wheel JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 4 of 3039

Four-Wheel Alignment

Front Toe Adjustment (57.65.01)

Rear Toe Adjustment (57.65.08)

Front Wheel Bearing and Wheel Hub Runout Check

Rear Wheel Bearing and Wheel Hub Runout Check204-01: Front SuspensionSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingFront SuspensionRemoval and InstallationFront Shock Absorber (60.30.04)

Front Lower Arm (60.35.53)

Rear Lower Arm (60.35.54)

Rear Lower Arm Bushing (60.40.12)

Shock Absorber Bushing (60.30.16) (60.30.23)

Front Stabilizer Bar - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Front Stabilizer Bar Link (60.10.02)

Stabilizer Bar Link Bushing (60.10.03)

Upper Arm LH (60.35.41)

Upper Arm RH (60.35.42)

Front Wheel Bearing and Wheel Hub - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol

Wheel Knuckle (60.25.23)

Front Lower Arm Bushing204-02: Rear SuspensionSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingRear SuspensionRemoval and InstallationLower Arm (64.35.43)

Shock Absorber and Spring Assembly

Shock Absorber Lower Bushing (64.30.39)

Rear Stabilizer Bar (64.35.08)

Rear Wheel Bearing

Upper Arm

Page 5 of 3039

Disassembly and AssemblyShock Absorber and Spring Assembly204-04: Wheels and TiresSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingWheels and TiresRemoval and InstallationTire Low Pressure Sensor

Tire Pressure Monitoring System (TPMS) Front Antenna

Tire Pressure Monitoring System (TPMS) Rear Antenna

Tire Pressure Monitoring System (TPMS) Module

Tire Pressure Monitoring System (TPMS) Receiver

Wheel and Tire204-05: Vehicle Dynamic Suspension

Description and OperationComponent Location - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Overview - V8 5.0L Petrol/V8 S/C 5.0L Petrol

System Operation and Component Description - V8 5.0L Petrol/V8 S/C 5.0L PetrolDiagnosis and TestingVehicle Dynamic SuspensionRemoval and InstallationAdaptive Damping Module

Front Suspension Vertical Accelerometer

Rear Suspension Vertical Accelerometer204-06: Ride and Handling Optimization

Description and OperationComponent Location

Overview

System Operation and Component Description205: Driveline

205-00: Driveline System - General Information

Diagnosis and TestingDriveline SystemGeneral ProceduresDriveline Angle Inspection205-01: DriveshaftSpecification

Page 7 of 3039

Diagnosis and TestingBrake SystemGeneral ProceduresBrake Disc Runout Check

Brake System Bleeding (70.25.03)

Front Brake Disc Runout Check - With Wheel On - Vehicles With: High Performance Brakes

Rear Brake Disc Runout Check - With Wheel On206-03B: Front Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionRemoval and InstallationBrake Caliper - Vehicles With: High Performance Brakes

Brake Disc - Vehicles With: High Performance Brakes

Brake Pads - Vehicles With: High Performance Brakes

Brake Disc Shield (70.10.18) - Vehicles With: High Performance Brakes206-04B: Rear Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L PetrolSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionRemoval and InstallationBrake Caliper - Vehicles With: High Performance Brakes

Brake Disc - Vehicles With: High Performance Brakes

Brake Pads - Vehicles With: High Performance Brakes

Brake Disc Shield (70.10.19)206-05: Parking Brake and ActuationSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingParking BrakeGeneral ProceduresParking Brake Cable Tension ReleaseRemoval and InstallationParking Brake Cable LH - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol

Parking Brake Cable RH - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol

Page 8 of 3039

Parking Brake Module

Parking Brake Switch

Parking Brake Release Actuator206-06: Hydraulic Brake ActuationSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingHydraulic Brake ActuationRemoval and InstallationBrake Fluid Reservoir (70.30.16)

Brake Master Cylinder (70.30.08)206-07: Power Brake ActuationSpecificationDescription and OperationComponent Location

