ecu JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2493 of 3039

Item Description Note: A = Hardwired; N = Medium speed CAN 1 Battery 2 Megafuse (250 A) 3 CJB 4 Radio frequency receiver 5 Keylesss vehicle module 6 Door handle, lock/unlock switch and antenna - front passenger 7 Door latch, fast latch - front passenger 8 Door latch, fast latch - RH rear passenger 9 Door handle, lock/unlock switch and antenna - RH rear passenger 10 Door latch, fast latch - LH rear passenger 11 Door handle, lock/unlock switch and antenna - LH rear passenger 12 Door latch, fast latch - driver door 13 Door handle, lock/unlock switch and antenna - driver door

System Operation

The hinged panels are secured with latches and strikers. A remotely operated central locking system controls the locking and

unlocking of the door and luggage compartment latches. A radio frequency Smart Key allows the vehicle to be locked and

unlocked by pressing the appropriate handset buttons. Two levels of central locking system are available: remote central

locking and an optional passive entry system.

The passive entry and associated passive start system allows the driver to unlock and start the vehicle without using a vehicle

key in a door-lock or ignition switch. The passive entry system is an optional fitment while the passive start system is a

standard fitment on all vehicles. The passive start system is combined with the passive anti-theft immobilization system.

Refer to: Anti-Theft - Passive (419-01B Anti-Theft - Passive, Description and Operation).

Emergency access to the vehicle is provided by two concealed key barrels: one located in the front left-hand door handle and

one located on the underside of the luggage compartment lid finisher. An emergency, removable key blade is fitted into the

Smart Key.

Operation of either key barrel unlocks the vehicle but does not disarm the alarm system. The key barrels in the door and

luggage compartment lid are concealed by a plastic cover which can be removed by inserting the blade of the emergency key

into a slot in the cover.

Locking and unlocking conditions using the emergency key in the door key barrel:

If the alarm is not armed the vehicle can be centrally unlocked.

If the alarm is armed the door only can be opened and the alarm will be triggered.

The vehicle cannot be double locked or the alarm system armed using the emergency key.

The vehicle can be centrally locked and unlocked from inside using the interior handle release levers on the front doors only.

Central locking and unlocking can also be performed using lock and unlock buttons on the vehicle's fascia. The driver can select

locking options, single point entry or drive away locking for example, from a menu available on the touch screen.

Central Locking – Radio Frequency Remote System

The radio frequency central locking system, provides locking and unlocking of the vehicle from inside and outside of the

vehicle. The system is operated using buttons on the Smart Key, which transmits radio frequency signals to the central locking

radio frequency receiver.

The system provides additional security by double-locking the doors from outside the vehicle if the lock button, on the Smart

Key, is pressed twice within 3 seconds; this function is not applicable in North American Specification (NAS) and Japanese

markets.

Additional buttons on the Smart Key provide for the convenience operation of the luggage compartment lid release, headlamp

delay and panic alarm functions. A global open or close feature is also available in certain markets using the lock/unlock

buttons.

Passive Entry

On vehicles fitted with the optional passive entry system, the vehicle can be unlocked without the use of a key blade or

pressing buttons on the Smart Key. The Smart Key operates the passive entry system in addition to the passive start system.

Refer to: Anti-Theft - Passive (419-01B Anti-Theft - Passive, Description and Operation).

The passive entry system is controlled by the keyless vehicle module and five low frequency antennas. One antenna located in

each door handle and one antenna located behind the rear bumper cover.

When a vehicle door handle is pulled to the first five-percent of its travel and the Smart Key is within one meter of the handle;

the Smart Key receives the low-frequency signal transmitted from the keyless vehicle module. The Smart Key responds with a

radio frequency transmission of its authorization code. The radio frequency signal is received by the central locking radio-

frequency receiver and passed to the keyless vehicle module which checks and approves the code as valid. Once the handle is

Page 2495 of 3039

Published: 18-Mar-2014

Handles, Locks, Latches and Entry Systems - Locks, Latches and Entry Systems

Diagnosis and Testing

Principle of Operation

For a detailed description of the locks, latches and entry systems and operation, refer to the relevant Description and

Operation section of the workshop manual. REFER to: Handles, Locks, Latches and Entry Systems (501-14, Description and

Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

1. Verify the customer concern, to be sure the correct issue is investigated

2. Visually inspect for obvious signs of damage and system integrity

Visual Inspection

Mechanical Electrical

Incorrectly aligned door(s), hood or tailgate

Fuel filler door lock actuator

Hood release handle

Hood release cables

Hood latch(es)

Exterior door handle(s)

Interior door handle(s)

Cable(s)

