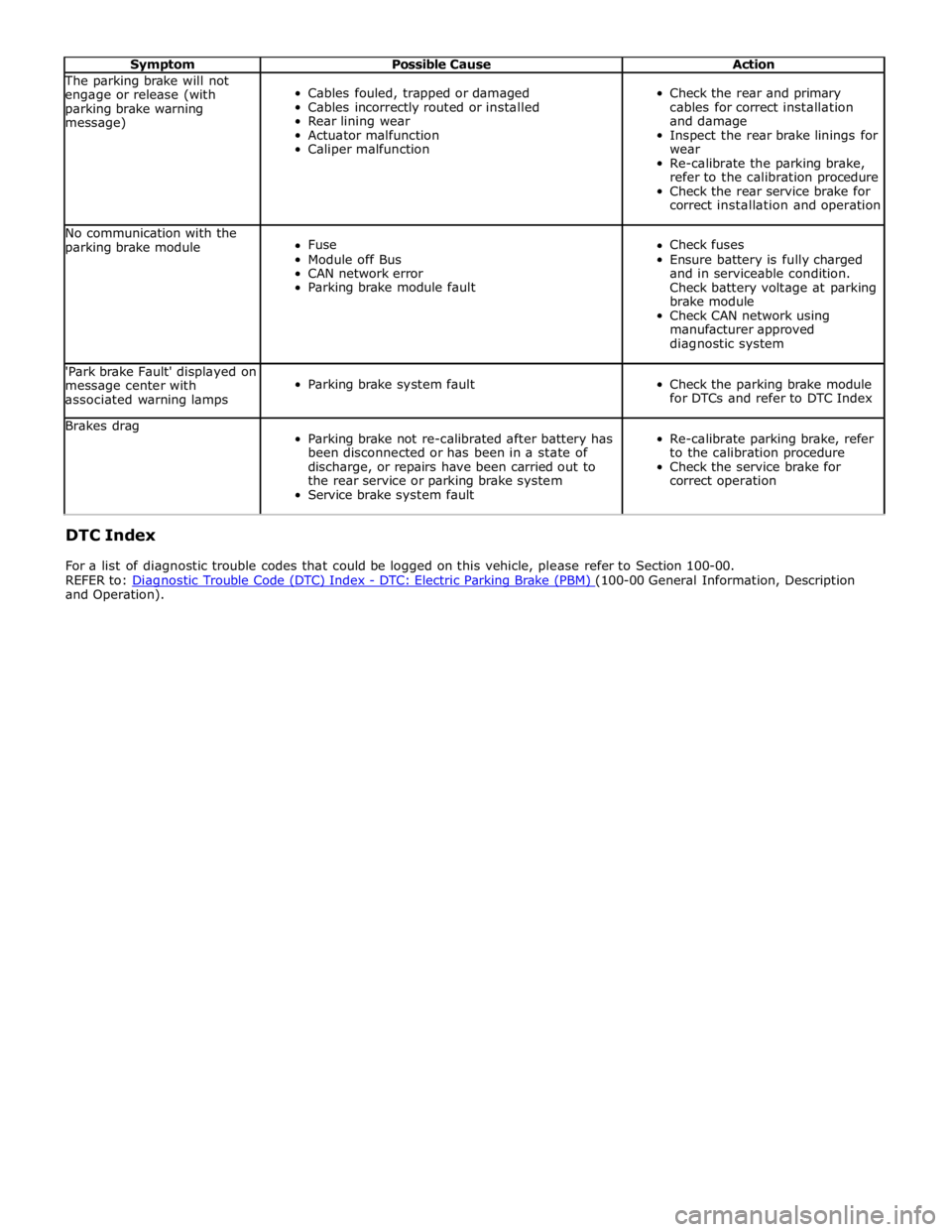

Symptom Possible Cause Action The parking brake will not

engage or release (with

parking brake warning

message)

Cables fouled, trapped or damaged

Cables incorrectly routed or installed

Rear lining wear

Actuator malfunction

Caliper malfunction

Check the rear and primary

cables for correct installation

and damage

Inspect the rear brake linings for

wear

Re-calibrate the parking brake,

refer to the calibration procedure

Check the rear service brake for

correct installation and operation No communication with the

parking brake module

Fuse

Module off Bus

CAN network error

Parking brake module fault

Check fuses

Ensure battery is fully charged

and in serviceable condition.