OverviewDiagnosis and TestingPower Brake SystemRemoval and InstallationBrake Booster (70.50.17)

Brake Vacuum Pump - V8 5.0L Petrol/V8 S/C 5.0L Petrol206-09: Anti-Lock Control - Stability AssistSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingAnti-Lock Control - Stability AssistRemoval and InstallationAnti-Lock Brake System (ABS) Module (70.60.02)

Front Wheel Speed Sensor

Hydraulic Control Unit (HCU) (70.60.18) (70.60.19)

Rear Wheel Speed Sensor (70.60.04)

Steering Wheel Rotation Sensor

Yaw Rate Sensor and Accelerometer211: Steering System

211-00: Steering System - General InformationSpecification

Page 9 of 3039

Diagnosis and TestingSteering SystemGeneral ProceduresPower Steering System Bleeding (57.15.02 )

Power Steering System Flushing (57.15.08)

Power Steering System Filling - V8 5.0L Petrol/V8 S/C 5.0L Petrol211-02: Power SteeringSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingPower SteeringRemoval and InstallationSteering Gear (57.10.01)

Power Steering Fluid Reservoir - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Power Steering Pump - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Power Steering Pump to Steering Gear Pressure Line - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Steering Gear to Fluid Cooler Return Hose - V8 5.0L Petrol/V8 S/C 5.0L Petrol211-03: Steering LinkageSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingSteering LinkageRemoval and InstallationTie Rod End (57.55.02)211-04: Steering ColumnSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingSteering ColumnRemoval and InstallationSteering Column

Steering Column Flexible Coupling

Steering Wheel (57.60.01)

Page 22 of 3039

Operation and

Component DescriptionCellular PhoneComponent

Location

Overview

System Operation

and Component DescriptionNavigation SystemComponent Location

Overview

System Operation and Component DescriptionVideo SystemComponent

Location

Overview

System Operation

and Component DescriptionDiagnosis and TestingInformation and Entertainment SystemRemoval and InstallationAudio Unit

Audio Unit Antenna Amplifier

Audio and Climate Control Assembly

Front Door Speaker

Information and Entertainment Display

Information and Entertainment Module

Instrument Panel Speaker

Rear Door Speaker

Steering Wheel Audio Controls

Subwoofer Amplifier

Subwoofer Speaker

Satellite Radio Tuner415-01B: Information and Entertainment System - DTC: Audio Input Control Module

Diagnosis and TestingAudio Input Control Module417: Lighting

417-01: Exterior LightingSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingHeadlampsGeneral ProceduresHeadlamp Adjustment (86.40.18)

Page 31 of 3039

Removal and InstallationFender Apron Closing Panel Front Section

Fender Apron Panel

Fender Apron Panel Closing Panel

Fender Apron Panel Front Extension

Fender Apron Panel Front Section

Front Bumper Mounting

Front Fender

Front Fender Support Bracket

Front Side Member

Front Side Member and Suspension Top Mount Assembly

Front Side Member Closing Panel

Front Side Member Closing Panel Section

Front Side Member Section

Front Wheelhouse Section

Hood Latch Panel

Hood Latch Panel Mounting Bracket501-28: Roof Sheet Metal Repairs

Description and OperationRoofRemoval and InstallationRoof Panel - Vehicles With: Sliding Roof Opening Panel

Roof Panel - Vehicles Without: Sliding Roof Opening Panel501-29: Side Panel Sheet Metal Repairs

Description and OperationSide Panel Sheet MetalRemoval and InstallationA-Pillar Outer Panel