Tailgate release switch

Rear window release switch

Fuses

Wiring harness

Wiring connector(s)

Door lock actuator(s)

Remote transmitter (key-fob or smart key)

Central locking switches

Controller Area Network (CAN) circuits

Radio frequency (RF) receiver

Central junction box (CJB)

Loose or corroded connections

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

Symptom Chart

NOTE: Complete the diagnostic steps below to confirm any concern prior to replacing any component

Symptom Possible Causes Action The message center indicates that the

hood, the luggage compartment is

open when it appears to be closed

Incorrect striker

alignment/adjustment

Ajar switch circuit short circuit to

ground

Ajar switch failure

Check/adjust the strikers as

necessary

Check for DTCs indicating an ajar

switch fault. Refer to the DTC index Vehicle indicates a miss-lock when the

hood, luggage compartment appear to

be closed Fuel flap does not lock/unlock

Fuel flap cable detached from body

Fuel flap actuator detached from

mounting bracket

Fuel flap actuator disconnected

Fuel flap actuator failure

Check the condition and installation

of the fuel flap cable

Check the security of the fuel flap

actuator and bracket

Check the security of the actuator

electrical connector

Check for DTCs indicating a fuel flap

actuator fault. Refer to the DTC

index Door(s) will not unlatch/open when

using outside door handle

Exterior door handle

condition/installation

Exterior release cable disconnected

from exterior door handle or door

latch

Check the exterior door handle

condition and installation

Check the condition and security of

the exterior release cable

Single door will not open from the

Page 2496 of 3039

Symptom Possible Causes Action outside (but opens from the

inside) GO to Pinpoint Test A. Door(s) will not unlatch/open when

using inside door handle

Child lock(s) engaged

Interior door handle

condition/installation

Interior release cable disconnected

from interior door handle or door

latch

Check that the child locks are

disengaged

Check the interior door handle

condition and installation

Check the condition and security of

the interior release cable

Single Door Will Not Open From

The Inside (but opens from the

outside) GO to Pinpoint Test B. Door(s) will not lock/unlock from key

fob, key or internal lock switch

Wiring harness/connectors

Central junction box (CJB)

Door lock switch

Cable fault

Check for relevant stored DTCs

Once any DTC related faults have

been rectified continue with the

diagnostic steps below

No lock / unlock function from

key-fob GO to Pinpoint Test C. Door ajar or miss lock signal at

message centre when door(s) are

closed or alarm triggering

Wiring harness

Instrument cluster

Incorrect striker

alignment/adjustment

Ajar switch circuit short circuit to

ground

Ajar switch failure

Latch Mounted Door Ajar Switch

Test GO to Pinpoint Test D. DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Communications Network (418-00, Diagnosis and Testing) /

Locks, Latches and Entry Systems - DTC: With (501-14, Diagnosis and Testing).

Pinpoint Test

PINPOINT TEST A : SINGLE DOOR WILL NOT OPEN FROM THE OUTSIDE (BUT OPENS FROM THE INSIDE) TEST CONDITIONS DETAILS/RESULTS/ACTIONS A1: CHECK THE EXTERIOR DOOR RELEASE CABLE TO EXTERIOR DOOR HANDLE IS INSTALLED CORRECTLY

1 Remove the door trim panel as necessary 2 Confirm the exterior door release cable is correctly installed to the exterior door handle Is the cable correctly installed?