Check battery voltage at parking

brake module

Check CAN network using

manufacturer approved

diagnostic system 'Park brake Fault' displayed on

message center with

associated warning lamps

Parking brake system fault

Check the parking brake module

for DTCs and refer to DTC Index Brakes drag

Parking brake not re-calibrated after battery has

been disconnected or has been in a state of

discharge, or repairs have been carried out to

the rear service or parking brake system

Service brake system fault

Re-calibrate parking brake, refer

to the calibration procedure

Check the service brake for

correct operation DTC Index

For a list of diagnostic trouble codes that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Electric Parking Brake (PBM) (100-00 General Information, Description and Operation).

Page 657 of 3039

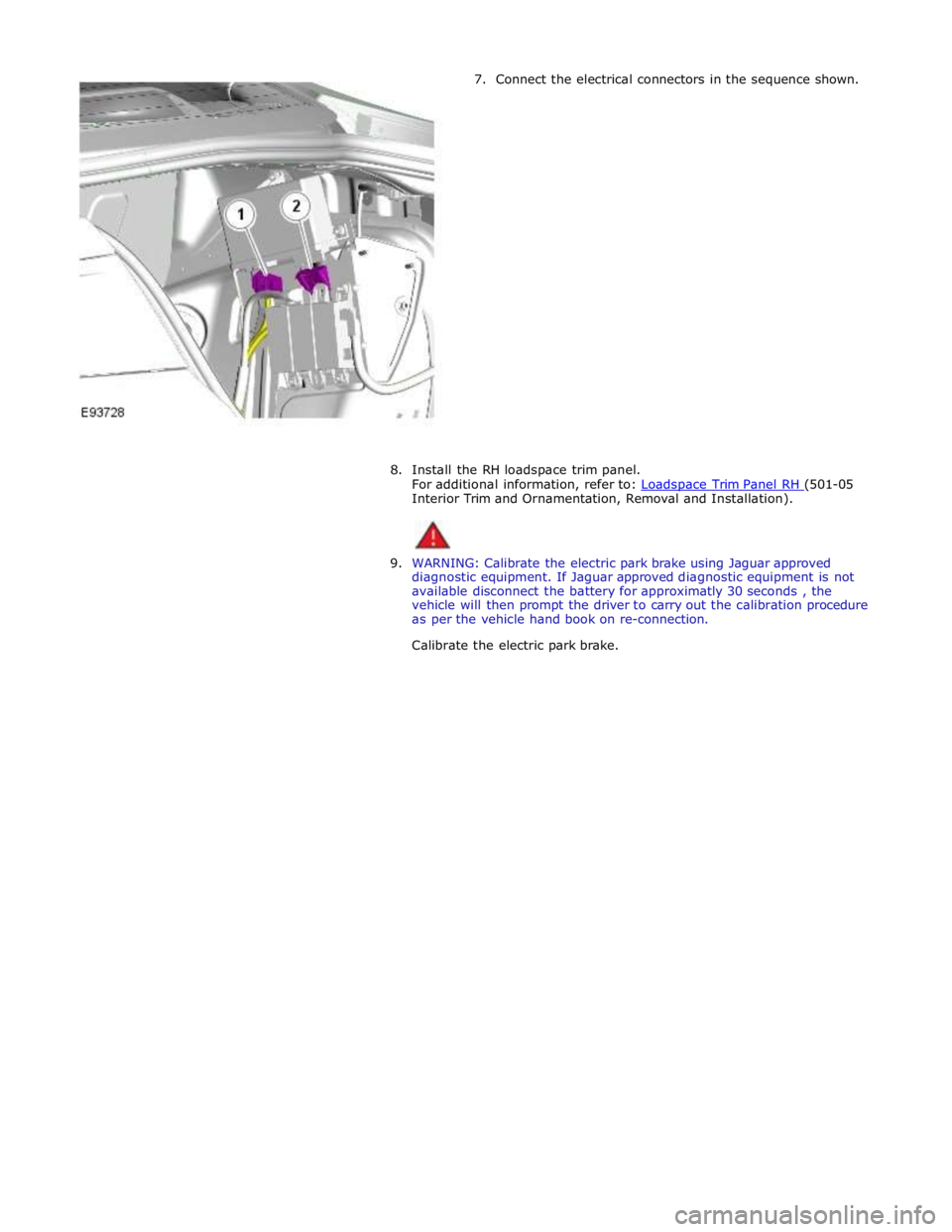

7. Connect the electrical connectors in the sequence shown.

8. Install the RH loadspace trim panel.

For additional information, refer to: Loadspace Trim Panel RH (501-05 Interior Trim and Ornamentation, Removal and Installation).

9. WARNING: Calibrate the electric park brake using Jaguar approved

diagnostic equipment. If Jaguar approved diagnostic equipment is not

available disconnect the battery for approximatly 30 seconds , the

vehicle will then prompt the driver to carry out the calibration procedure

as per the vehicle hand book on re-connection.