A-Pillar Reinforcement

B-Pillar Inner Panel

B-Pillar Reinforcement

Front Door Skin Panel

Rear Door Skin Panel

Rocker Panel

Rocker Panel and B-Pillar Outer Panel

Rocker Panel Front Section

Rocker Panel Inner Reinforcement

Rocker Panel Rear Section501-30: Rear End Sheet Metal Repairs

Description and OperationRear End Sheet Metal

Page 32 of 3039

Removal and InstallationBack Panel

Quarter Panel

Quarter Panel Lower Extension

Rear Bumper Mounting

Rear Floor Side Extension

Rear Side Member Closing Panel Section

Rear Side Member Section

Rear Wheelhouse Outer

Spare Wheel Well502: Frame and Mounting

502-00: Uni-Body, Subframe and Mounting SystemSpecificationRemoval and InstallationFront Subframe - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Rear Subframe - V8 5.0L Petrol/V8 S/C 5.0L Petrol

Rear Subframe Rear Bushing (64.25.36) - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol

Page 33 of 3039

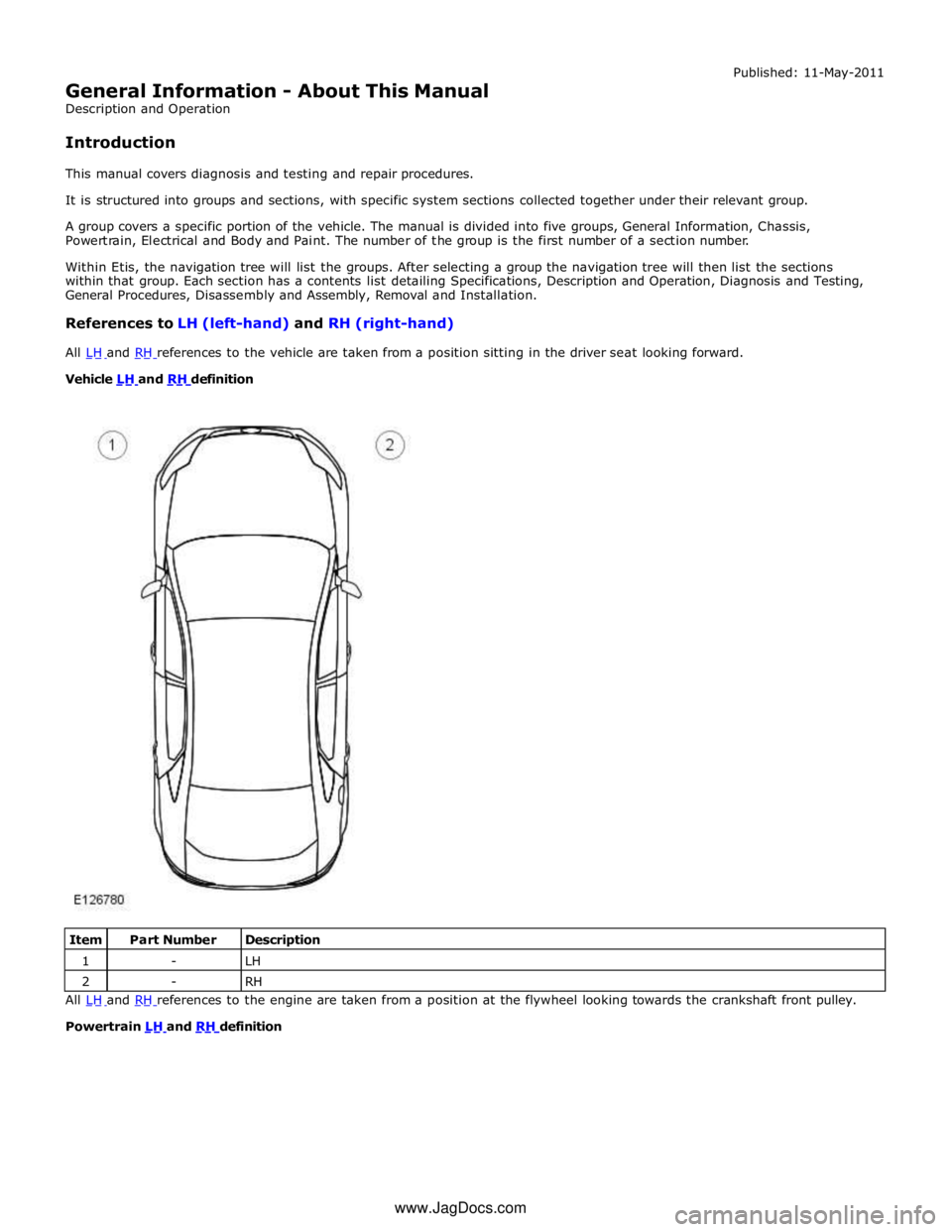

Vehicle LH and RH definition

Item Part Number Description 1 - LH 2 - RH All LH and RH references to the engine are taken from a position at the flywheel looking towards the crankshaft front pulley.