Yes

GO to A2. No

Page 2508 of 3039

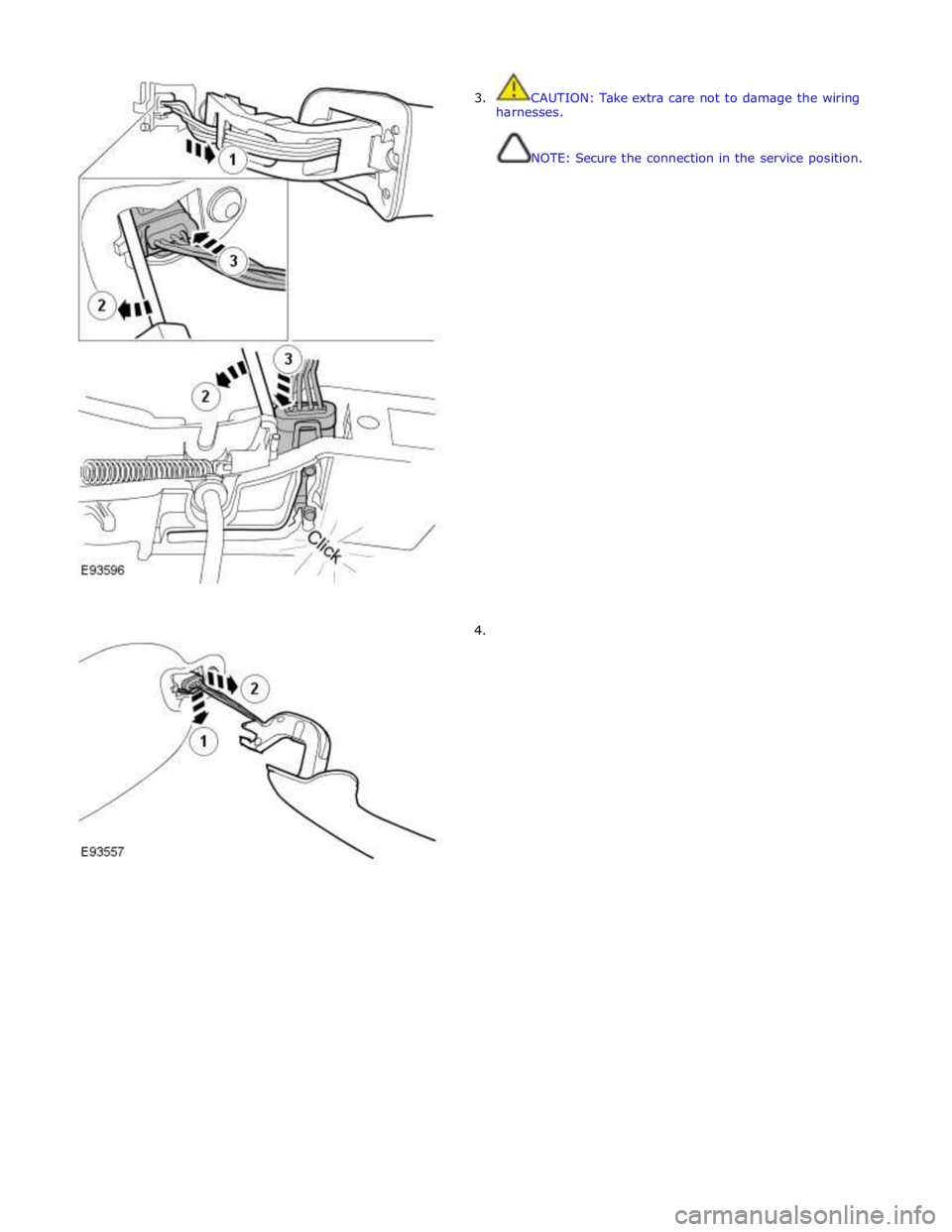

3.