Calibrate the electric park brake.

Page 662 of 3039

Parking Brake and Actuation - Parking Brake Module

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Loadspace Trim Panel RH (501-05 Interior Trim and Ornamentation, Removal and Installation).

Installation

3. Torque: 4 Nm

1. To install, reverse the removal position

2. Configure the electronic parking brake (EPB) using the diagnostic tool.

Page 663 of 3039

Parking Brake and Actuation - Parking Brake Switch

Removal and Installation

Removal

NOTES: Published: 12-Jun-2013

The parking brake switch is part of the transmission control switch (TCS) assembly and therefore can not be serviced

separately.

Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Transmission Control Switch (TCS) (307-05A Automatic Transmission/Transaxle External Controls - V6 3.0L Petrol, Removal and

Installation).

Installation

1. CAUTION: Make sure that all diagnostic trouble codes (DTCs) have

been removed after the road test.

To install, reverse the removal procedure.

Page 666 of 3039

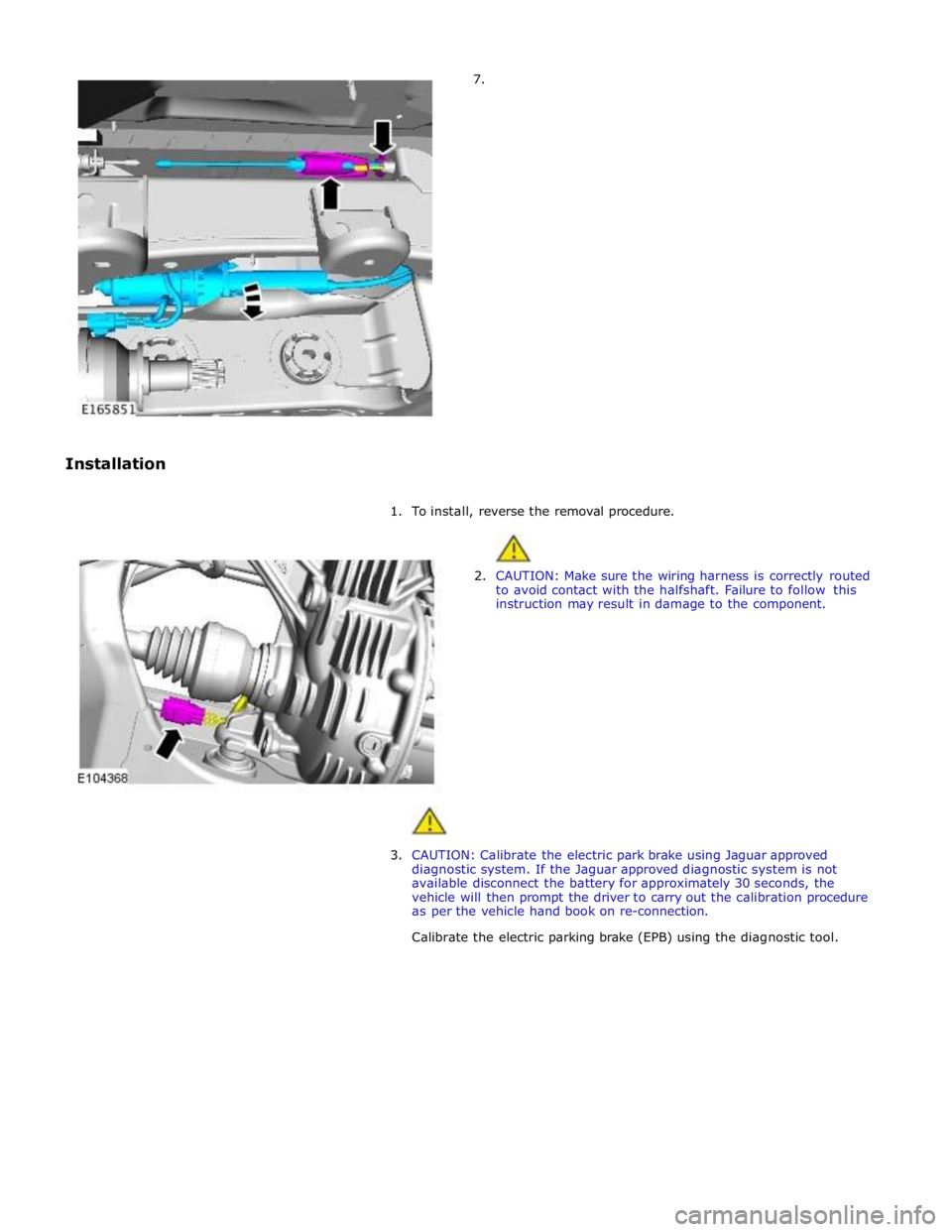

7.