Powertrain LH and RH definition

www.JagDocs.com

Page 49 of 3039

General Information - General Service Information

Description and Operation

Repairs and Replacements Published: 28-Dec-2012

When service parts are required, it is essential that only genuine Jaguar/Daimler replacements are used.

Attention is drawn to the following points concerning repairs and the installation of replacement parts and accessories:

Safety features embodied in the vehicle may be impaired if other than genuine parts are installed. In certain territories,

legislation prohibits the installation of parts which are not produced to the vehicle manufacturer's specification.

Torque wrench setting figures given in this manual must be strictly adhered to. Locking devices, where specified, must

be installed. If the efficiency of a locking device is impaired during removal it must be renewed.

Owners purchasing accessories while travelling abroad should make sure that the accessory and its installed location on

the vehicle conform to mandatory requirements existing in their country of origin.

The vehicle warranty may be invalidated by the installation of other than genuine Jaguar/Daimler parts. All

Jaguar/Daimler replacements have the full backing of the factory warranty.

Jaguar/Daimler dealers are obliged to supply only genuine service parts.

Vehicle Specifications

Purchasers are advised that the specification details set out in this manual apply to a range of vehicles and not to any specific

one. For the specification of a particular vehicle, purchasers should consult their dealer.

The Manufacturer reserves the right to vary the specifications, with or without notice, and at such times and in such manner as

the Manufacturer thinks fit. Major as well as minor changes may be involved, in accordance with the Manufacturer's policy of

continuous improvement.

Whilst every effort is made to make sure the accuracy of the particulars contained in this manual, neither the Manufacturer nor

the Dealer, by whom the manual is supplied, shall in any circumstances be held liable for any inaccuracy or the consequences

thereof.

Service Repair Operation Numbering

A master index of numbered operations has been compiled for universal application to all vehicles manufactured by Jaguar

Land Rover Limited.

Each operation is allocated a number from the master index and cross-refers with an identical number in the Repair Operation

Times schedule. The number consists of six digits arranged in three pairs.

Each maintenance procedure in this manual is described in the sequence necessary to complete the operation in the minimum

time, as specified in the Repair Operation Times schedule.

References to Bank-1 and Bank-2

References to Bank-1 and Bank-2 are made with regard to the engine. When viewed from the flywheel the right-hand bank will

be Bank-1 and the left-hand bank will be Bank-2.

Special Tools

Any special tools and equipment required to perform a maintenance procedure, are shown at the beginning of each procedure.

When possible, illustrations are given to assist in identifying the tool needed.

Disconnecting/Connecting the Battery

Always stop the engine before disconnecting the battery negative lead and make sure the battery positive lead is isolated i.e.

wrapped in a suitable cloth.

WARNING: Radio code saving devices must not be used when conducting work on Air Bag or Fuel systems. It must be

noted that, when using these devices, the vehicle electrical system is still live albeit with a reduced current flow.

NOTE: Before disconnecting the battery make sure that the radio receiver/cassette player/mini disc player and compact

disc player keycodes are known and, that no data is required from the Engine Control Module (ECM) as battery disconnection

will erase any fault codes and idle/drive values held in the Keep Alive Memory (KAM).

Always disconnect the battery before commencing repair operations which require:

The vehicle to be jacked up

Work on the engine

Work underneath the vehicle

Arc welding

Alternatively a Radio Code Saver may be used, when not working on the Air Bag or Fuel systems. With the battery