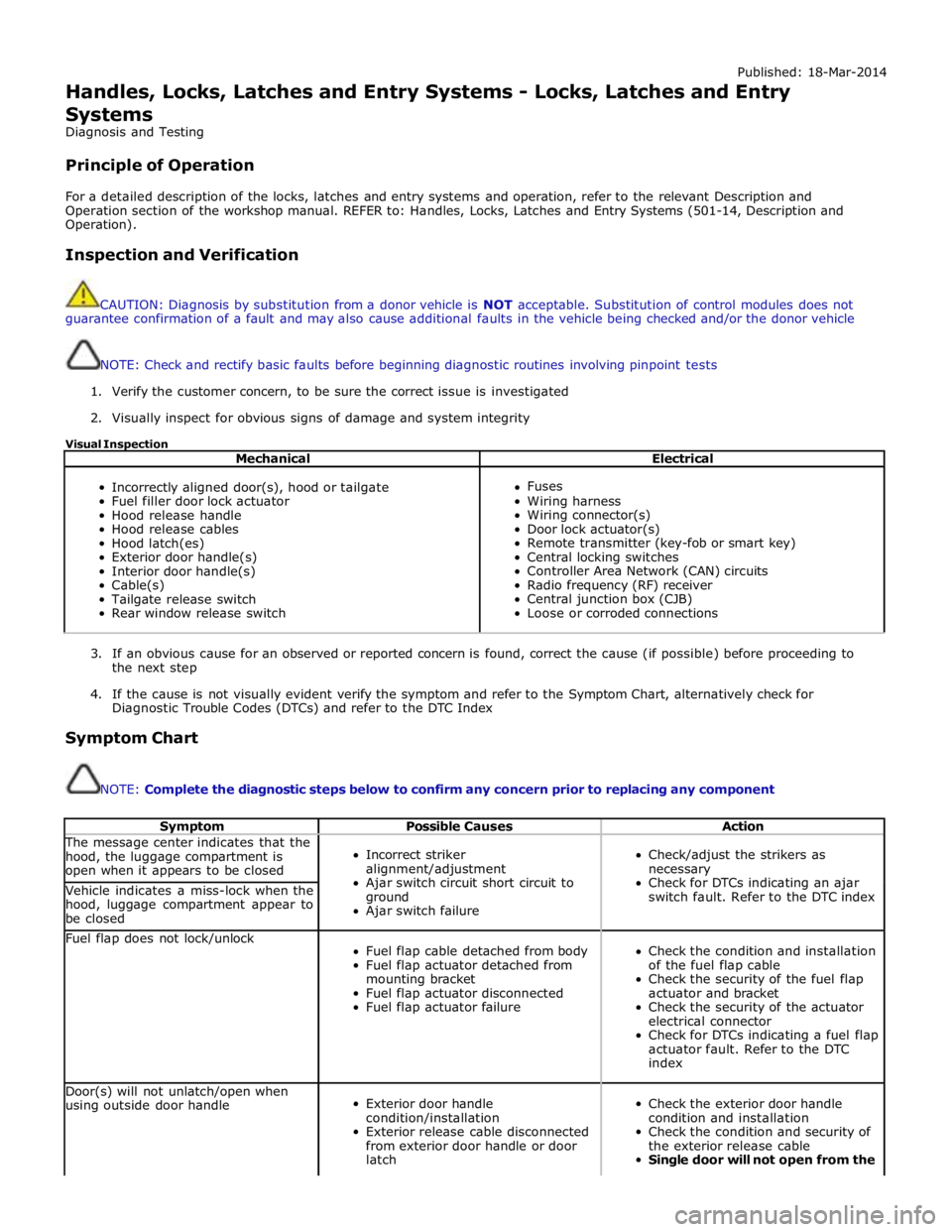

Installation

1. CAUTION: Make sure that the door lock cylinder cover

is pushed firmly in the sequence shown to install all 3 clips,

and that the door lock cylinder cover is securely attached to

the vehicle. Failure to follow this instruction may result in

damage to the vehicle.