Installation

1. To install, reverse the removal procedure.

2. CAUTION: Make sure the wiring harness is correctly routed

to avoid contact with the halfshaft. Failure to follow this

instruction may result in damage to the component.

3. CAUTION: Calibrate the electric park brake using Jaguar approved

diagnostic system. If the Jaguar approved diagnostic system is not

available disconnect the battery for approximately 30 seconds, the

vehicle will then prompt the driver to carry out the calibration procedure

as per the vehicle hand book on re-connection.

Calibrate the electric parking brake (EPB) using the diagnostic tool.

Page 693 of 3039

Published: 11-May-2011

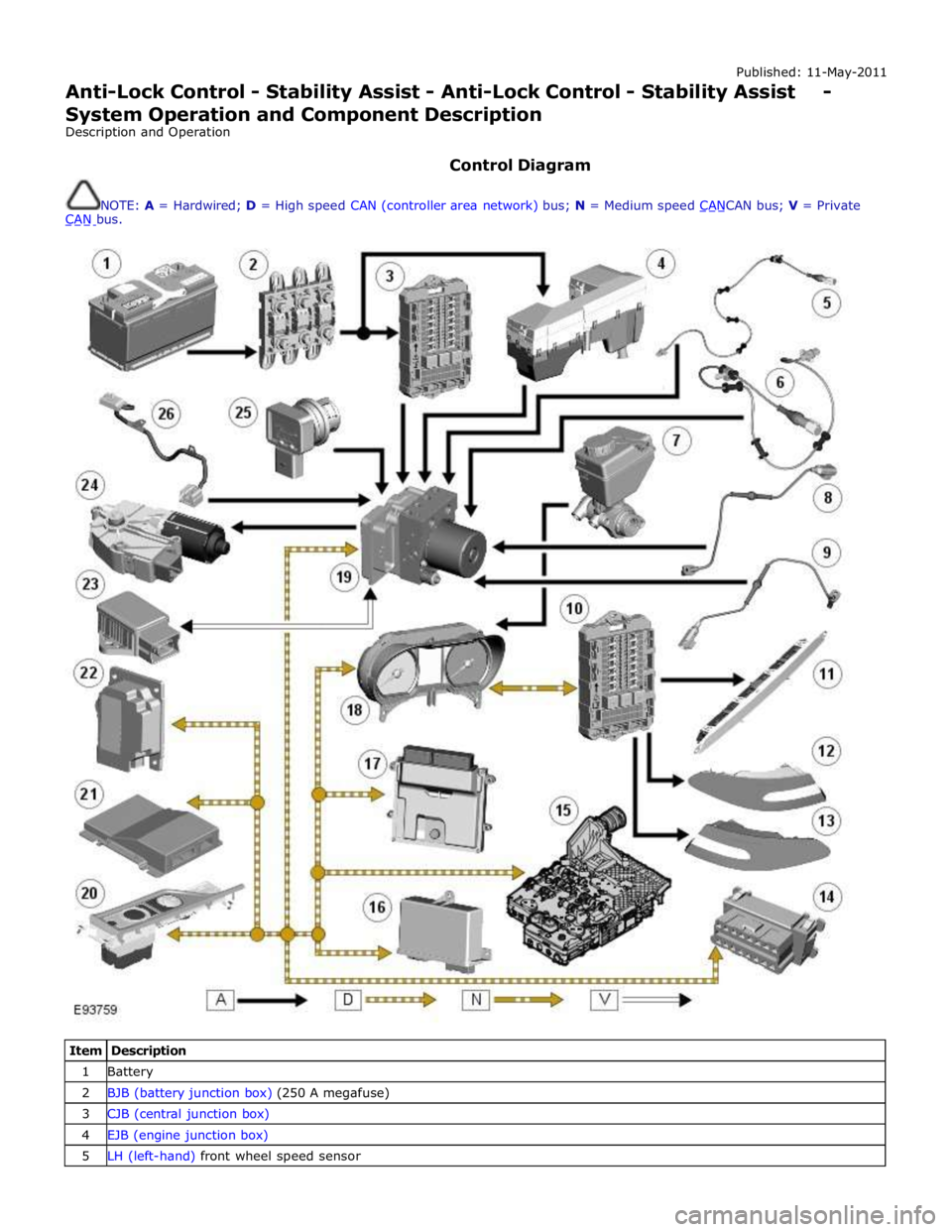

Anti-Lock Control - Stability Assist - Anti-Lock Control - Stability Assist - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; D = High speed CAN (controller area network) bus; N = Medium speed CANCAN bus; V = Private CAN bus.