Page 2510 of 3039

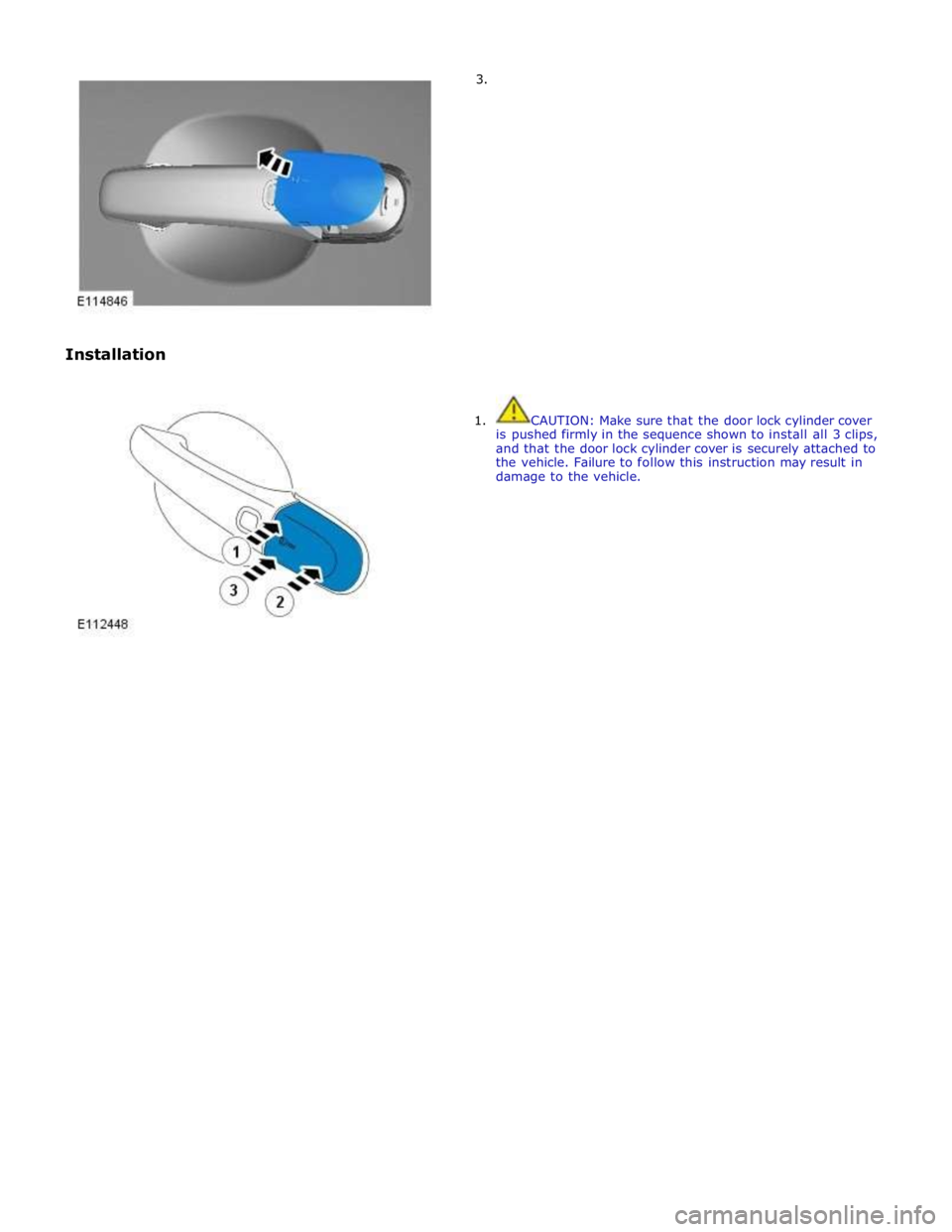

3. CAUTION: Take extra care not to damage the wiring

harnesses.

NOTE: Secure the connection in the service position.

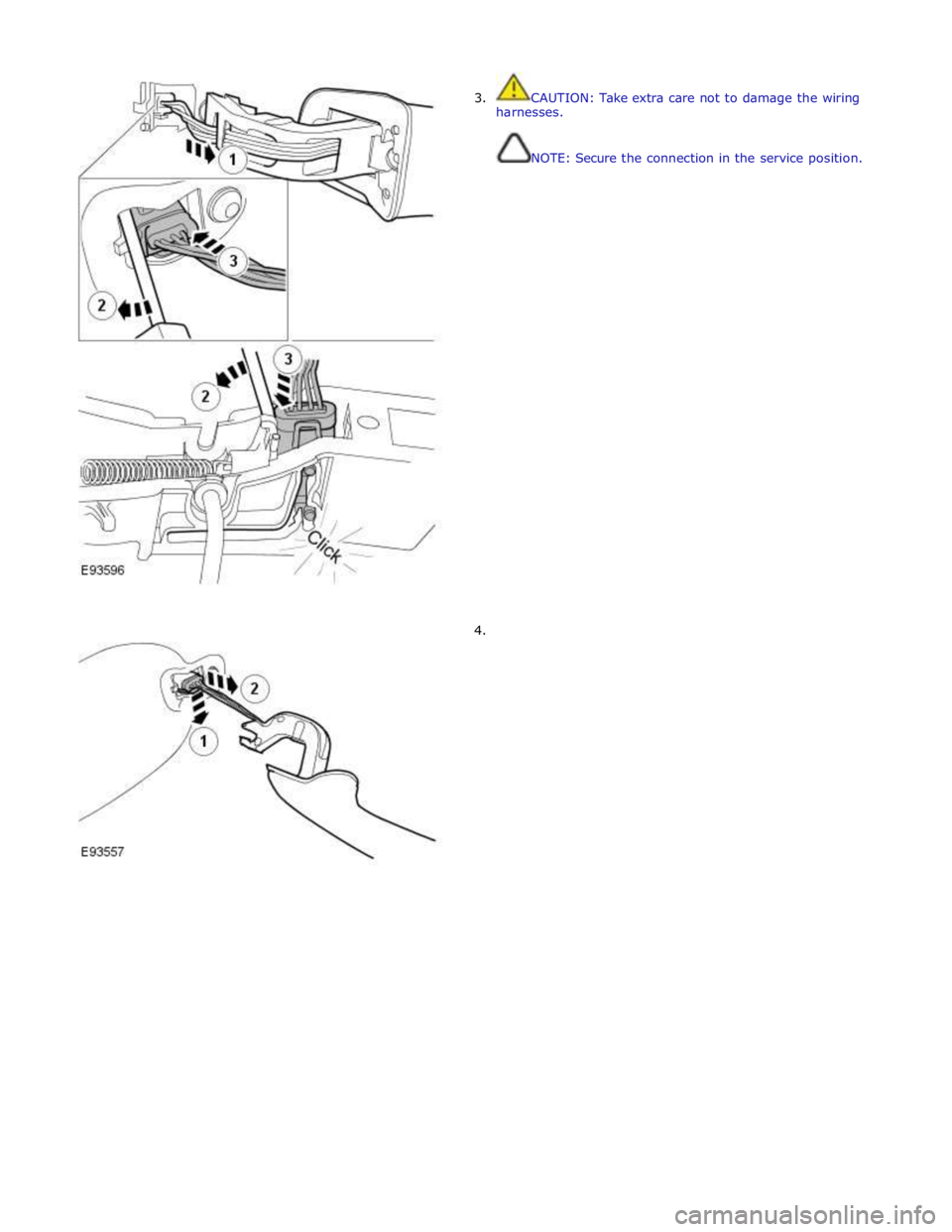

4.