Item Description 1 Battery 2 BJB (battery junction box) (250 A megafuse) 3 CJB (central junction box) 4 EJB (engine junction box) 5 LH (left-hand) front wheel speed sensor

Page 708 of 3039

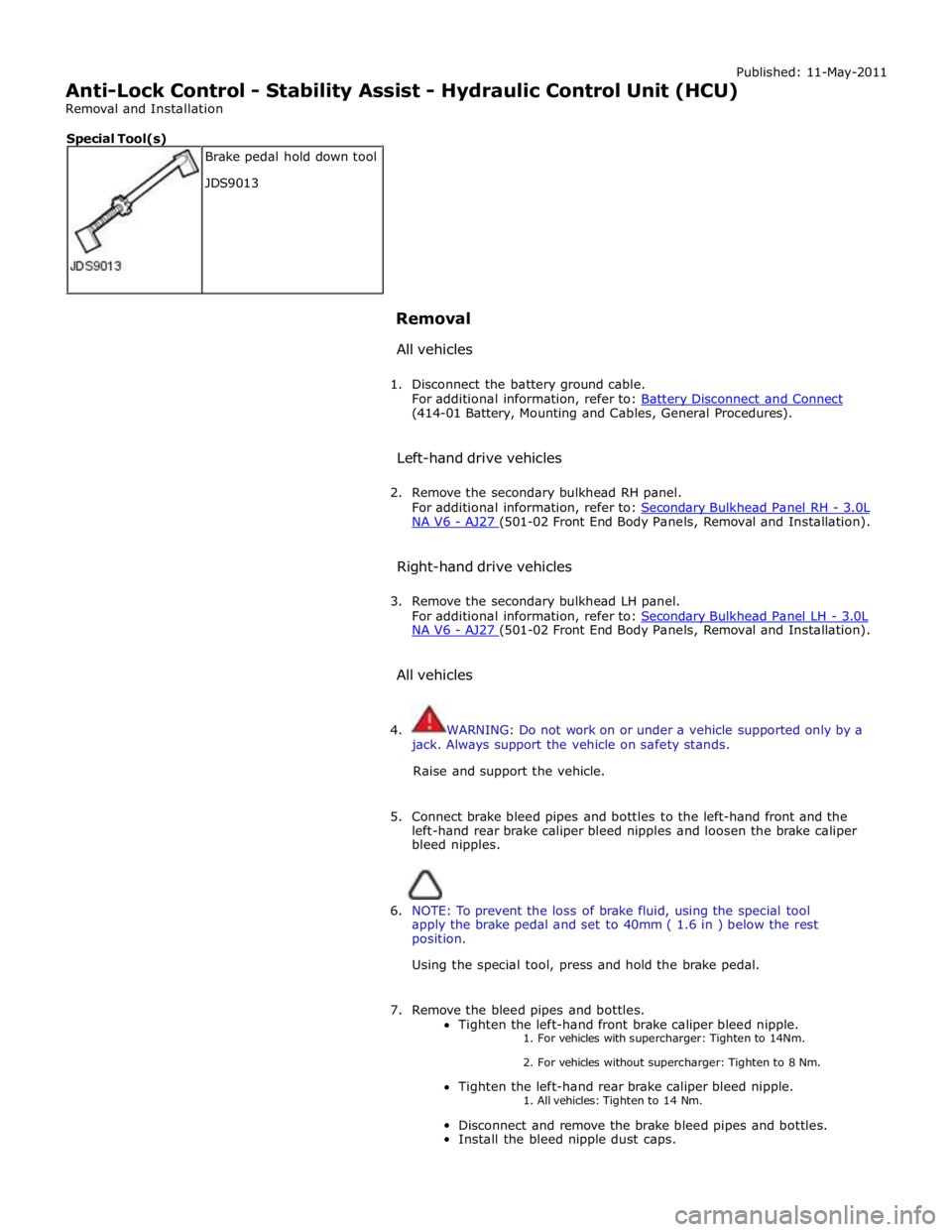

Published: 11-May-2011

Anti-Lock Control - Stability Assist - Hydraulic Control Unit (HCU)

Removal and Installation

Removal

All vehicles

1. Disconnect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

Left-hand drive vehicles

2. Remove the secondary bulkhead RH panel.

For additional information, refer to: Secondary Bulkhead Panel RH - 3.0L NA V6 - AJ27 (501-02 Front End Body Panels, Removal and Installation).