Page 2515 of 3039

3. CAUTION: Take extra care not to damage the wiring

harnesses.

NOTE: Secure the connection in the service position.

4.

Page 2540 of 3039

and is connected at the opposite end to the LH pivot housing via a crank. The LH pivot housing crank is fitted with a second link rod which is connected directly to the crank on the RH pivot housing.

The motor crank converts rotary motion from the motor output shaft into linear movement of the link rods. The cranks

connected to each pivot housing, convert the linear motion of the link rods back to rotary motion of the pivot housings. This

rotary motion is passed to the wiper arms and blades causing the blades to wipe an arc across the windshield.

Each wiper arm is located on a taper spline on the respective pivot housing. A nut is screwed on the end of the pivot housing

shaft and positively secures the wiper arm on the taper spline.

The wiper blades are attached to the wiper arms with a quick release fittings. The blades are of the flat blade type. These

blades have an integral spring along their full length which curves the blade to match the windshield and provides even blade

to windshield contact pressure along the entire length of the blade.

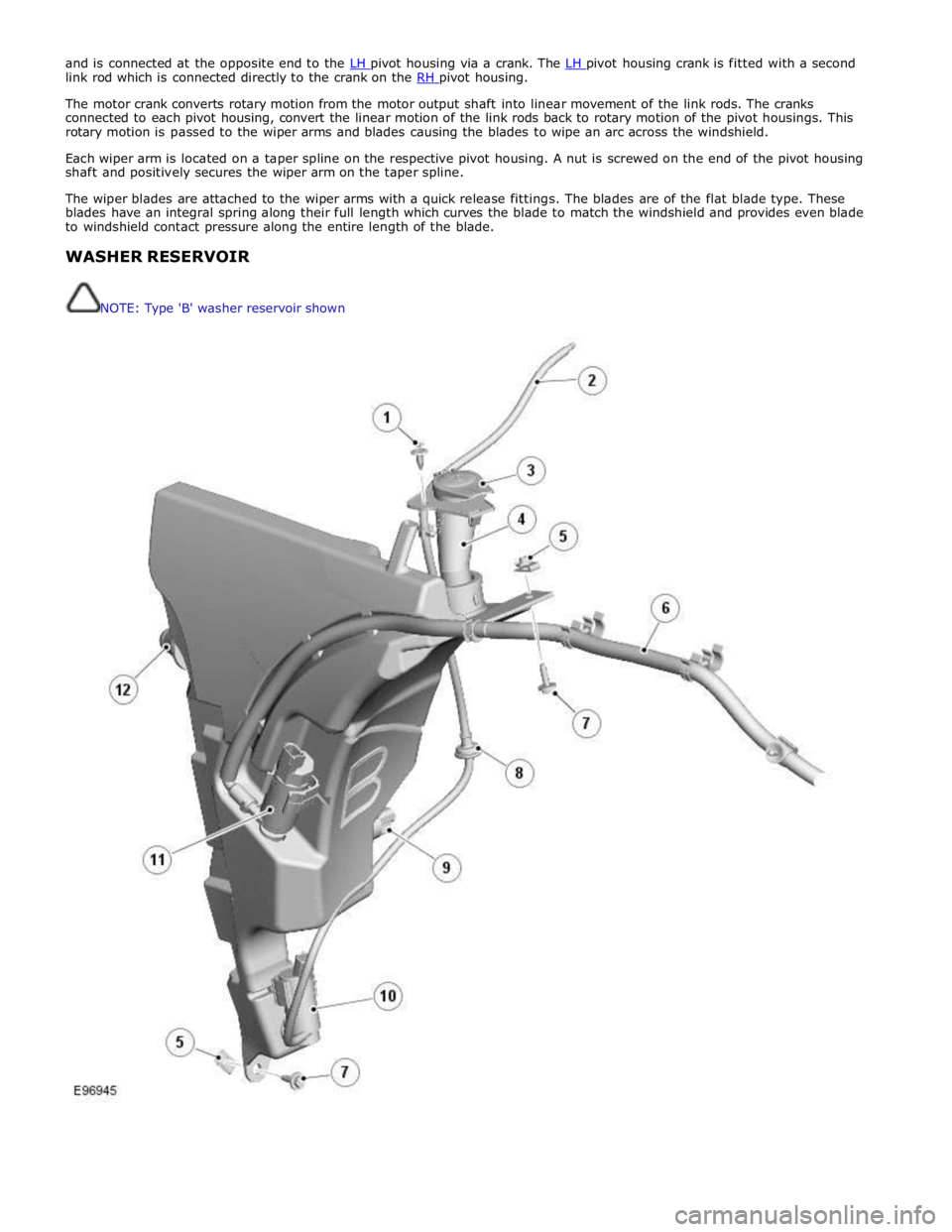

WASHER RESERVOIR

NOTE: Type 'B' washer reservoir shown

Page 2541 of 3039

1 Scrivet 2 Windshield washer feed pipe to washer jets 3 Reservoir cap 4 Reservoir filler neck 5 Captive nut (2 off) 6 Headlamp powerwash feed pipe to telescopic washer jets 7 Screw and washer (2 off) 8 Grommet 9 Washer fluid level sensor 10 Windshield washer pump 11 Headlamp washer pump 12 Location spigot The washer reservoir is located in the RH wheel arch. The reservoir is a plastic moulding and is secured in the wheel arch with 2 screws and washers and a scrivet. A level sensor is located in the reservoir and is connected to the CJB. The reservoir is fitted with a washer pump which supplies pressurized washer fluid to the windshield washer jets mounted on the wiper arms.

A vehicle fitted with optional headlamp washers is fitted with a larger reservoir and an additional pump for the headlamp

washers. The larger reservoir is identifiable by a letter 'B' moulded on the casing and has a capacity of 5.5 liters. Reservoirs

moulded with the letter 'A' are for use on vehicles with windshield washers only and have a capacity of 4.4 liters.

A filler cap is located at the top of the reservoir and is accessible from the engine compartment.

The pumps are located in rubber sealing grommets in holes in the reservoir and secured with clips. The pump fluid hoses have

quick release connectors which mate with the pumps. The fluid level sensor is a push fit into a sealing grommet in one side of

the reservoir body.

HEADLAMP POWERWASHERS (if fitted)

Item Description 1 Powerwash trim cap 2 Washer jets 3 Self-tapping screws (2 off) 4 Pressure feed from powerwash pump 5 Telescopic arm

Page 2542 of 3039

On vehicles with headlamp powerwash, each headlamp assembly is fitted with a headlamp powerwasher. The powerwasher is

located on the underside of the headlamp assembly. The powerwasher is located in a clip at the front of the headlamp and

secured with 2 self tapping screws to the headlamp body.

The powerwasher is a telescopic unit which extends forwards from the headlamp assembly under washer fluid pressure

supplied by the headlamp powerwash pump. When the pump pressure decreases the powerwasher is automatically retracted

back into the housing. The outer end of the powerwasher is fitted with a trim which blends the powerwasher into the headlamp

when it is not operating. The powerwasher has two washer jets which direct washer fluid under high pressure onto the

headlamp lens when the powerwasher is extended.