Right-hand drive vehicles

3. Remove the secondary bulkhead LH panel.

For additional information, refer to: Secondary Bulkhead Panel LH - 3.0L NA V6 - AJ27 (501-02 Front End Body Panels, Removal and Installation).

All vehicles

4. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

5. Connect brake bleed pipes and bottles to the left-hand front and the

left-hand rear brake caliper bleed nipples and loosen the brake caliper

bleed nipples.

6. NOTE: To prevent the loss of brake fluid, using the special tool

apply the brake pedal and set to 40mm ( 1.6 in ) below the rest

position.

Using the special tool, press and hold the brake pedal.

7. Remove the bleed pipes and bottles.

Tighten the left-hand front brake caliper bleed nipple. 1. For vehicles with supercharger: Tighten to 14Nm.

2. For vehicles without supercharger: Tighten to 8 Nm.

Tighten the left-hand rear brake caliper bleed nipple.

1. All vehicles: Tighten to 14 Nm.

Disconnect and remove the brake bleed pipes and bottles.

Install the bleed nipple dust caps. Brake pedal hold down tool

JDS9013 Special Tool(s)

Page 711 of 3039

NA V6 - AJ27 (501-02 Front End Body Panels, Removal and Installation).

Right-hand drive vehicles

7. Install the secondary bulkhead LH panel.

For additional information, refer to: Secondary Bulkhead Panel LH - 3.0L NA V6 - AJ27 (501-02 Front End Body Panels, Removal and Installation).

All vehicles

8. Connect the battery ground cable.

For additional information, refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

9. Using the diagnostic tool, configure the new HCU.

Page 715 of 3039

Published: 11-May-2011

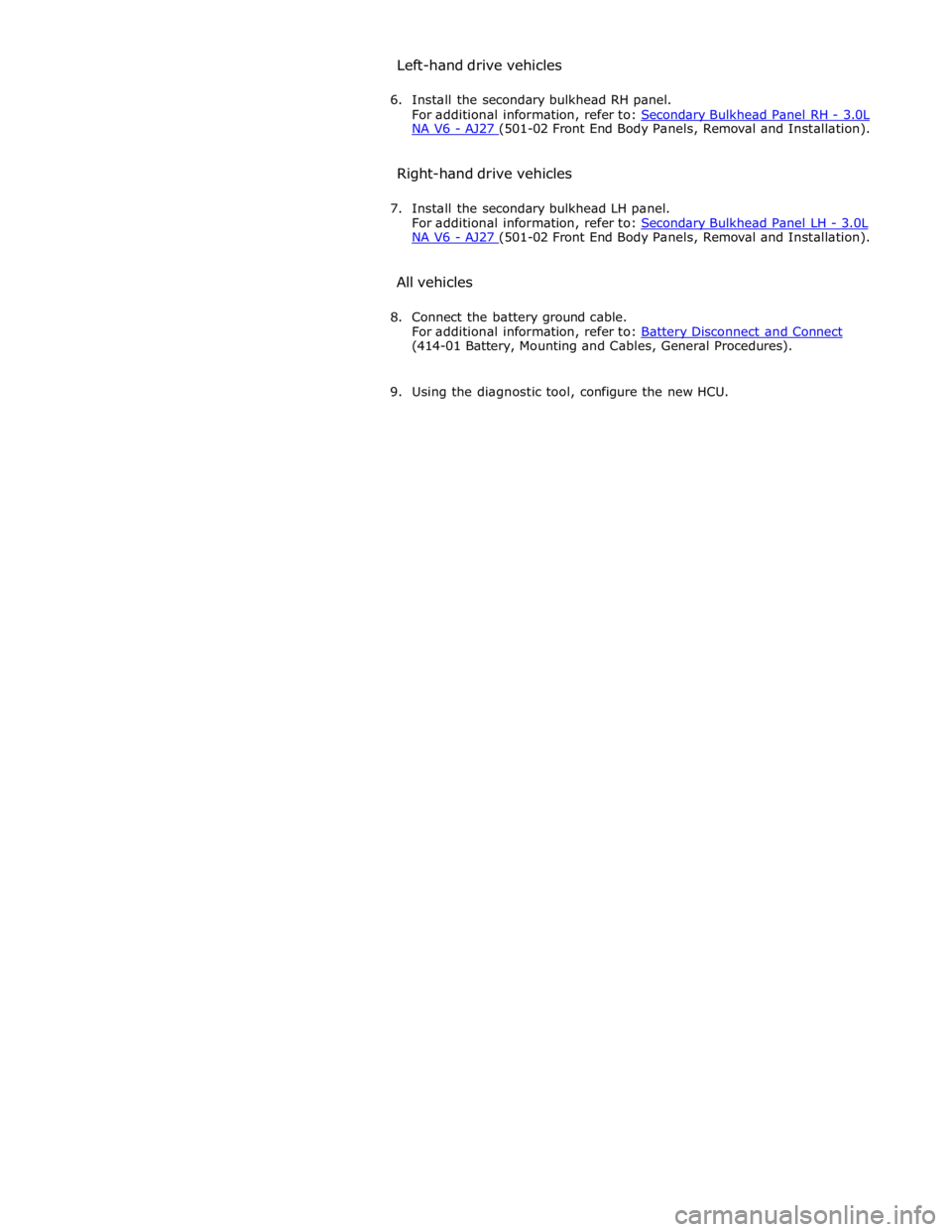

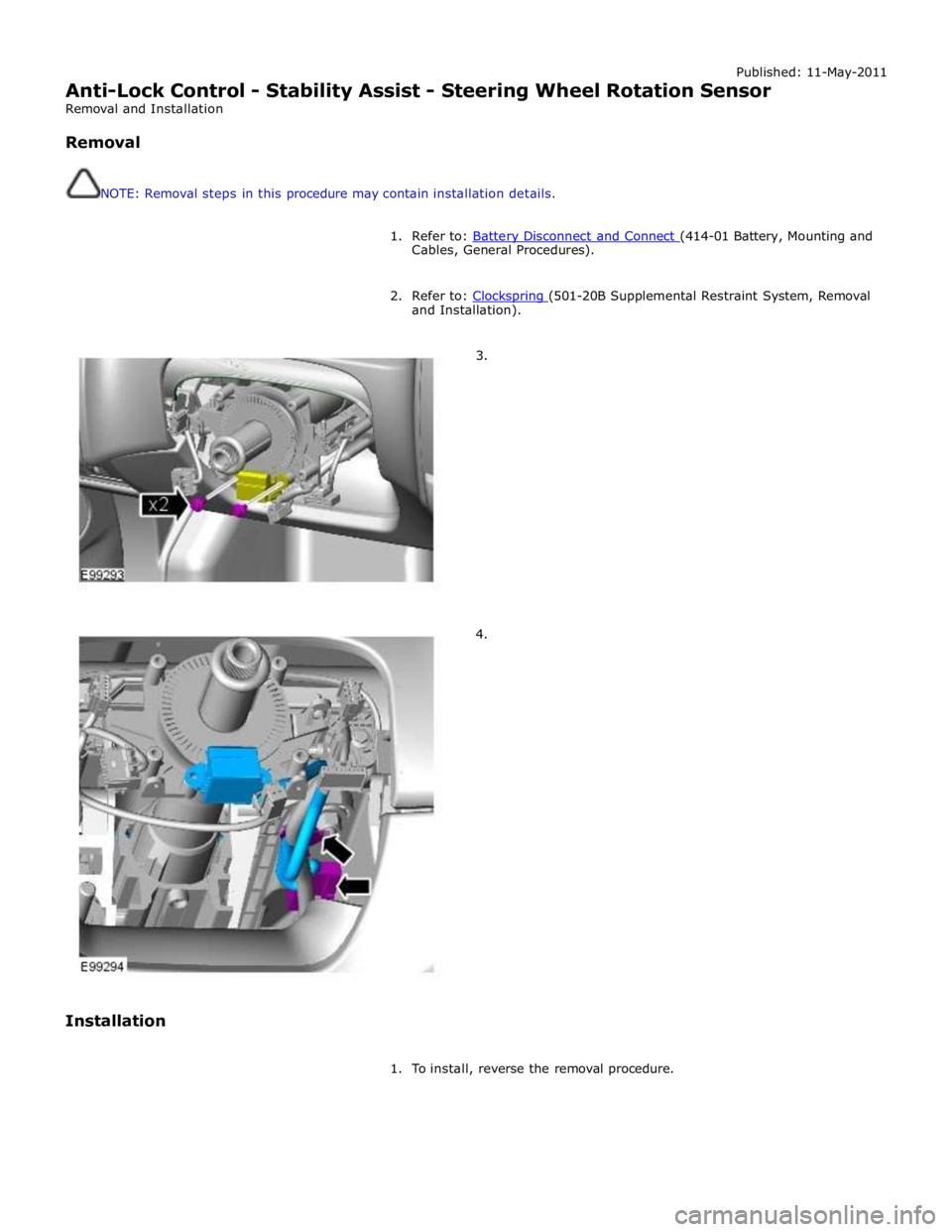

Anti-Lock Control - Stability Assist - Steering Wheel Rotation Sensor

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Clockspring (501-20B Supplemental Restraint System, Removal and Installation).