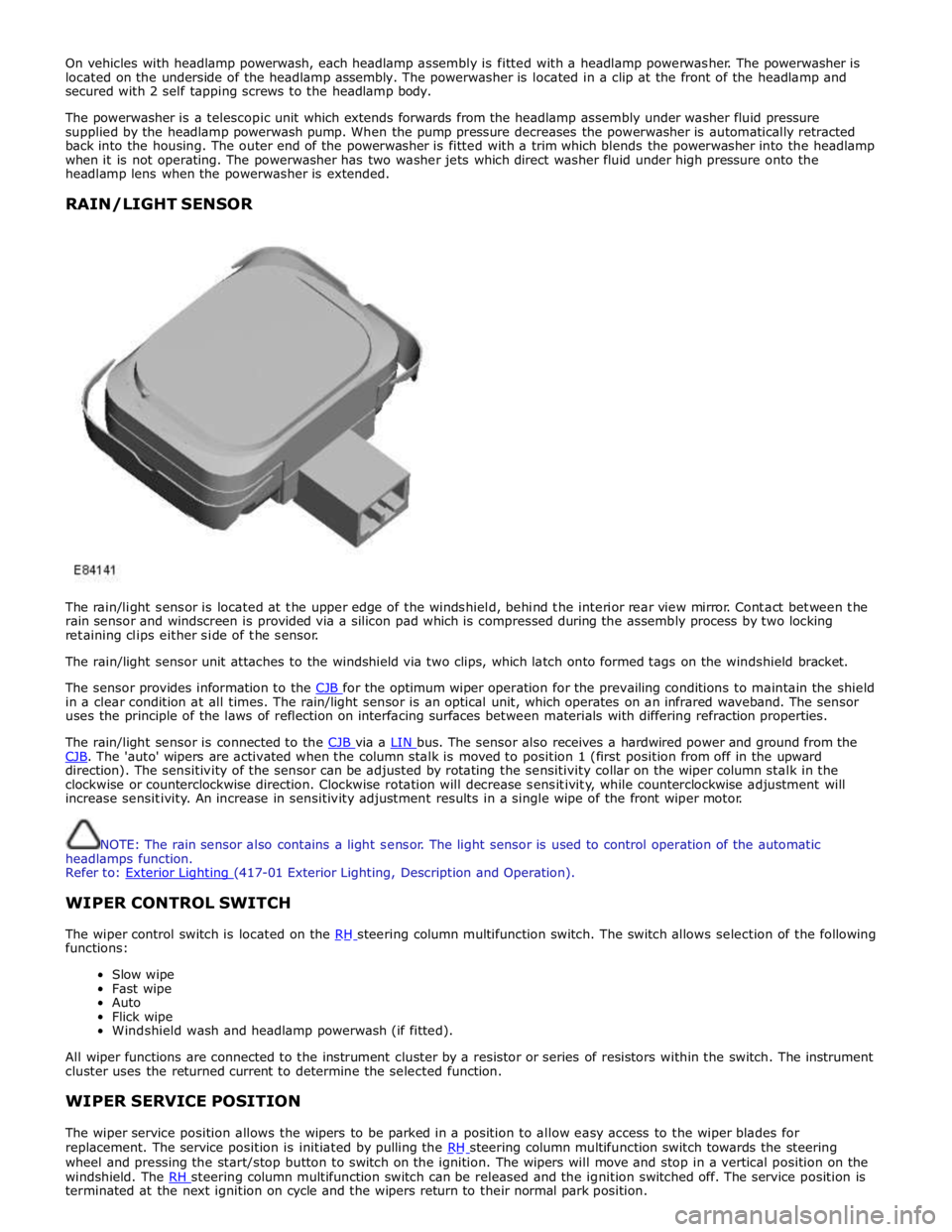

RAIN/LIGHT SENSOR

The rain/light sensor is located at the upper edge of the windshield, behind the interior rear view mirror. Contact between the

rain sensor and windscreen is provided via a silicon pad which is compressed during the assembly process by two locking

retaining clips either side of the sensor.

The rain/light sensor unit attaches to the windshield via two clips, which latch onto formed tags on the windshield bracket.

The sensor provides information to the CJB for the optimum wiper operation for the prevailing conditions to maintain the shield in a clear condition at all times. The rain/light sensor is an optical unit, which operates on an infrared waveband. The sensor

uses the principle of the laws of reflection on interfacing surfaces between materials with differing refraction properties.

The rain/light sensor is connected to the CJB via a LIN bus. The sensor also receives a hardwired power and ground from the CJB. The 'auto' wipers are activated when the column stalk is moved to position 1 (first position from off in the upward direction). The sensitivity of the sensor can be adjusted by rotating the sensitivity collar on the wiper column stalk in the

clockwise or counterclockwise direction. Clockwise rotation will decrease sensitivity, while counterclockwise adjustment will

increase sensitivity. An increase in sensitivity adjustment results in a single wipe of the front wiper motor.

NOTE: The rain sensor also contains a light sensor. The light sensor is used to control operation of the automatic

headlamps function.

Refer to: Exterior Lighting (417-01 Exterior Lighting, Description and Operation).

WIPER CONTROL SWITCH

The wiper control switch is located on the RH steering column multifunction switch. The switch allows selection of the following functions:

Slow wipe

Fast wipe

Auto

Flick wipe

Windshield wash and headlamp powerwash (if fitted).

All wiper functions are connected to the instrument cluster by a resistor or series of resistors within the switch. The instrument

cluster uses the returned current to determine the selected function.

WIPER SERVICE POSITION

The wiper service position allows the wipers to be parked in a position to allow easy access to the wiper blades for

replacement. The service position is initiated by pulling the RH steering column multifunction switch towards the steering wheel and pressing the start/stop button to switch on the ignition. The wipers will move and stop in a vertical position on the

windshield. The RH steering column multifunction switch can be released and the ignition switched off. The service position is terminated at the next ignition on cycle and the wipers return to their normal park position.

Page 2549 of 3039

Wipers and Washers - Rain Sensor

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Refer to: Interior Rear View Mirror (501-09 Rear View Mirrors, Removal and Installation).

2.

3.

Installation

1. CAUTIONS:

Make sure that the component is secured in the

retainer.

Make sure that the clips are correctly located.

To install, reverse the removal procedure. www.JagDocs.com