3.

4.

Installation

1. To install, reverse the removal procedure.

Page 716 of 3039

Published: 11-May-2011

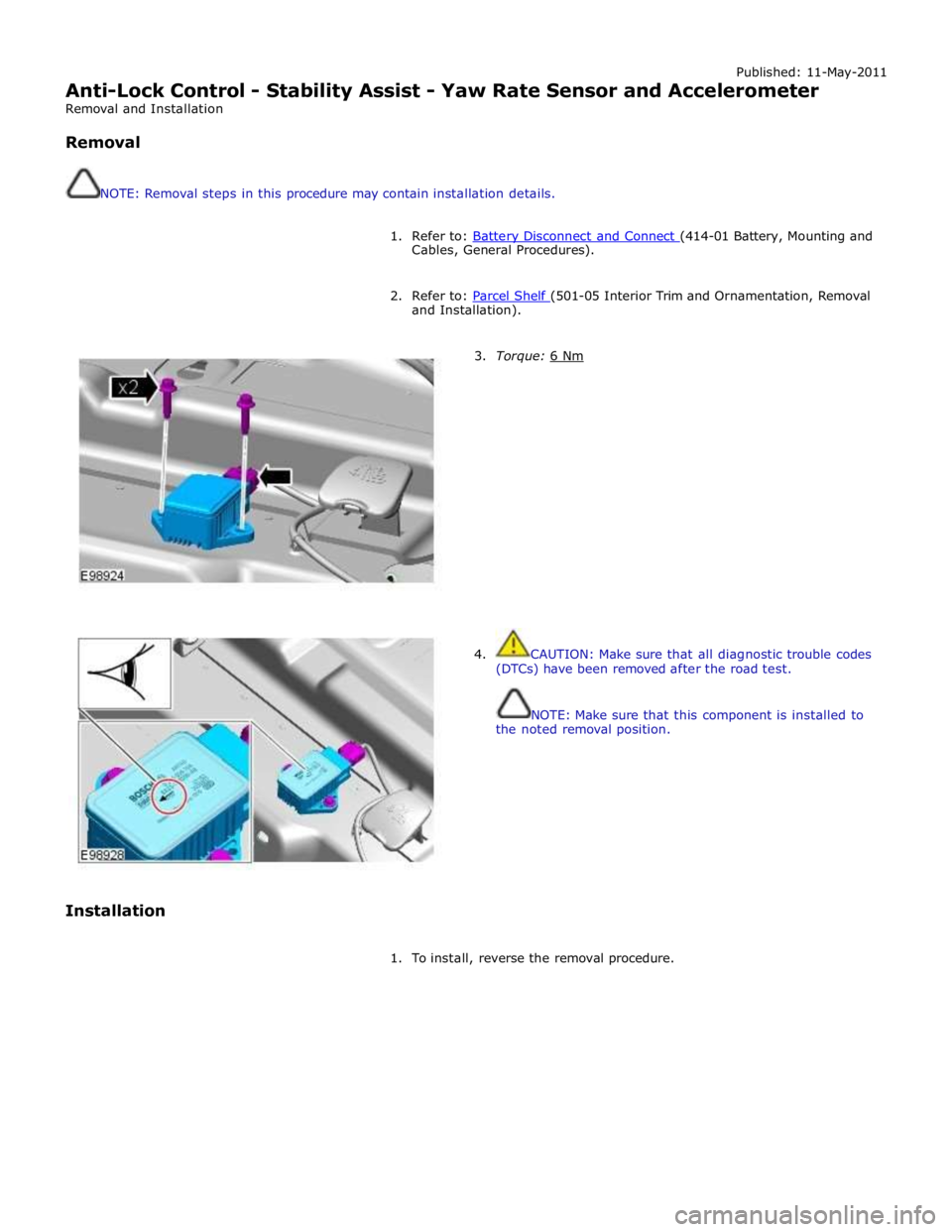

Anti-Lock Control - Stability Assist - Yaw Rate Sensor and Accelerometer

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. Refer to: Parcel Shelf (501-05 Interior Trim and Ornamentation, Removal and Installation).

Installation

3. Torque: 6 Nm

4. CAUTION: Make sure that all diagnostic trouble codes

(DTCs) have been removed after the road test.

NOTE: Make sure that this component is installed to

the noted removal position.

1. To install, reverse the removal procedure.